Anti-static coating carton and preparation method thereof

An anti-static coating and anti-static technology, applied to chemical instruments and methods, coatings, paper, etc., can solve the problems of anti-static performance decline, unstable quality of corrugated boxes, uneven printing layer, etc., and achieve stable electrostatic protection performance , Excellent electrostatic protection performance, good coating binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Example: antistatic coated carton

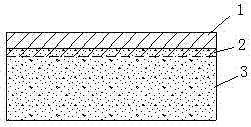

[0028] See attached figure 2 As shown, the antistatic coated carton has an antistatic coating layer 1 on the inner paper of the carton, and the coating of the antistatic coating layer 1 is partially pressed into the fiber pores in the cardboard paper 3 of the carton by high temperature and high pressure. Therefore, a dense antistatic new material layer 2 is formed between the antistatic coating layer 1 and the cardboard paper 3 .

[0029] A piece of antistatic coated paper and a piece of ordinary containerboard are combined into an antistatic cardboard through a special adhesive or molten PE; and then these antistatic coated paperboards are used to make corresponding cartons.

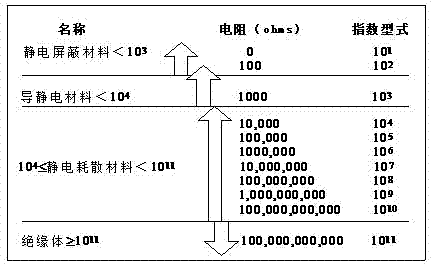

[0030] Antistatic coating amount is 8g / m in the present embodiment 2 At that time, it is already a static dissipative material with good static protection performance. About 1 / 3 of the coating amount of the antistatic coating is pressed into the fiber pores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com