Patents

Literature

30results about How to "Quantitative control is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

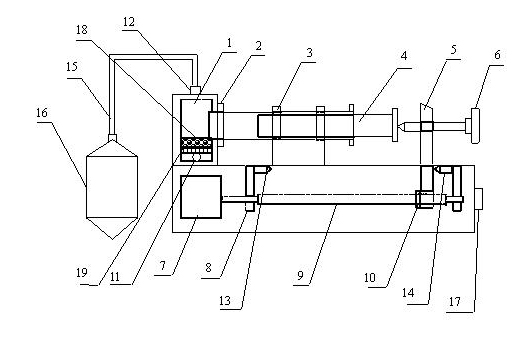

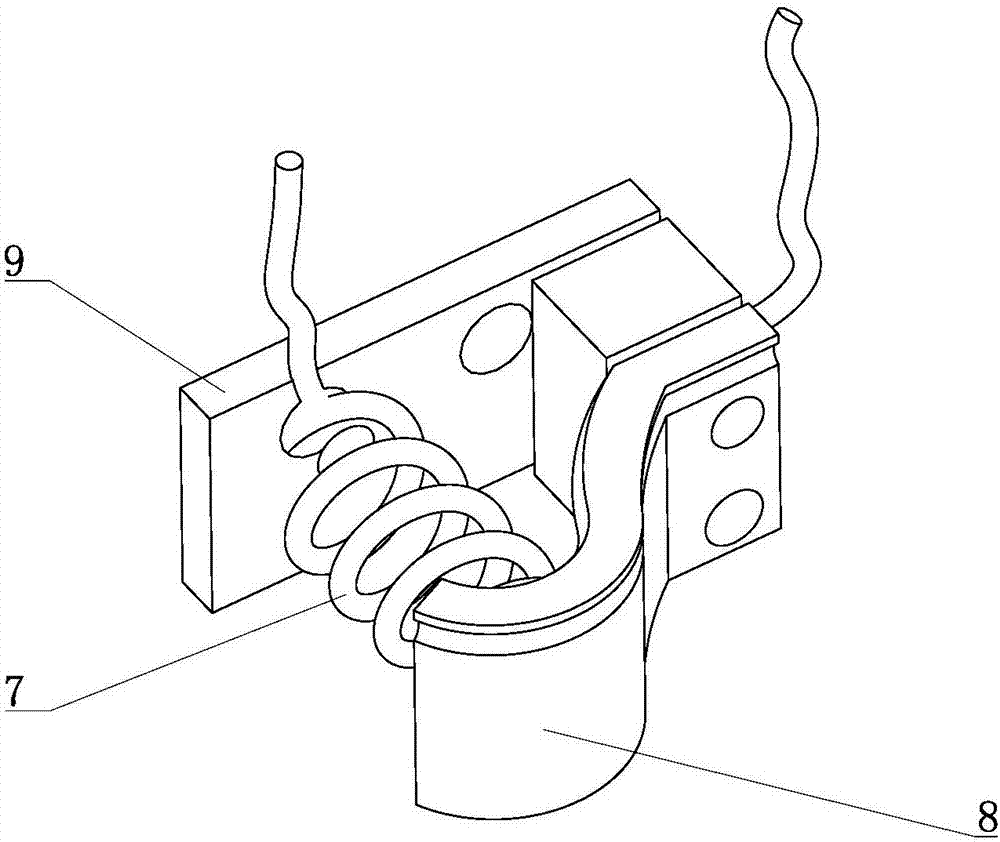

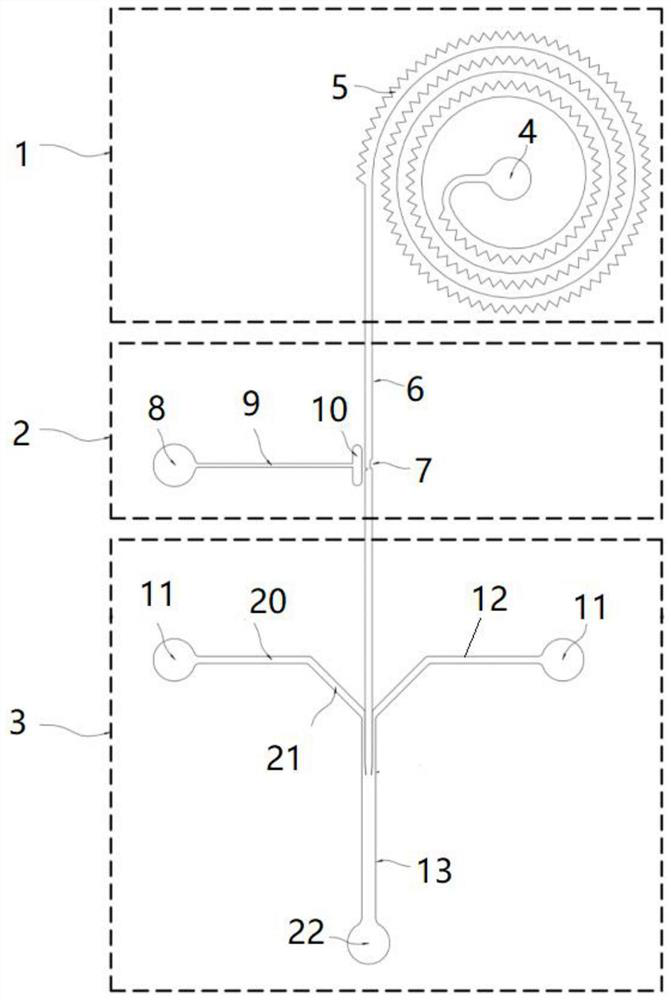

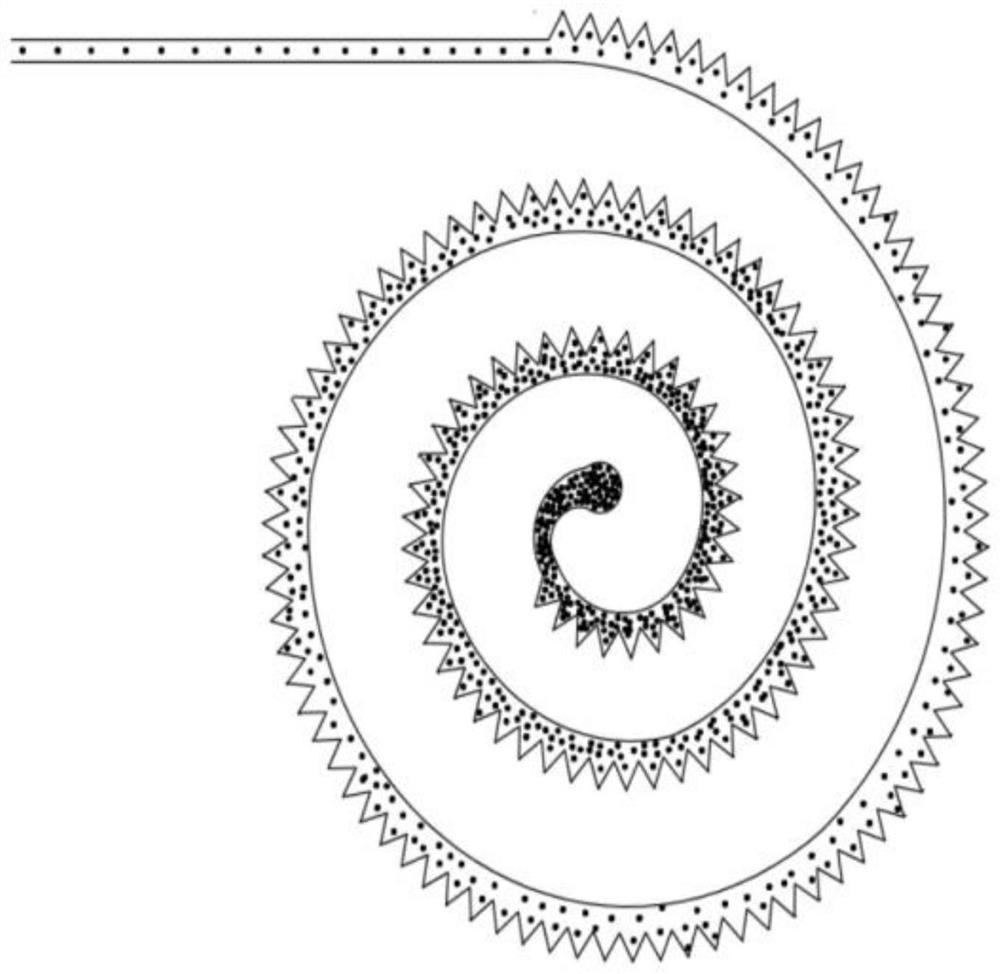

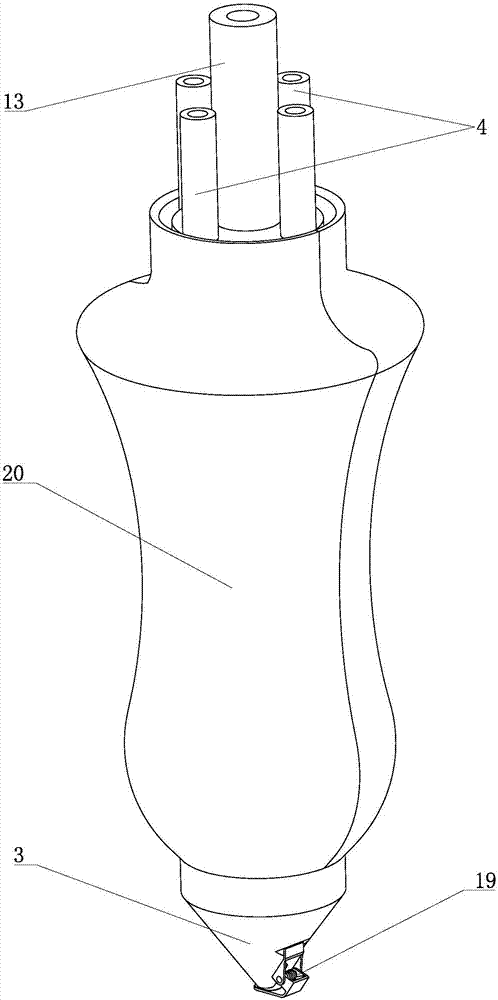

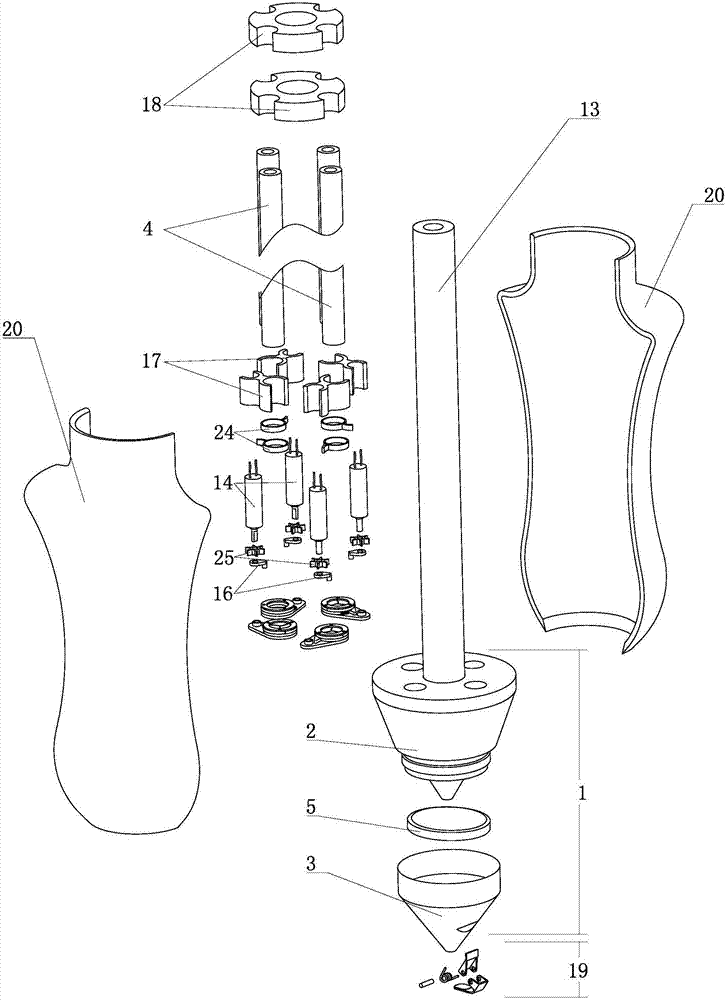

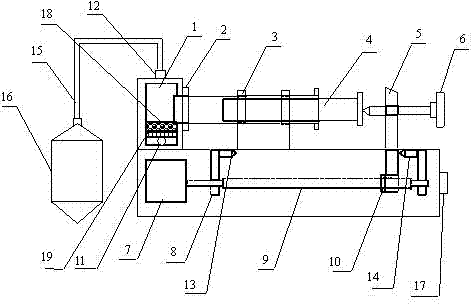

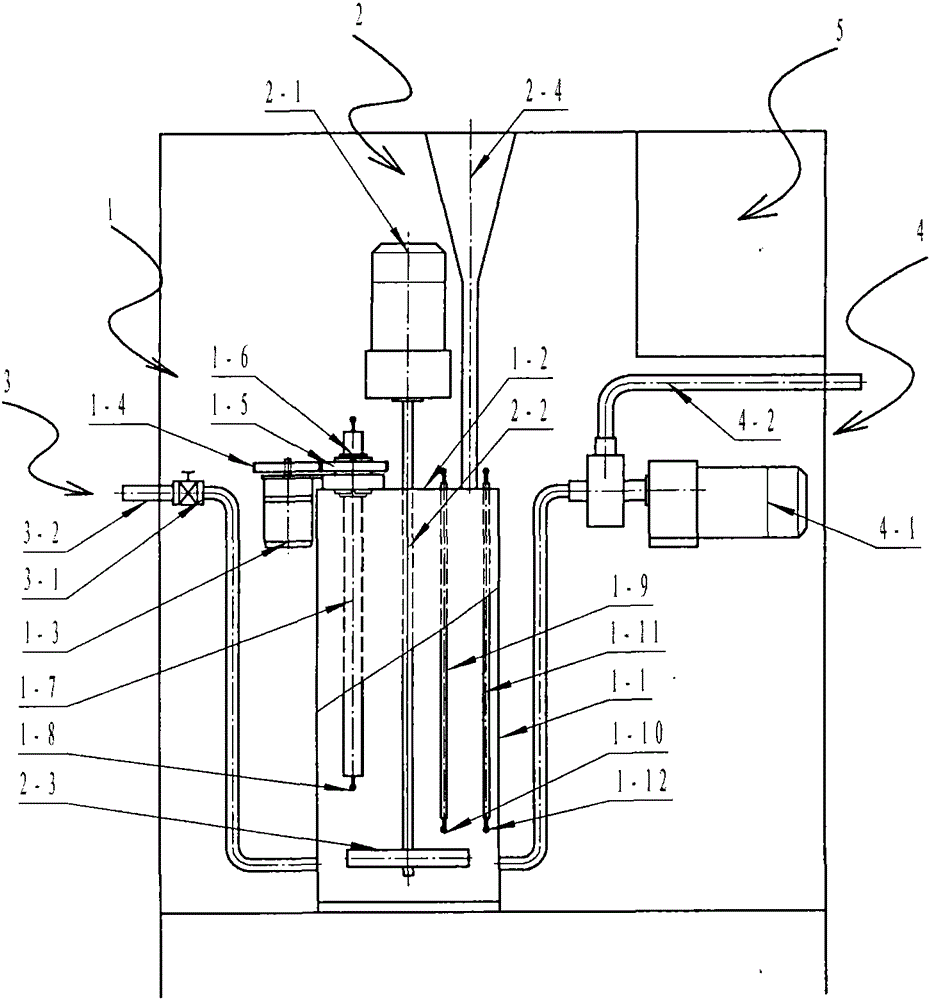

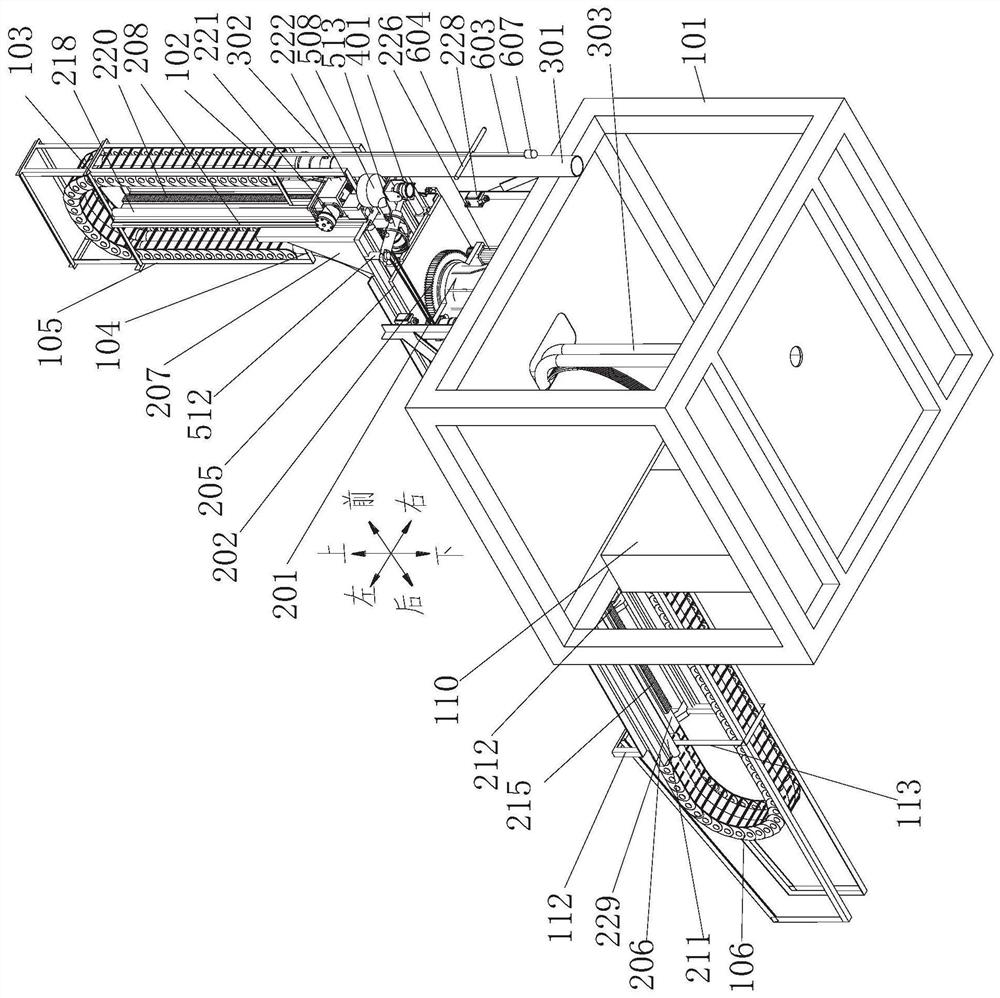

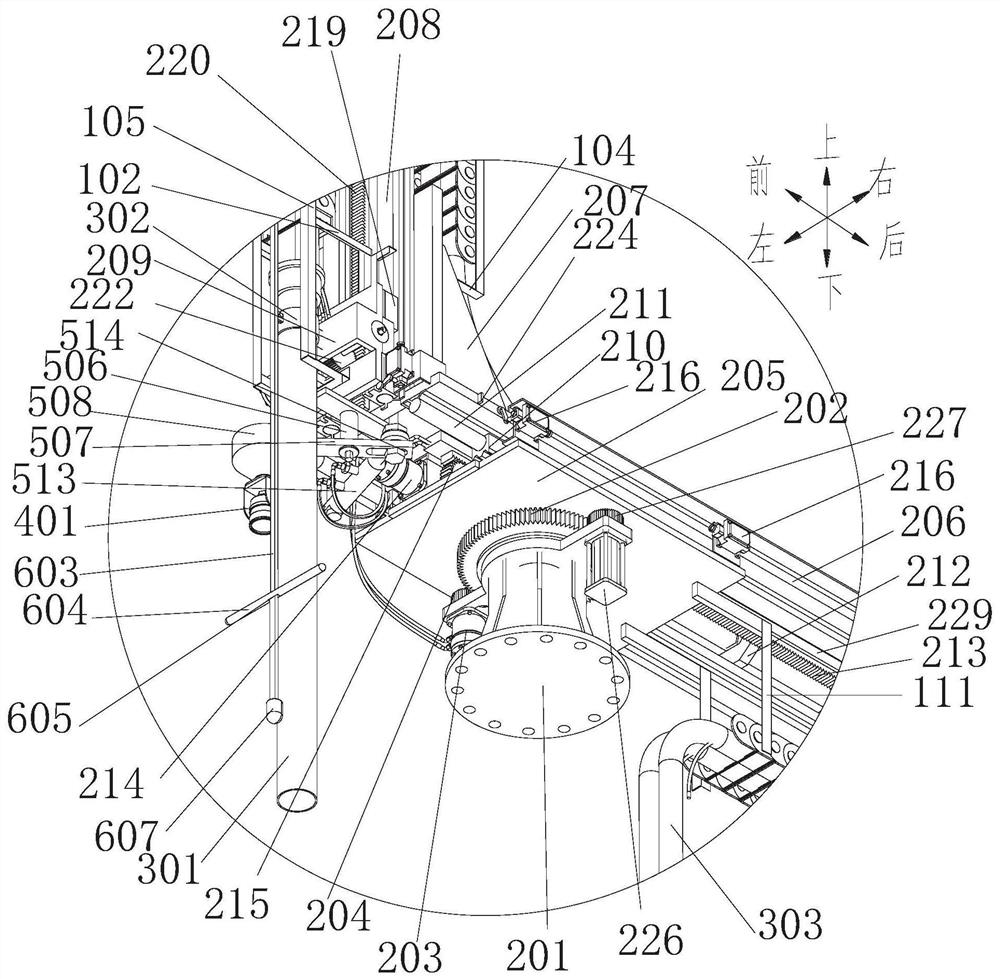

Propelled dust aerosol generating equipment

InactiveCN102166488AQuantitative control is accurateEasy to cleanTransportation and packagingMixer accessoriesMotor driveBall screw

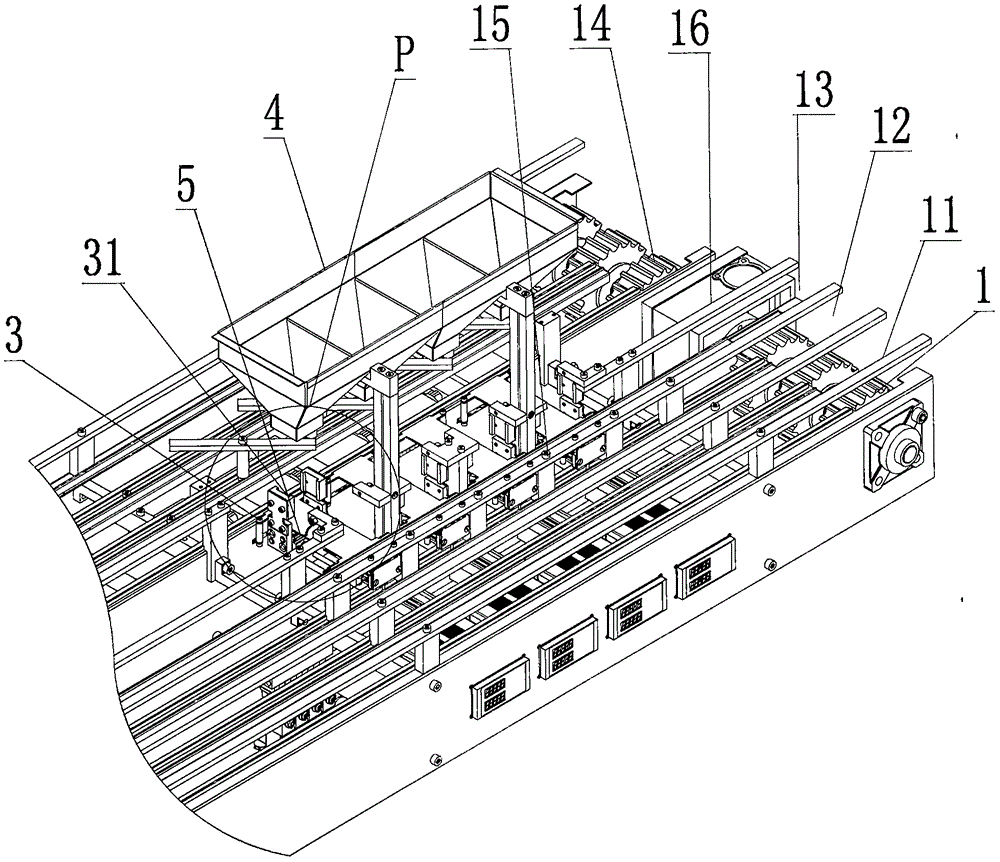

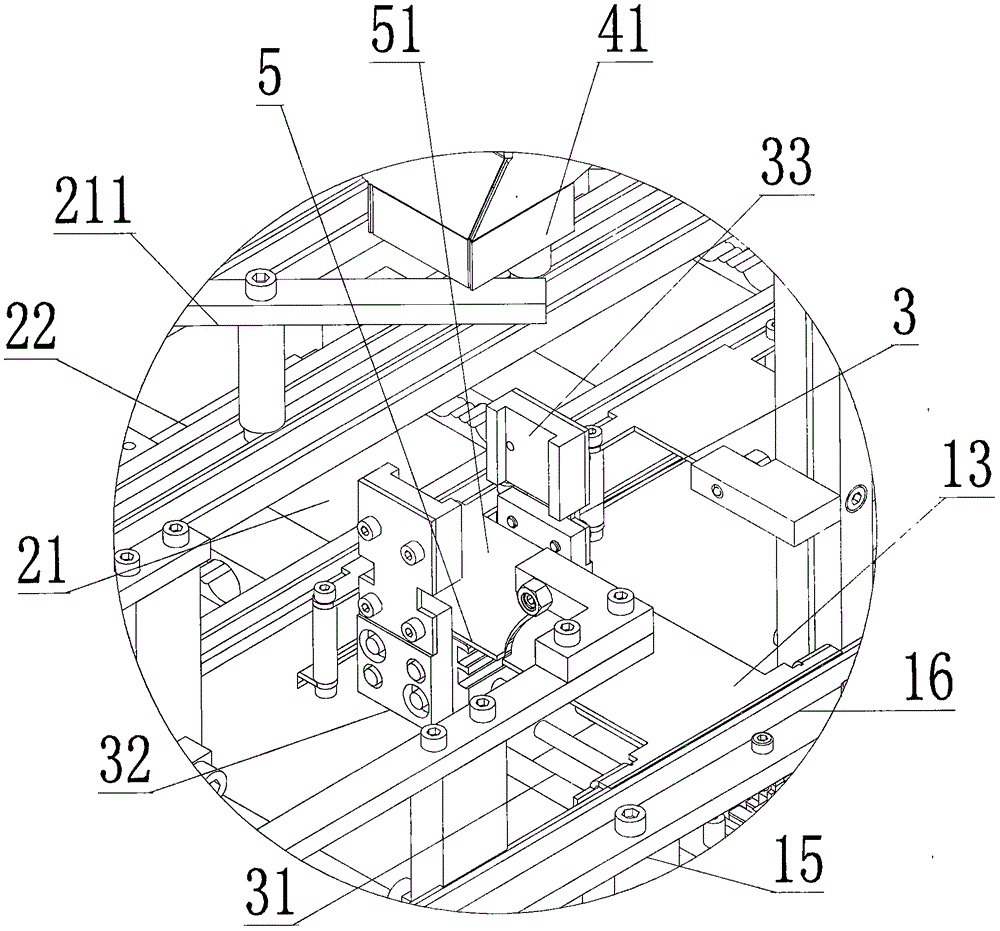

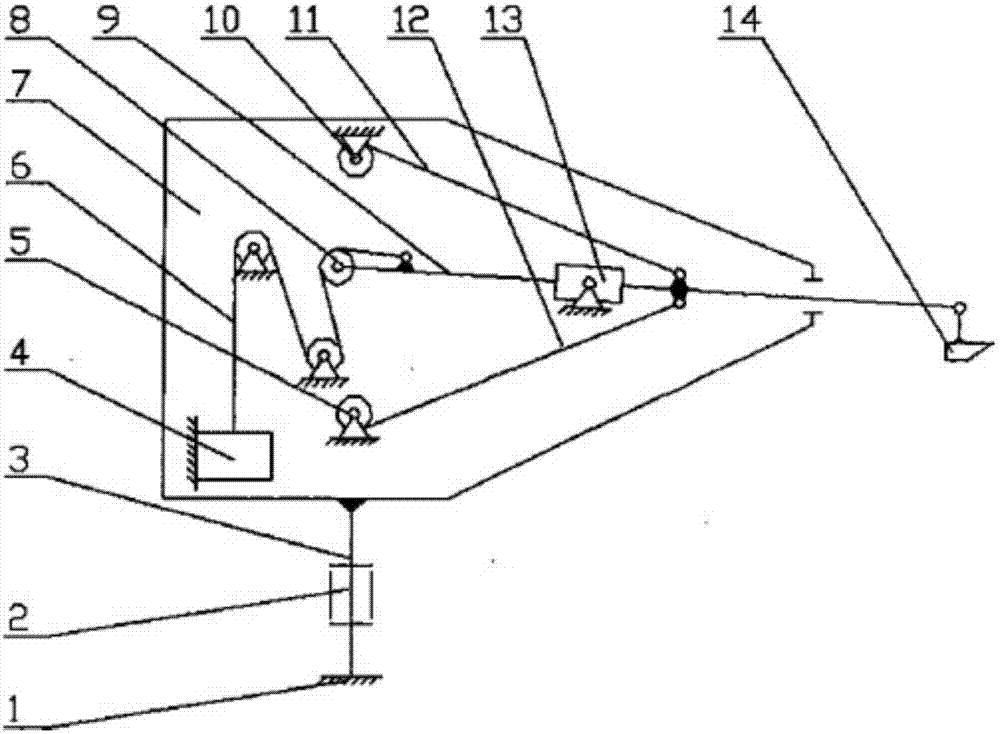

The invention provides propelled dust aerosol generating equipment. The equipment comprises a front opened syringe and a stepping motor, wherein the front opened syringe loads powder; the rotation speed of the stepping motor can be adjusted; the stepping motor drives a ball screw to rotate so that a ball nut drives an advancing block to move; a manual adjusting wheel is arranged on the advancing block and can slightly adjust the front opened syringe; a front limit switch and a rear limit switch control the maximal stroke of the advancing block; the powder is pushed into a dust dissolving and separating cavity and bumps with microspheres driven by air flow entering from an air inlet to generate atomized aerosol; and the atomized aerosol is sent to a sealed diffusing cabin through an air outlet and a pipeline. The invention provides the dust aerosol generating equipment, which is precisely and quantificationally controlled, is not easy to block and uniformly dissolves and separates dust; a large amount of dust aerosol can be convenient to prepare reliably; the equipment is applied to researches in the aspects of environmental science, atmosphere physics and chemistry, weather science, industrial manufacturing, medicament and health, and the like, and required dust aerosol related tests and production; a new method is developed; and the precision and the efficiency are improved.

Owner:TIANJIN HOPE IND & TRADE

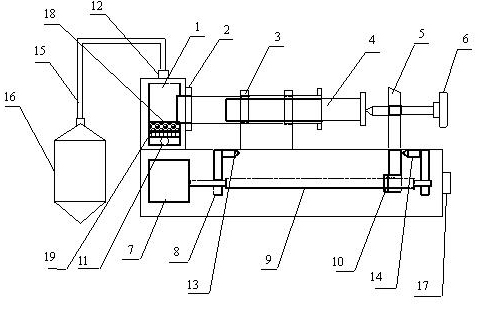

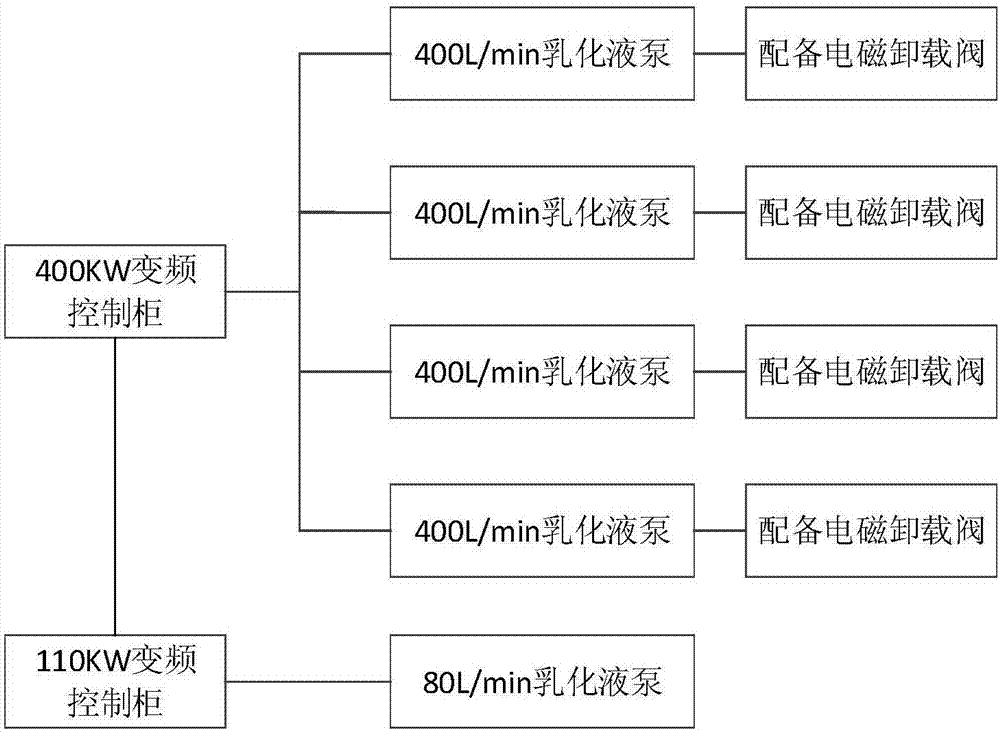

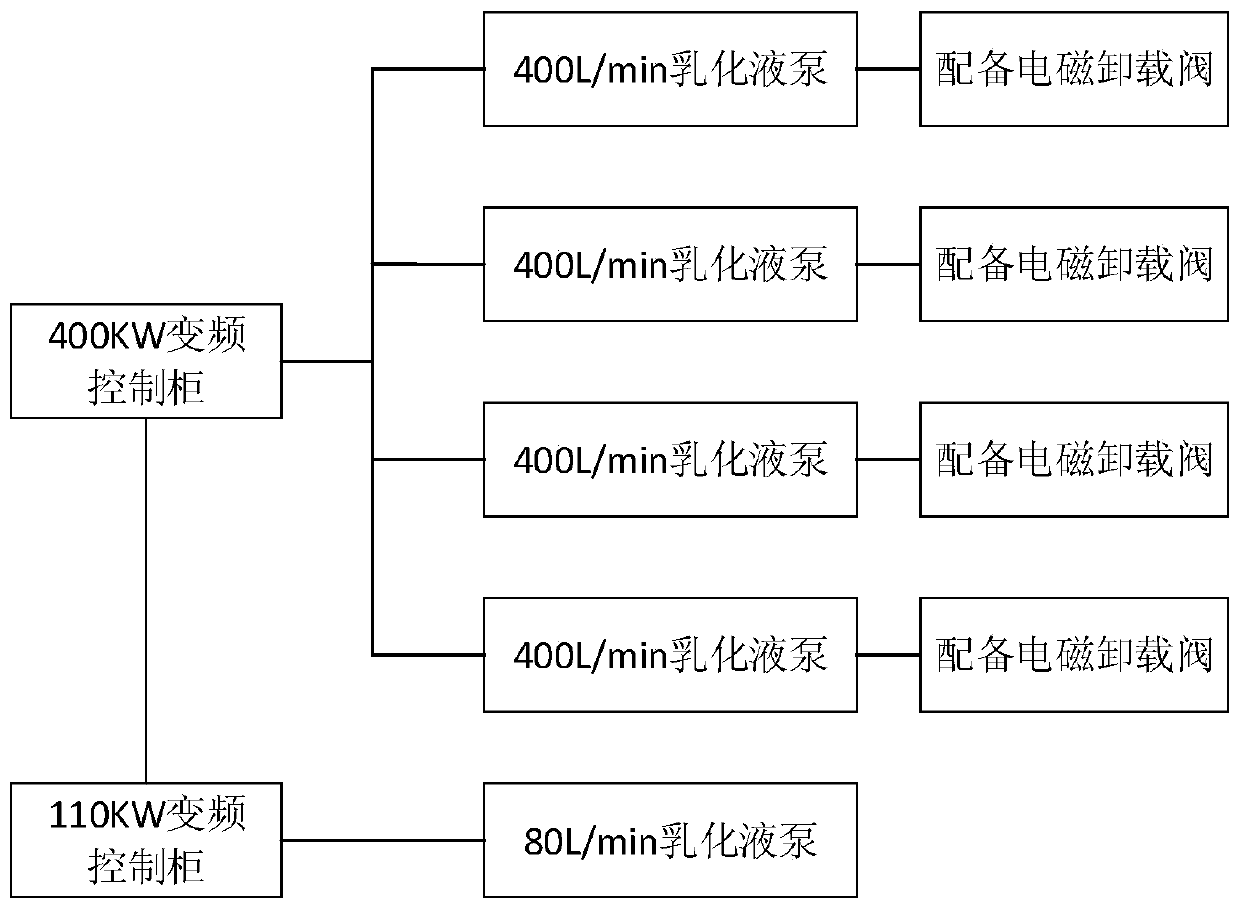

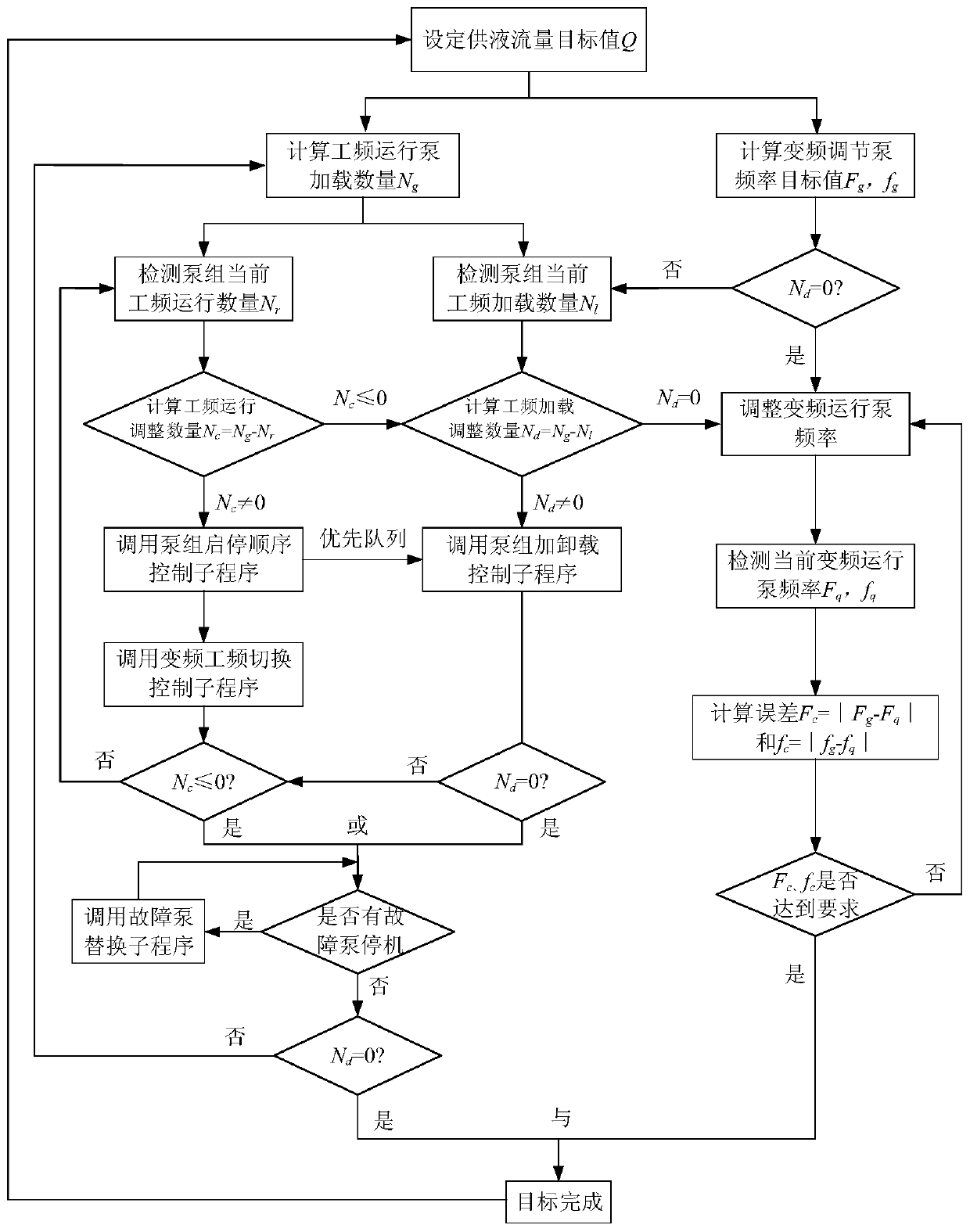

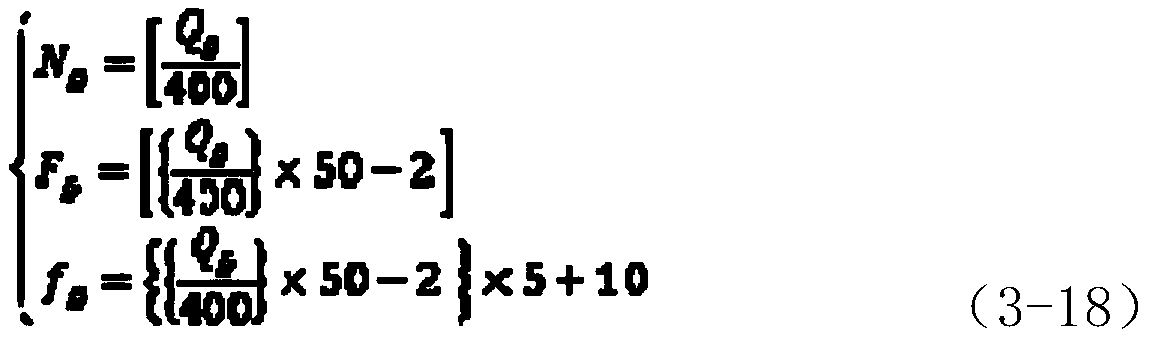

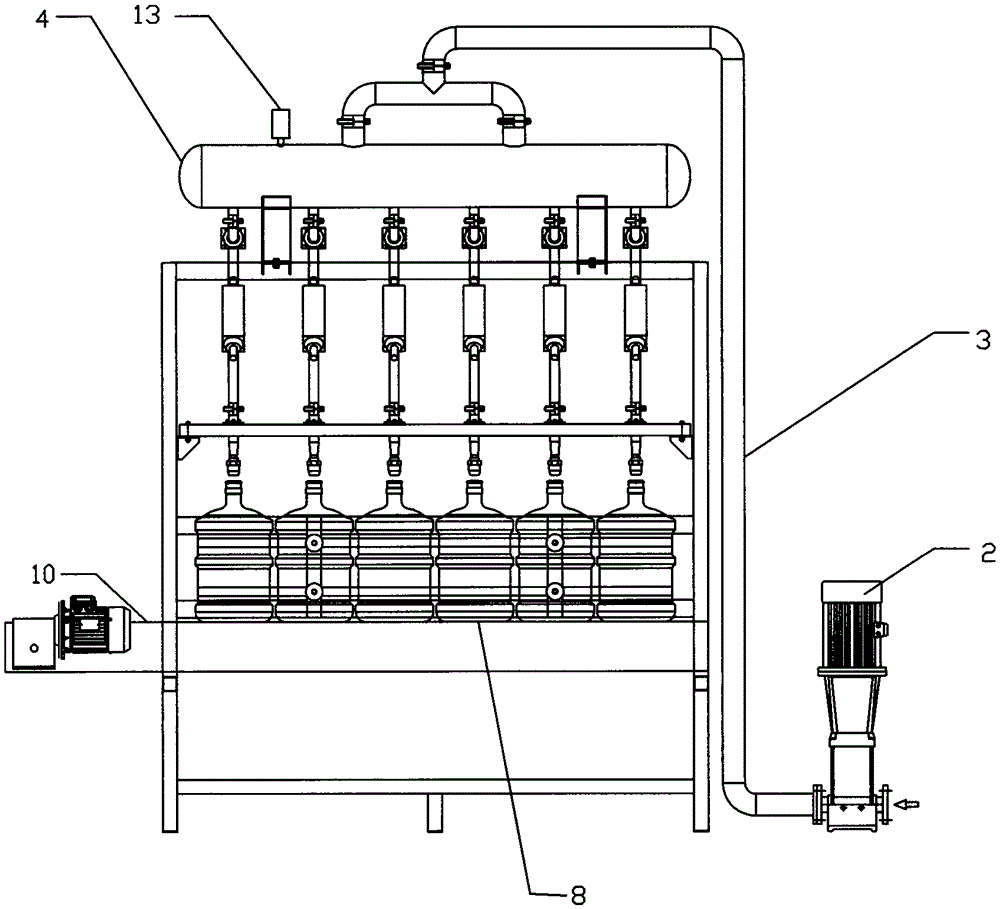

Multi-pump multi-frequency-conversion emulsion pump station system for mining and quantitative emulsion supply control method

ActiveCN107461321ARealize frequency conversion speed regulationRealize electronically controlled loading and unloadingPump controlPositive-displacement liquid enginesTraffic volumeEmulsion

The invention provides a multi-pump multi-frequency-conversion emulsion pump station system for mining. The multi-pump multi-frequency-conversion emulsion pump station system for mining comprises 400 KW frequency conversion control cabinet, a 110KW frequency conversion control cabinet, four 400 L / min emulsion pumps and a 80 L / min emulsion pump. One end of the 400 KW frequency conversion control cabinet is connected with the 110 KW frequency conversion control cabinet, and the other end of the 400 KW frequency conversion control cabinet is connected with the four 400 L / min emulsion pumps. The 110KW frequency conversion control cabinet is further connected with the 80 L / min emulsion pump. The multi-pump multi-frequency-conversion emulsion pump station for mining adopts the multi-pump multi-frequency-conversion drive manner, the four emulsion pumps with the rated flow of 400 L / min and the emulsion pump with the rated flow of 80 L / min are arranged, each pump can achieve frequency conversion speed control and electronic control loading and unloading, the emulsion supply flow adjustment range can reach 0-1680L / min, and the highest adjustment precision can reach 1.6 L / min; on the basis of the multi-pump multi-frequency-conversion emulsion pump station system for mining, a rated emulsion supply control method is provided. According to the rated emulsion supply control method, through PLC programming in the control cabinet, the multiple pumps are controlled to operate at the industrial frequency, multi-frequency-conversion speed adjustment is controlled, accurate and quantitative control over high-pressure emulsion flow is achieved, and a reliable underlying control basis is provided for further intelligent emulsion supply.

Owner:TAIYUAN UNIV OF TECH

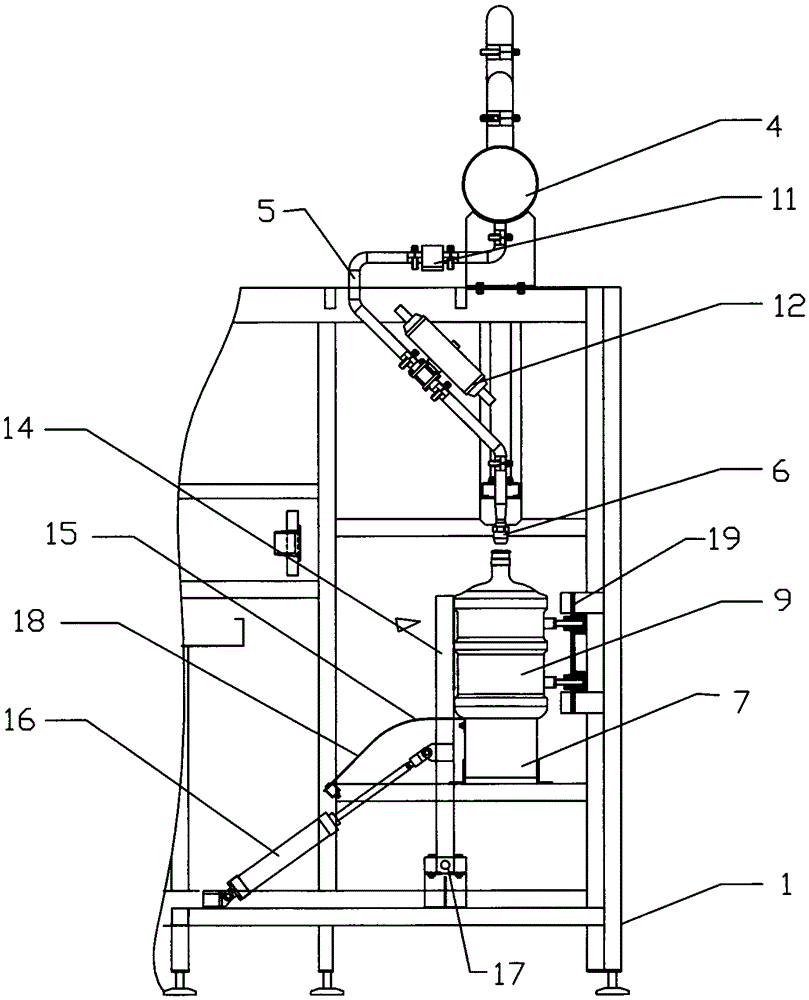

Liquid remote quantitative loading system

InactiveCN111977601AQuick alignmentRealize start-stop controlLiquid transferring devicesAutomatic controlLiquid level measurement

The invention relates to a liquid remote quantitative loading system. The system comprises an upper support, a remote alignment system, an automatic loading crane pipe, a control box and a metering system, wherein the automatic loading crane pipe, the control box and the metering system are installed on the upper support. A feeler lever touches a tank opening of an oil storage tank, the control box controls a vertical pipe to extend into the tank opening of the oil storage tank and stop moving after an inlet distance is reached, the control box controls an oil pump to start for oil loading, aprotective shell floats along with the liquid level, and when the inner bottom wall of the protective shell triggers a float switch, the control box controls the oil pump to stop. According to the system, the vertical pipe can be quickly aligned with the tank opening of a tank truck, and a float liquid level meter is designed for automatic control over start and stop of the oil pump and liquid level measurement of the tank truck, so that a flow meter or manual control can be replaced, control over start and stop of the oil pump can be achieved, and quantitative control is more accurate. The system can realize on-site unmanned liquid filling and accurate metering, can improve the oil loading operation efficiency, and achieves the purposes of safety, energy conservation and yield increase.

Owner:SINOPEC NORTHWEST OIL FIELD

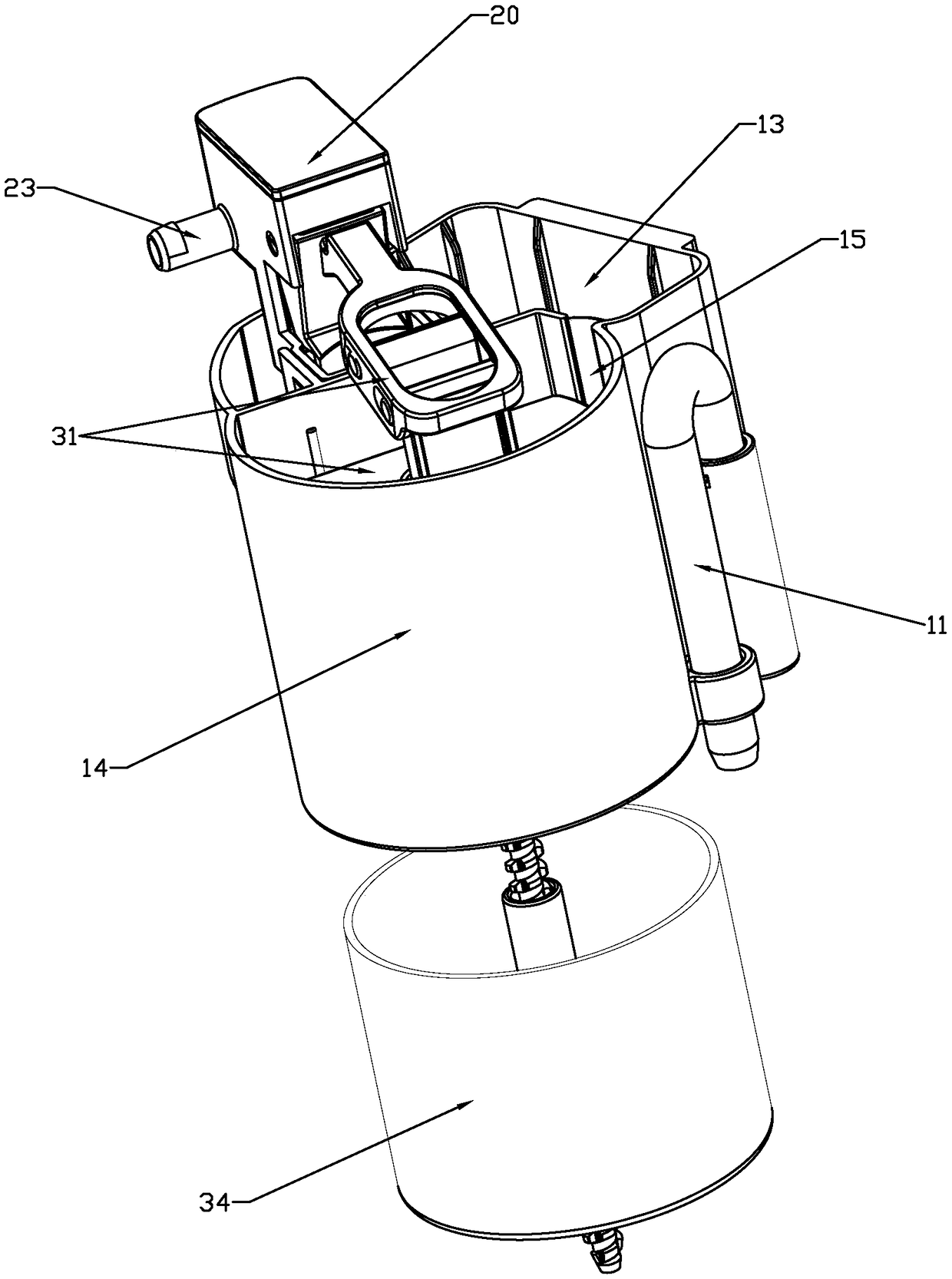

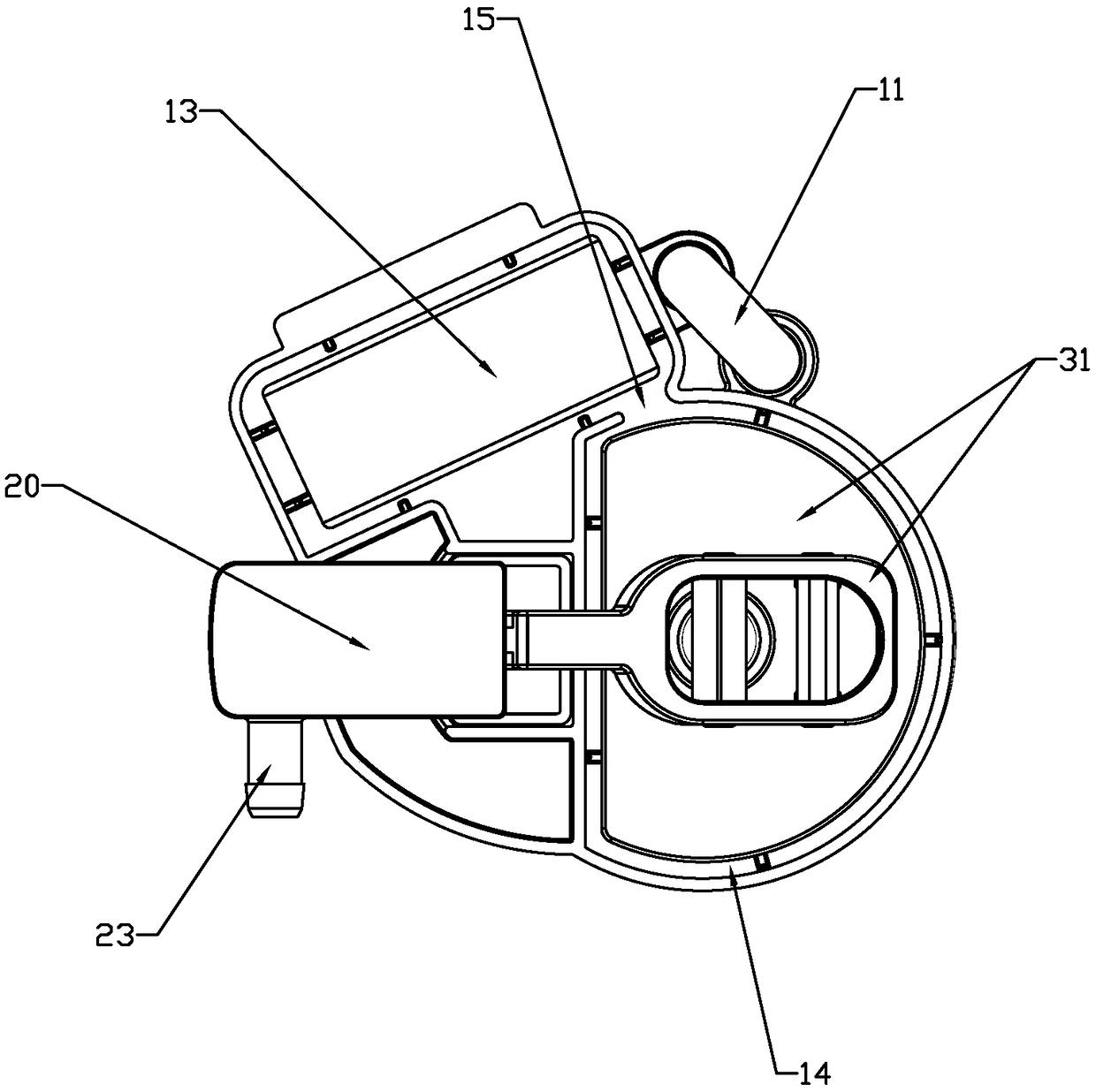

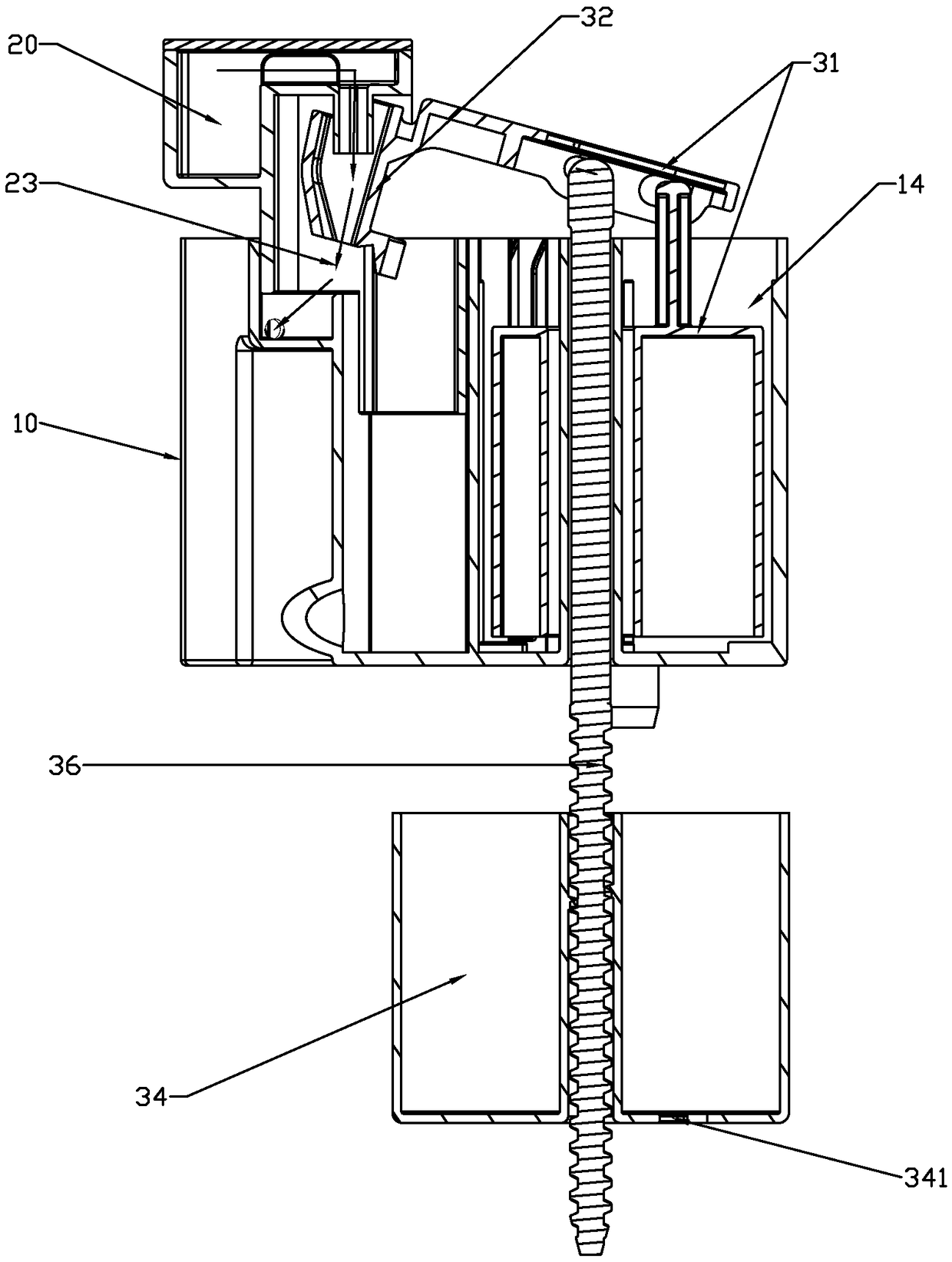

Device for adding cleaning fluid

PendingCN108824582ARealize quantitative supplyAvoid wastingFlushing devicesLavatory sanitoryEngineeringToilet

The invention discloses a device for adding cleaning fluid. The device is arranged in a water tank of a toilet and used for supplying the cleaning fluid to the toilet; the device for adding the cleaning fluid comprises a fluid box, a fluid supplementing mechanism and a fluid supplementation control mechanism, wherein the fluid box is used for storing the cleaning fluid and provided with a fluid outlet channel; the fluid supplementing mechanism is used for supplementing the fluid to the fluid box; the liquid supplementation control mechanism is used for controlling the fluid supplementing mechanism to stop supplementing of the fluid to the fluid box. In this way, when the toilet is flushed, the cleaning fluid can be supplied quantificationally, and unnecessary waste is avoided.

Owner:XIAMEN R&T PLUMBING TECH

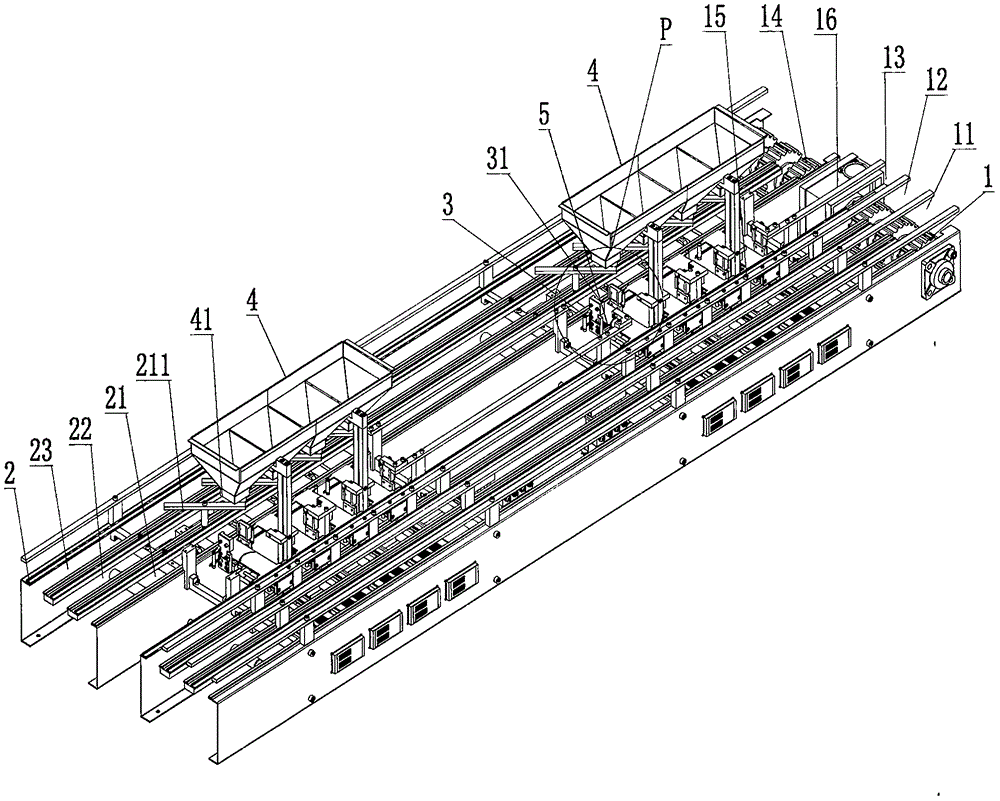

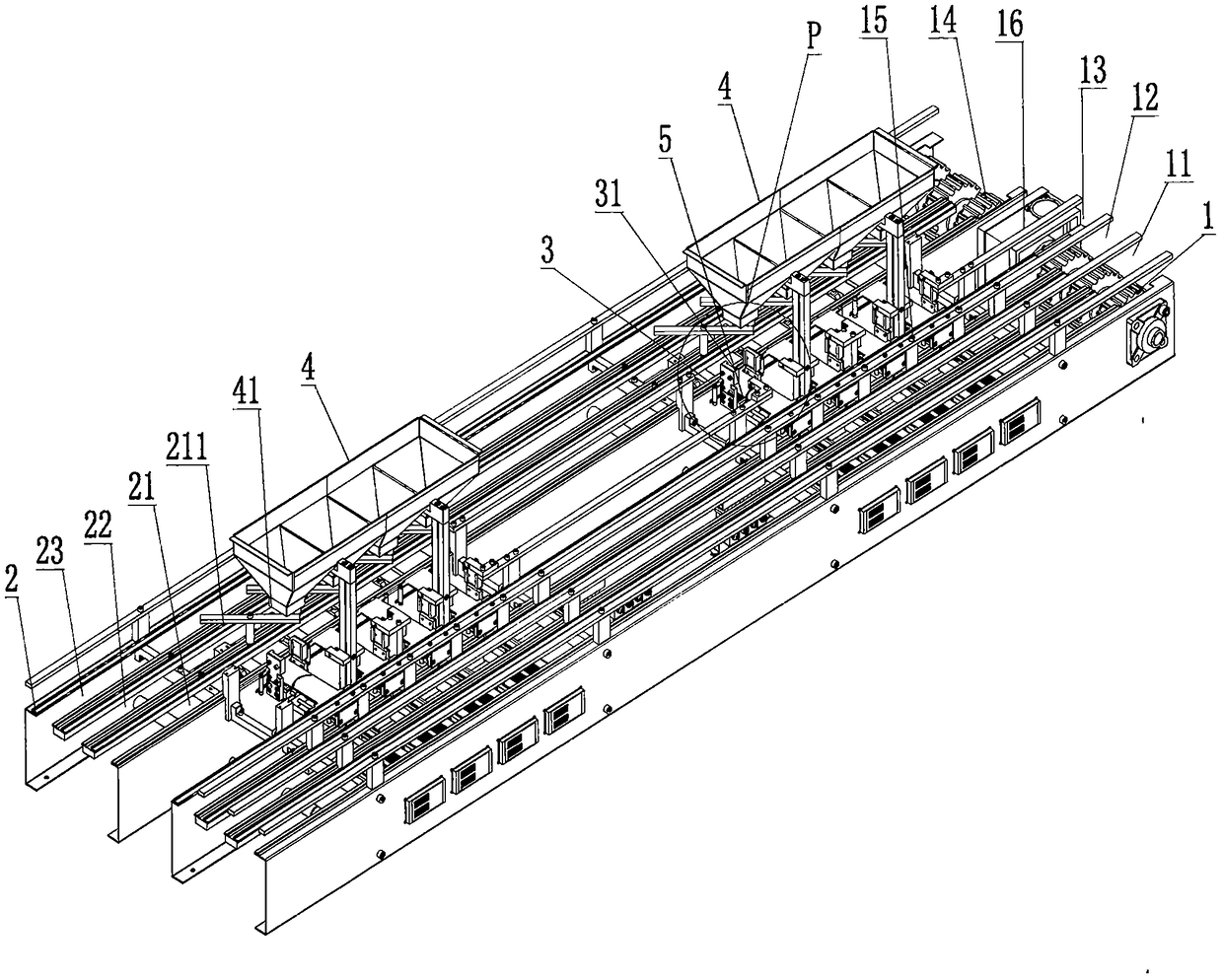

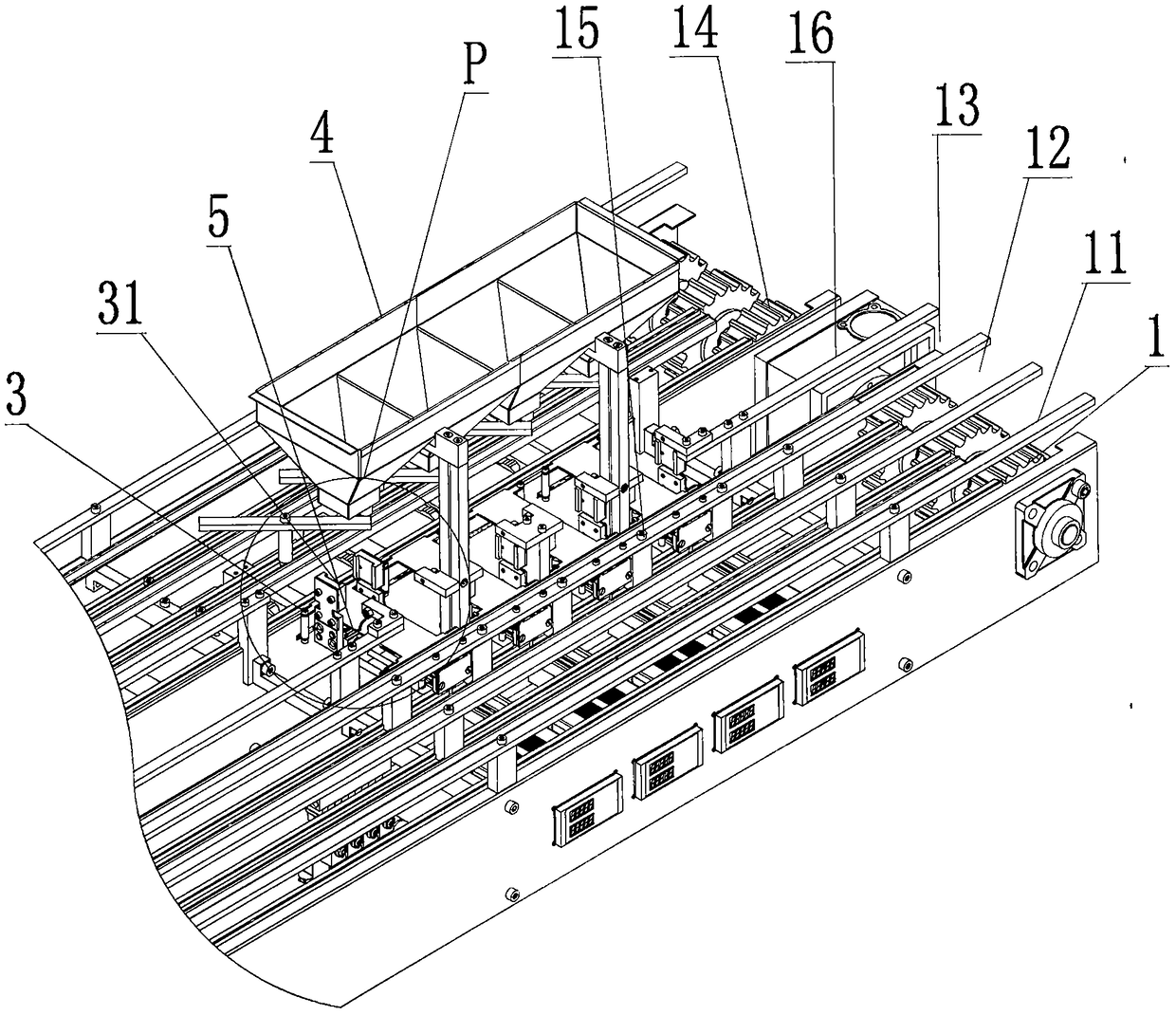

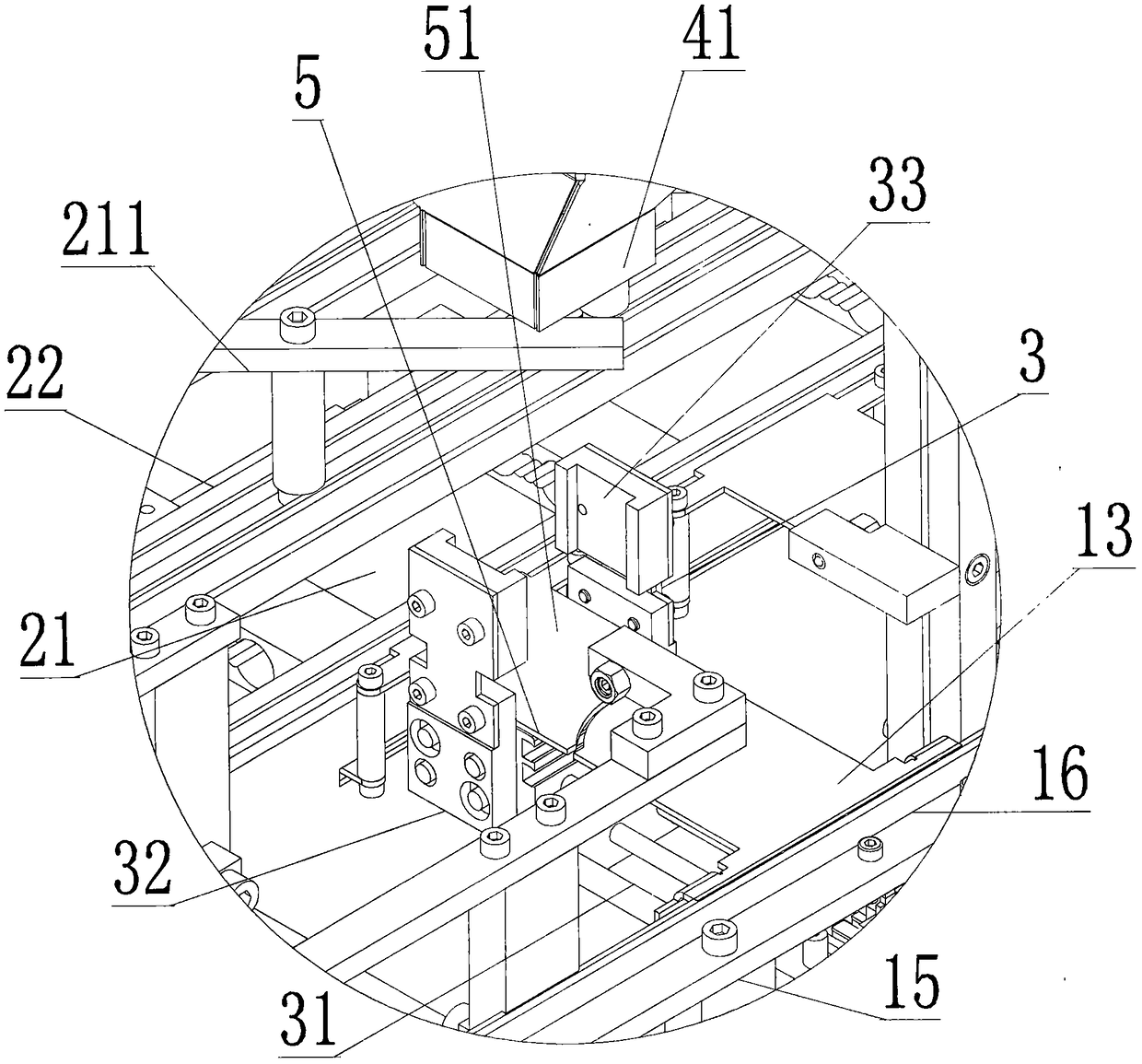

Drink bottle transport system

ActiveCN106144428AStreaming is simple and fastAvoid pouring bottlesConveyorsLiquid bottlingTransport systemBottle

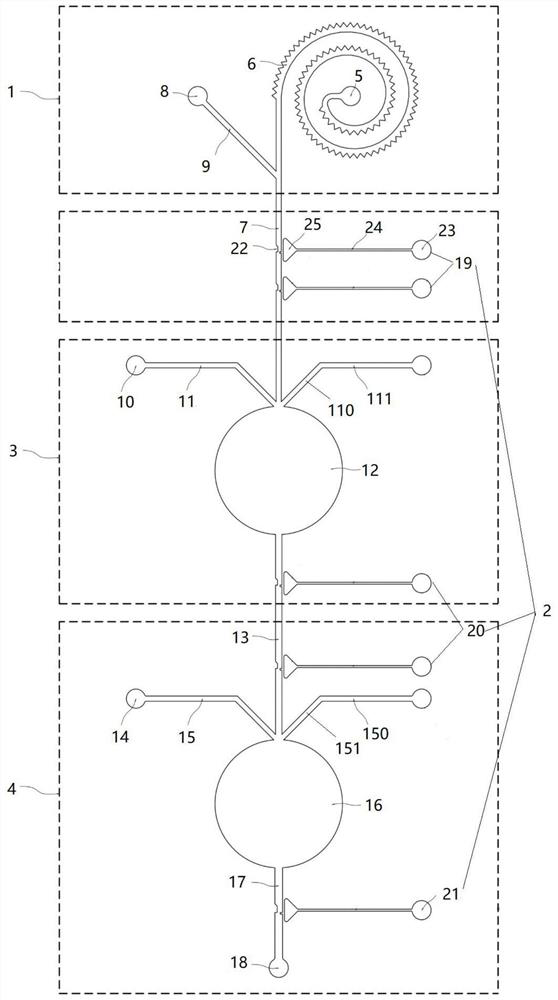

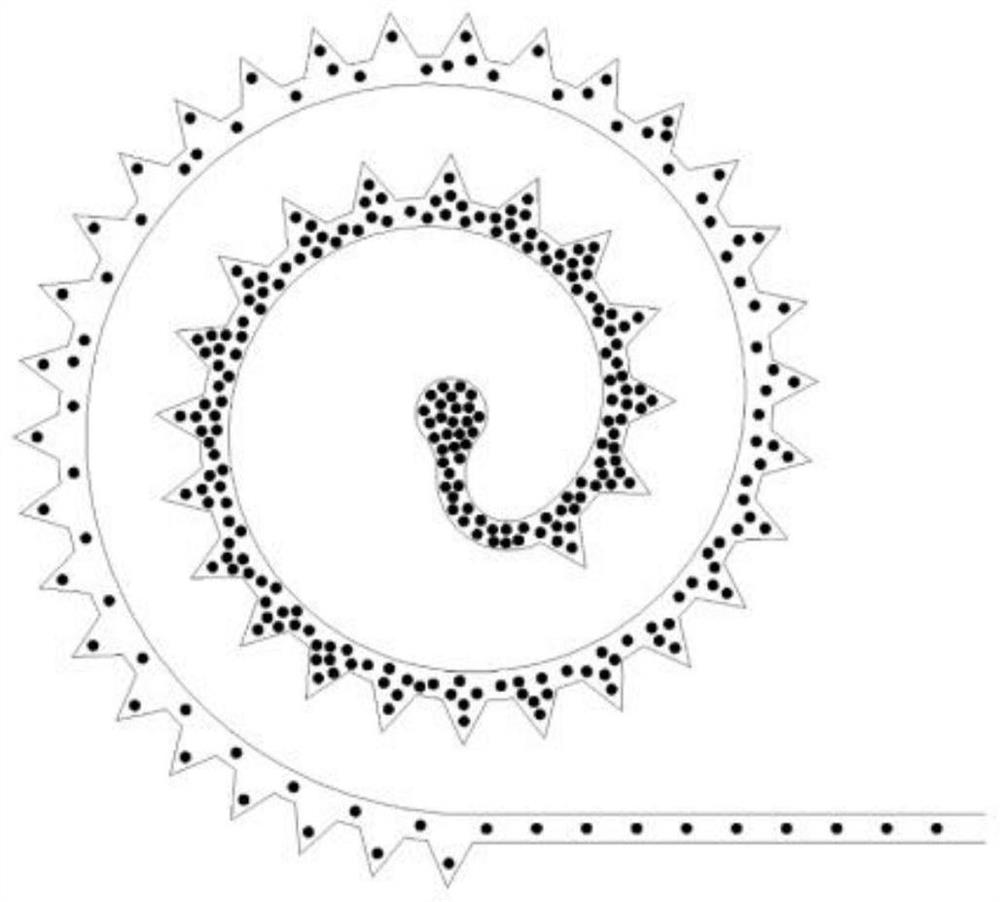

Provided is a drink bottle transport system. The drink bottle transport system comprises a bottle-feeding conveyor belt, a bottle-discharge conveyor belt and a plurality of push components for connecting the bottle-feeding conveyor belt with the bottle-discharge conveyor belt. The bottle-feeding conveyor belt comprises a circular conveyor belt, an outer side conveyor belt is additionally arranged on the outer side of the circular conveyor belt, a bottle-discharge opening connected with one of the push components is formed in the inner side of the circular conveyor belt, a horizontal air blowing valve corresponding to the bottle-discharge opening is arranged in the middle of the circular conveyor belt, and a guide rod is arranged at a bottle-feeding opening of the bottle-discharge conveyor belt. A feeding device and a weighing device are further arranged between the bottle-feeding conveyor belt and the bottle-discharge conveyor belt, and a bottle body at the bottle-feeding opening is pushed to a weighing component for feeding and continues to be pushed to the bottle-discharge opening by the push components. The drink bottle transport system is comparatively simple in structure of each part and reasonable in design, prevents a drink bottle from being jammed in front of and behind the feeding device and falling down, guarantees the efficiency and the order of the whole transport process, also is favorable for completing feeding safely and stably, and improves the product qualification ratio.

Owner:邵阳欣源机械有限公司

Multi-stage reaction micro-channel structure, micro-fluidic chip and heterogeneous reaction method

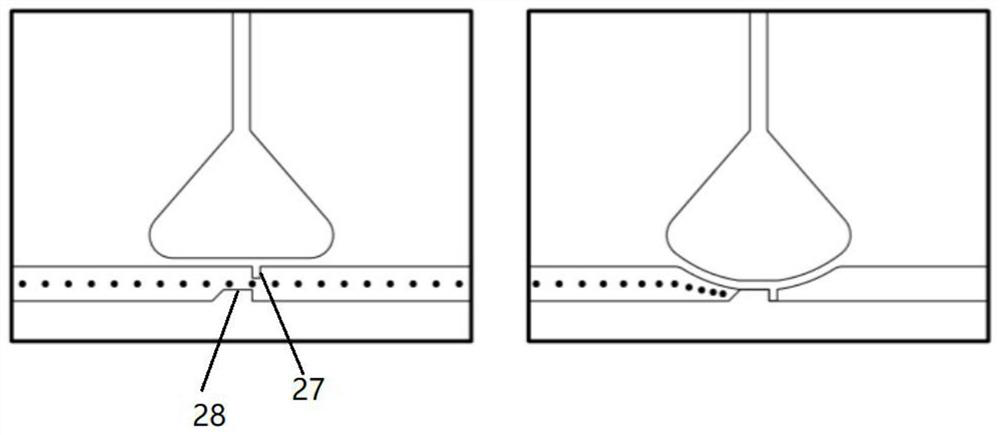

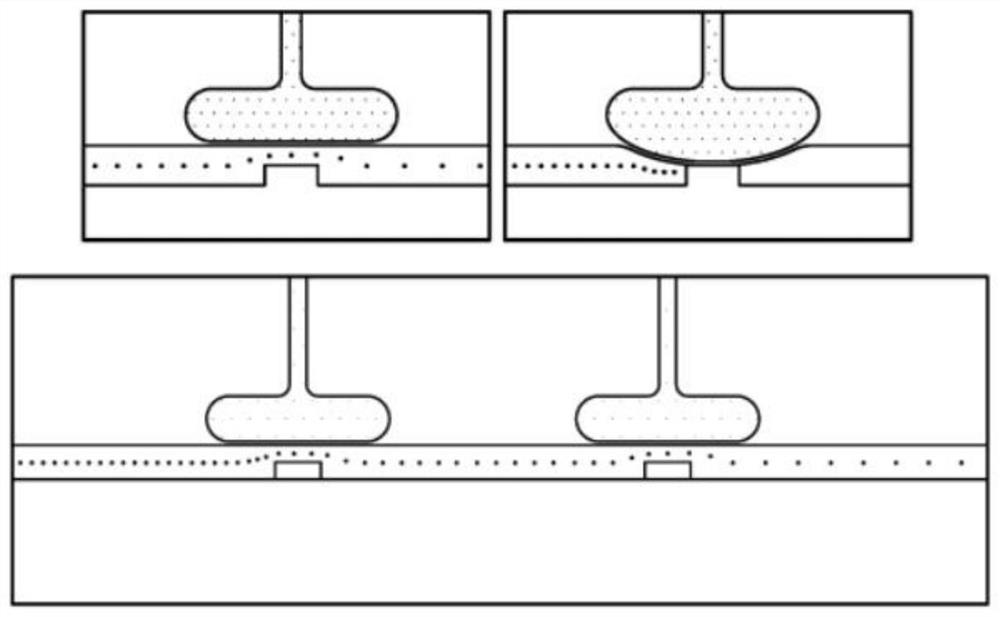

PendingCN112755933AIncrease distanceImprove stabilityChemical/physical/physico-chemical microreactorsLaboratory glasswaresFluid phaseControl cell

The invention provides a multi-stage reaction micro-channel structure, a micro-fluidic chip and a heterogeneous reaction method. The multi-stage reaction micro-channel structure comprises a continuous outer triangular expansion focusing unit, an active valve quantitative uniform control unit and a multi-stage heterogeneous reaction tank unit, the continuous outer triangular expansion focusing unit comprises a continuous outer triangular expansion focusing flow channel and a continuous liquid phase flow channel; the active valve quantitative uniform control unit comprises a first active valve, a second active valve and a third active valve; the first active valve comprises a built-in valve plug, a gas phase channel and a gas buffer chamber; a built-in valve plug is arranged on the inner wall of the continuous liquid phase flow channel; and the multi-stage heterogeneous reaction tank unit comprises a first-stage heterogeneous reaction tank unit and a second-stage heterogeneous reaction tank unit. The invention solves the technical problems of how to design a microfluidic device and an operation process, so that on the basis of generating high-dispersion liquid drops and particles, the microfluidic device and the operation process can realize rapid and accurate quantitative control to carry out accurate and efficient heterogeneous reaction and improve the sufficiency of the reaction.

Owner:GUANGDONG UNIV OF TECH

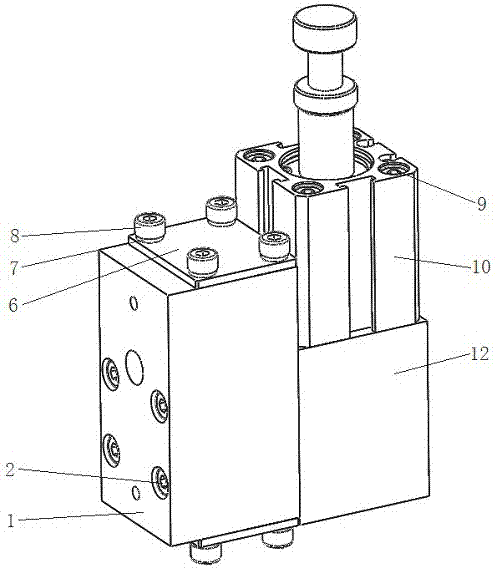

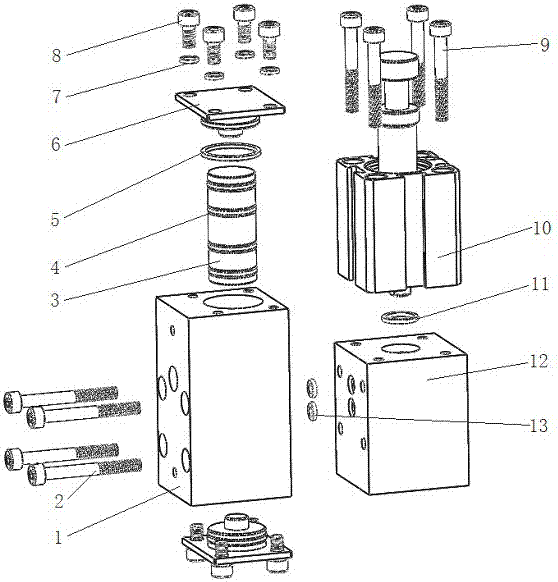

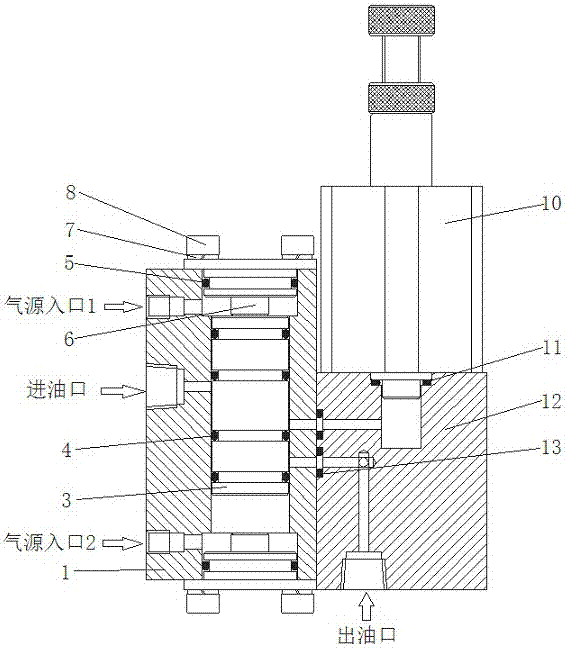

Quantitative distribution valve with low-viscosity lubricating oil as working medium

InactiveCN107191774AAccurate outputStable outputProportioning devicesDistribution equipmentAtmospheric pressureViscosity

The invention discloses a quantitative distribution valve with low-viscosity lubricating oil as a working medium. The quantitative distribution valve is composed of a switch valve body, a switch valve element, an end cover, an oil injection valve body, air cylinders and the like. The output amount of the low-viscosity lubricating oil can be accurately controlled. Air cylinder adjusting nuts are manually adjusted to adjust the range of the output amount. The switch valve element is controlled through the air pressure to be located in the upper position. The lubricating oil enters the oil injection valve cavity from switch valve oil inlet hole. The switch valve element is controlled through the air pressure again to be located in the lower position. The air cylinders conduct piston motion and press out the lubricating oil in the oil injection valve cavity. The quantitative distribution valve can be applied to the situations that the low-viscosity lubricating oil serves as the working medium, the output amount is extremely less, and the precision requirement is high, for example, the quantitative distribution valve can be used for smearing of vaseline oil on an electrode end column of an accumulator, the output amount of the lubricating oil can be controlled accurately, thus equipment is guaranteed, and the service life is prolonged.

Owner:SHANGHAI UNIV

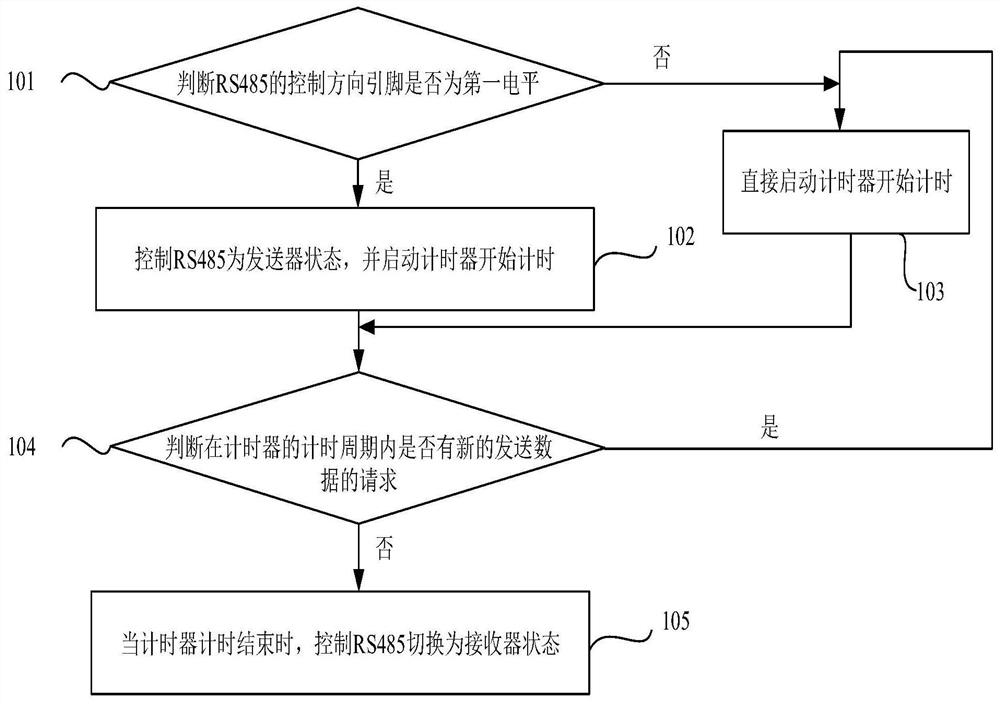

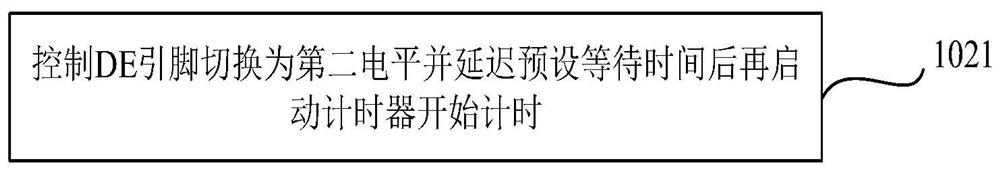

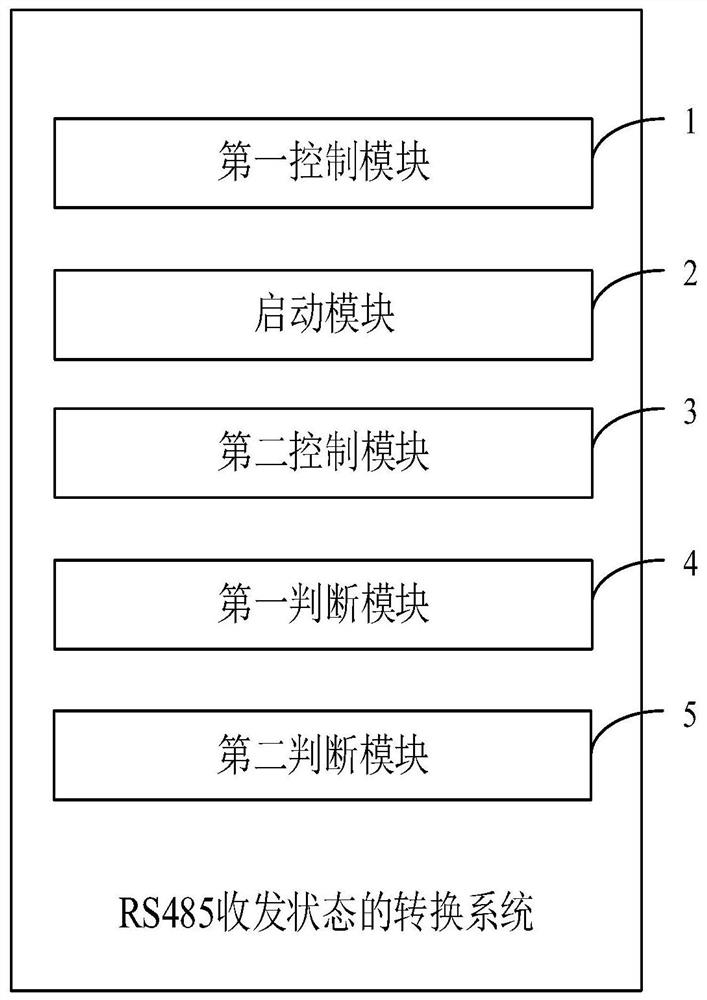

RS485 transceiving state conversion method, system and device, and medium

The invention discloses an RS485 transceiving state conversion method, system and device and a medium, and the method comprises the steps: controlling RS485 to be in a transmitter state, and starting a timer to start timing, wherein the timing period of the timer is calculated according to the current baud rate of RS485; and when the timing of the timer is finished, controlling the RS485 to be switched to a receiver state. The RS485 is controlled to be in the sending state, the timer is started to start timing, the timing period of the timer is calculated according to the current baud rate of the RS485, and when timing of the timer is finished, the RS485 is controlled to be in the receiver state, so that accurate quantitative control over the data sending time is achieved; and the data can be completely sent within reasonable and accurate delay time, and the problem of data packet loss or serial port jamming is avoided.

Owner:重庆芯讯通无线科技有限公司

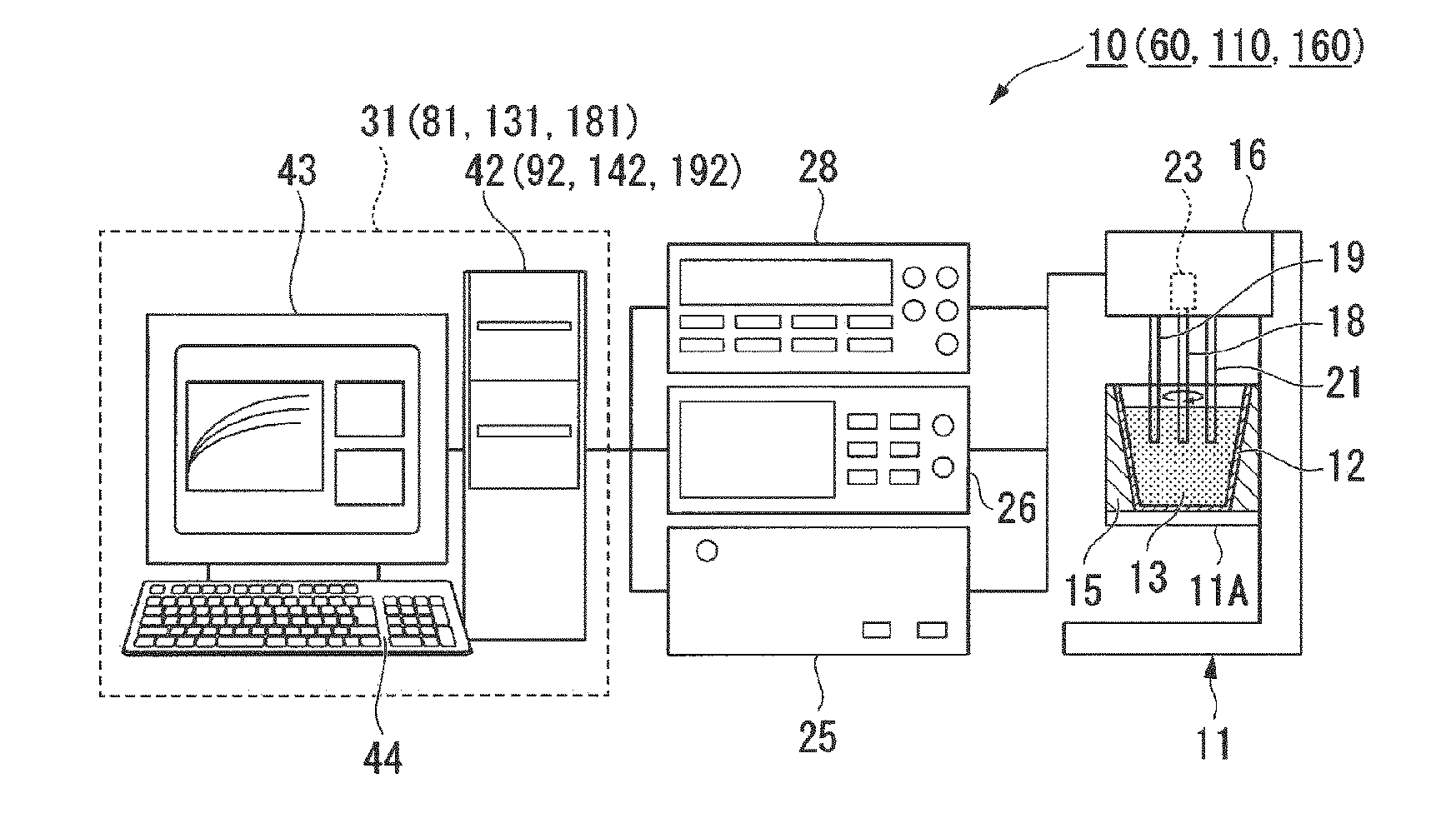

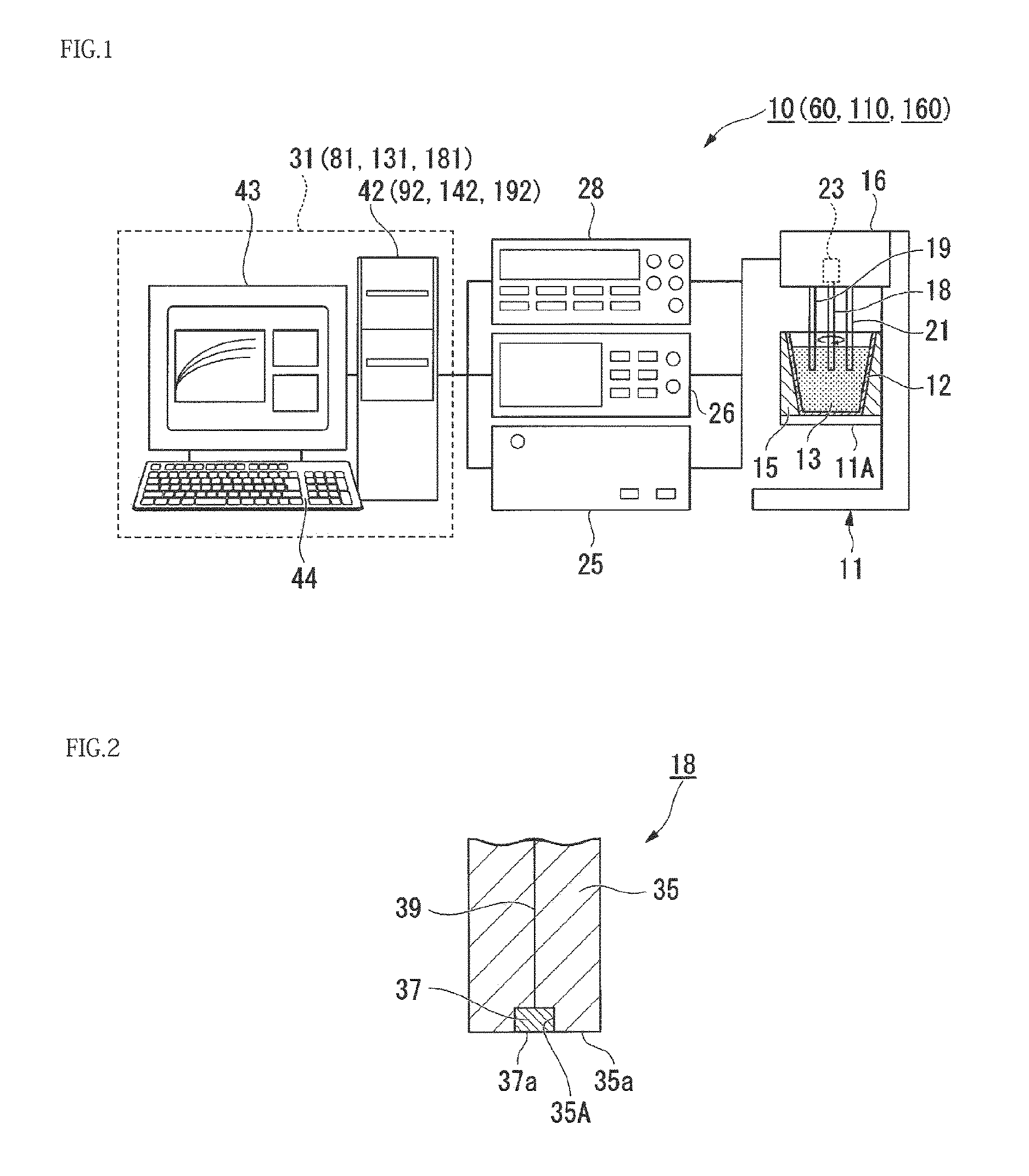

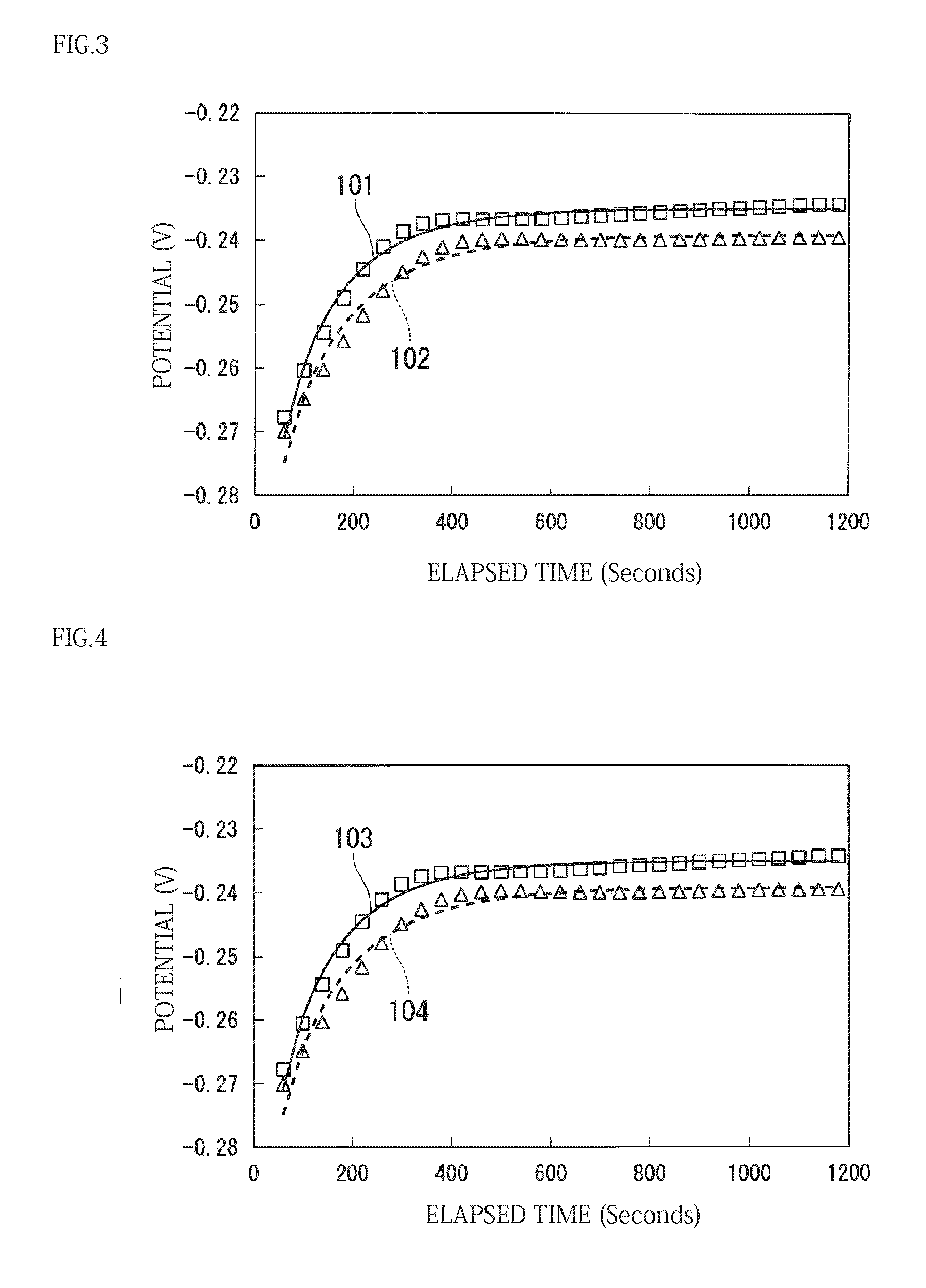

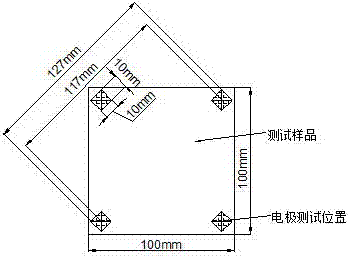

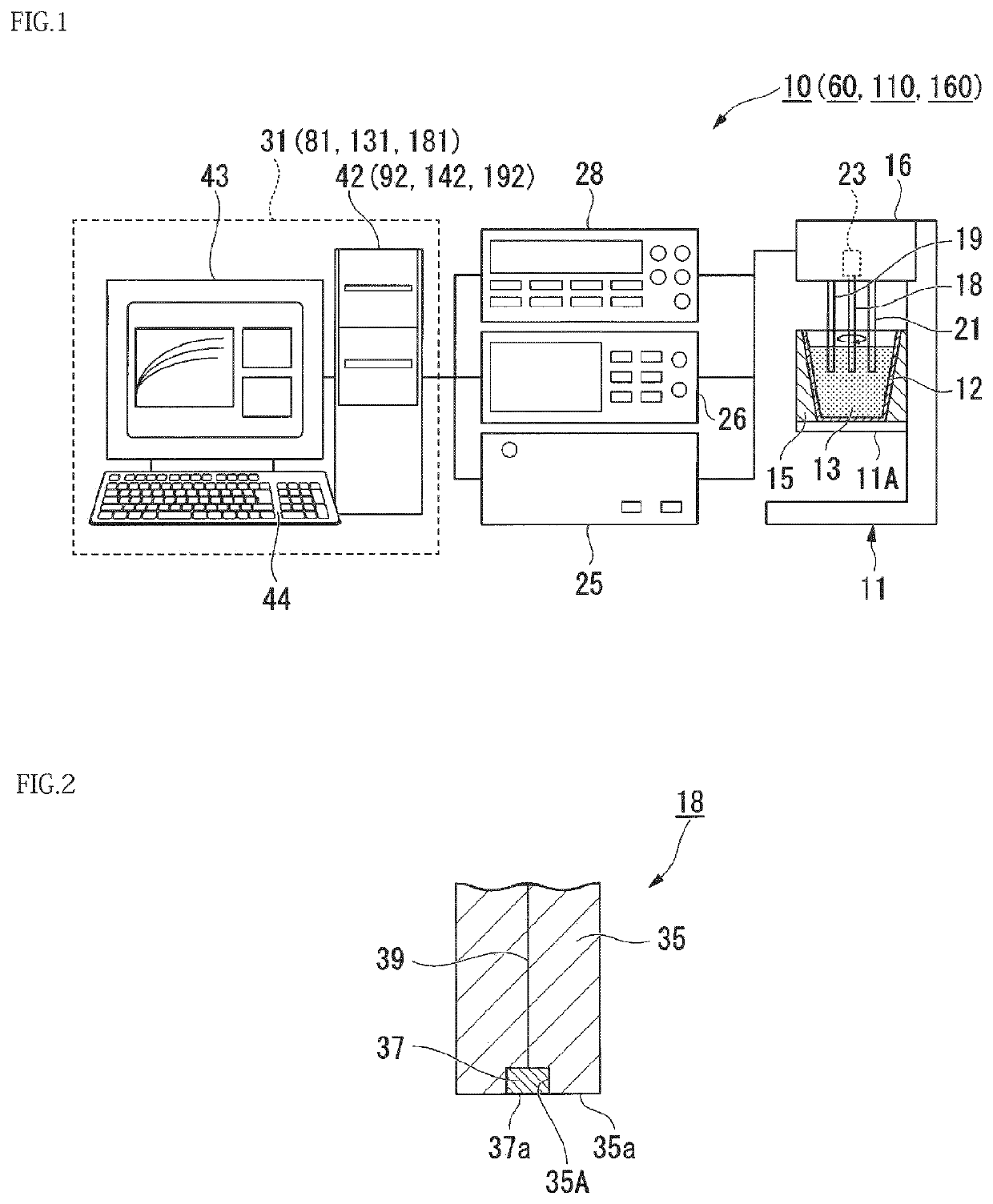

Electrolytic copper plating solution analyzer, and electrolytic copper plating solution analysis method

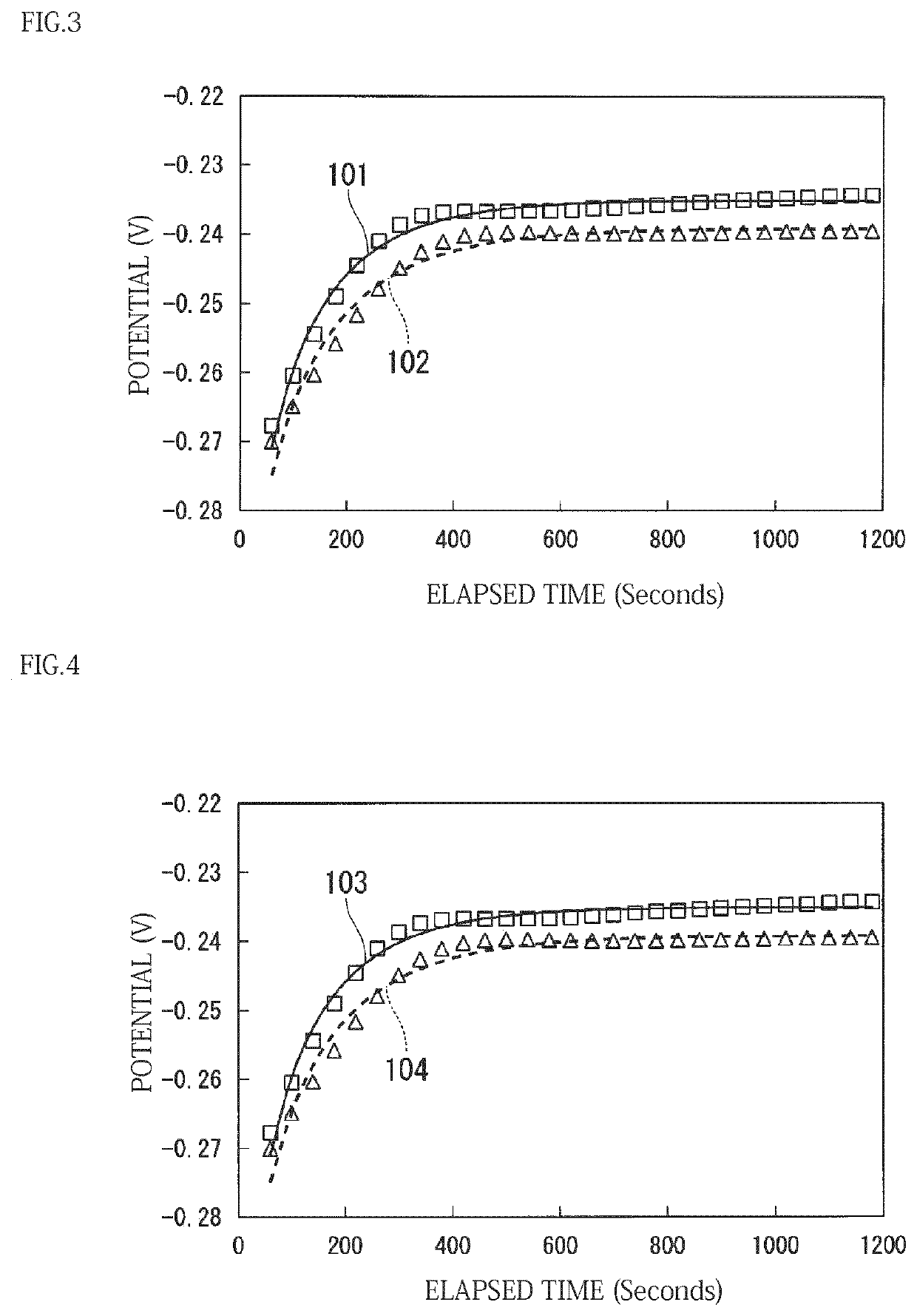

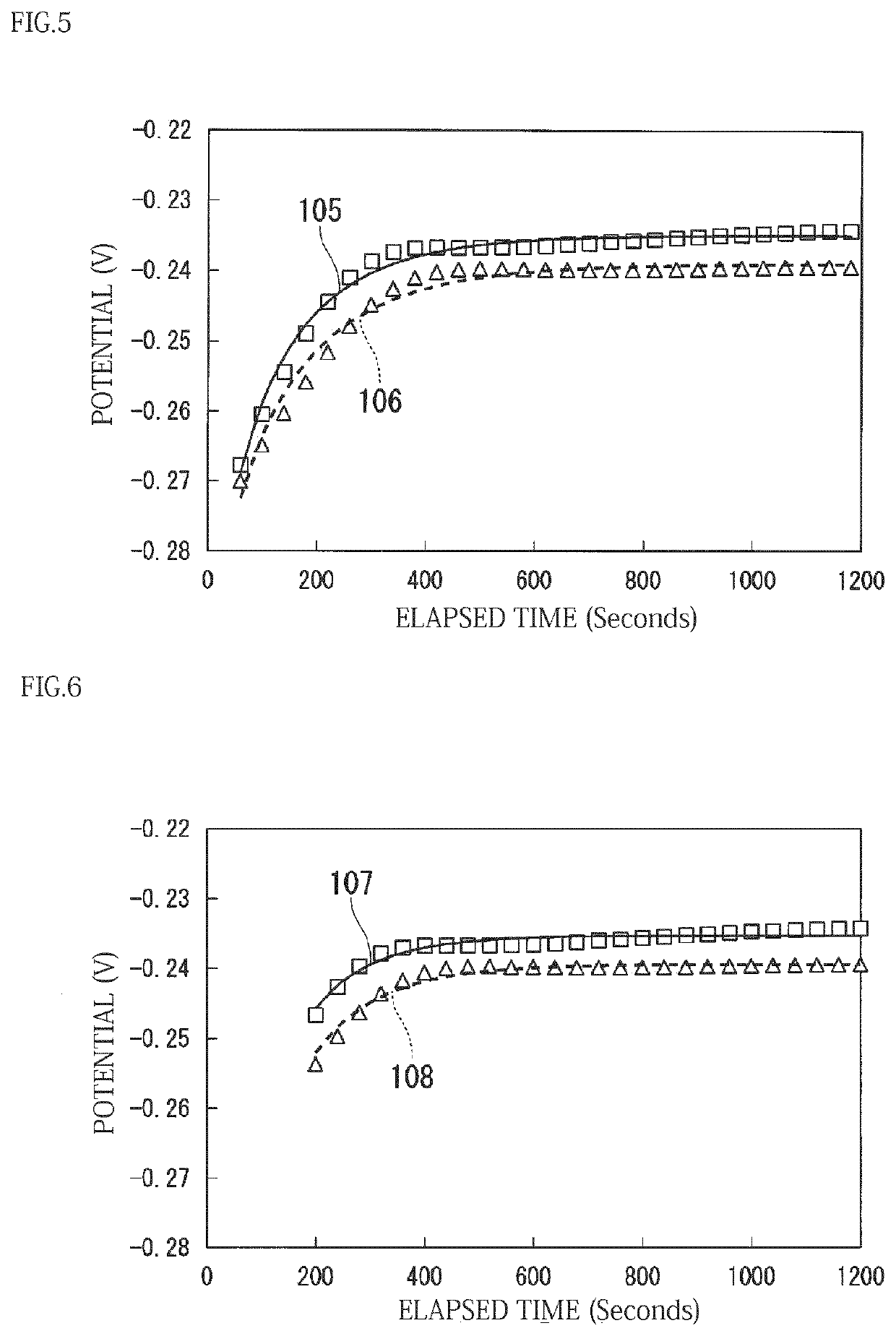

ActiveUS20160377573A1Quantitative control is accurateCellsMaterial electrochemical variablesPotential measurementElectrolysis

An electrolytic copper plating solution analyzer comprises an analysis container for accommodating a part of an electrolytic copper plating solution containing additives including a promoter, an inhibitor and a leveler, a working electrode immersed in the electrolytic copper plating solution accommodated in the analysis container, a reference electrode immersed in the electrolytic copper plating solution and used as a reference when a potential of the working electrode is determined, a counter electrode immersed in the electrolytic copper plating solution, a rotation drive unit for rotating the working electrode at a given speed, a current generation unit passing an electric current with a given current density between the working electrode and the counter electrode, a potential measurement unit for measuring the potential between the working electrode and the reference electrode, and an analysis unit for analyzing the relationship between an elapsed time after the current passage and the potential.

Owner:TOPPAN PRINTING CO LTD

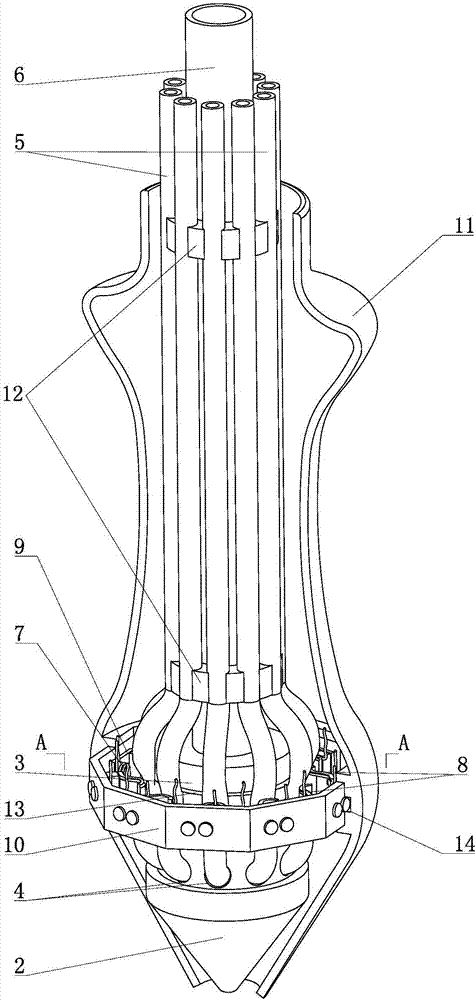

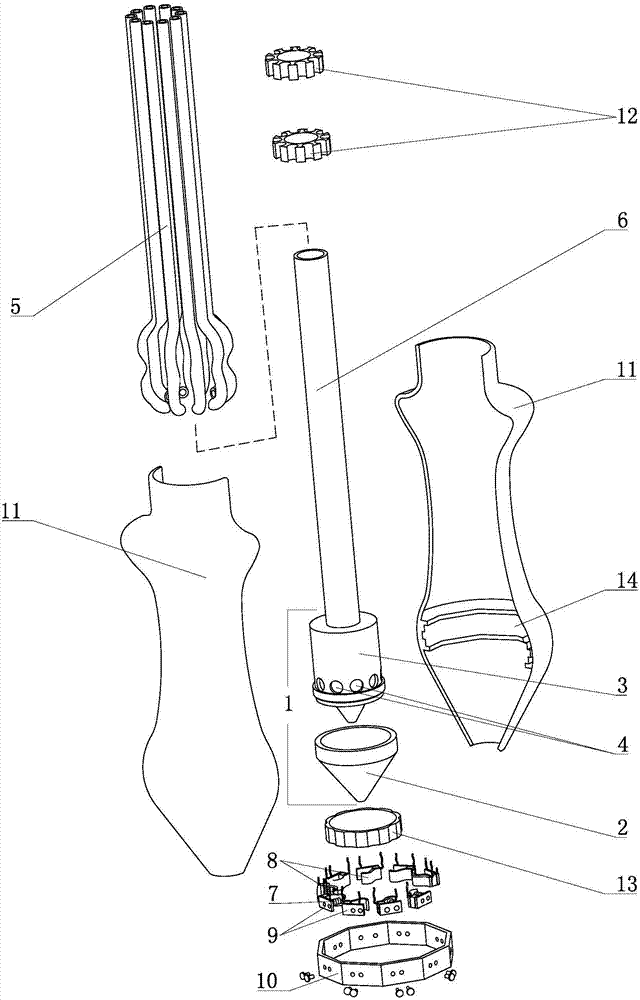

Novel nozzle which can be precisely controlled

PendingCN106859356AQuantitative control is accuratePrecise Control Quantitative ControlCooking vesselsLiquid spraying apparatusPhysicsSeasoning

The invention discloses a novel nozzle which can be precisely controlled. The novel nozzle comprises a nozzle body, input pipes, an air inlet pipe, a memory alloy spring switch device, fixing rings and a housing, and memory alloy springs are arranged among spring sheets and insulating plates; the two sides of each memory alloy spring are connected to a power line. In the novel nozzle which can be precisely controlled, characteristics of the memory alloy springs are originally utilized, the memory alloy springs are originally made to emit heat so as to produce distortion and accordingly achieve different states of stretch and retraction through power on and power off, extrusion and non-extrusion of the input pipes through the spring sheets are achieved, accordingly opening and closing of the input pipes are achieved, and thus precise quantitative flow control is achieved; meanwhile air entering through the air inlet pipe drives liquid entering through the input pipes to be ejected from a jet; different mixed ejection effects can be precisely achieved by controlling the input pipes with different quantities to be closed and opened, and the novel nozzle can achieve different flavor tastes when is applied to seasoners.

Owner:傅峰峰

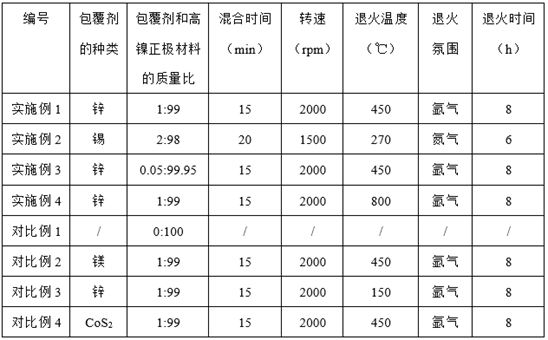

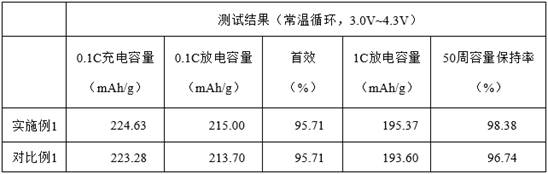

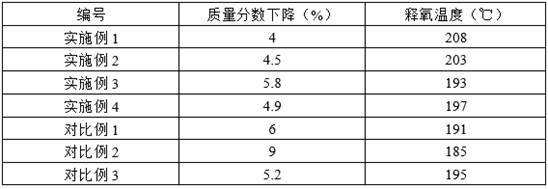

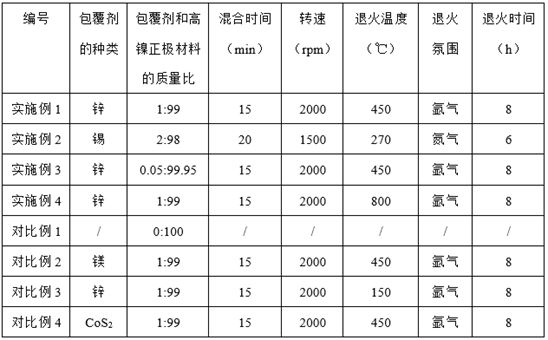

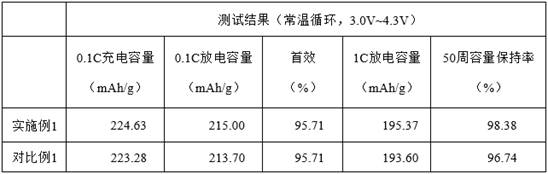

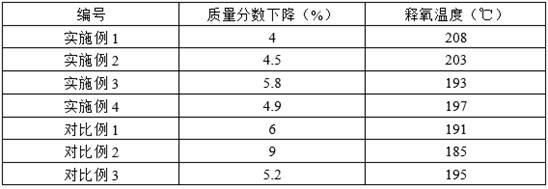

Coated positive electrode material capable of slowly releasing oxygen as well as preparation method and application of coated positive electrode material

ActiveCN113517429AImprove securityImprove electrochemical performanceFuel and secondary cellsSecondary cellsElectrical batteryLithium-ion battery

The invention discloses a coated positive electrode material capable of slowly releasing oxygen as well as a preparation method and application of the coated positive electrode material. The coated positive electrode material comprises a positive electrode active material and a metal layer coated on the surface of the positive electrode active material, the metal layer is formed by melting a metal simple substance, and the metal activity of the metal simple substance is stronger than that of hydrogen and weaker than that of magnesium. When the positive electrode material disclosed by the invention is applied to the lithium ion battery, an excellent slow release and oxygen release effect is shown, the safety performance of the battery is improved, and good electrochemical performance is also ensured.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Micro-channel structure, micro-fluidic chip and heterogeneous reaction method

PendingCN112755934AQuantitative control is accurateChemical/physical/physico-chemical microreactorsLaboratory glasswaresFluid phaseGas phase

The invention provides a micro-channel structure, a micro-fluidic chip and a heterogeneous reaction method. The micro-channel structure comprises a continuous outer triangular expansion focusing unit, an active valve quantitative uniform control unit and a coaxial flow heterogeneous reaction unit, the continuous outer triangular expansion focusing unit comprises a continuous liquid phase sample inlet, a continuous outer triangular expansion focusing runner and a continuous liquid phase runner; the active valve quantitative uniform control unit comprises a runner built-in valve plug, a gas phase sample inlet, a gas phase channel and a gas buffer chamber; a built-in valve plug is arranged on the inner wall of the continuous liquid phase flow channel; and the coaxial flow heterogeneous reaction unit comprises a reaction liquid phase sample inlet, a reaction liquid phase flow channel and a mixed liquid phase flow channel. The invention solves the technical problem of how to design a microfluidic device and an operation process to realize rapid and accurate quantitative control for accurate and efficient heterogeneous reaction on the basis of generating high-dispersion liquid drops and particles.

Owner:GUANGDONG UNIV OF TECH

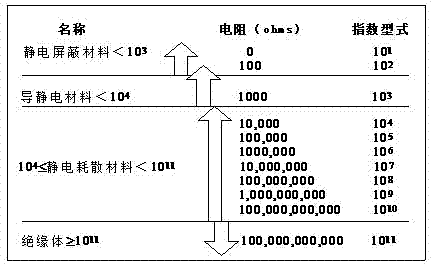

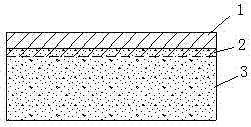

Anti-static coating carton and preparation method thereof

InactiveCN106894293AImprove bindingNot easy to fall offNon-fibrous pulp additionFlexible coversFiberCardboard

Anti-static coated carton and its preparation method, using special imported equipment to achieve precise control of different coating amounts, coating anti-static coating on the inner paper of the carton, and then pressing the anti-static coating part into it through high temperature (about 170°C) and high pressure A new material layer (2) is formed in the superficial layer of fiber of the cardboard (3), and the antistatic coating forms a new antistatic protective film layer (1) on the surface of the cardboard. Control the pressure between different helical rods and the cardboard coated with antistatic coating to achieve quantitative coating of antistatic coating, which can easily reach 10 3 The Ω grade makes the insulating linerboard become a static dissipative material or a static conductive material. When the package is subjected to harsh transportation environments such as high temperature and high humidity, vibration and shock, the anti-static carton can not only protect the contents from electrostatic damage, but also has stable electrostatic protection performance and is not easy to fall off. And it has the advantages of remarkable effect, convenient production, low cost and the like.

Owner:DACHENG PACKAGING PROD SUZHOU

Sprayer with precise and quantitative powder adding function

ActiveCN107054897AEasy to controlQuantitative control is accuratePowdered material dispensingEngineering

The invention discloses a sprayer with a precise and quantitative powder adding function. The sprayer comprises a sprayer body, input pipes, a screwing switch, a synchronous vibration device, an air inlet pipe, servo motors and a shell. The sprayer with the precise and quantitative powder adding function has the advantages of being compact and exquisite in structure, capable of achieving seamless, alternate, continuous, precise and quantitative spraying of varieties of powder or mixed spraying of the varieties of powder and the like, and the power can be sprayed to the surfaces of objects more uniformly; and meanwhile, by adoption of the optimized scheme, the problem that a pipeline is prone to being blocked when the powder is continuously added and fed is solved.

Owner:傅峰峰

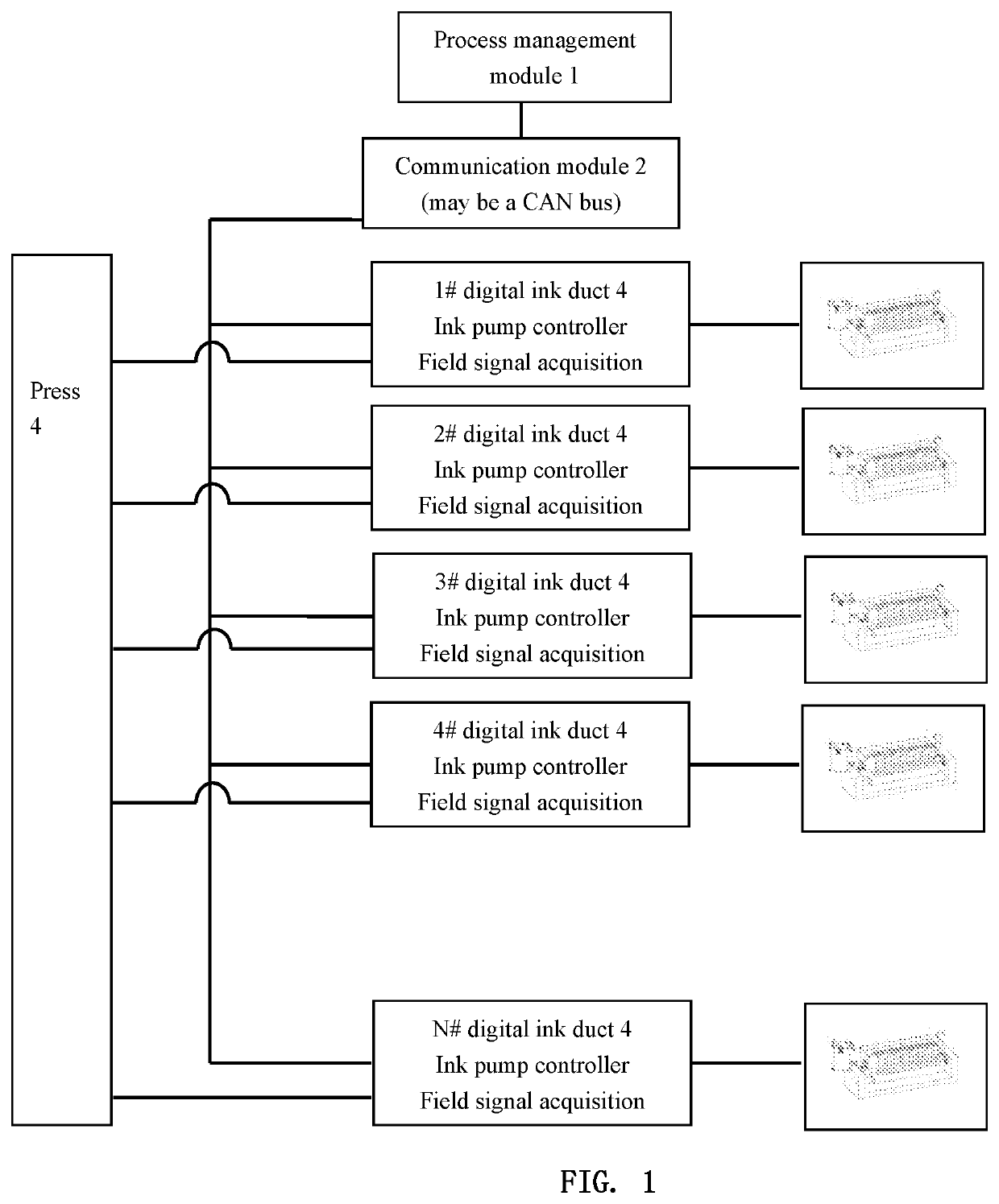

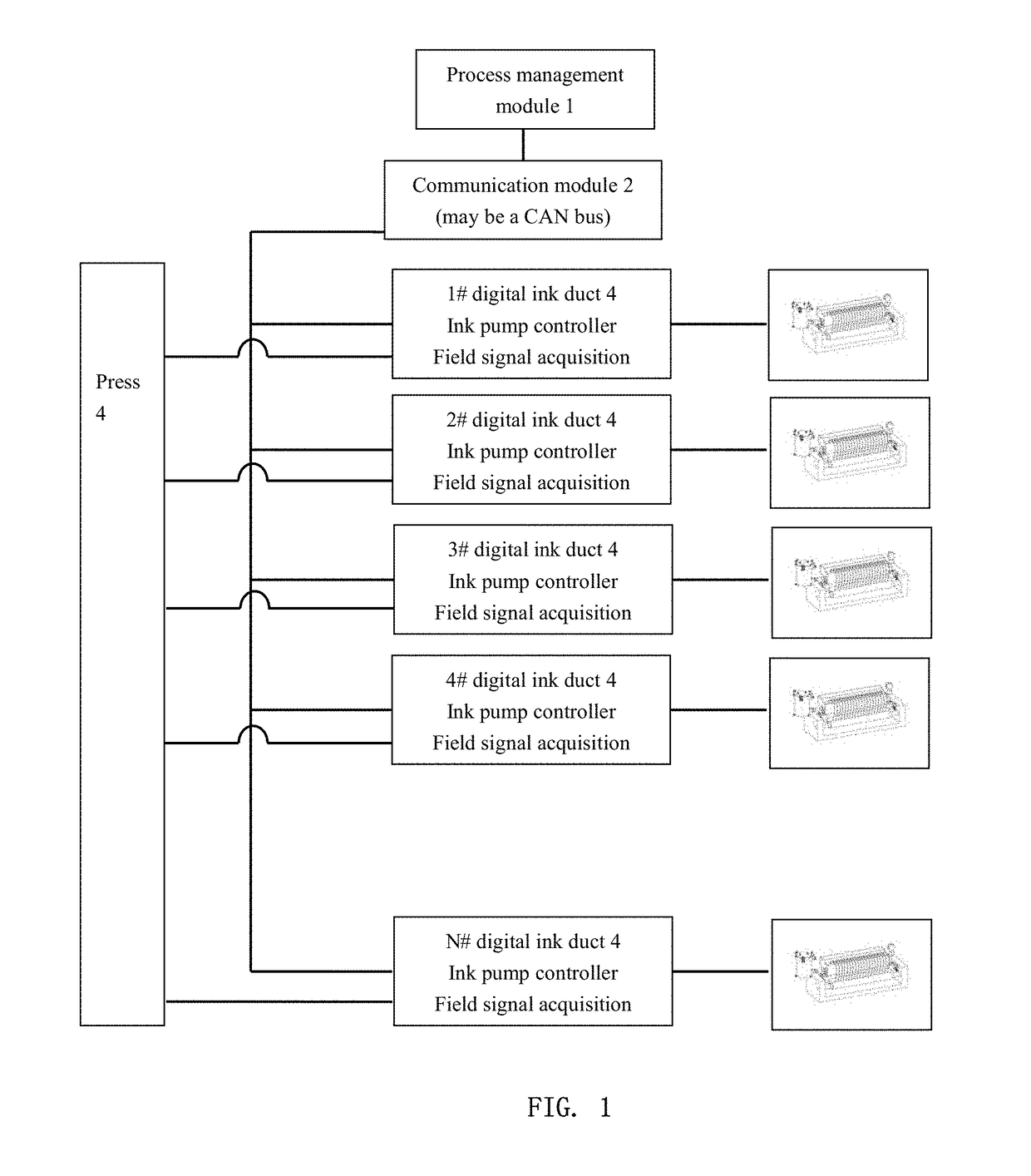

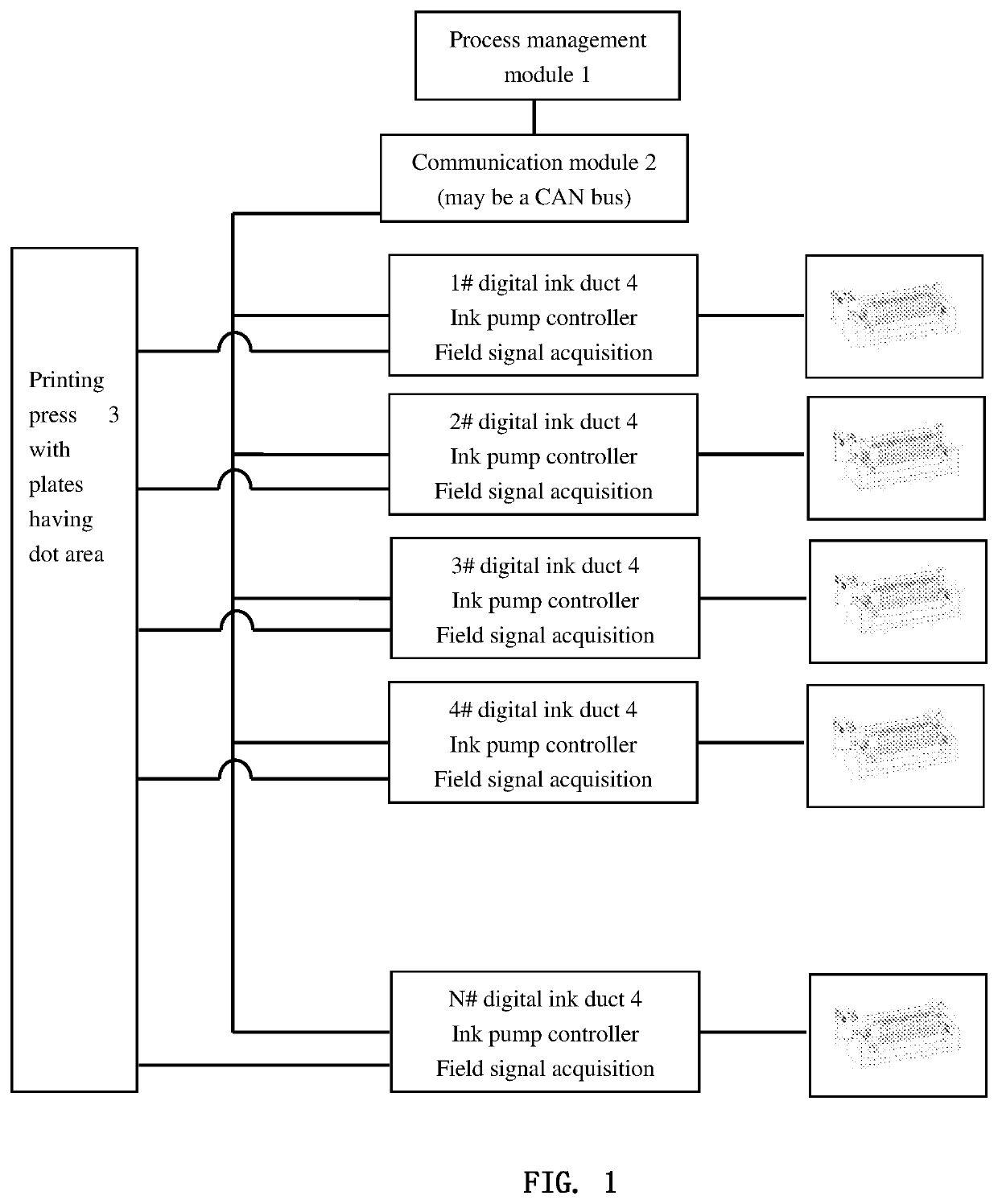

Digital ink-supplying method for printing press

ActiveUS11007771B2Quantitative control is accurateLimited supplyDuplicating/marking methodsColor matchingProcess engineeringPrinting press

The present invention discloses an accurate digital ink supply method for a printing press. The present invention adopts metering-type ink delivery units to replace the ink keys of the traditional printing press, and the metering-type ink delivery units directly deliver the ink to the corresponding ink zones on the metering basis of either volume or mass, realizing the quantitative supply of ink to each one of the ink zones. The present invention can perform accurate adjustment in real time, is high in automation and digitalization degree and large in adjustable range, realizes one-way ink delivery and avoids ink return.

Owner:HANGZHOU CRON MACHINERY & ELECTRONICS CO LTD

Propelled dust aerosol generating equipment

InactiveCN102166488BQuantitative control is accurateEasy to cleanTransportation and packagingMixer accessoriesMotor driveBall screw

The invention provides propelled dust aerosol generating equipment. The equipment comprises a front opened syringe and a stepping motor, wherein the front opened syringe loads powder; the rotation speed of the stepping motor can be adjusted; the stepping motor drives a ball screw to rotate so that a ball nut drives an advancing block to move; a manual adjusting wheel is arranged on the advancing block and can slightly adjust the front opened syringe; a front limit switch and a rear limit switch control the maximal stroke of the advancing block; the powder is pushed into a dust dissolving and separating cavity and bumps with microspheres driven by air flow entering from an air inlet to generate atomized aerosol; and the atomized aerosol is sent to a sealed diffusing cabin through an air outlet and a pipeline. The invention provides the dust aerosol generating equipment, which is precisely and quantificationally controlled, is not easy to block and uniformly dissolves and separates dust; a large amount of dust aerosol can be convenient to prepare reliably; the equipment is applied to researches in the aspects of environmental science, atmosphere physics and chemistry, weather science, industrial manufacturing, medicament and health, and the like, and required dust aerosol related tests and production; a new method is developed; and the precision and the efficiency are improved.

Owner:TIANJIN HOPE IND & TRADE

An automatic quantitative water supply device

ActiveCN103058118BHigh degree of automationQuantitative control is accurateLiquid transferring devicesAutomatic controlEngineering

Owner:王朝民 +1

A kind of coated positive electrode material with slow decomposing oxygen, its preparation method and application

ActiveCN113517429BImprove securityImprove electrochemical performanceFuel and secondary cellsSecondary cellsElectrical batteryLithium-ion battery

The invention discloses a coated positive electrode material for slow decomposing oxygen, its preparation method and application. The coated positive electrode material includes a positive electrode active material and a metal layer coated on the surface of the positive electrode active material. The metal layer is formed after the melting of a metal element, and the metal activity of the metal element is stronger than hydrogen and weaker than hydrogen. magnesium. When the positive electrode material of the present invention is applied to a lithium ion battery, it not only exhibits an excellent effect of slowing and decomposing oxygen, improves the safety performance of the battery, but also ensures good electrochemical performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

A beverage bottle conveying system

ActiveCN106144428BStreaming is simple and fastAvoid pouring bottlesConveyorsLiquid bottlingTransport systemEngineering

Provided is a drink bottle transport system. The drink bottle transport system comprises a bottle-feeding conveyor belt, a bottle-discharge conveyor belt and a plurality of push components for connecting the bottle-feeding conveyor belt with the bottle-discharge conveyor belt. The bottle-feeding conveyor belt comprises a circular conveyor belt, an outer side conveyor belt is additionally arranged on the outer side of the circular conveyor belt, a bottle-discharge opening connected with one of the push components is formed in the inner side of the circular conveyor belt, a horizontal air blowing valve corresponding to the bottle-discharge opening is arranged in the middle of the circular conveyor belt, and a guide rod is arranged at a bottle-feeding opening of the bottle-discharge conveyor belt. A feeding device and a weighing device are further arranged between the bottle-feeding conveyor belt and the bottle-discharge conveyor belt, and a bottle body at the bottle-feeding opening is pushed to a weighing component for feeding and continues to be pushed to the bottle-discharge opening by the push components. The drink bottle transport system is comparatively simple in structure of each part and reasonable in design, prevents a drink bottle from being jammed in front of and behind the feeding device and falling down, guarantees the efficiency and the order of the whole transport process, also is favorable for completing feeding safely and stably, and improves the product qualification ratio.

Owner:邵阳欣源机械有限公司

Electrolytic copper plating solution analyzer, and electrolytic copper plating solution analysis method

ActiveUS10557819B2Quantitative control is accurateCellsMaterial electrochemical variablesElectrolysisCopper plating

An electrolytic copper plating solution analyzer comprises an analysis container for accommodating a part of an electrolytic copper plating solution containing additives including a promoter, an inhibitor and a leveler, a working electrode immersed in the electrolytic copper plating solution accommodated in the analysis container, a reference electrode immersed in the electrolytic copper plating solution and used as a reference when a potential of the working electrode is determined, a counter electrode immersed in the electrolytic copper plating solution, a rotation drive unit for rotating the working electrode at a given speed, a current generation unit passing an electric current with a given current density between the working electrode and the counter electrode, a potential measurement unit for measuring the potential between the working electrode and the reference electrode, and an analysis unit for analyzing the relationship between an elapsed time after the current passage and the potential.

Owner:TOPPAN PRINTING CO LTD

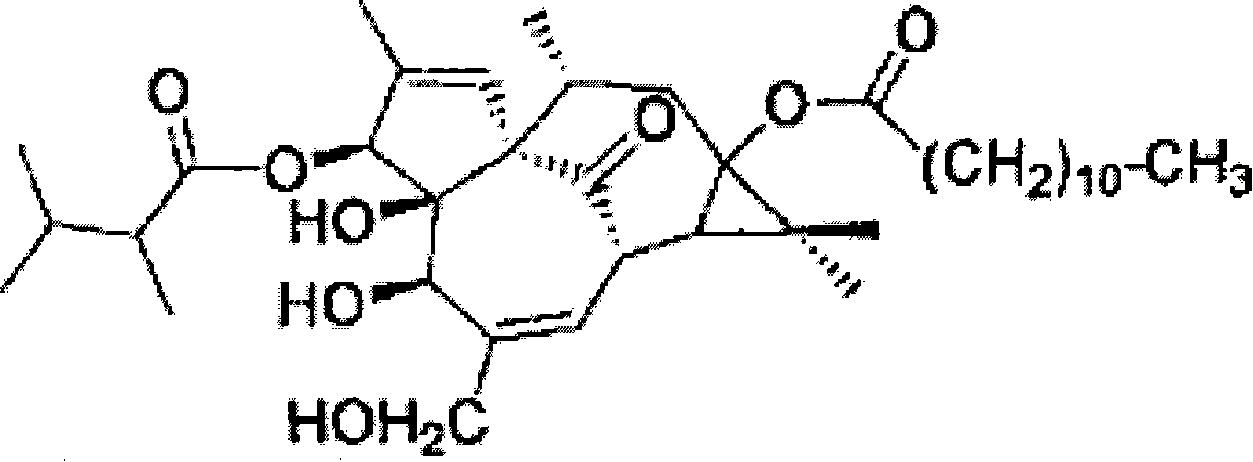

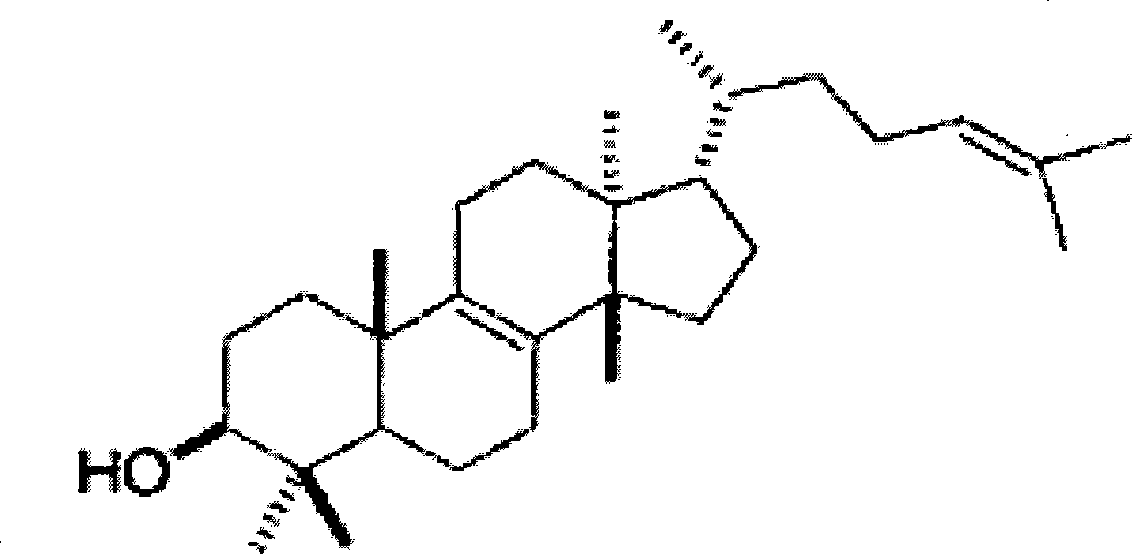

Method for controlling quality of euphorbia kansui decoction pieces

InactiveCN101618060BEffective quality controlQuality improvementComponent separationEuphorbia kansuiEngineering

The invention discloses a method for controlling quality of euphorbia kansui decoction pieces, which comprises a step of determining the content of 3-O-(2,3-dimethylbutanoyl)-13-O-oxododecyl ingenol and euphol in fresh and processed euphorbia kansui. The method uses the separated 3-O-(2,3-dimethylbutanoyl)-13-O-oxododecyl ingenol and euphol as indexes, establishes a method for detecting HPLC-ELSDfor controlling the quality of the euphorbia kansui decoction pieces, has simple and quick operation, and is applicable to quality control of the fresh euphorbia kansui and the processed euphorbia kansui decoction pieces.

Owner:SHANGHAI UNIV OF T C M

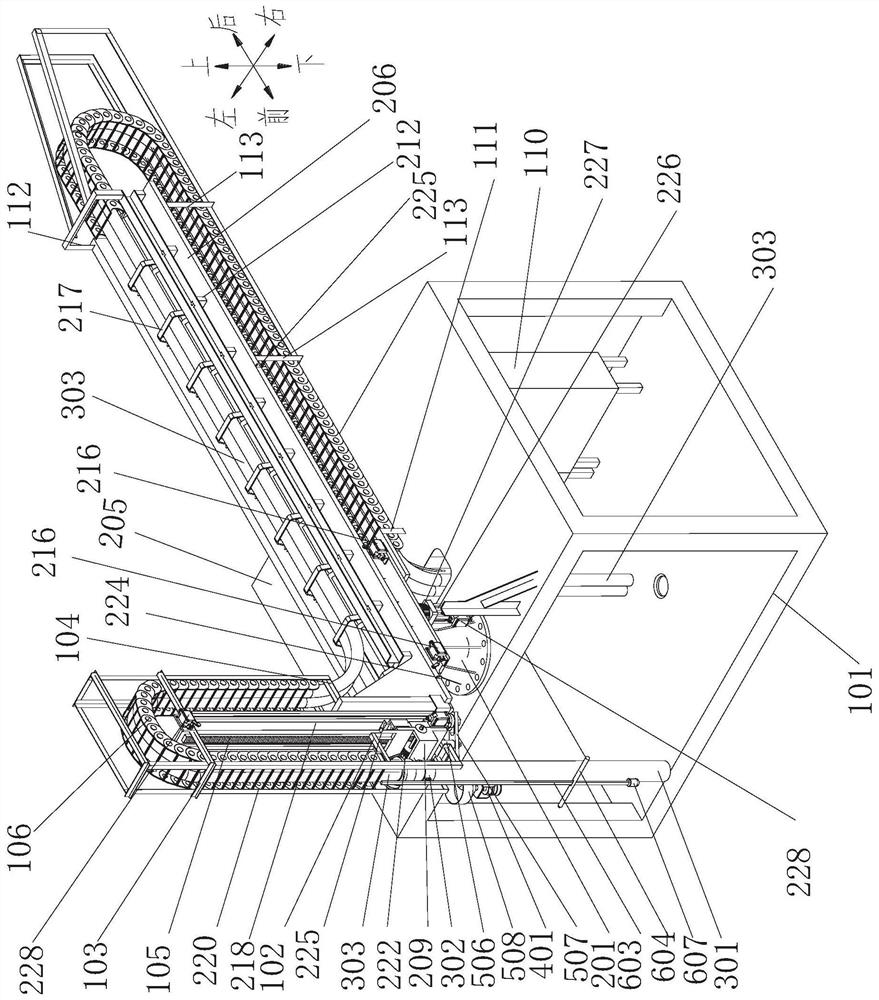

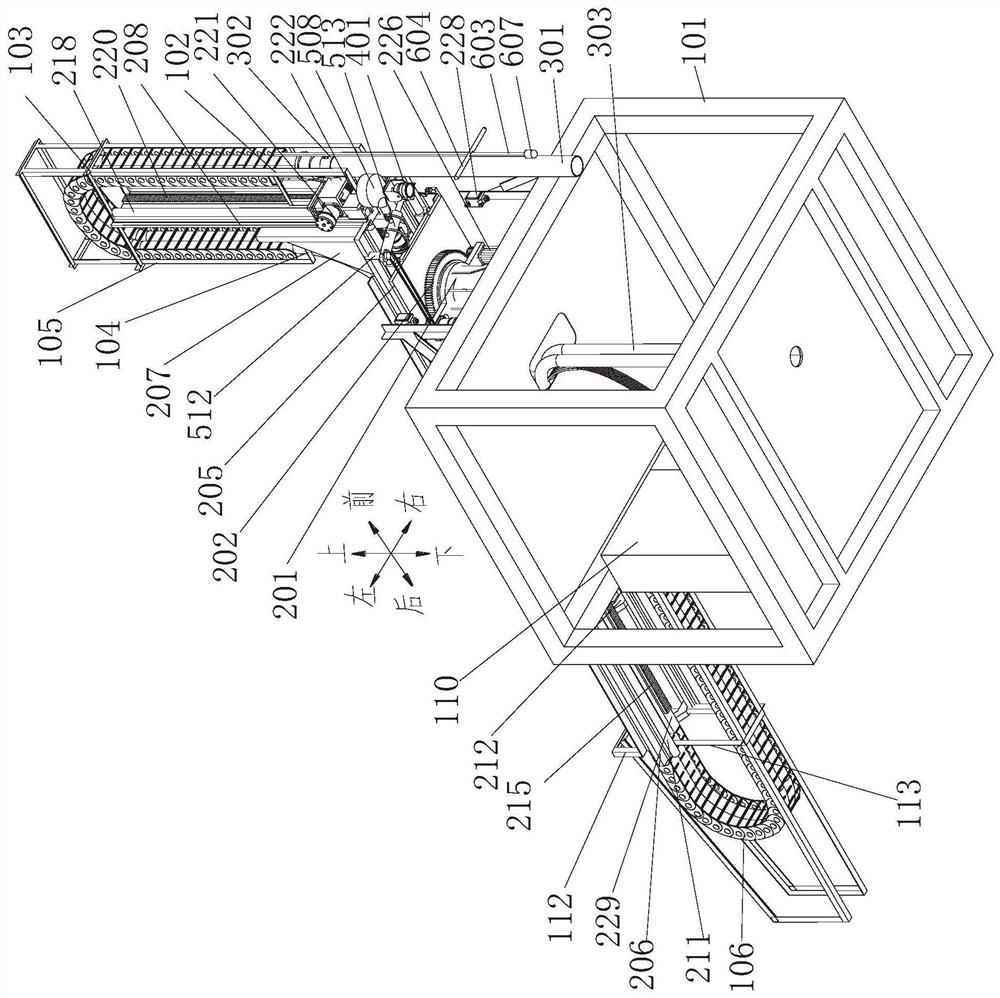

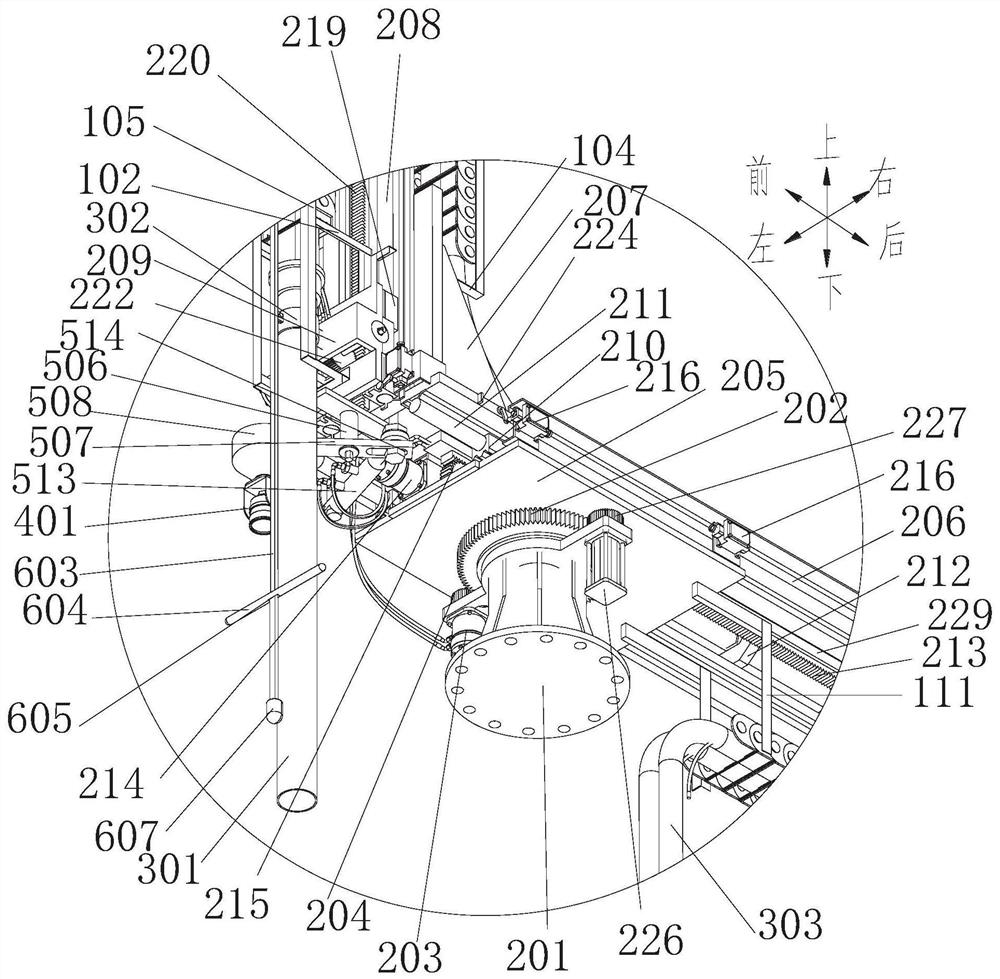

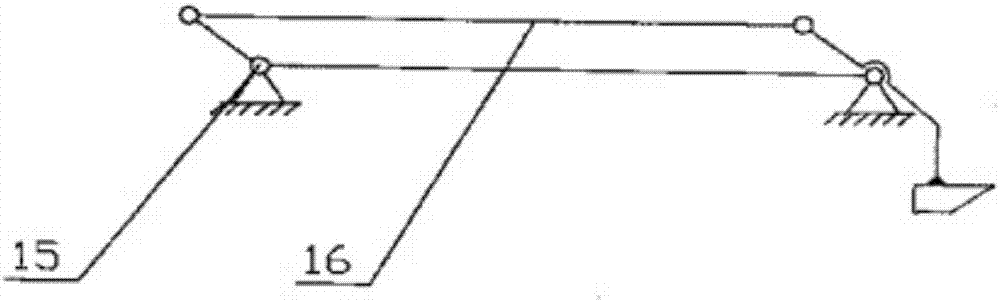

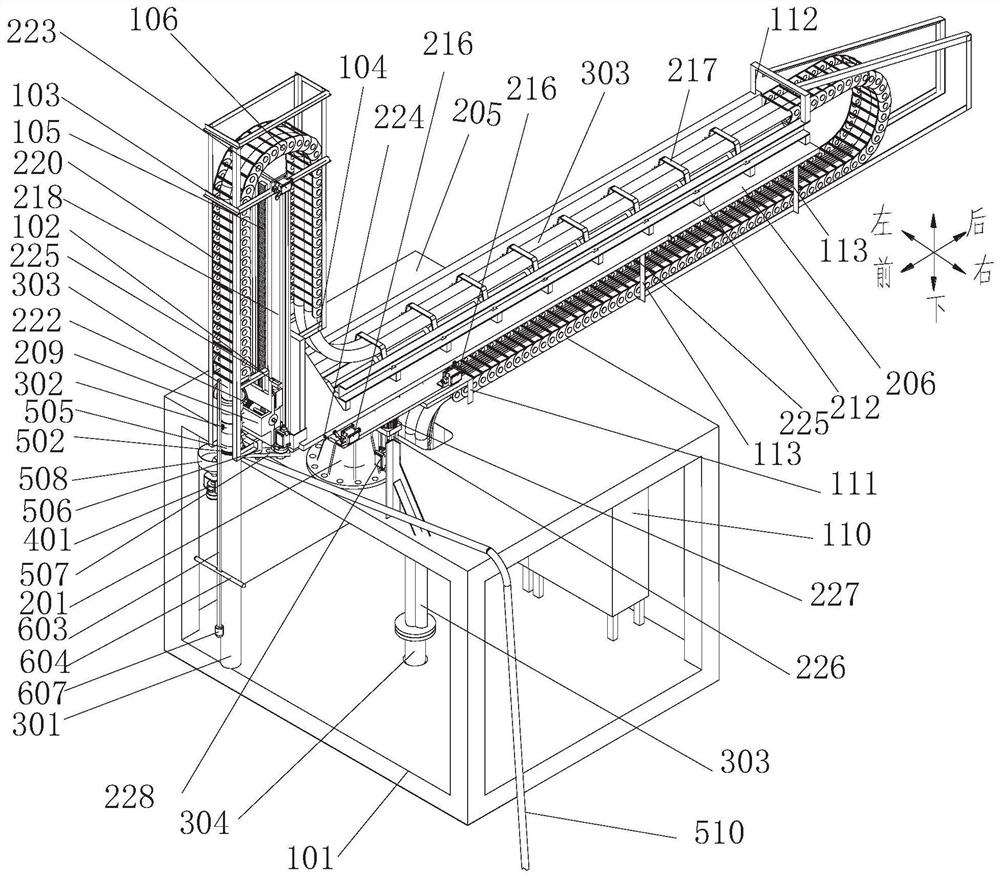

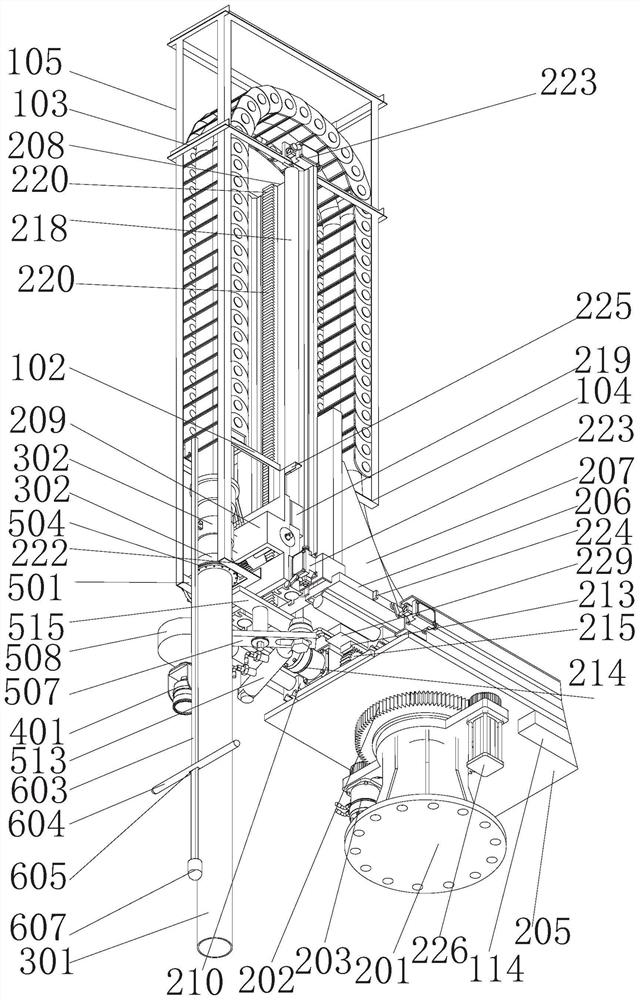

Novel parallel pouring robot

InactiveCN107443357ASolve the problem of super large working rangeOptimize the movement processProgramme-controlled manipulatorMolten metal pouring equipmentsFlexible cableMotor drive

The invention provides a novel parallel pouring robot which comprises a base, a rotating pair, a turnplate, a robot body and a pouring ladle. A cross arm penetrates into a swing slider and is in sliding fit connection with the same, one end of the cross arm is connected with the pouring ladle while the other end of the same is fixedly connected with a balance weight through a balance weight flexible cable wound on a pulley block, and a first coiling block and a second coiling block are arranged inside the robot body and are in hinge-type connection with the cross arm through an upper flexible cable and a lower flexible cable; the robot body adopts a parallel movement mechanism, so that high rigidity and heavy load are realized; the pouring ladle is connected with a pouring ladle swing motor through a parallelogram four-bar mechanism arranged in the cross arm. The robot body capable of rotating horizontally is connected with the motor through the turnplate and the rotating pair, and a volume method is adopted according to requirements of a pouring machine, so that accuracy in liquid taking of each time is ensured; the pouring ladle swing motor drives the parallelogram four-bar mechanism to realize swinging of the pouring ladle within an angle range of -45-75 degrees, and accurate positioning of the pouring ladle is realized; an action program is adopted, so that the novel parallel pouring robot has the advantages of high efficiency and high stability in operating.

Owner:CHANGSHA ZHANSHUO XUANXING INFORMATION TECH CO LTD

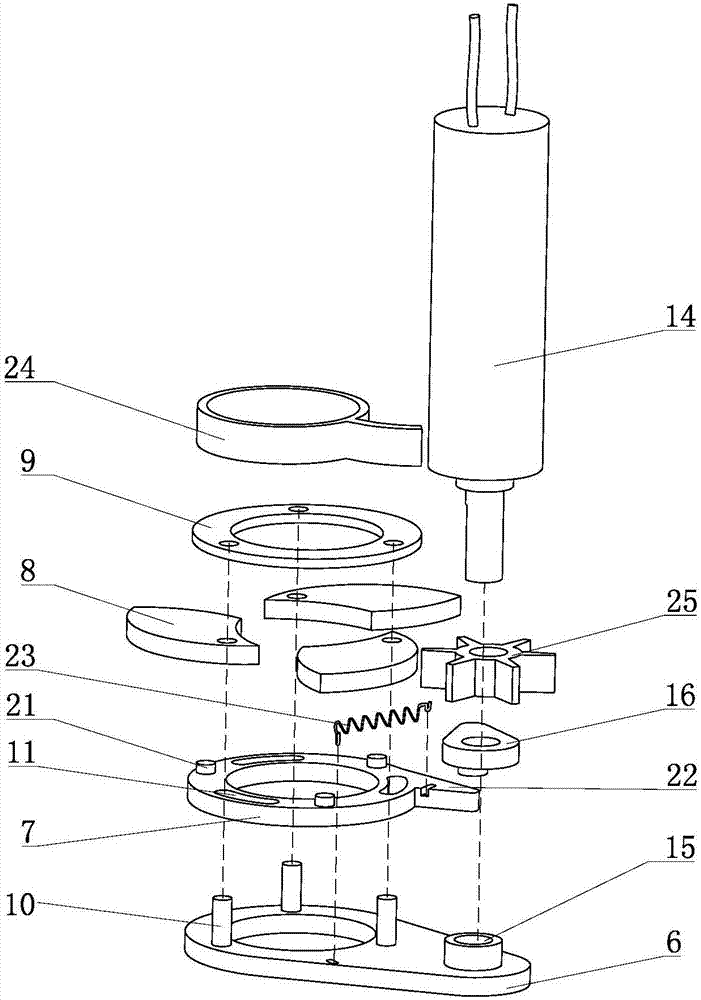

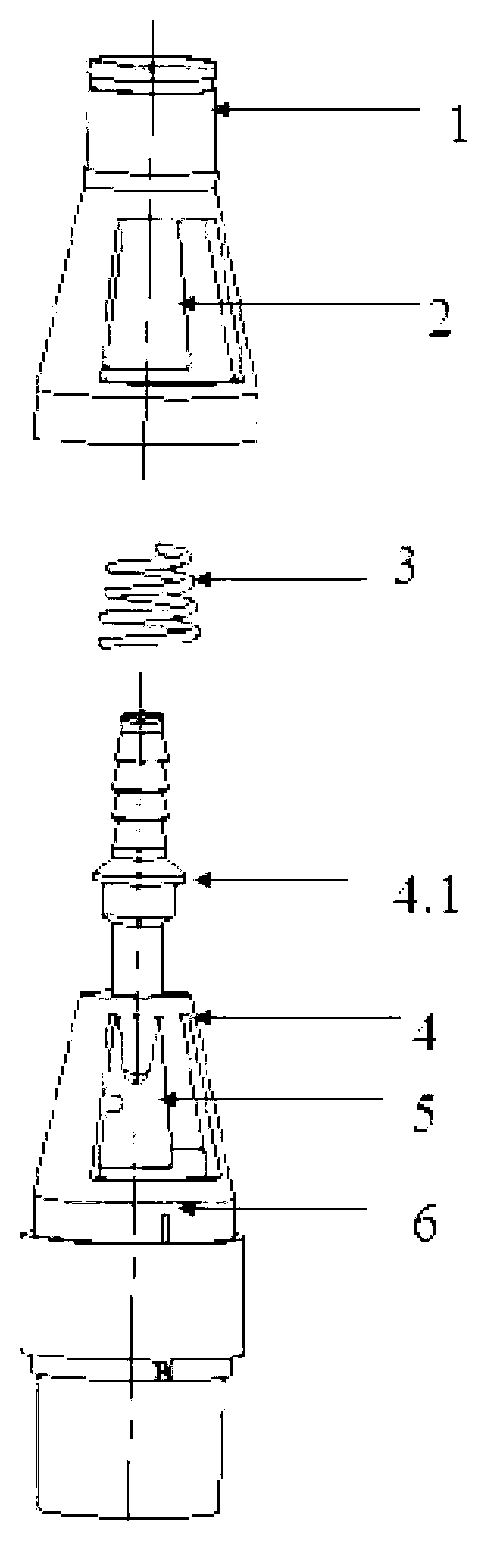

Adjuster for oxygen conveying device

The invention relates to the technical field of medical instruments and discloses an adjuster for an oxygen conveying device. The adjuster comprises an adjuster upper end, wherein the lower end of the adjuster upper end is provided with a first oxygen and air mixing window; the first oxygen and air mixing window is connected with an adjuster main body; a spring is arranged between the first oxygen and air mixing window and the adjuster main body; the adjuster main body is connected with a second oxygen and air mixing window; and the lower end of the second oxygen and air mixing window is provided with an adjuster positioning device. The adjuster of the oxygen conveying device can precisely and quantitatively control oxygen conveying.

Owner:NINGBO SHENGYURUI MEDICAL APPLIANCES

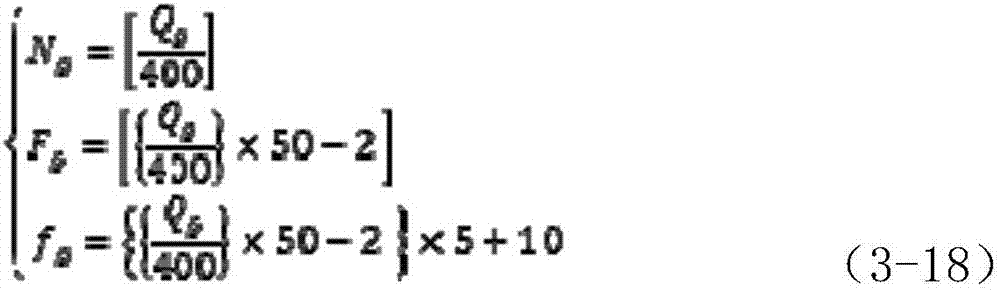

Mine multi-pump multi-frequency conversion emulsion pumping station system and quantitative liquid supply control method

ActiveCN107461321BHigh adjustment accuracyQuantitative control is accuratePump controlPositive-displacement liquid enginesEmulsionFrequency conversion

The invention provides a multi-pump multi-frequency-conversion emulsion pump station system for mining. The multi-pump multi-frequency-conversion emulsion pump station system for mining comprises 400 KW frequency conversion control cabinet, a 110KW frequency conversion control cabinet, four 400 L / min emulsion pumps and a 80 L / min emulsion pump. One end of the 400 KW frequency conversion control cabinet is connected with the 110 KW frequency conversion control cabinet, and the other end of the 400 KW frequency conversion control cabinet is connected with the four 400 L / min emulsion pumps. The 110KW frequency conversion control cabinet is further connected with the 80 L / min emulsion pump. The multi-pump multi-frequency-conversion emulsion pump station for mining adopts the multi-pump multi-frequency-conversion drive manner, the four emulsion pumps with the rated flow of 400 L / min and the emulsion pump with the rated flow of 80 L / min are arranged, each pump can achieve frequency conversion speed control and electronic control loading and unloading, the emulsion supply flow adjustment range can reach 0-1680L / min, and the highest adjustment precision can reach 1.6 L / min; on the basis of the multi-pump multi-frequency-conversion emulsion pump station system for mining, a rated emulsion supply control method is provided. According to the rated emulsion supply control method, through PLC programming in the control cabinet, the multiple pumps are controlled to operate at the industrial frequency, multi-frequency-conversion speed adjustment is controlled, accurate and quantitative control over high-pressure emulsion flow is achieved, and a reliable underlying control basis is provided for further intelligent emulsion supply.

Owner:TAIYUAN UNIV OF TECH

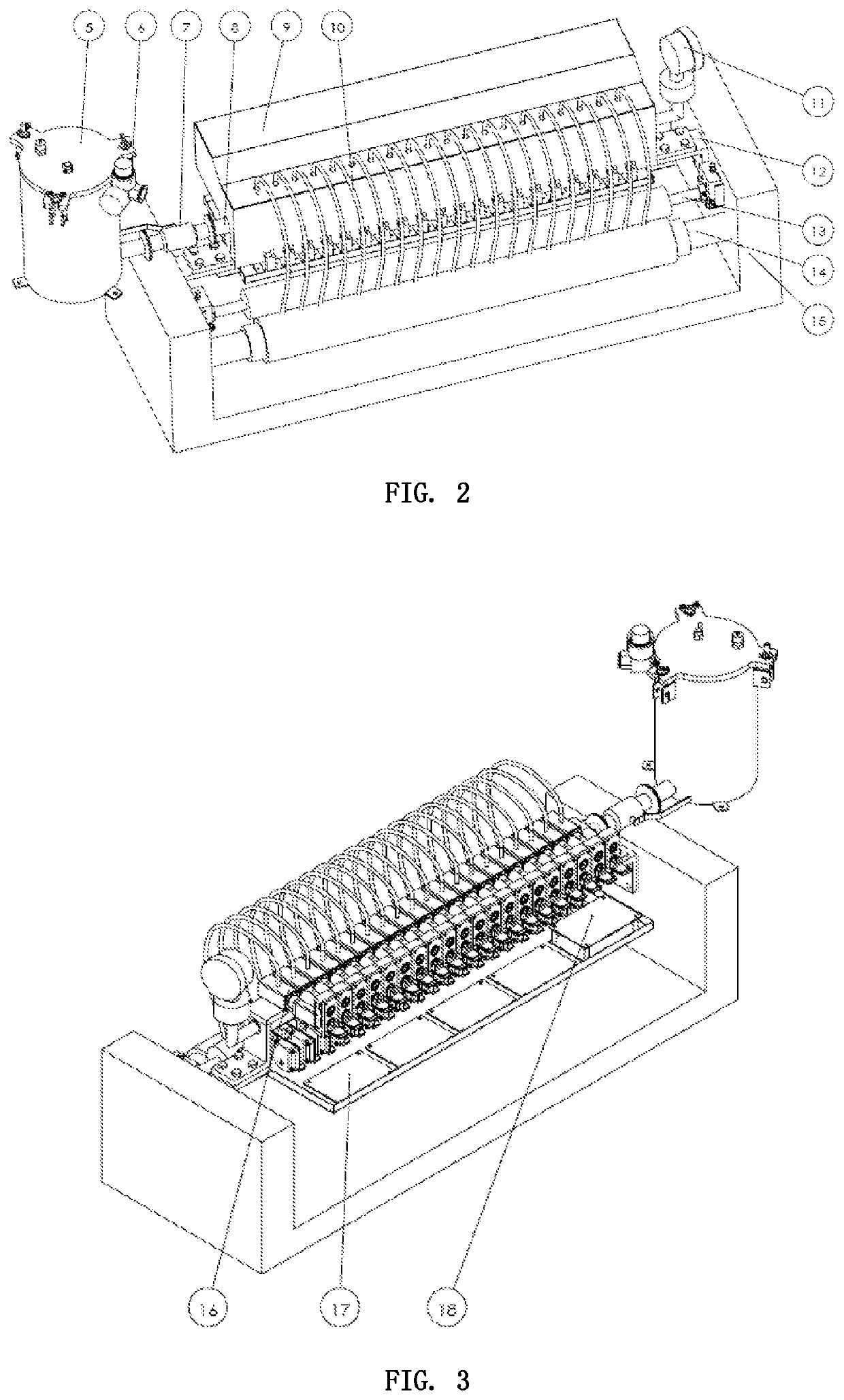

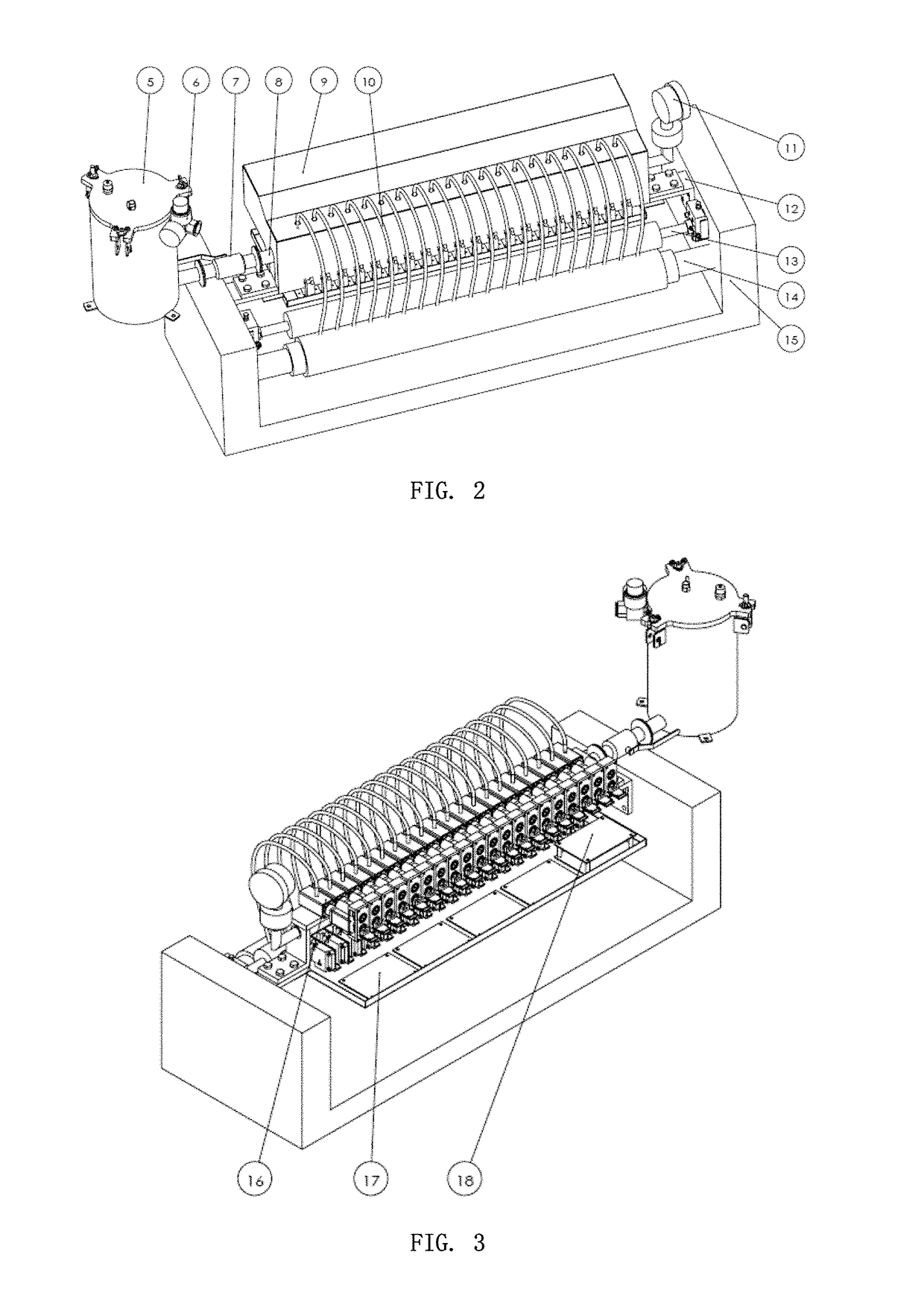

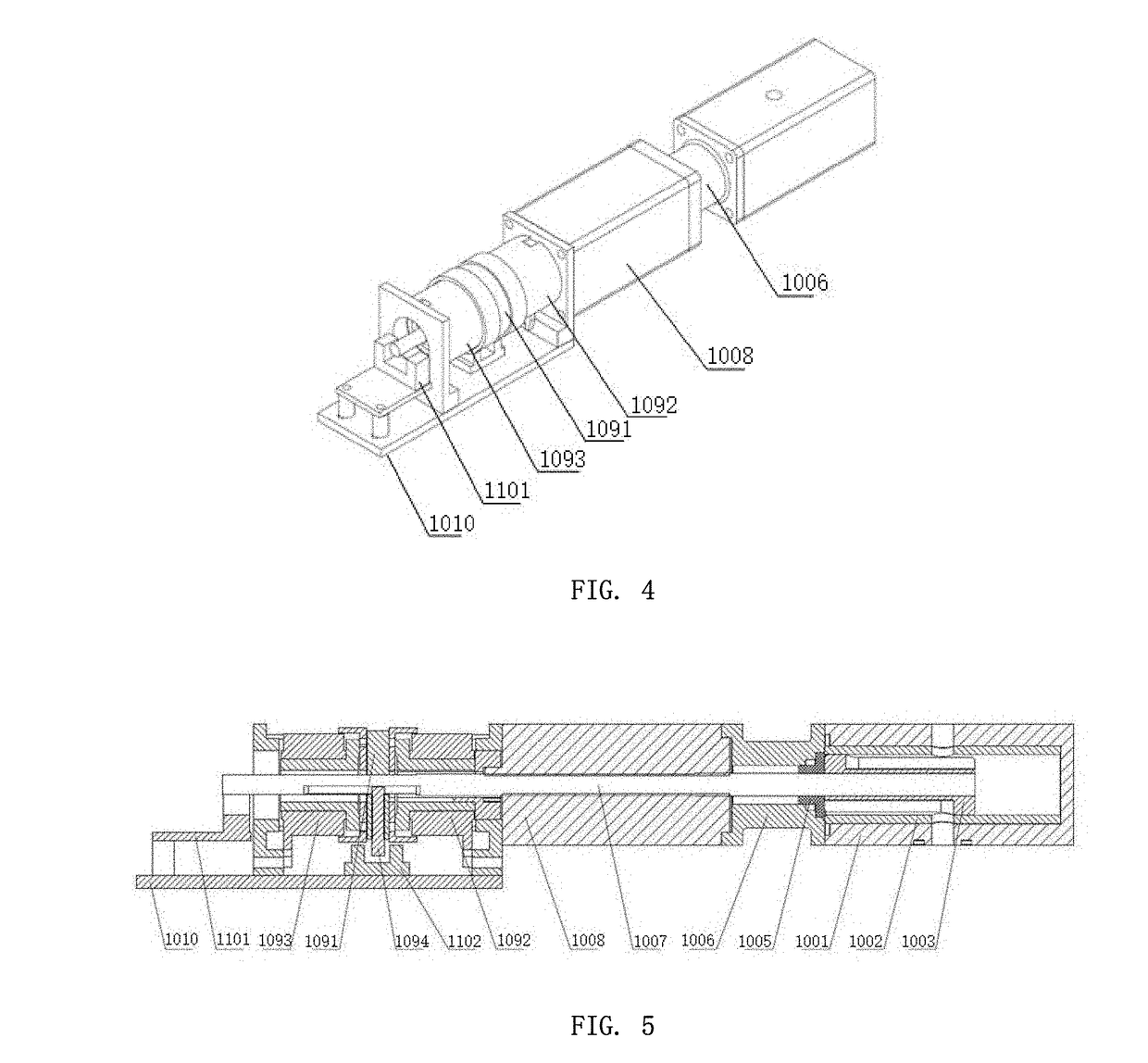

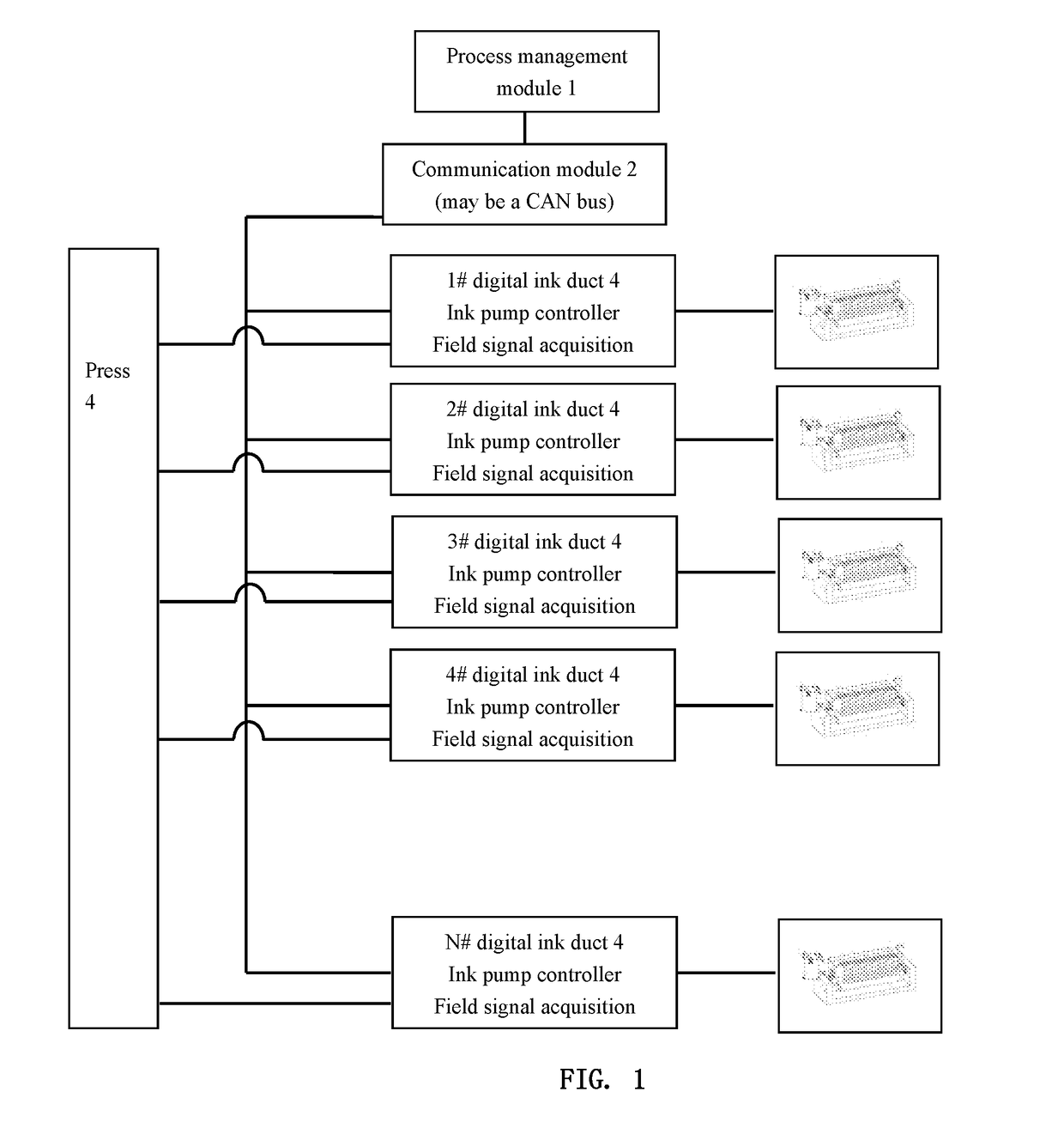

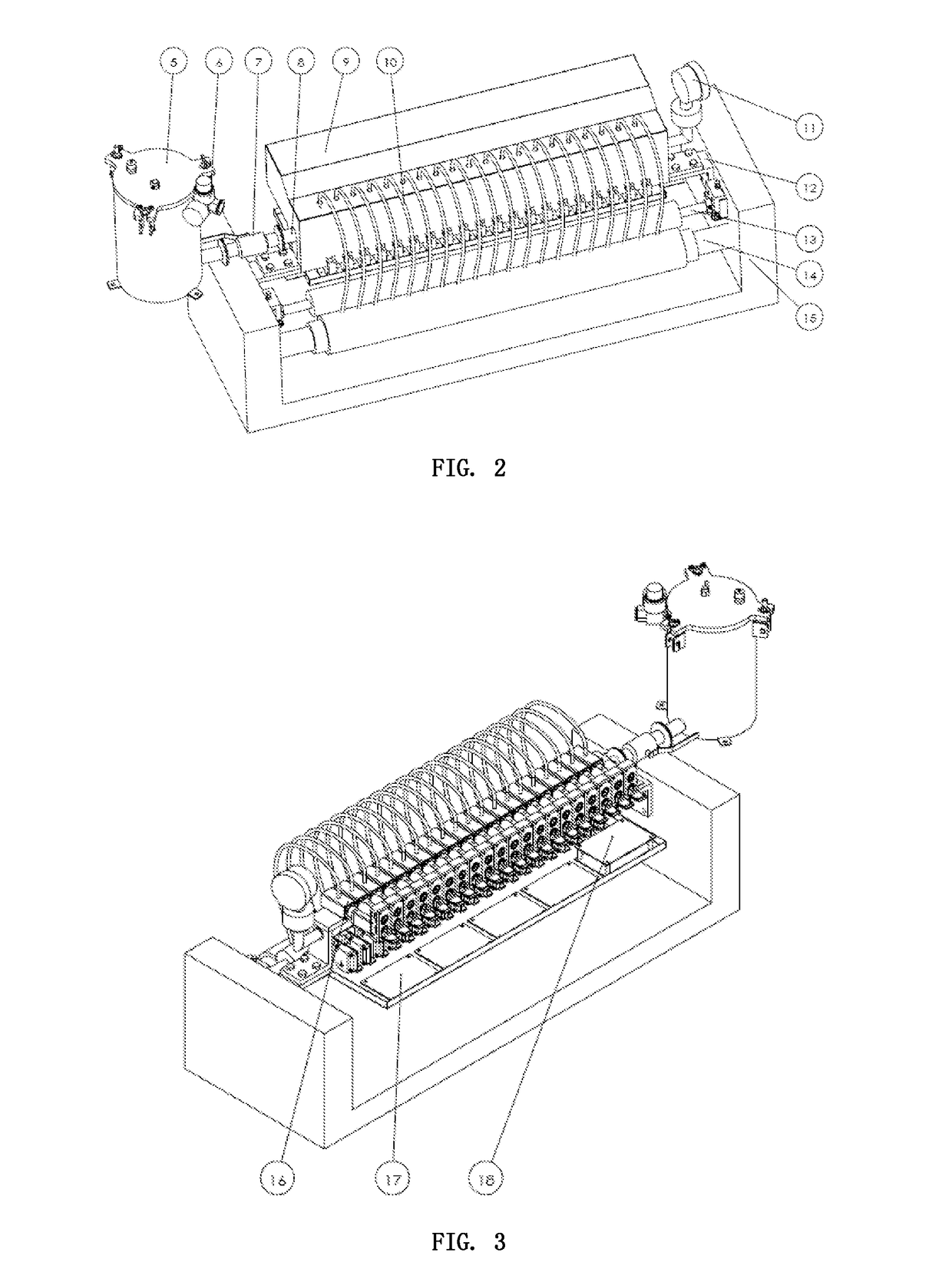

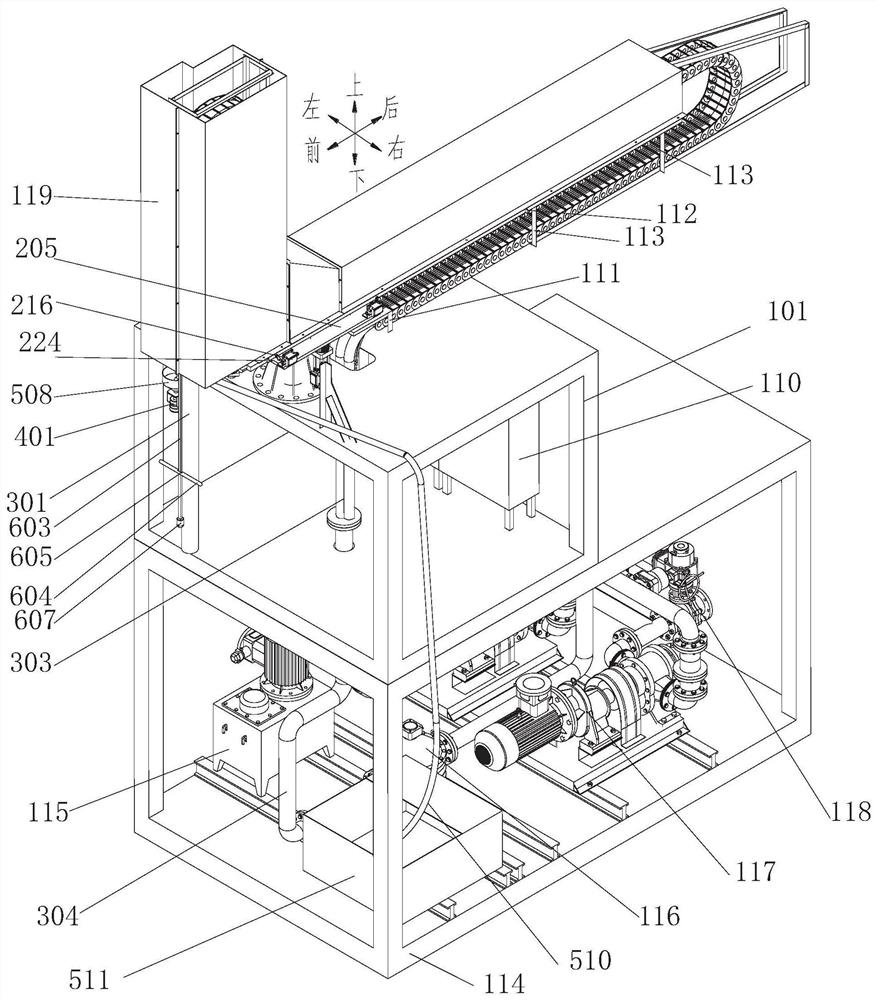

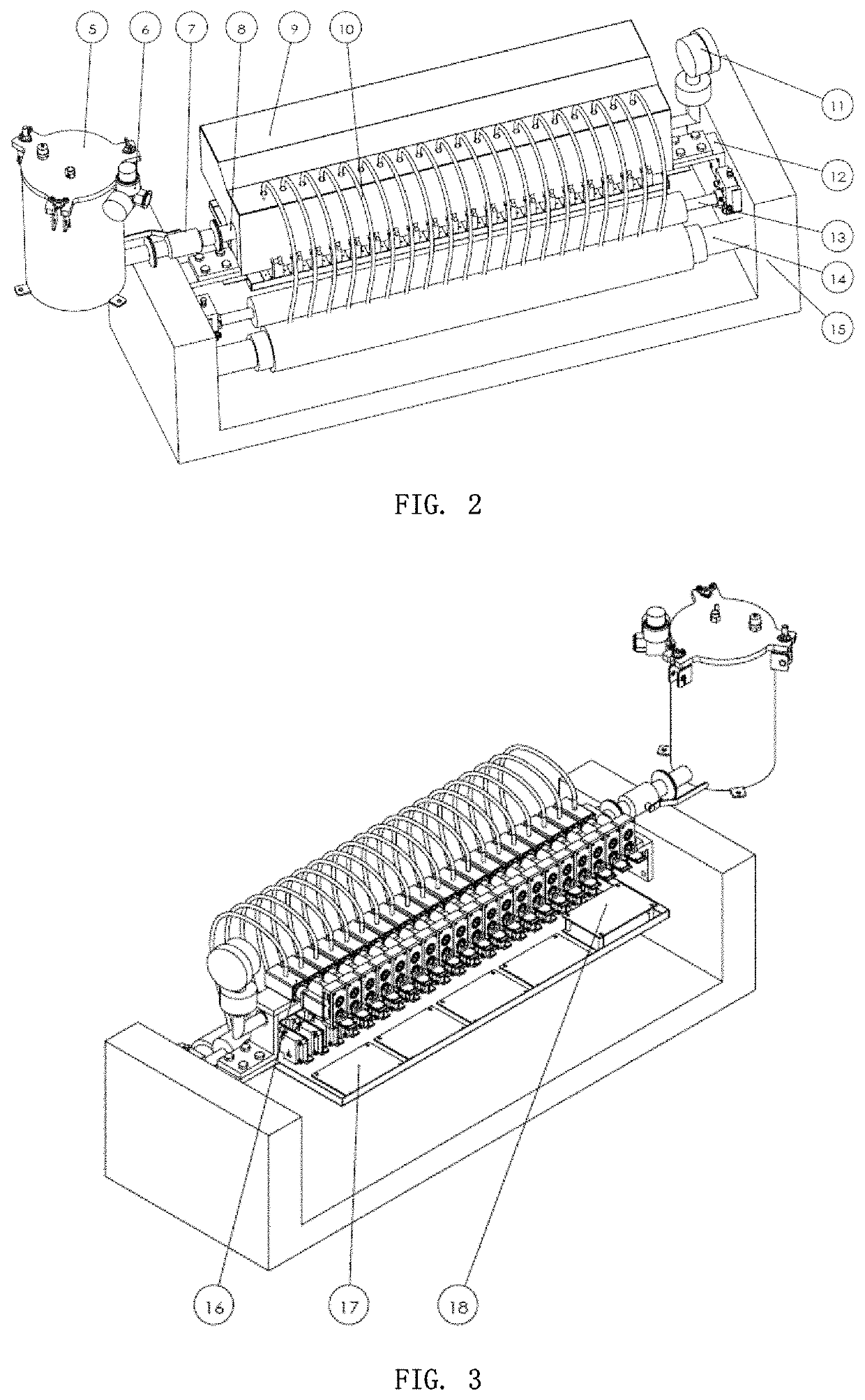

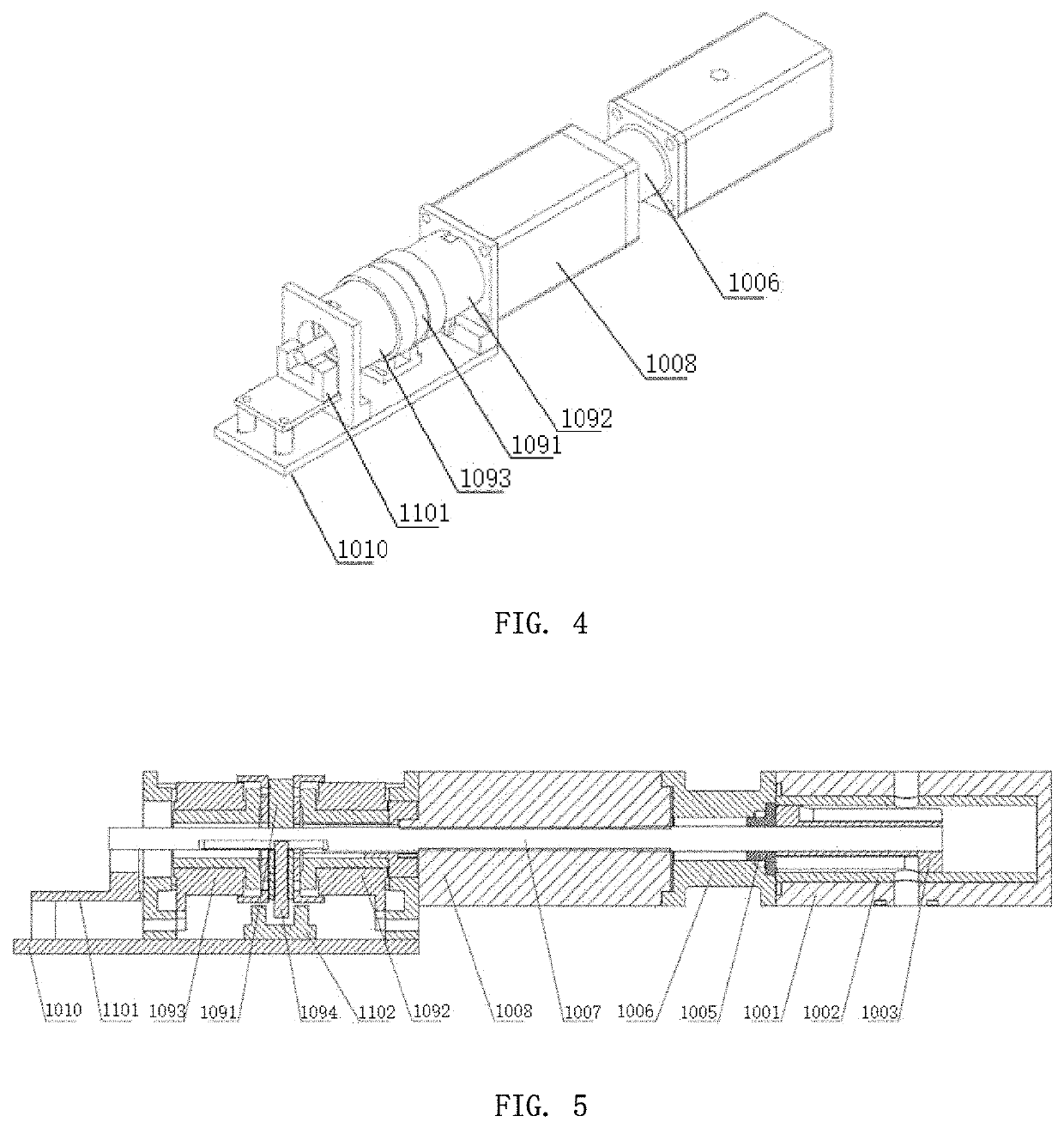

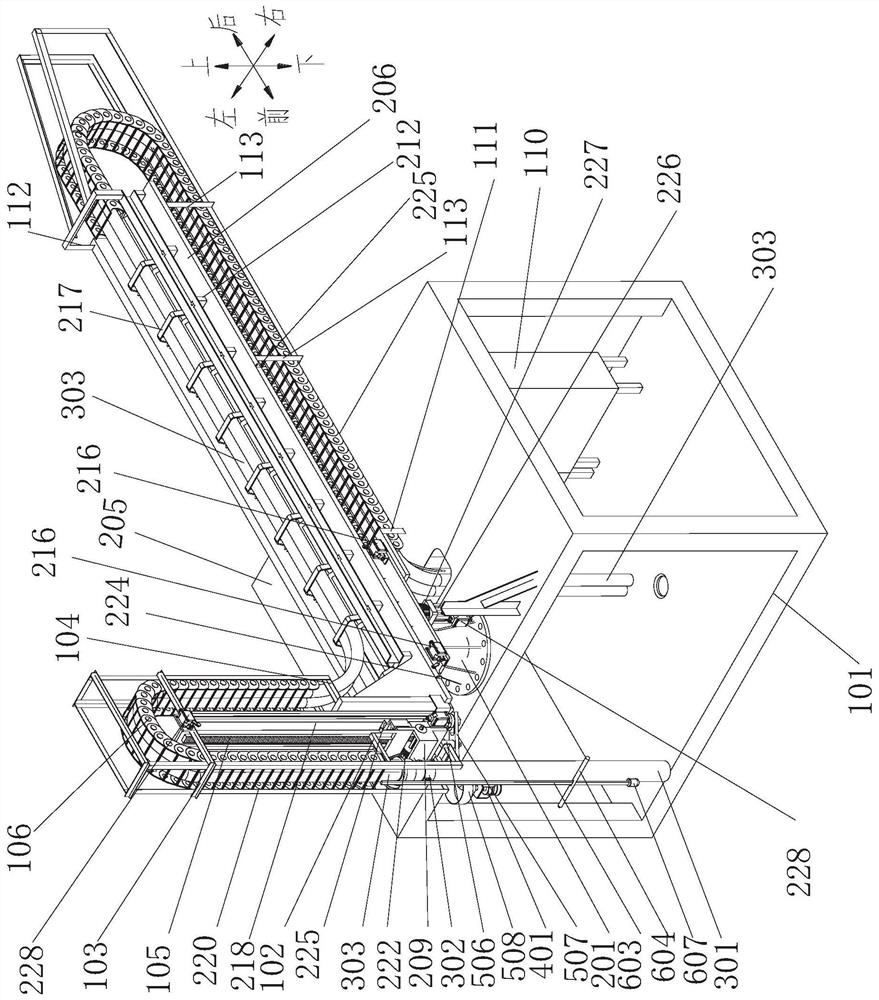

Digital ink duct for a press, digital ink supply system and application method thereof

ActiveUS20190039370A1Quantitative control is accurateAccurate calculationPrinting press partsPrinting pressDigital ink

The present invention discloses a digital ink duct for a printing press, comprising an ink tank for storing ink, a main ink pipe that communicates with the ink tank, at least one metering-type ink delivery device, ink delivery pipes, a controller and a signal acquisition device. In the present invention, high-accuracy, metering-type ink delivery devices are arranged in a queue to form a digital ink duct which replaces the traditional ink duct and supplies ink for the ink zones. The present invention can perform accurate adjustment in real time, is high in automation and digitalization degree, and can realize one-way ink delivery and avoid ink return.

Owner:DIGITAL INK DUCT FOR A PRESS DIGITAL INK SUPPLY SYST & APPL METHOD THEREOF +1

Digital ink-supplying method for printing press

ActiveUS20190084294A1Accurate calculationQuantitative control is accurateDuplicating/marking methodsColor matchingEngineeringPrinting press

The present invention discloses an accurate digital ink supply method for a printing press. The present invention adopts metering-type ink delivery units to replace the ink keys of the traditional printing press, and the metering-type ink delivery units directly deliver the ink to the corresponding ink zones on the metering basis of either volume or mass, realizing the quantitative supply of ink to each one of the ink zones. The present invention can perform accurate adjustment in real time, is high in automation and digitalization degree and large in adjustable range, realizes one-way ink delivery and avoids ink return.

Owner:HANGZHOU CRON MACHINERY & ELECTRONICS CO LTD

A remote crane tube loading device

InactiveCN111977602BQuick alignmentNo viewing angle errorLiquid transferring devicesMarine engineeringHydraulic pump

The invention relates to a remote crane tube loading device, comprising a pump skid, an upper bracket arranged on the upper end surface of the pump skid, a remote alignment system, an automatic loading crane tube installed on the upper bracket, a control Tank and metering system; the pump skid includes a lower bracket, a hydraulic pump station arranged in the lower bracket, a recovery container, an oil connection port and an oil pump connected by pipelines along the fluid flow direction, and an oil delivery pipe is connected to the outlet of the oil pump. The oil pipeline penetrates upwards through the top plate of the lower support and the bottom plate of the upper support; the first camera, the hydraulic pump station, the oil pump, the electronic warehouse and the float switch are respectively connected to the control box by communication; the control box controls the start and stop of the oil pump according to the signal from the electronic warehouse; The remote crane tube loading device invented can realize on-site unmanned liquid loading, accurate measurement, reliable work, long-term safe operation, and improved transfer efficiency.

Owner:SINOPEC NORTHWEST OIL FIELD

Quantitative filling method

InactiveCN102718177BAchieving Quantitative ControlSave waterBarrels/casks fillingWater resourcesEngineering

The invention provides a quantitative filling method for barreled water, which comprises the following steps: (1) filling with large flow rate and high speed: first, conveying liquid to a filling barrel through a filling pump, filling fast into a bucket from the filling barrel through a filling pipeline, and detecting filling quantity through a flowmeter; (2), filling accurately: adjusting an automatic valve on the filling pipeline automatically through a signal device when the flowmeter detects that the filling quantity approaches to a set value, so as to reduce the flow rate, and measuring the filling quantity through the flowmeter; and (3) stopping filling when the total filling quantity of the step (1) and the step (2) reaches a set value. The method has the benefits that quantitative control can be realized; the water resource is saved; the filling speed and the yield are high; the quantitative filling is accurate; the average precision of industrial production can reach 0.2 percent; the structure and the control are simple; and the limitation of a pipeline is avoided.

Owner:深圳市步先包装机械有限公司

Digital ink duct for a press, digital ink supply system and application method thereof

ActiveUS10919290B2Quantitative control is accurateAccurate calculationPrinting press partsEngineeringProcess engineering

The present invention discloses a digital ink duct for a printing press, comprising an ink tank for storing ink, a main ink pipe that communicates with the ink tank, at least one metering-type ink delivery device, ink delivery pipes, a controller and a signal acquisition device. In the present invention, high-accuracy, metering-type ink delivery devices are arranged in a queue to form a digital ink duct which replaces the traditional ink duct and supplies ink for the ink zones. The present invention can perform accurate adjustment in real time, is high in automation and digitalization degree, and can realize one-way ink delivery and avoid ink return.

Owner:DIGITAL INK DUCT FOR A PRESS DIGITAL INK SUPPLY SYST & APPL METHOD THEREOF +1

A liquid remote quantitative loading system

InactiveCN111977601BQuick alignmentRealize start-stop controlLiquid transferring devicesAutomatic controlMarine engineering

The invention relates to a liquid remote quantitative loading system, which includes an upper bracket, a remote alignment system, an automatic loading crane installed on the upper bracket, a control box and a metering system; the touch rod touches the oil storage tank The control box controls the vertical pipe to extend into the tank mouth of the oil storage tank and stops when it reaches the entrance distance. The control box controls the oil pump to start and start loading oil. The protective shell floats with the liquid surface. When the inner bottom wall of the protective shell triggers the float switch The control box controls the stop of the oil pump; the invention can quickly align the vertical pipe with the tank mouth of the tanker, and designs a float level gauge to automatically control the start and stop of the oil pump and measure the liquid level of the tanker, so that it can replace the flow meter Or manual control to realize the start and stop control of the oil pump, and the quantitative control is more accurate; the invention can realize unmanned filling on site, accurate measurement, can improve the efficiency of oil filling operation, and achieve the goals of safety, energy saving and production increase.

Owner:SINOPEC NORTHWEST OIL FIELD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com