Patents

Literature

36results about How to "Realize quantitative supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

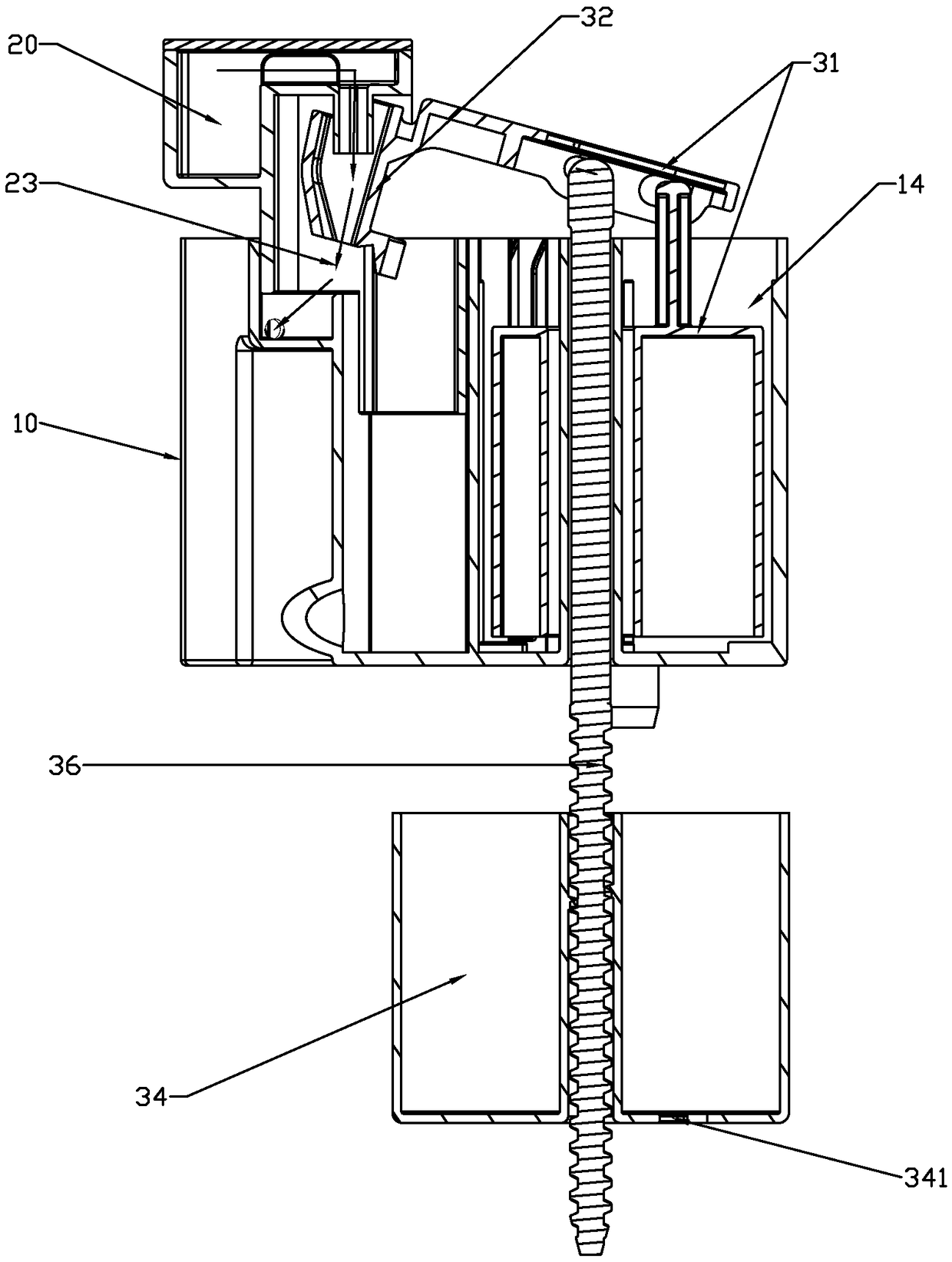

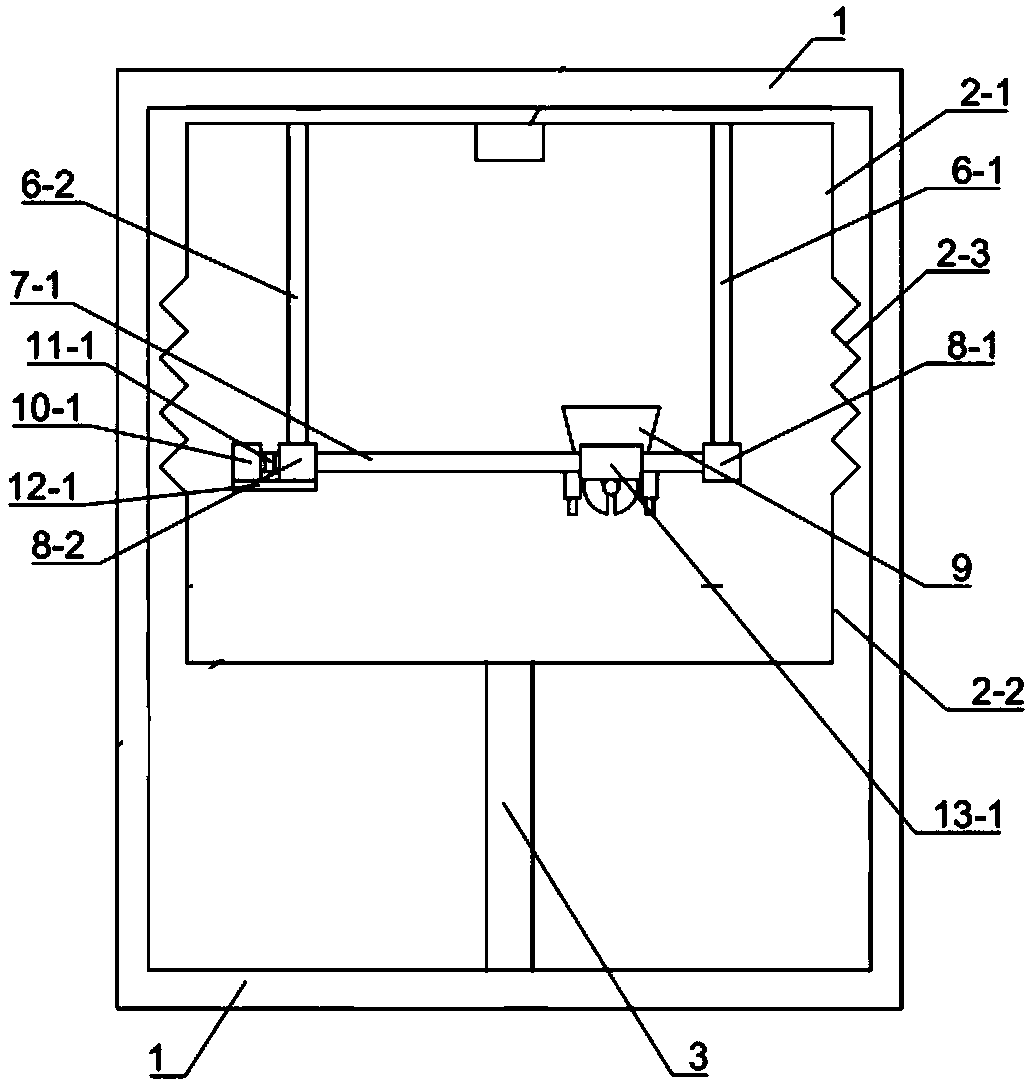

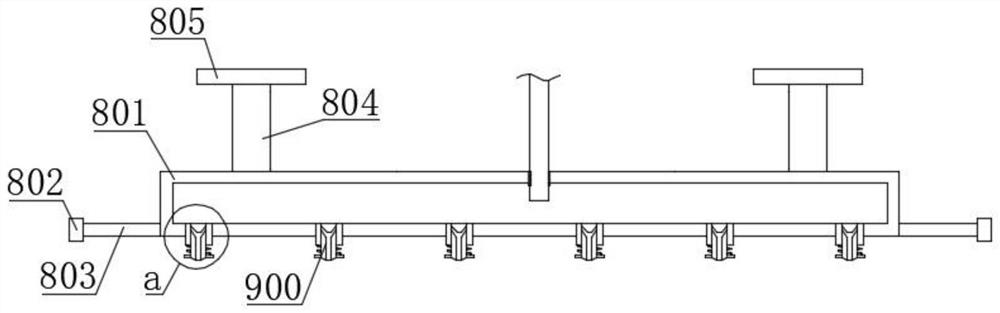

Automatic dosing machine with mobile receiving function

InactiveCN103932616ARealize mobile picking functionSimple structureKitchen equipmentEngineeringMechanical engineering

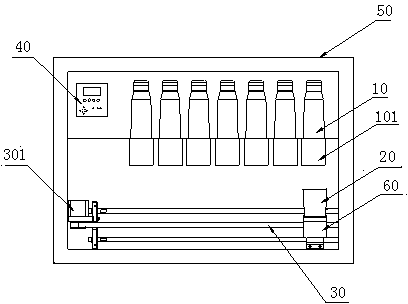

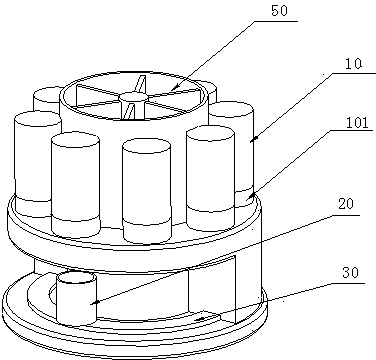

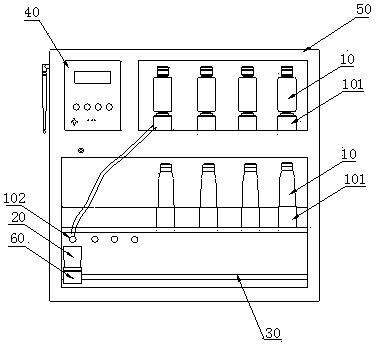

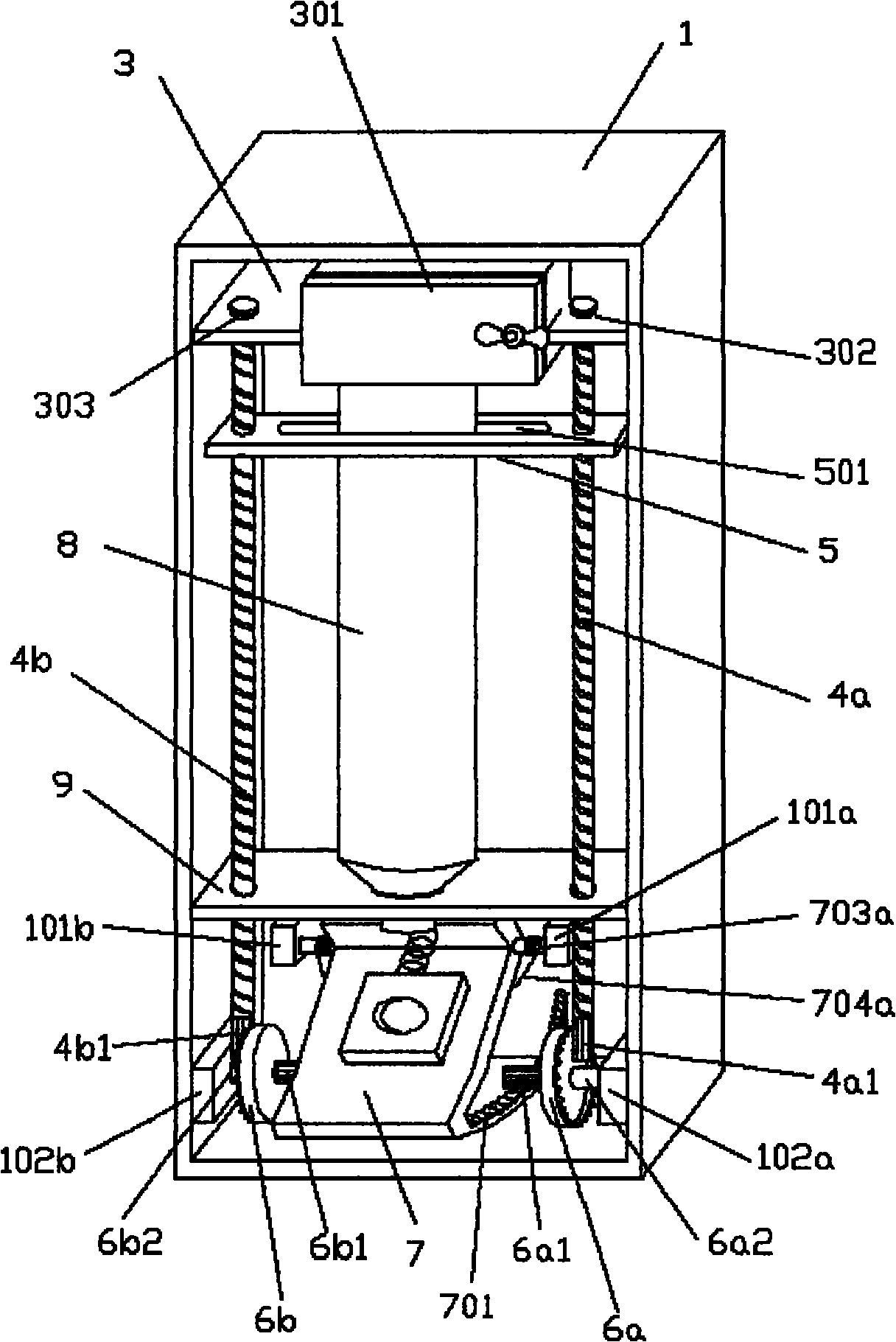

The invention discloses an automatic dosing machine with the mobile receiving function. The automatic dosing machine comprises a storing container, a receiving container, a sliding component, a control component and a rack. The storing container is installed on the rack, and a discharging outlet of the storing container is located above the receiving container. The receiving container is placed on the sliding component. The sliding component is installed on the rack. The control component is installed on the rack and respectively connected with a storing container control mechanism and a sliding component control mechanism. The storing container control mechanism receives a control instruction of the control component, and dosing materials stored in the storing container are sent out; the sliding component control mechanism receives a control instruction of the control component, and drives the receiving container arranged on the sliding component to move to the position below the storing container. The receiving container receives dosing materials discharged by the storing container. The automatic dosing machine has the automatic dosing material discharging and mobile receiving functions, and is simple in structure, low in cost and convenient to clean.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

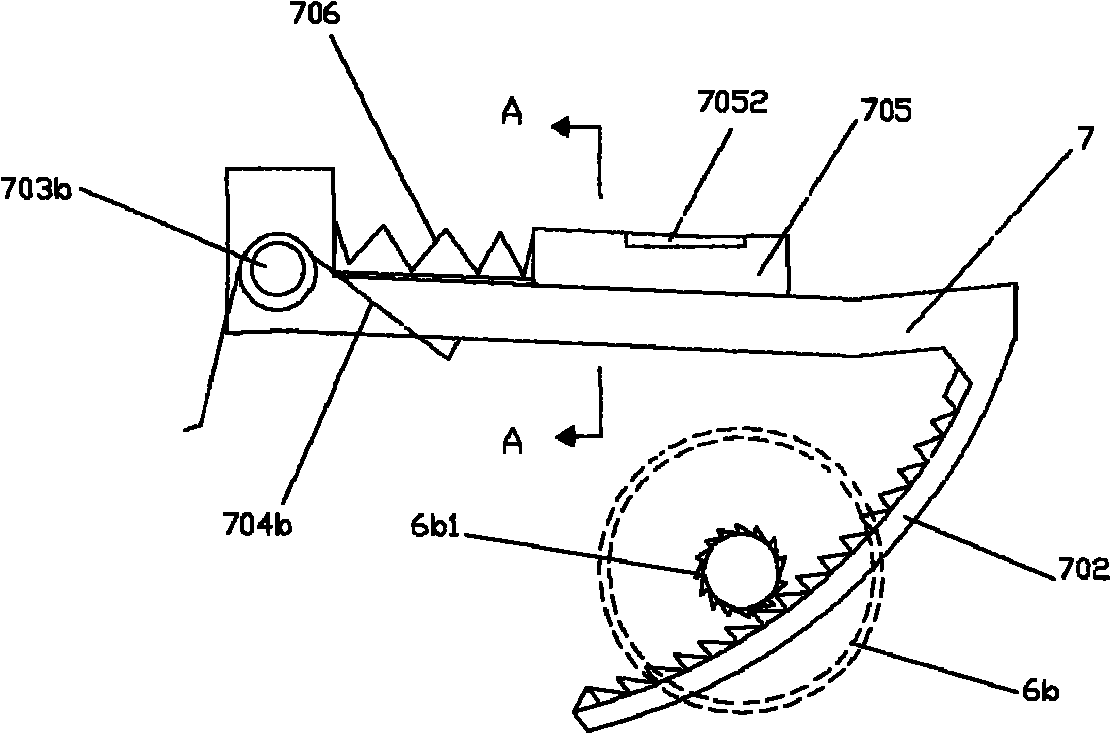

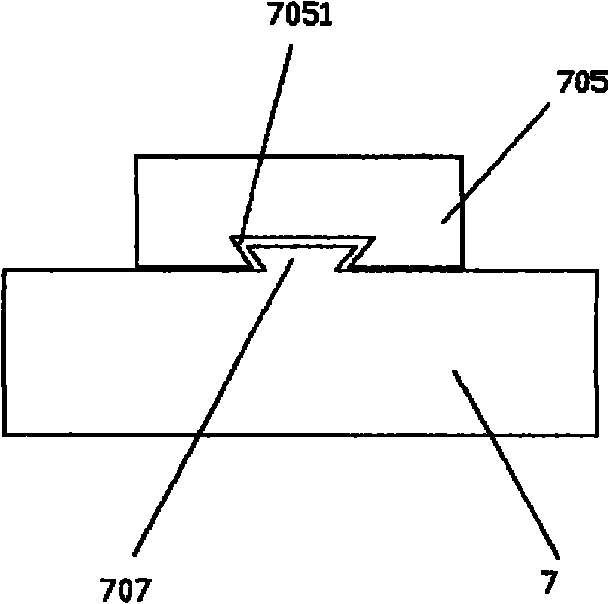

Extrusion type automatic toothpaste supplier

InactiveCN102119839AAvoid secondary pollutionAchieve the purpose of supplyHolders and dispensersToothpasteEngineering

The invention discloses an extrusion type automatic toothpaste supplier, which comprises an upper shell, a lower shell and a connecting plate fixed on the lower shell, wherein a fixing shelf is arranged on the upper part of the inside of the lower shell and is provided with a clamping part for clamping the tail part of a toothpaste tube body; the two ends of the fixed shelf have round holes through which the tops of a screw I and a screw II pass; the screw I and the screw II pass through the through threaded holes at the two ends of an extrusion board so as to form rotation fit; the lower ends of the screw I and the screw II are provided with straight teeth and meshed with a gear plate I and a gear plate II; protruding cylinders on the other sides of the gear plates are provided with ratchets meshed with the ratchets on a rack I and a rack II on the two sides of a pressing plate; linked shafts on the two sides of the rear end of the pressing plate extend into torsional spring inner holes to be fixed in the shaft holes in a lower shell fixing piece; the toothpaste tube is vertical, and a toothpaste opening is positioned in a baffle plate hole above the pressing plate; and the upper shell is provided with a toothpaste supplying opening at a position corresponding to the pressing plate. In the technique, toothpaste is extruded out by the extrusion plate, the toothpaste in the toothpaste tube can be extruded out completely, the operation is simple, convenient and easy, and energy is saved.

Owner:胡海明

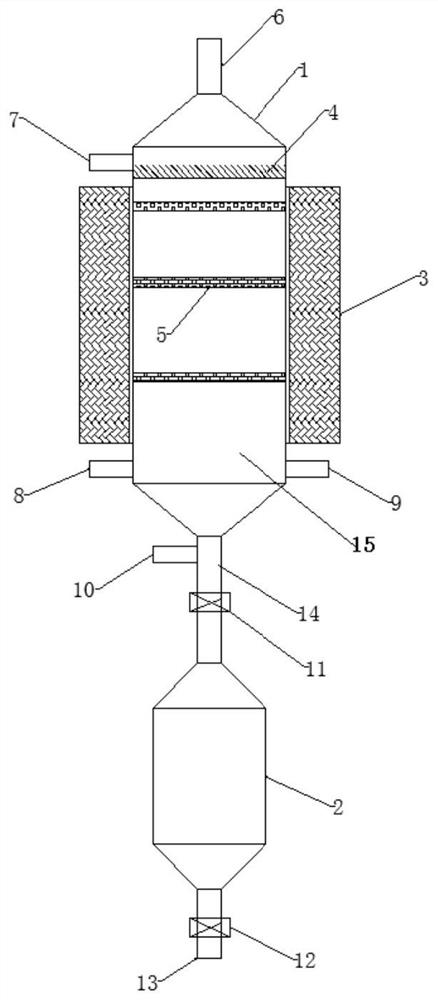

Quantifiable anesthetic gas purification device used for anesthesiology department

The invention discloses a quantifiable anesthetic gas purification device used for the anesthesiology department. The device comprises a housing. The upper end of the housing is opened. The upper endof the housing is fixedly connected with the lower end of a gasbag. The interior of the gasbag communicates with the interior of the housing. The middle of the bottom surface in the housing is fixed with a fan. Two gas inlet holes in the lower part of the left side surface of the housing respectively communicate with one end of a gas inlet pipe of anesthetic gases and one end of an oxygen gas inlet pipe. Only when a patient inhale, mixed gases of anesthetic gases and oxygen gas are provided. The power of a gas pump is adjustable. The quantifiable supply of anesthetic gases is achieved while resources are saved. An annular heating coil is used in conjunction with a fan such that anesthetic gases and oxygen gas are uniformly mixed and the temperature is proper. A patient feels more comfortable. An ultraviolet germicidal lamp is used for sterilizing the mixed gases of anesthetic gases and oxygen gas, which lowers the possibility of infections of the patient.

Owner:刘夕江

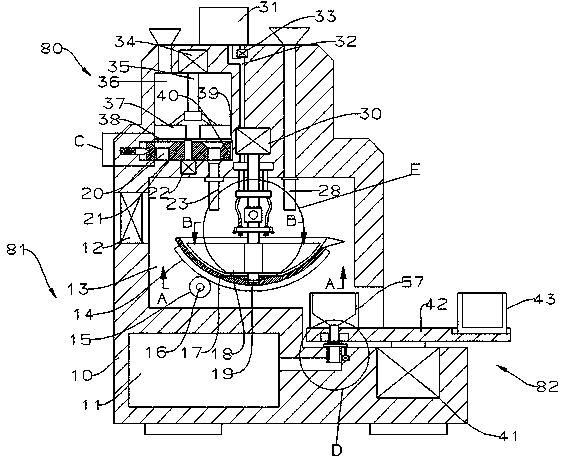

Powder quantitative supply device for selective laser melting 3D printing

ActiveCN107855526ARealize quantitative supplySimple appearanceAdditive manufacturing apparatusIncreasing energy efficiencyElectricitySelective laser melting

The invention discloses a powder quantitative supply device for selective laser melting 3D printing. The powder quantitative supply device comprises a powder supply mechanism, a powder discharging mechanism which is fixed on the lower part of the powder supply mechanism and a control system; the powder discharging mechanism comprises a powder discharging box body, a powder discharging shaft and apowder discharging motor; the powder discharging box body comprises a first box body, wherein a powder inlet communicating with the powder supply mechanism is formed in the top part of the first box body, and a powder outlet is formed in the bottom part of the first box body; the powder discharging shaft comprises a powder discharging shaft main body and a powder discharging shaft end part, and the powder discharging shaft main body is provided with a single axial powder picking groove; the powder discharging shaft main body is rotatably arranged in the first box body, and divides the first box body into a top space and a bottom space which are isolated from each other; the powder discharging motor is arranged at one end of the powder discharging box body, and an output shaft of the powderdischarging motor is in driving connection with the powder discharging shaft end part; and the control system is electrically connected with the powder discharging motor. Compared with a spline shaftin the prior art, the powder discharging shaft with the single groove has the advantages of being simple in appearance and low in manufacturing requirement.

Owner:SHAOGUAN COLLEGE

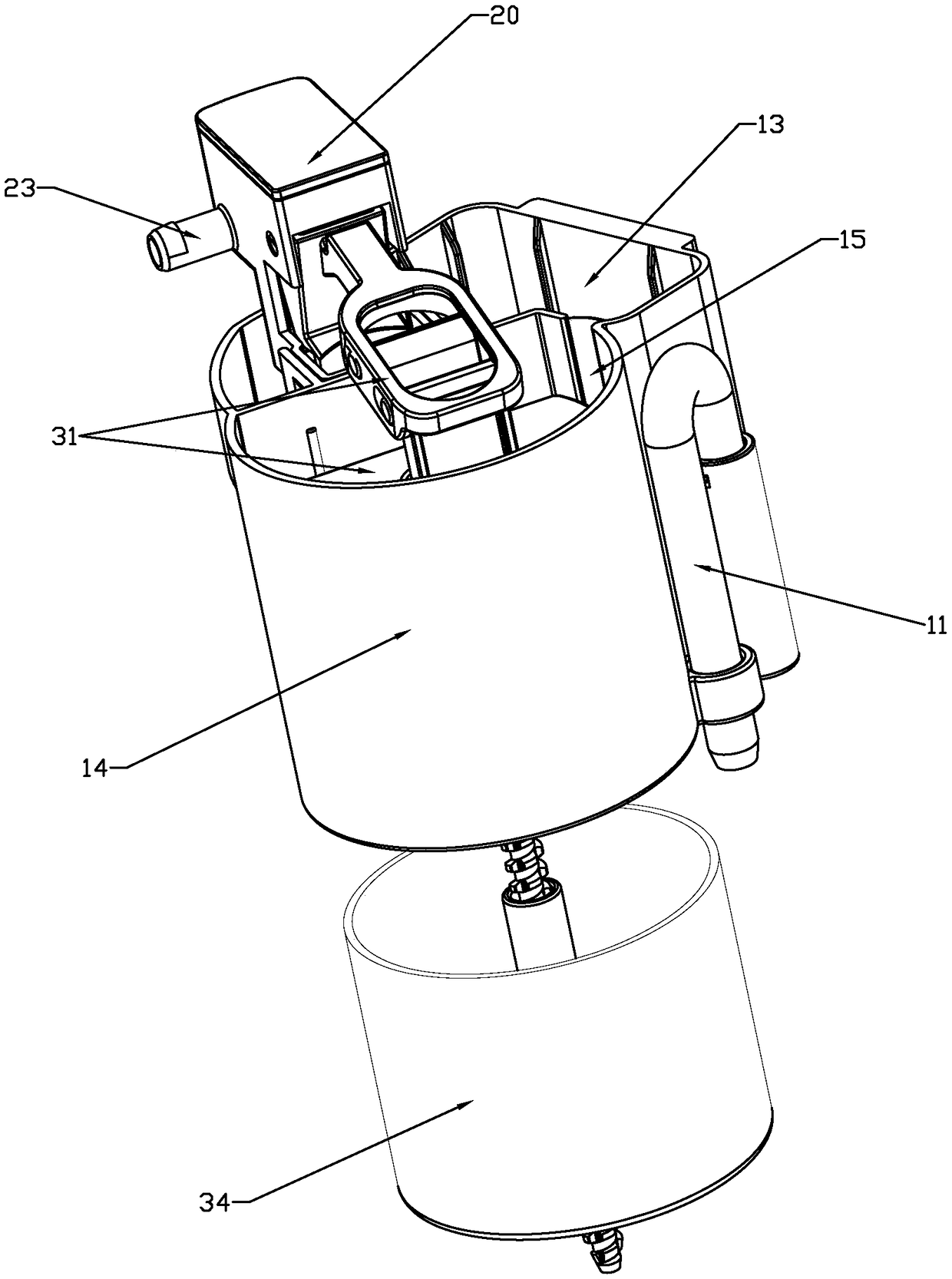

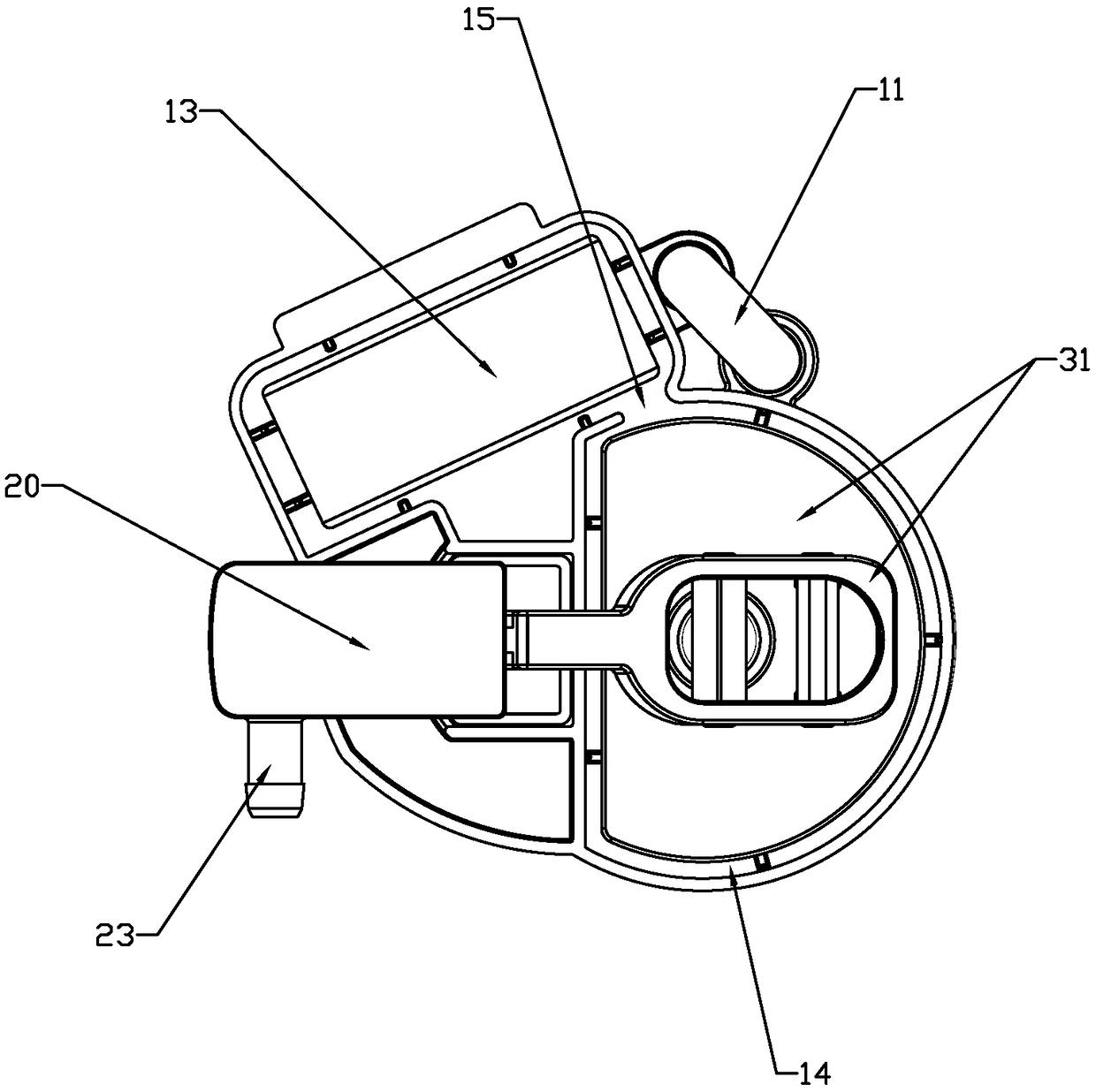

Device for adding cleaning fluid

PendingCN108824582ARealize quantitative supplyAvoid wastingFlushing devicesLavatory sanitoryEngineeringToilet

The invention discloses a device for adding cleaning fluid. The device is arranged in a water tank of a toilet and used for supplying the cleaning fluid to the toilet; the device for adding the cleaning fluid comprises a fluid box, a fluid supplementing mechanism and a fluid supplementation control mechanism, wherein the fluid box is used for storing the cleaning fluid and provided with a fluid outlet channel; the fluid supplementing mechanism is used for supplementing the fluid to the fluid box; the liquid supplementation control mechanism is used for controlling the fluid supplementing mechanism to stop supplementing of the fluid to the fluid box. In this way, when the toilet is flushed, the cleaning fluid can be supplied quantificationally, and unnecessary waste is avoided.

Owner:XIAMEN R&T PLUMBING TECH

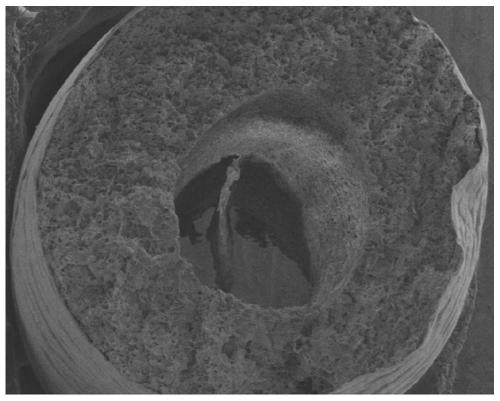

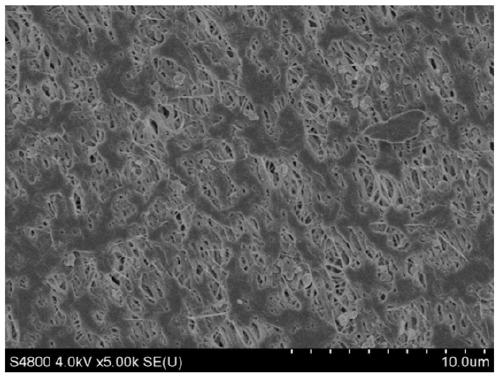

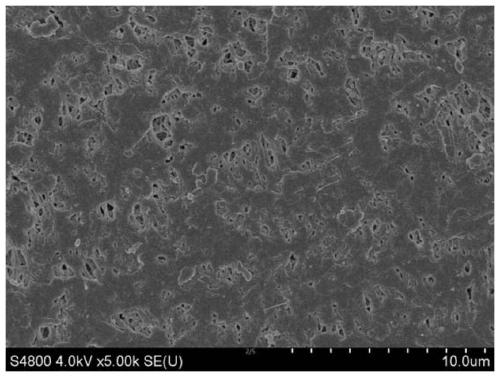

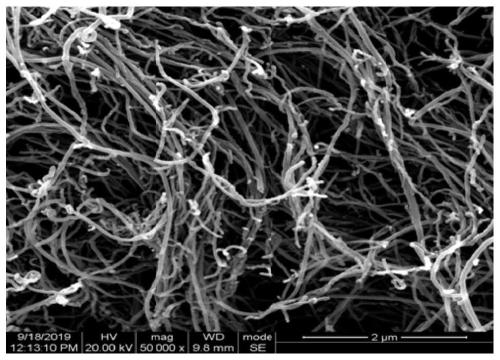

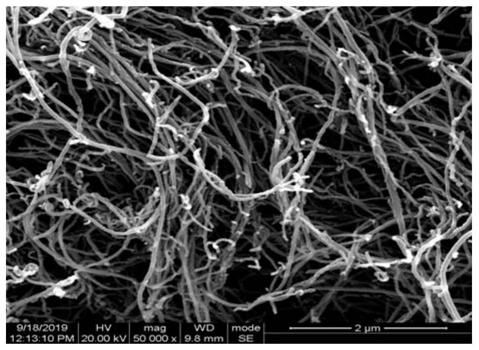

PTFE composite film for MABR, and preparation method thereof

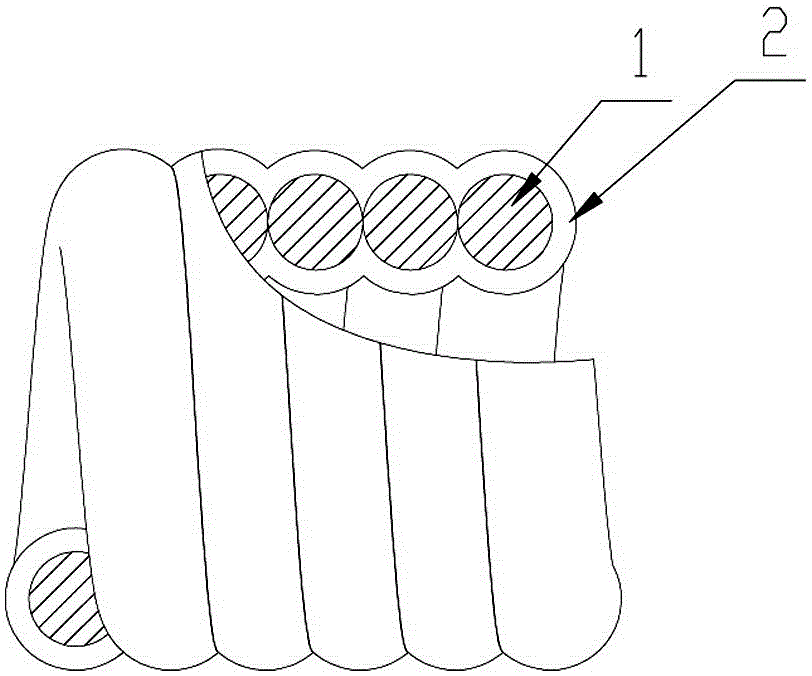

ActiveCN111359442AExcellent oxygen mass transfer performanceHigh affinityMembranesUltrafiltrationHollow fibreFiber

The invention discloses a PTFE composite membrane for MABR. The PTFE composite membrane comprises a hydrophobic hollow fiber porous support tube membrane and a hydrophilic polytetrafluoroethylene porous flat membrane wrapping layer arranged on the surface of the hydrophobic hollow fiber porous support tube membrane; the contact angle of the hydrophobic hollow fiber porous support tube membrane isgreater than 130 DEG; the instantaneous contact angle of the hydrophilic polytetrafluoroethylene porous flat membrane wrapping layer is less than 60 DEG, and is reduced to 0 DEG within 30 s. The surface of the hydrophobic microporous membrane is wrapped with the thin hydrophilic PTFE membrane layer through ultrasonic spot welding, the internal main body of the prepared PTFE composite membrane hasthe super-hydrophobic characteristic and has the excellent oxygen mass transfer performance, and the surface thin layer of the PTFE composite membrane has the super-hydrophilic characteristic and hasthe excellent microbial affinity performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

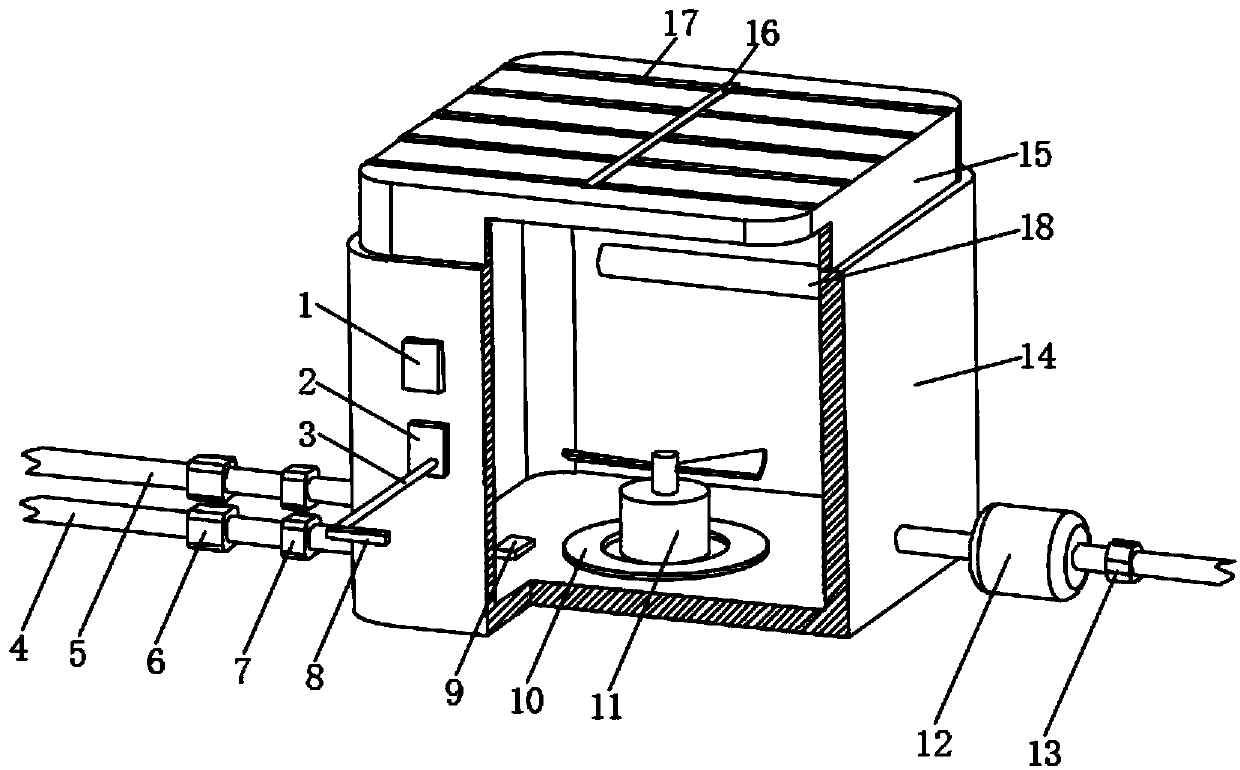

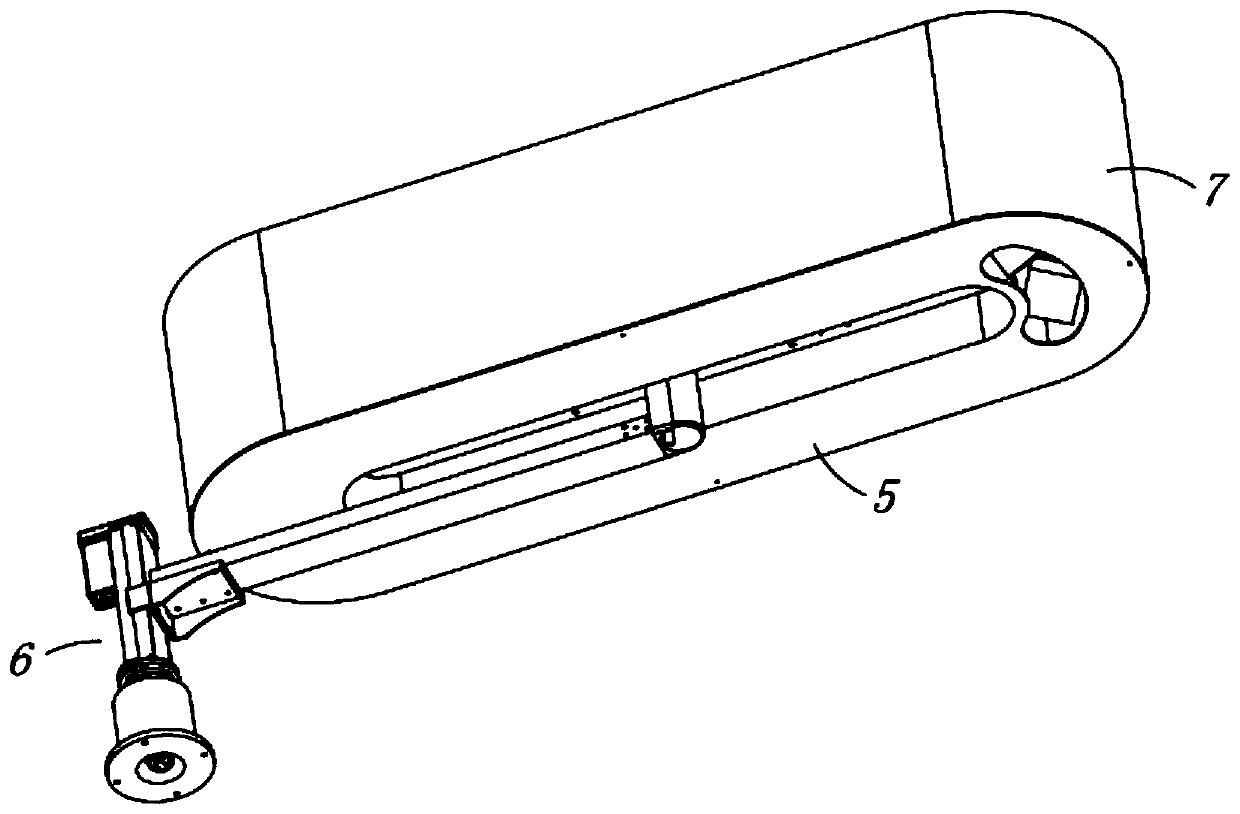

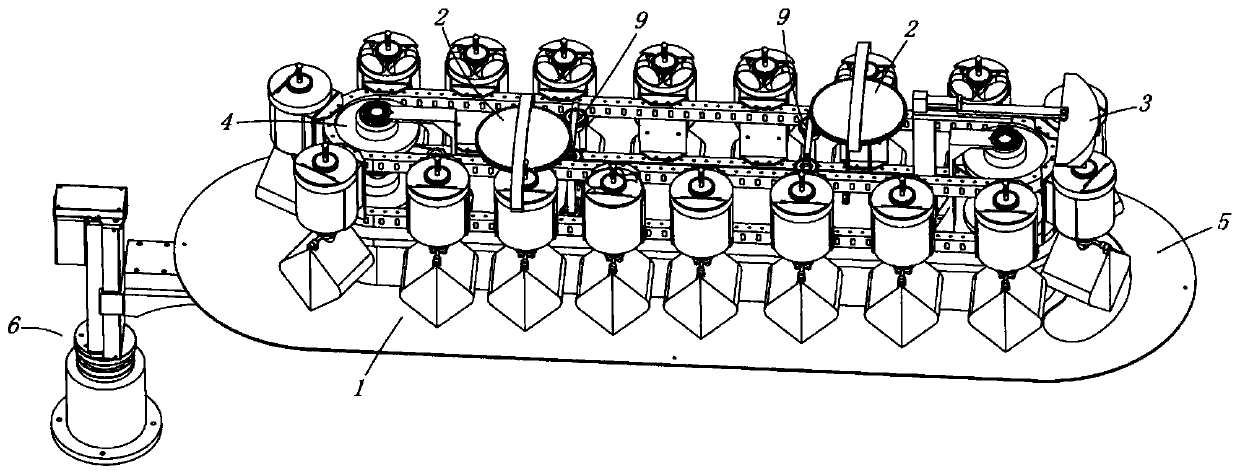

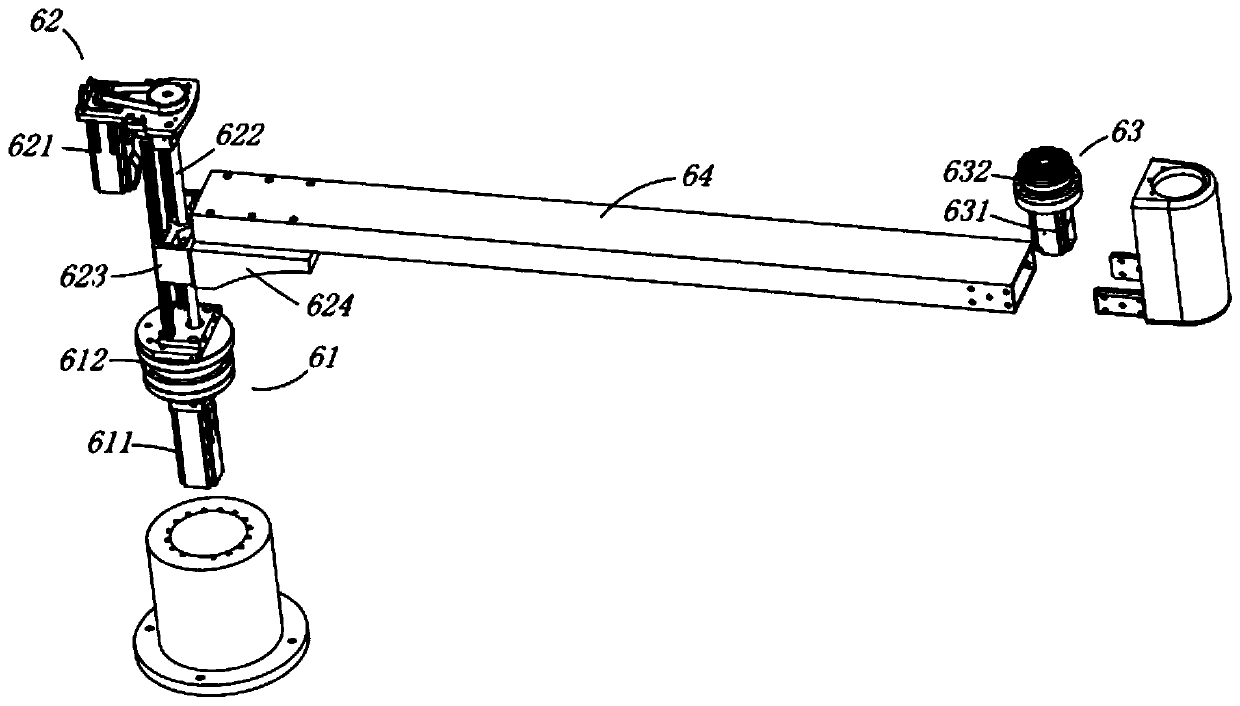

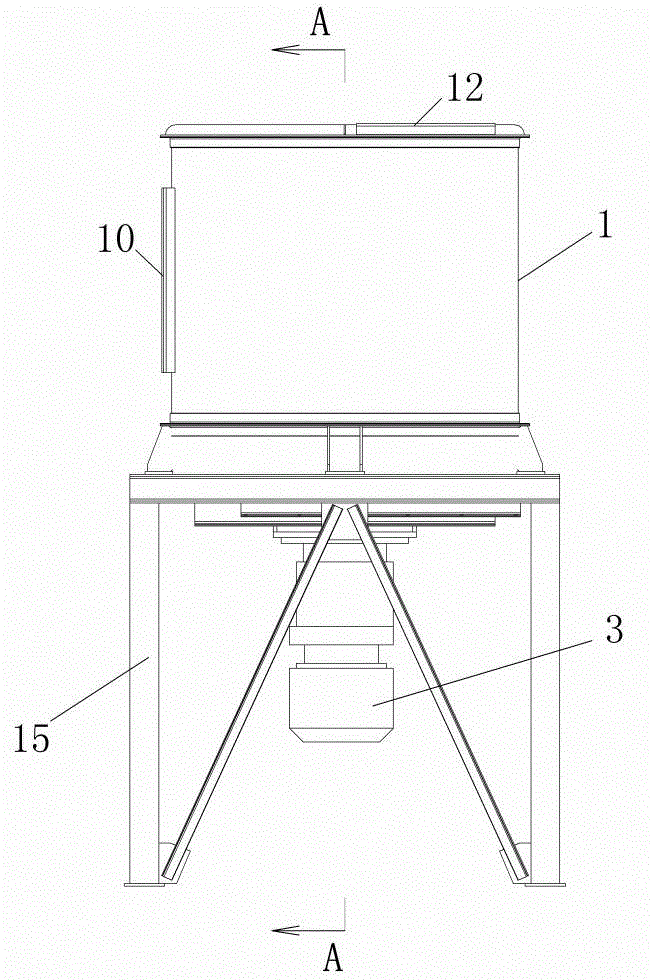

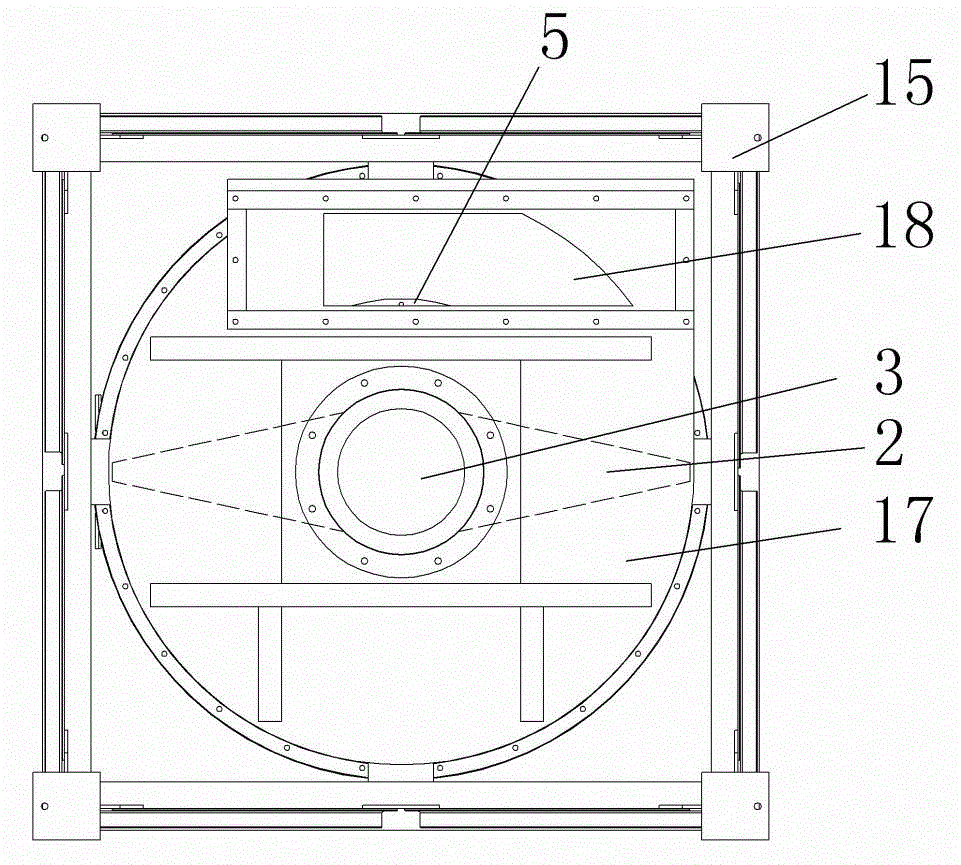

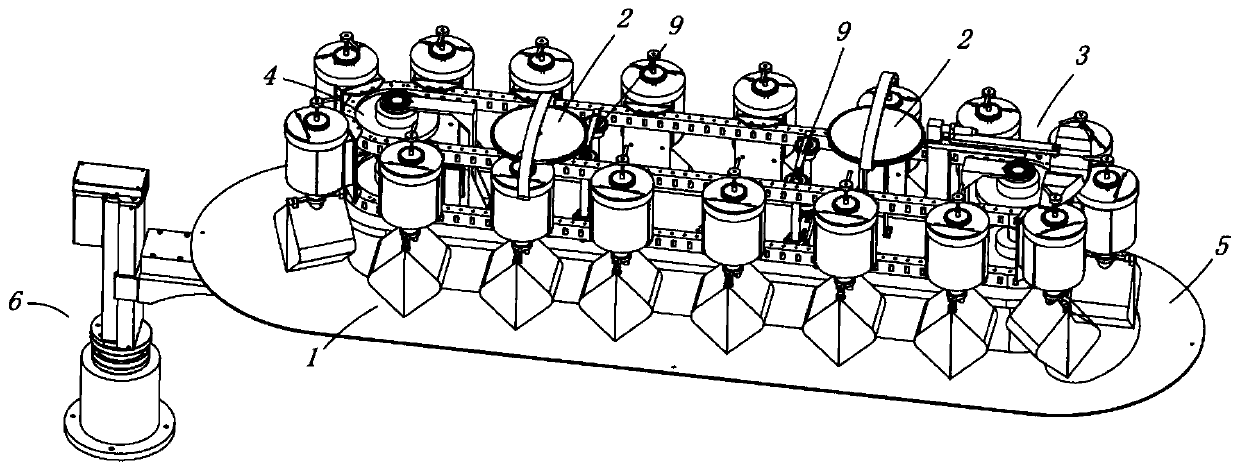

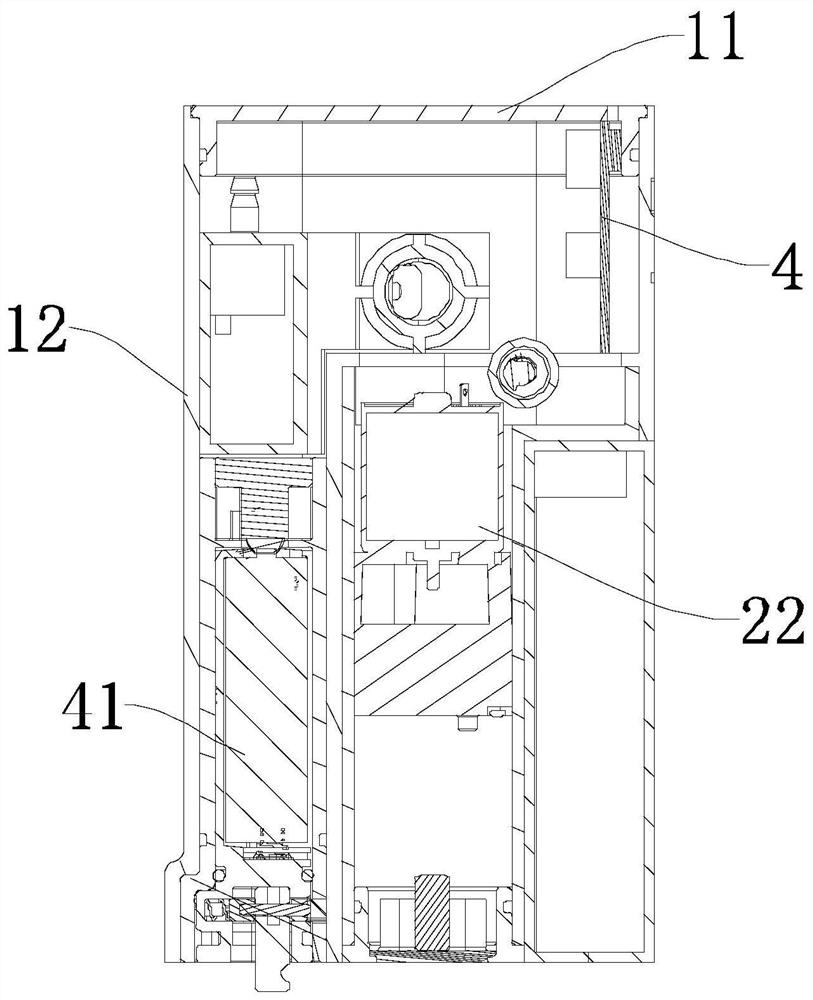

Seasoning adding full-automatic robot

InactiveCN110693333ARealize quantitative supplyGuaranteed standardizationGearingCooking vesselsChemistryProcess engineering

The invention provides a full-automatic robot for adding seasonings. The full-automatic robot comprises a batching tank, a batching driving mechanism, a discharging mechanism and a circulating mechanism. The full-automatic robot for adding the seasonings has the advantages that the seasonings can be automatically added, the types of the seasonings needed when different dishes are cooked can be metby arranging the multiple ingredient tanks, and the actual cooking requirement is fully met. Besides, by controlling the burdening amount of the burdening tank, quantitative supply of the seasoningscan be achieved, and standardization of the taste of cooked dishes can be guaranteed.

Owner:SUZHOU SHENYUN ROBOT

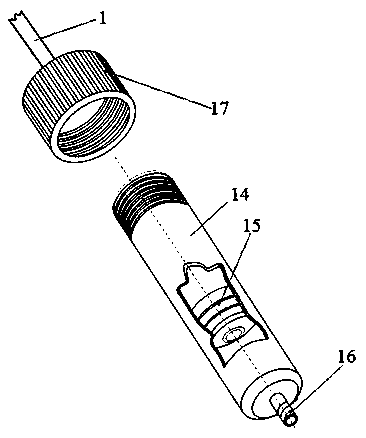

Cleaning device for gynaecology and obstetrics

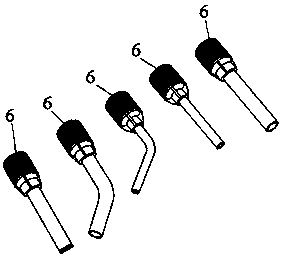

InactiveCN107174725ARealize quantitative supplyEasy to sprayEnemata/irrigatorsMedical devicesObstetric historyFixed frame

The invention relates to a cleaning device for gynaecology and obstetrics. The cleaning device comprises a cleaning head, a cleaning pipe and a fixing frame, wherein the front end of the cleaning pipe is in threaded connection with the cleaning head; a sealing pad is arranged between the cleaning head and the cleaning pipe; the fixing frame is arranged at the rear end of the cleaning pipe; the fixing frame is provided with a flow guide pipe communicating with the cleaning pipe; and a liquid inlet pipe is obliquely arranged, one end of the liquid inlet pipe is connected with an air bag and the other end communicates with the flow guide pipe. The cleaning device has the advantages that the cleaning device is simple in structure and easy to control, quantitative supply of a liquid medicine is achieved through movable fit of a control handle and the air bag, ejection of the liquid medicine is facilitated through a conical nozzle, and the flushing effect is better achieved.

Owner:颜芸

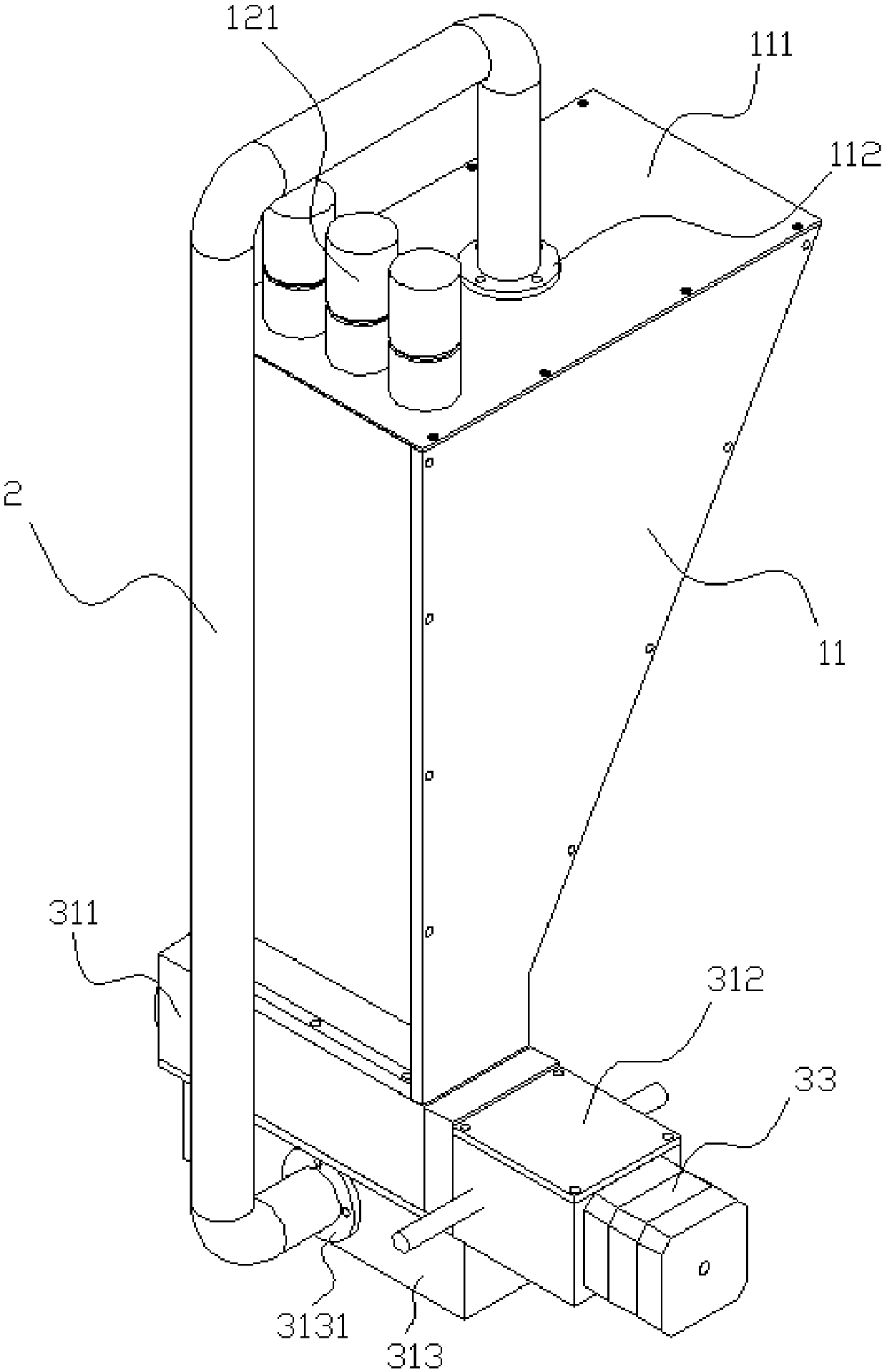

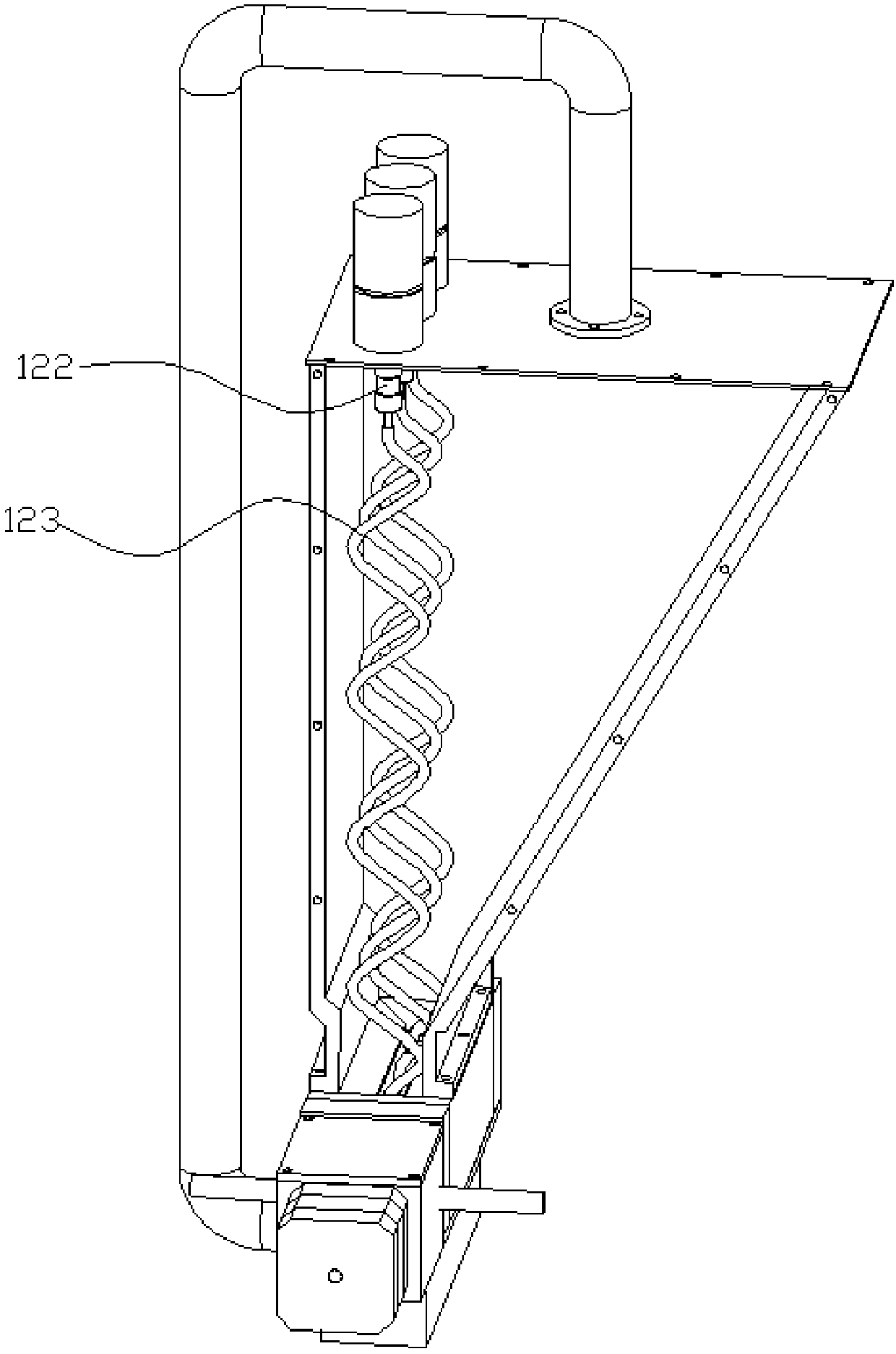

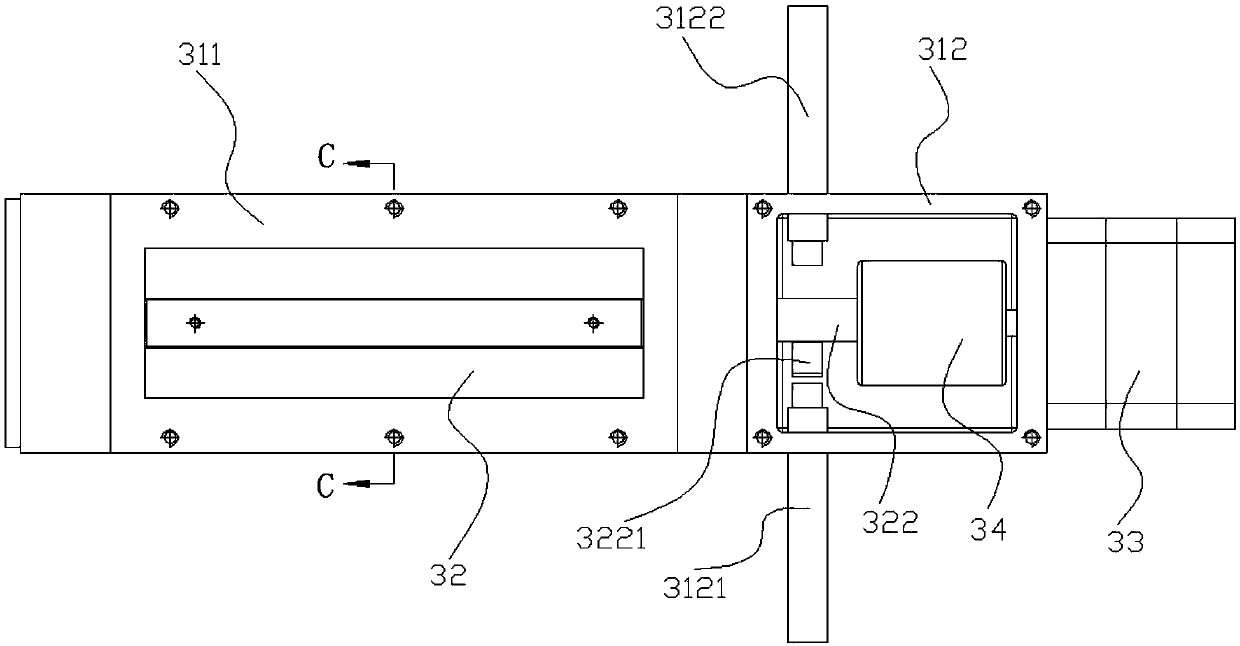

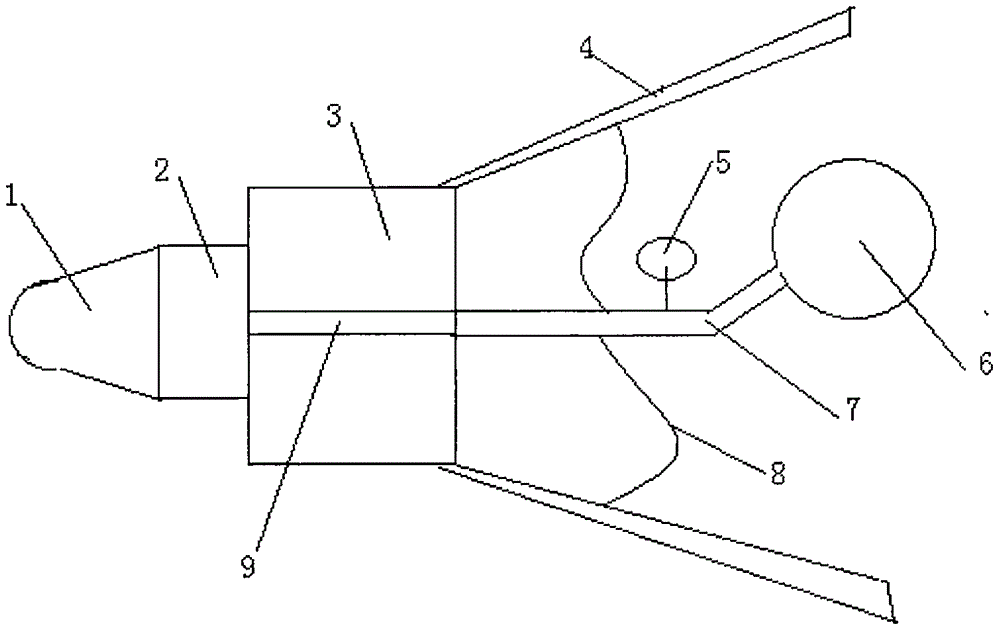

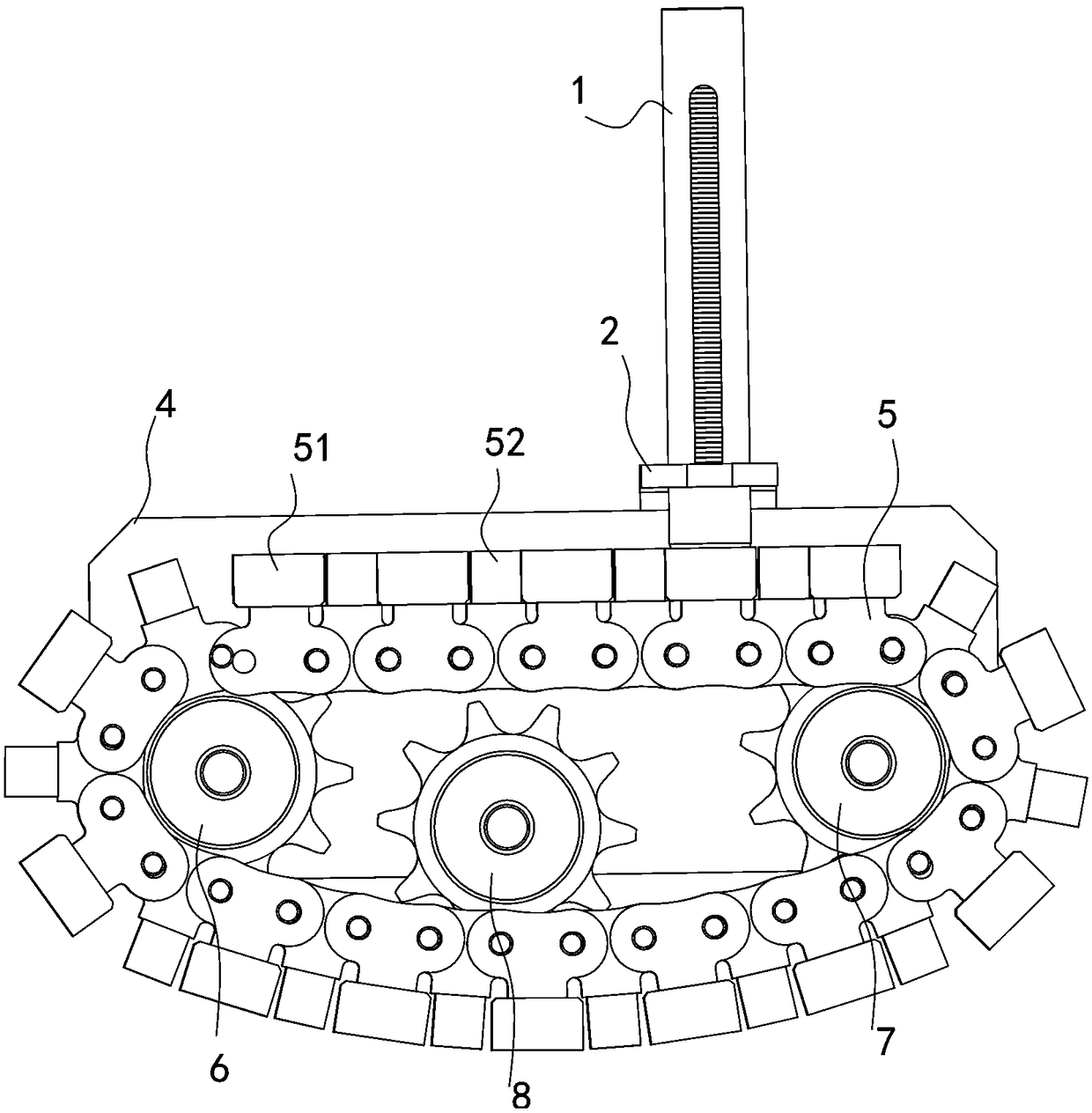

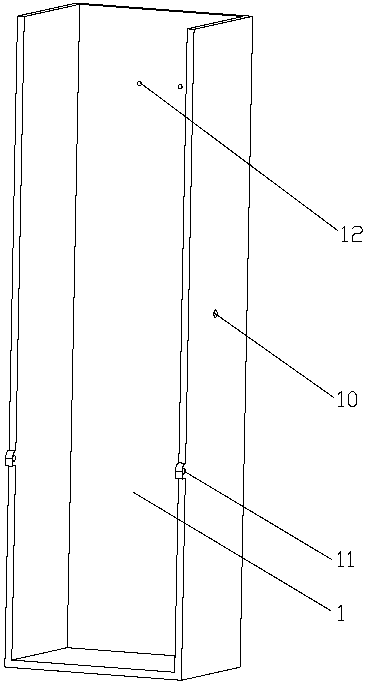

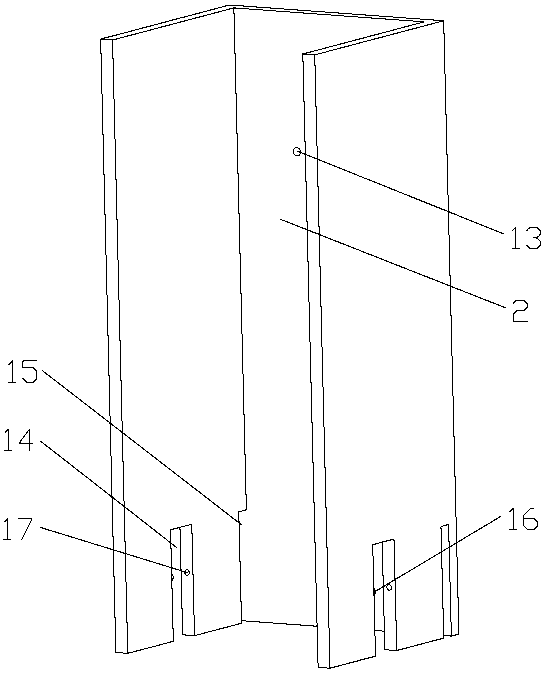

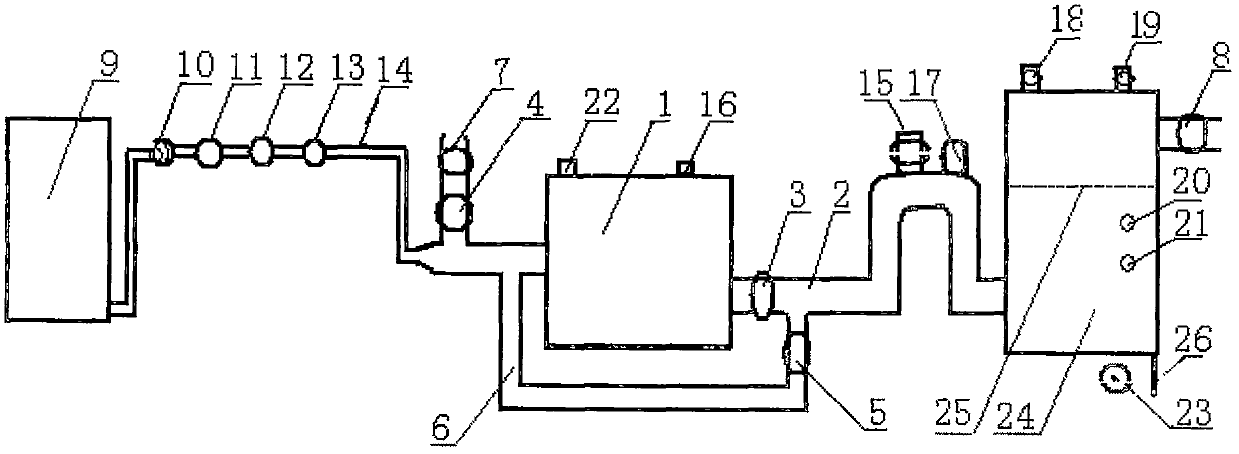

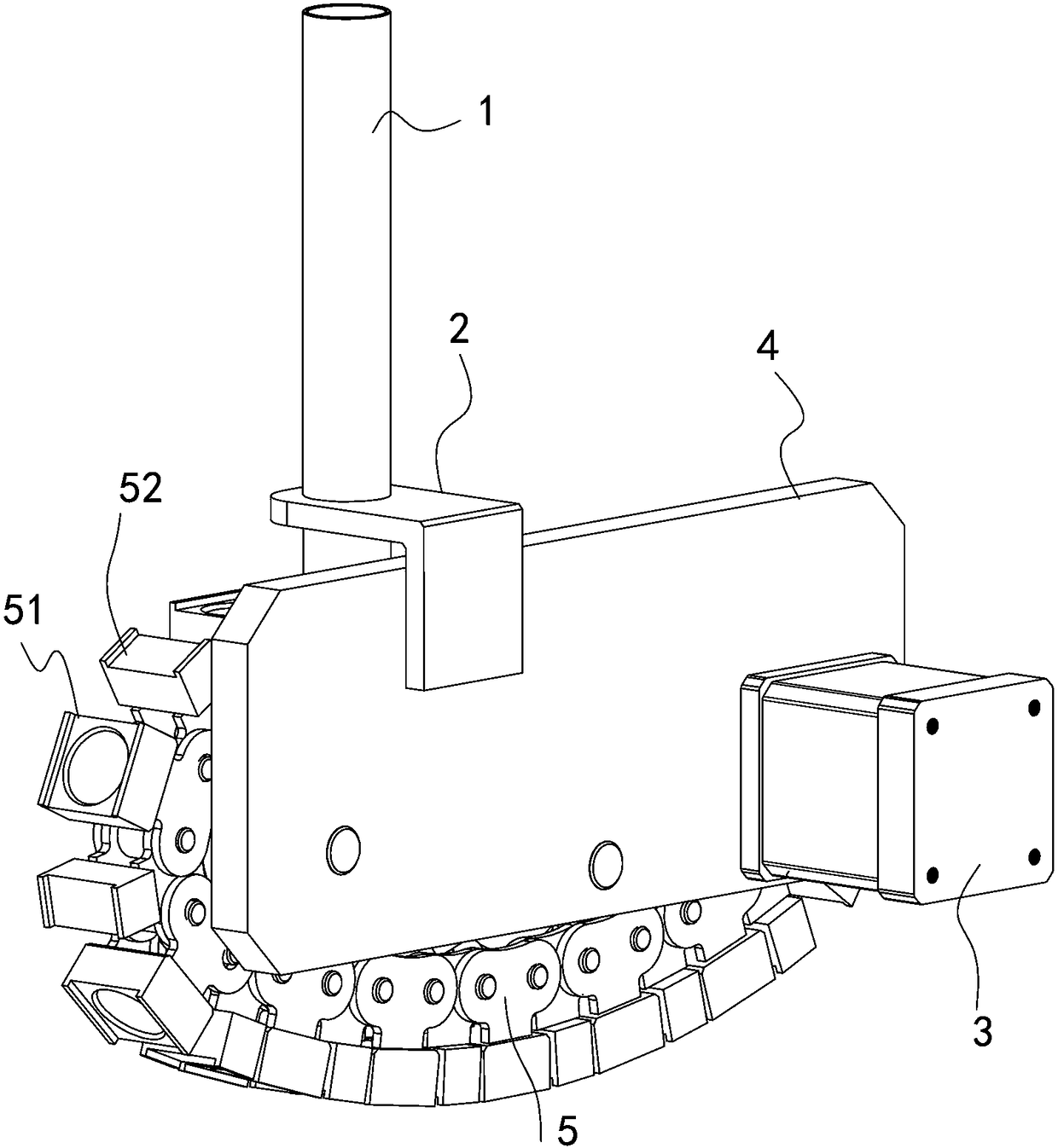

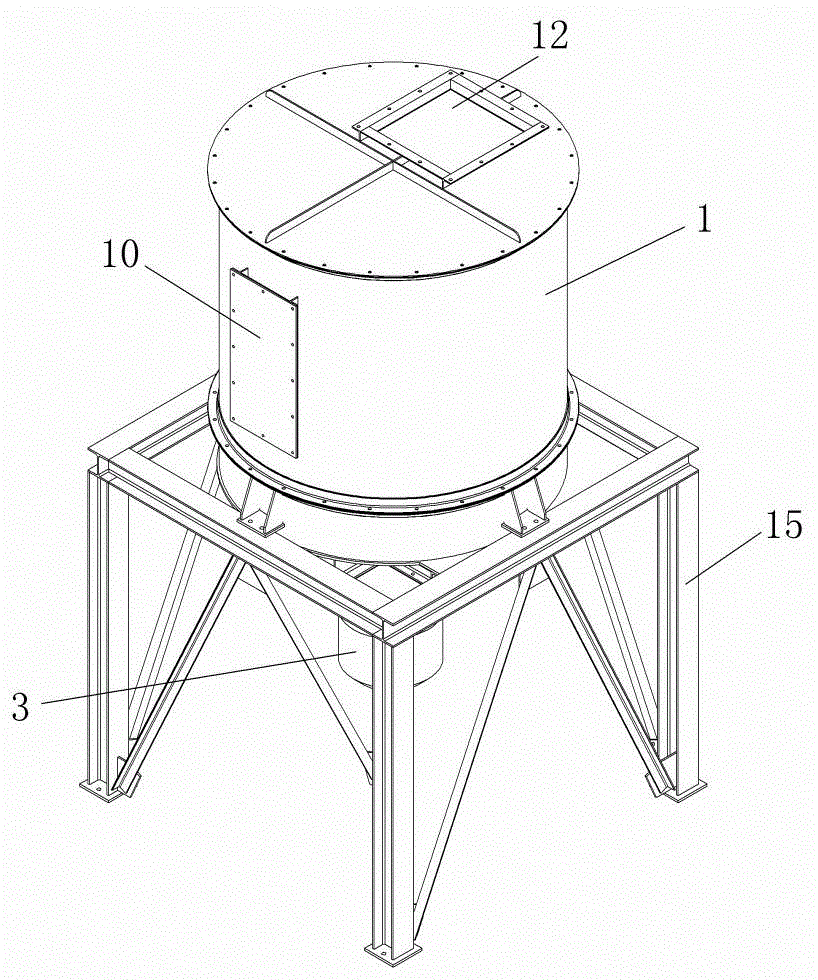

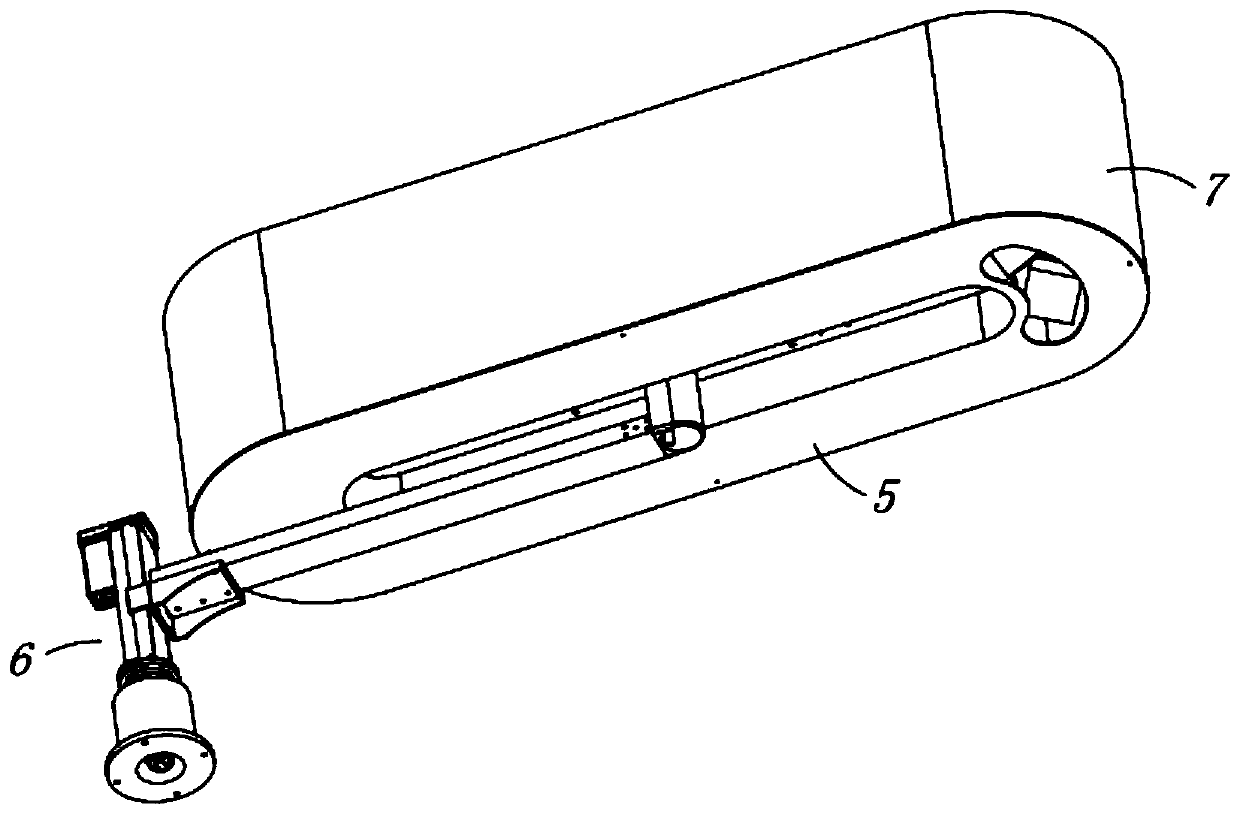

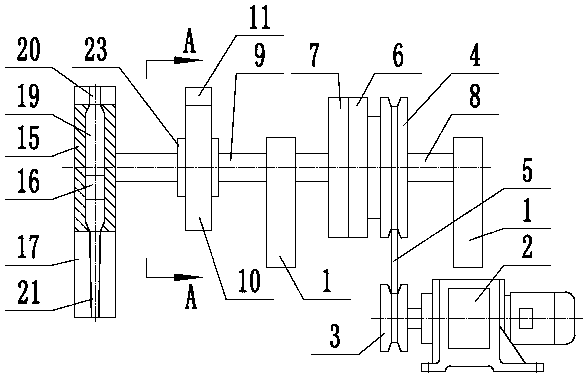

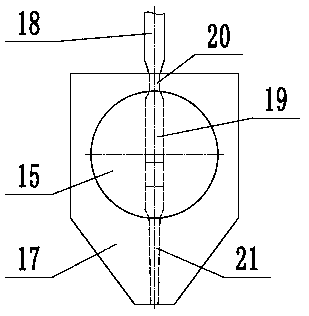

Biomass burner

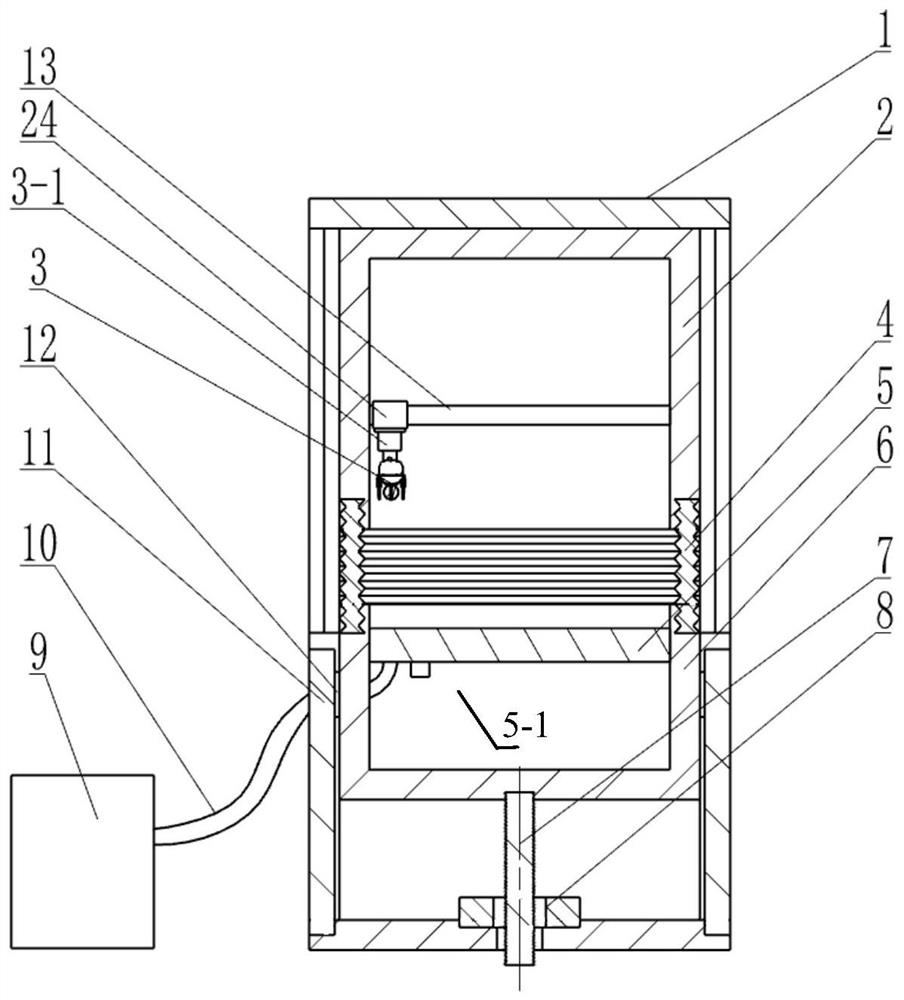

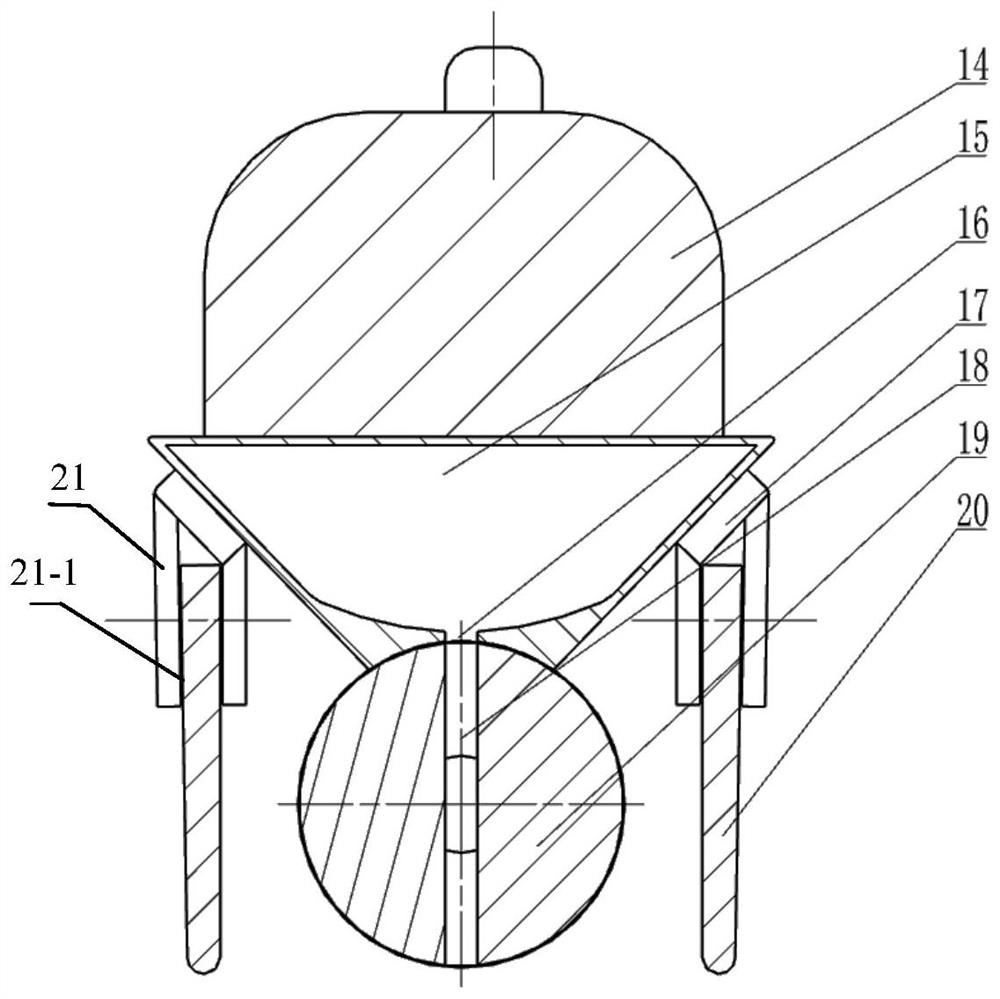

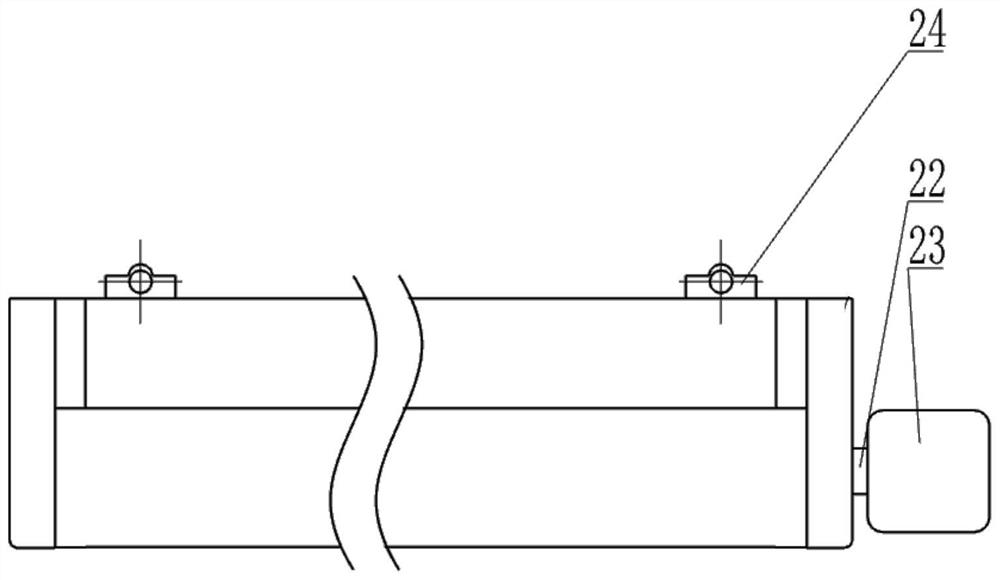

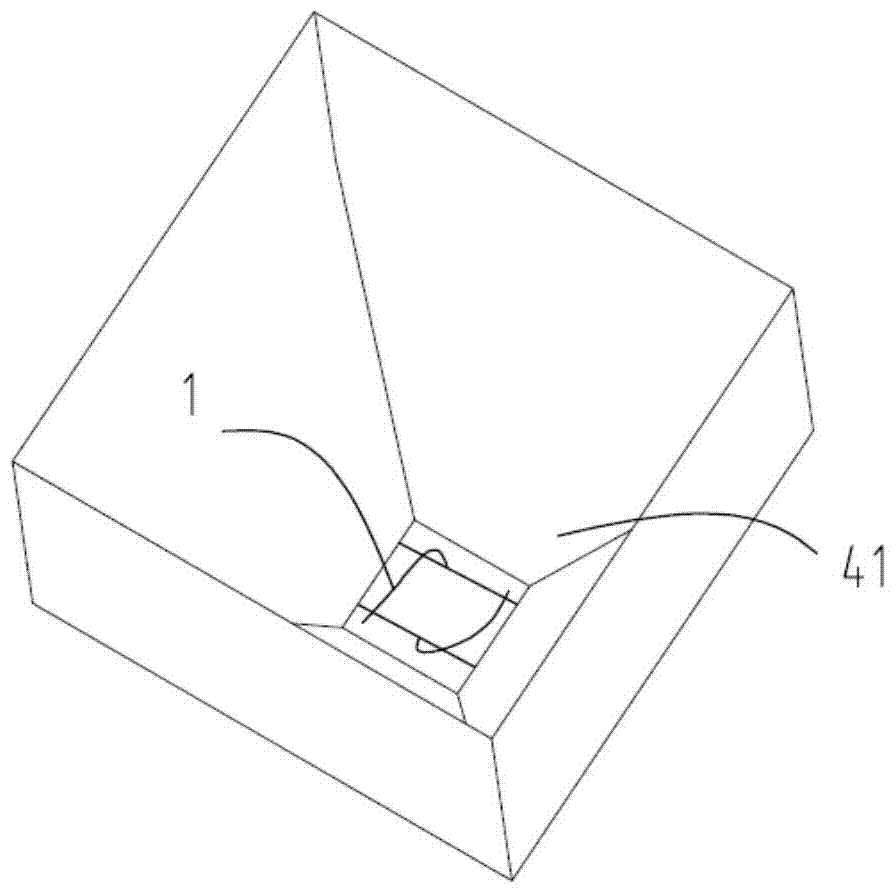

ActiveCN104791770ASmall granularitySolve not working properlySolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberHeat power

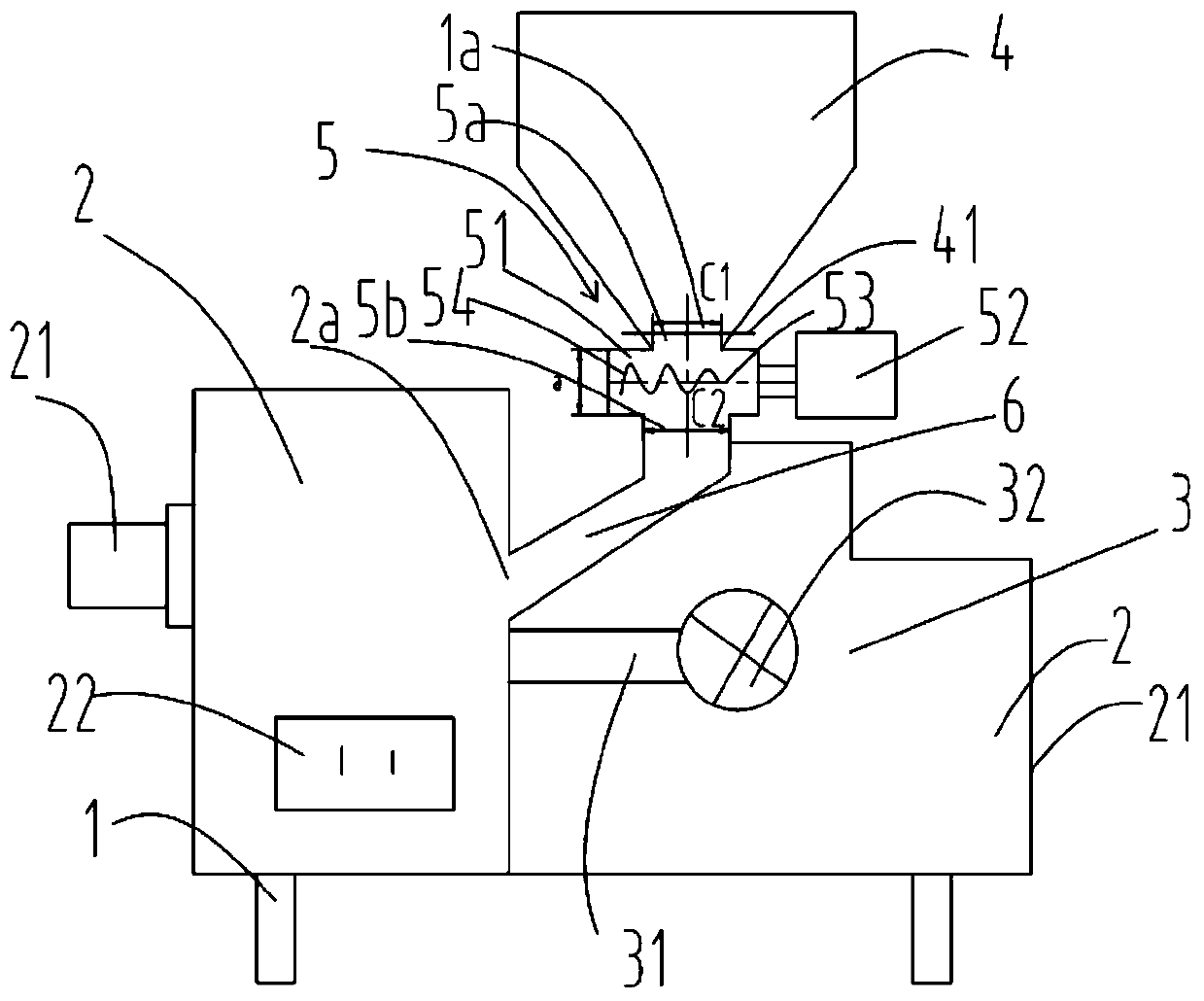

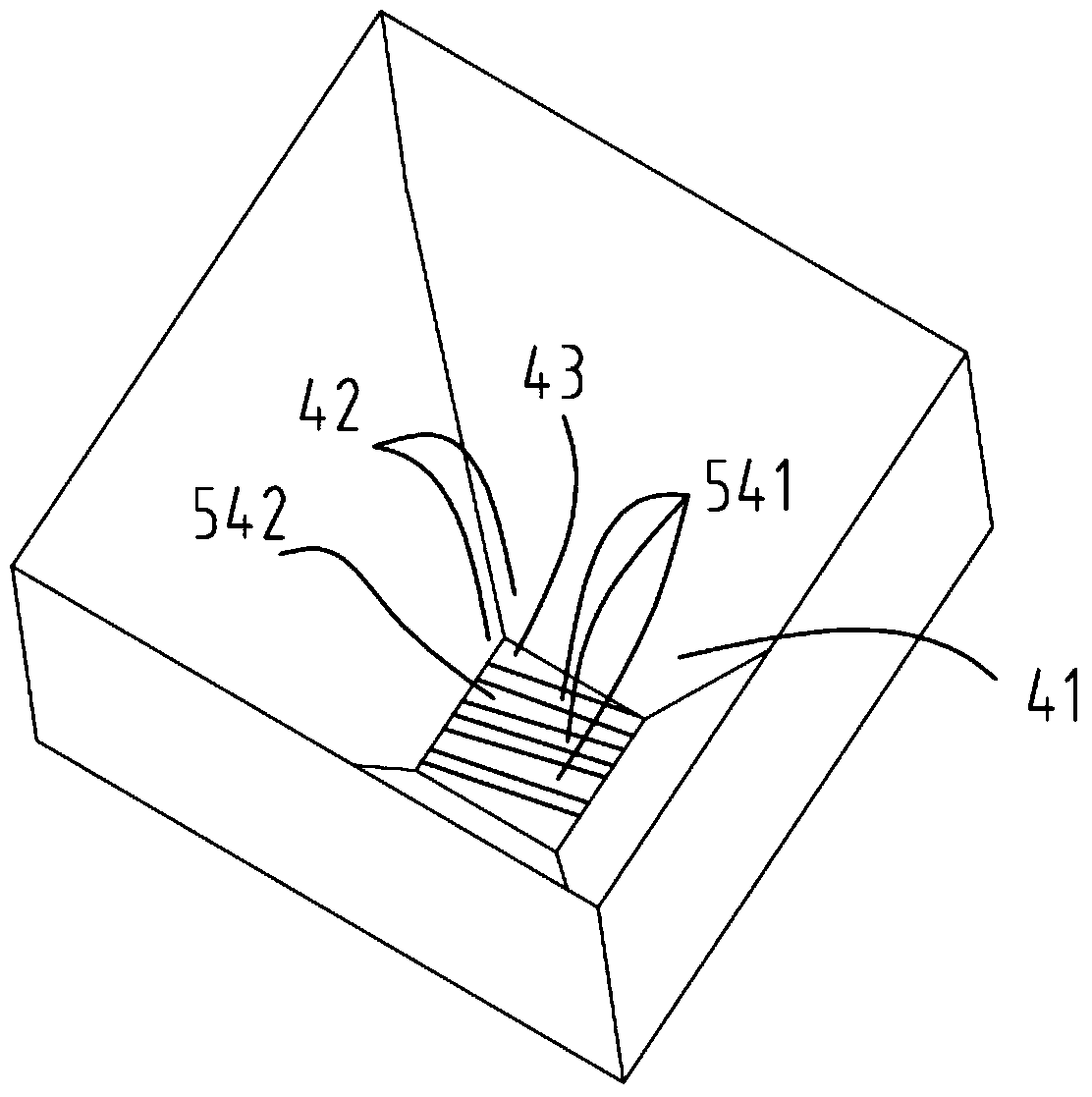

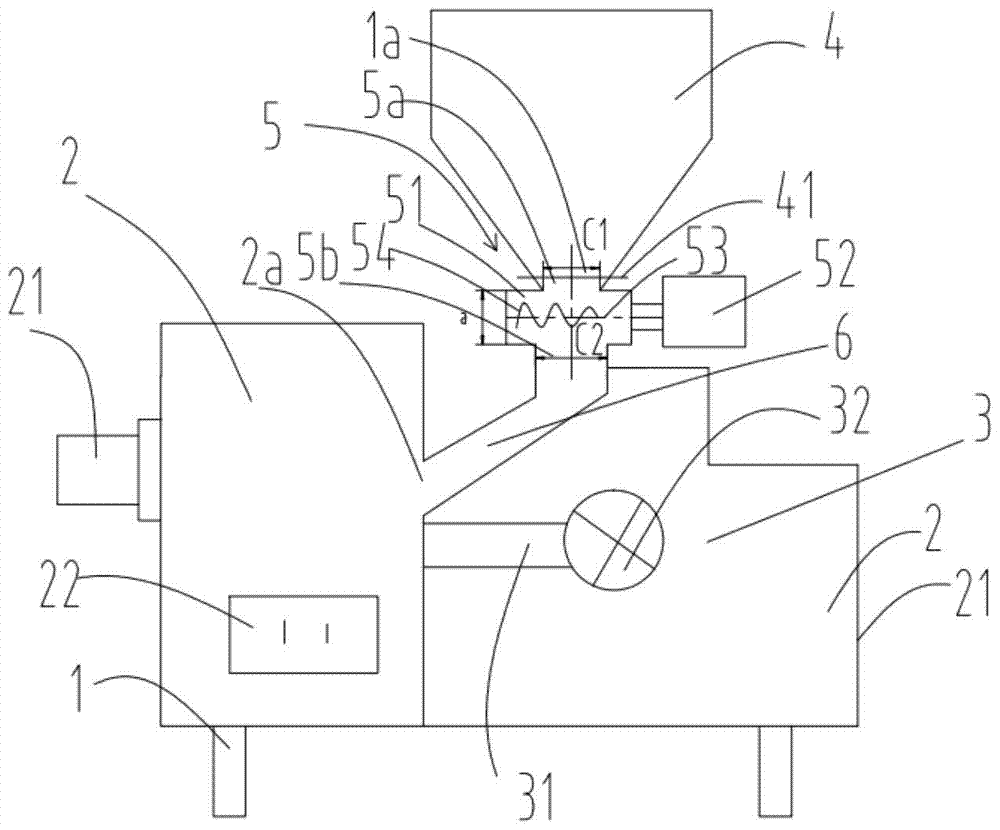

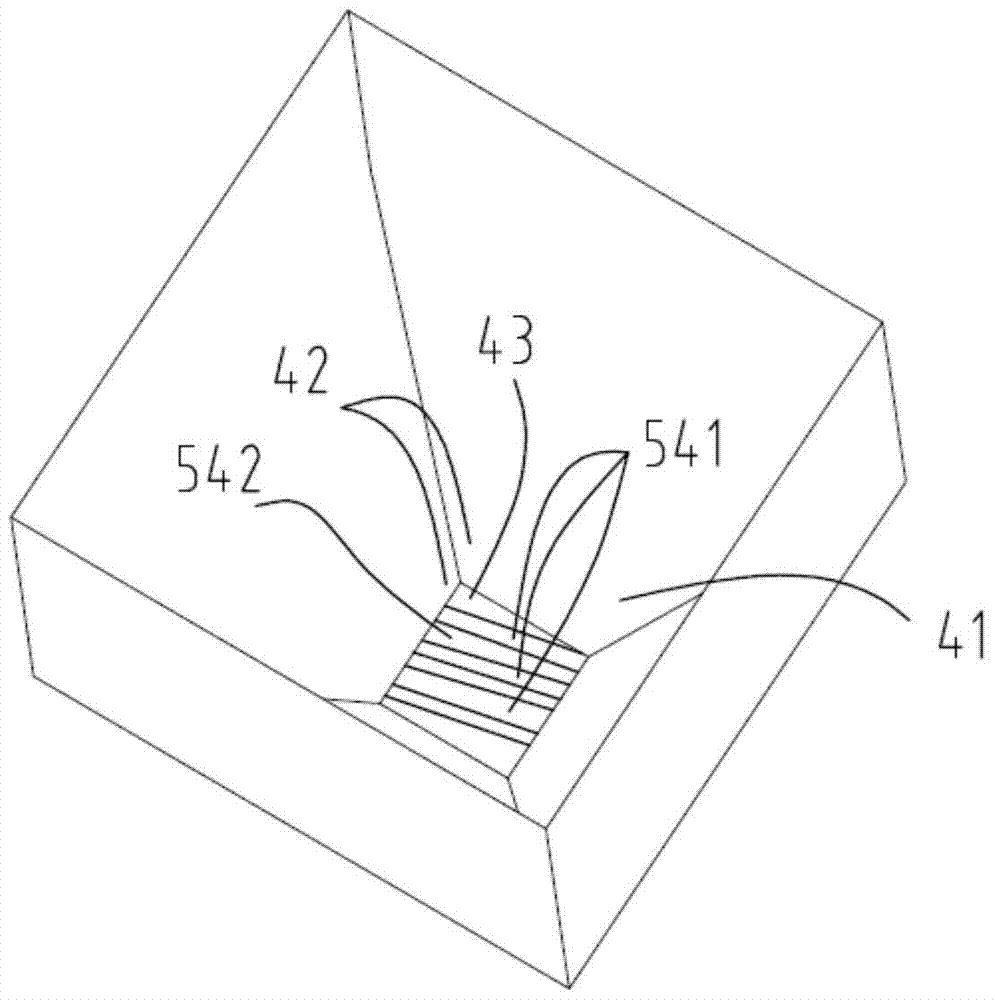

The invention relates to a biomass burner. The biomass burner comprises a rack (1), a combustion chamber (2), a wind chamber (3) and a storage bin (4). The wind chamber (3) is communicated with the combustion chamber (2) through an air induced channel (31). One end of the air induced channel (31) is provided with a draught fan (32). The other end of the air induced channel (31) extends inside the combustion chamber (2). Biomass particles enter the combustion chamber (2) from the storage bin (4) to be subjected to combusting. A boccacrater (21) and a dust outlet (22) are further arranged on the combustion chamber (2). The biomass burner further comprises a feeding module (5). The feeding module (5) comprises a feeding channel (51) and a spiral shaft (53). A bevel gear (54) is arranged on the spiral shaft (53). An inclined shearing opening (43) is formed by helical teeth (541) of the bevel gear (54) and the wall face (42) of a material outlet (41). The biomass particles enter a channel inlet (5a) from the inclined shearing opening (43). The problem that the device cannot work normally due to the fact that the biomass particles easily block the material outlet is solved, quantitative feeding is achieved, the heat power is continuous and adjustable, automatic controlling is achieved, the shearing effect is good, and the phenomena of material blocking and tempering are avoided.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

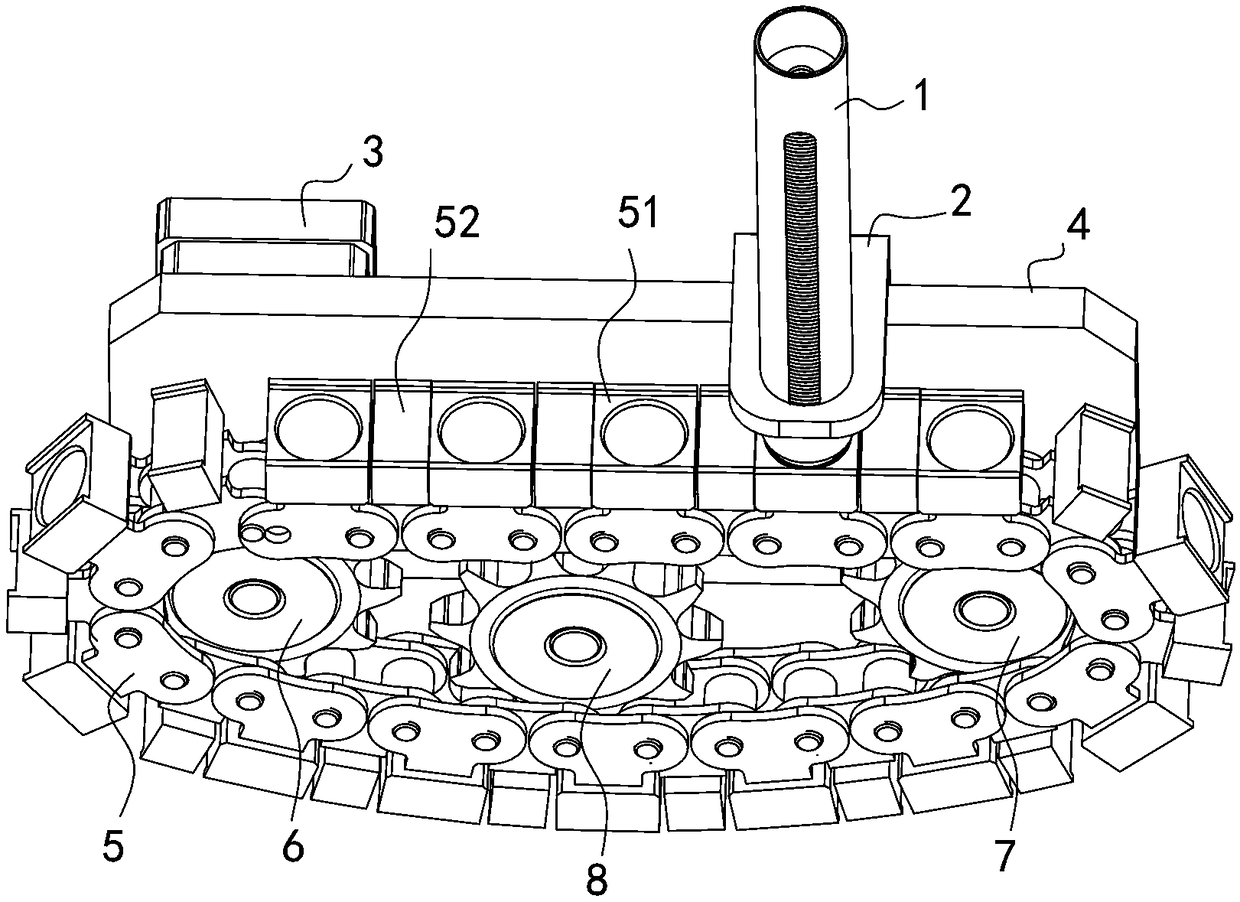

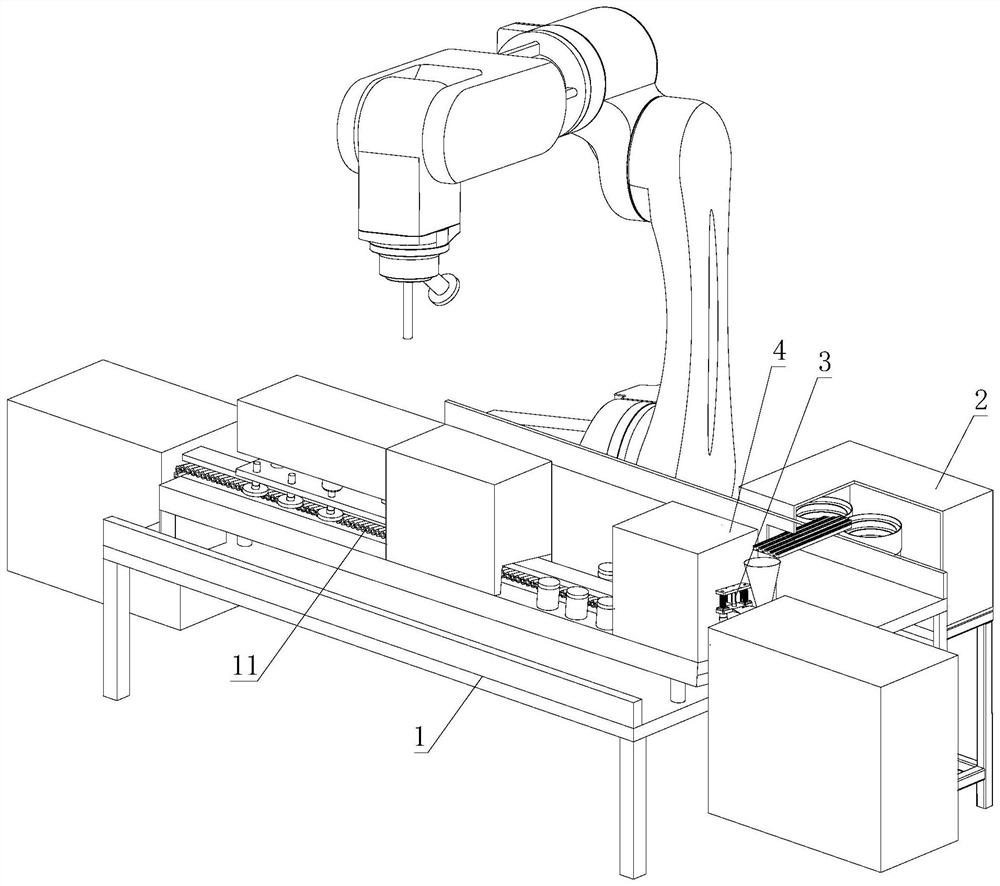

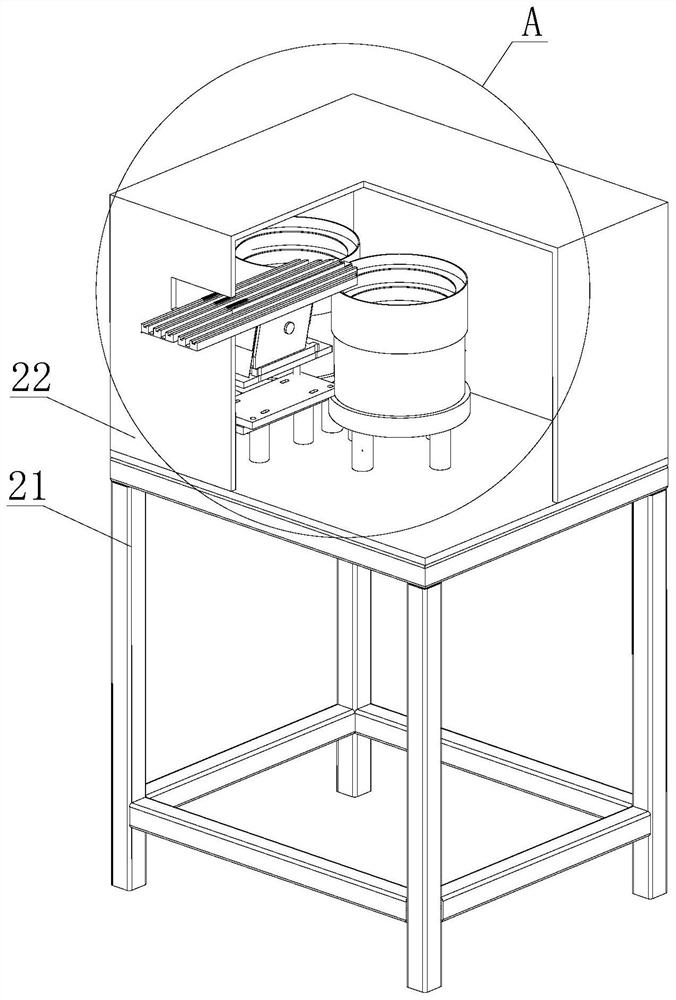

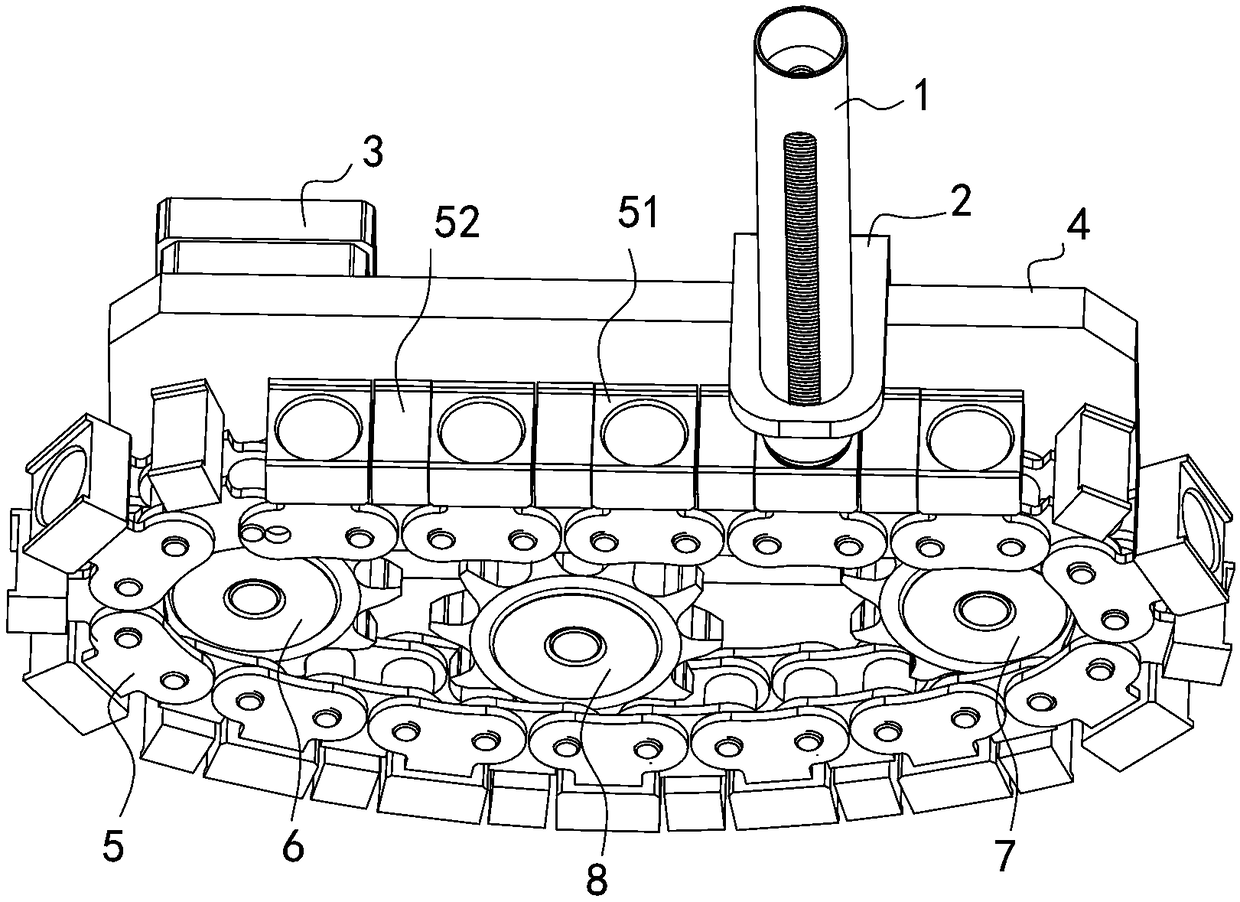

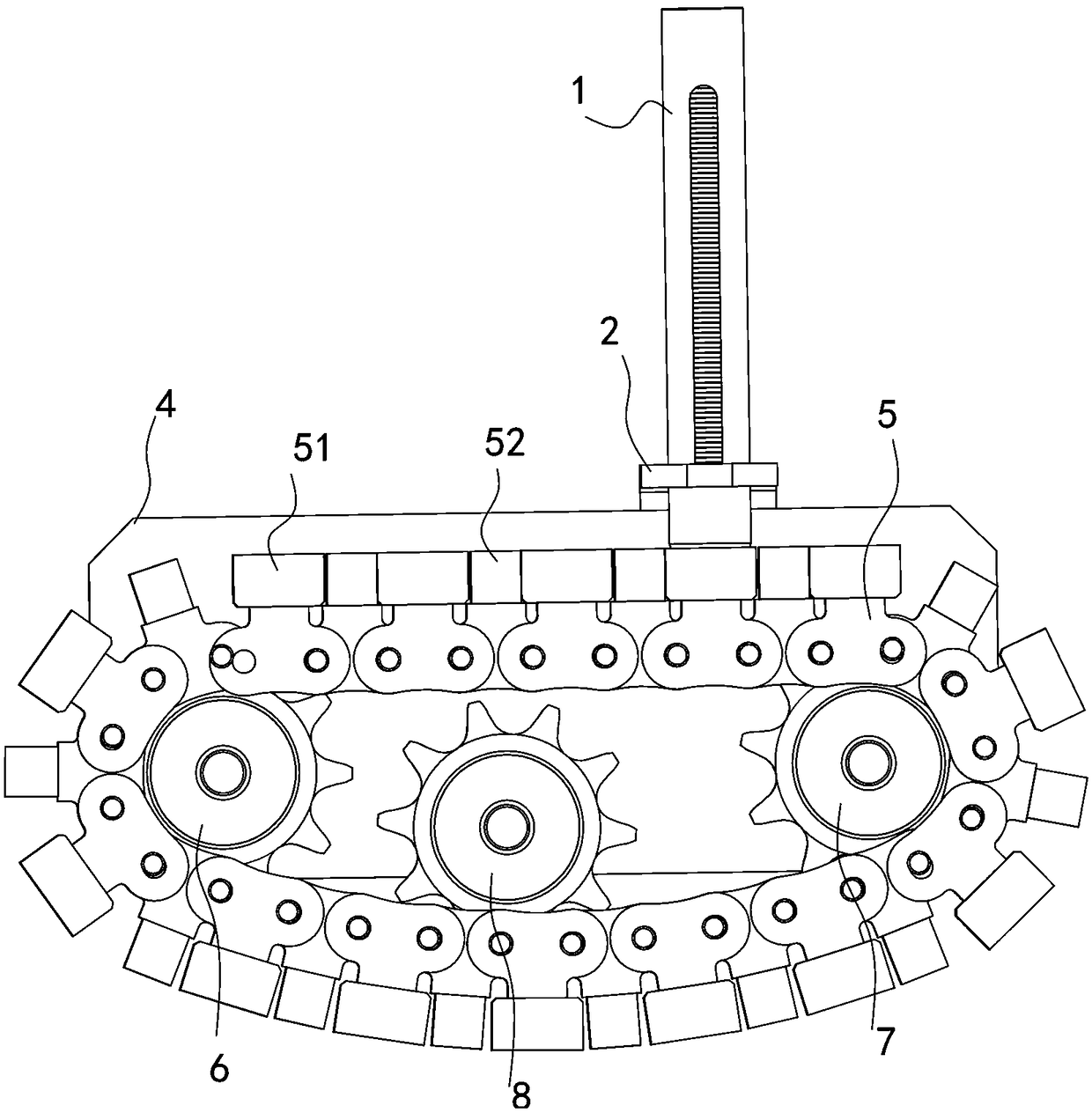

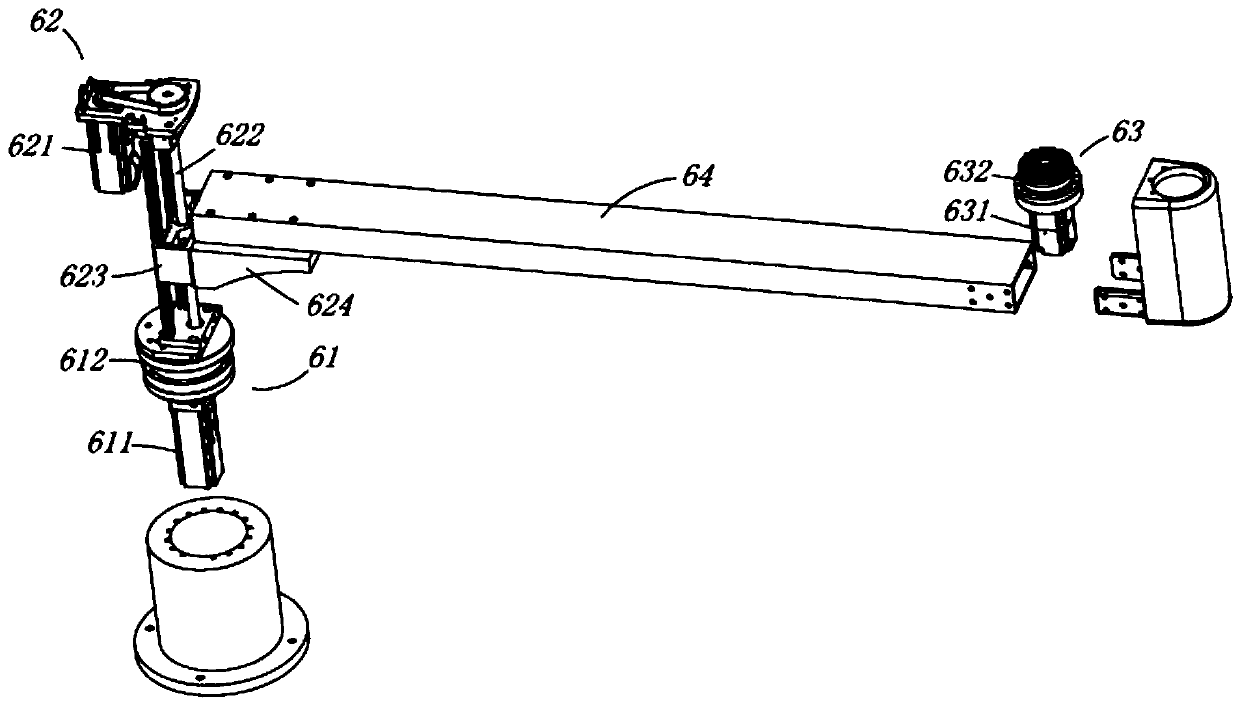

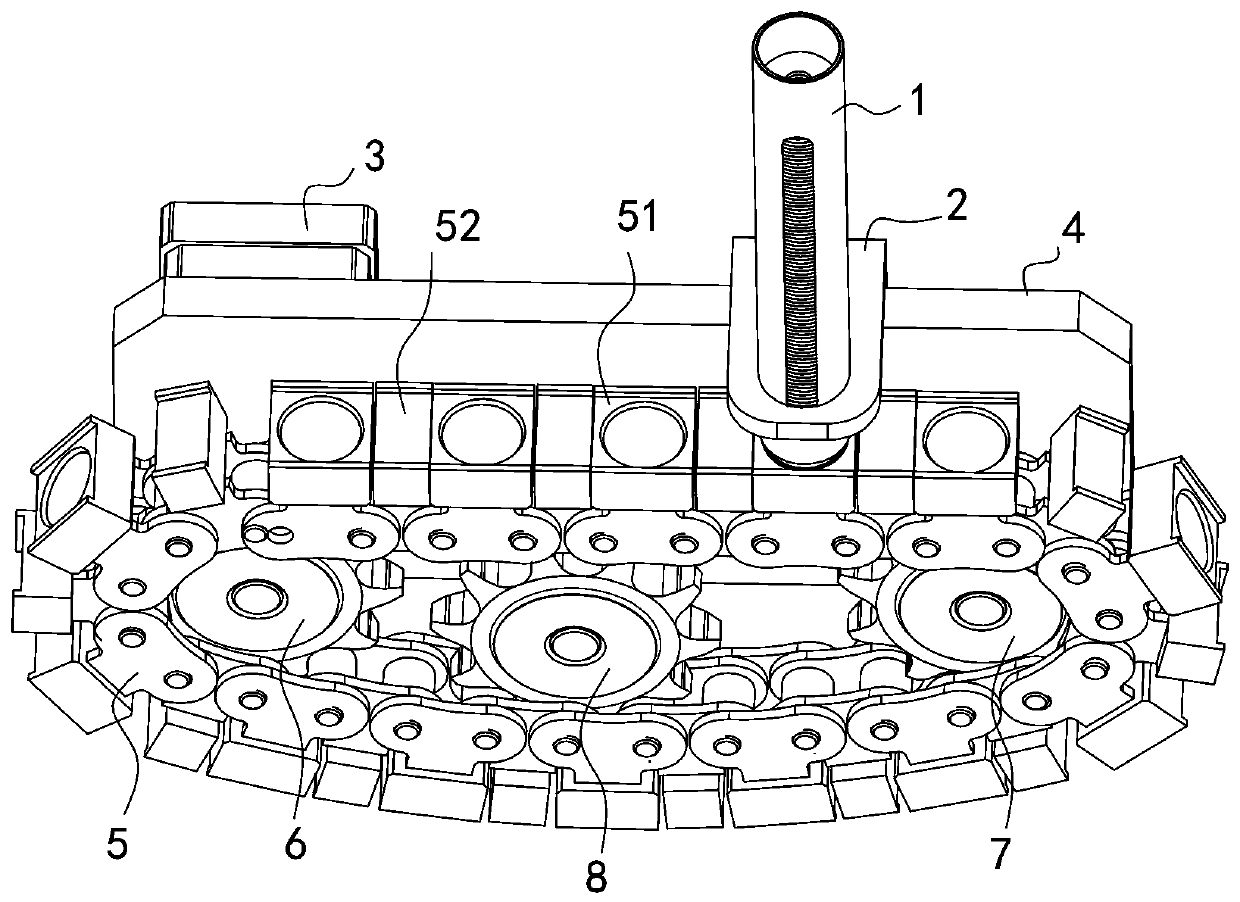

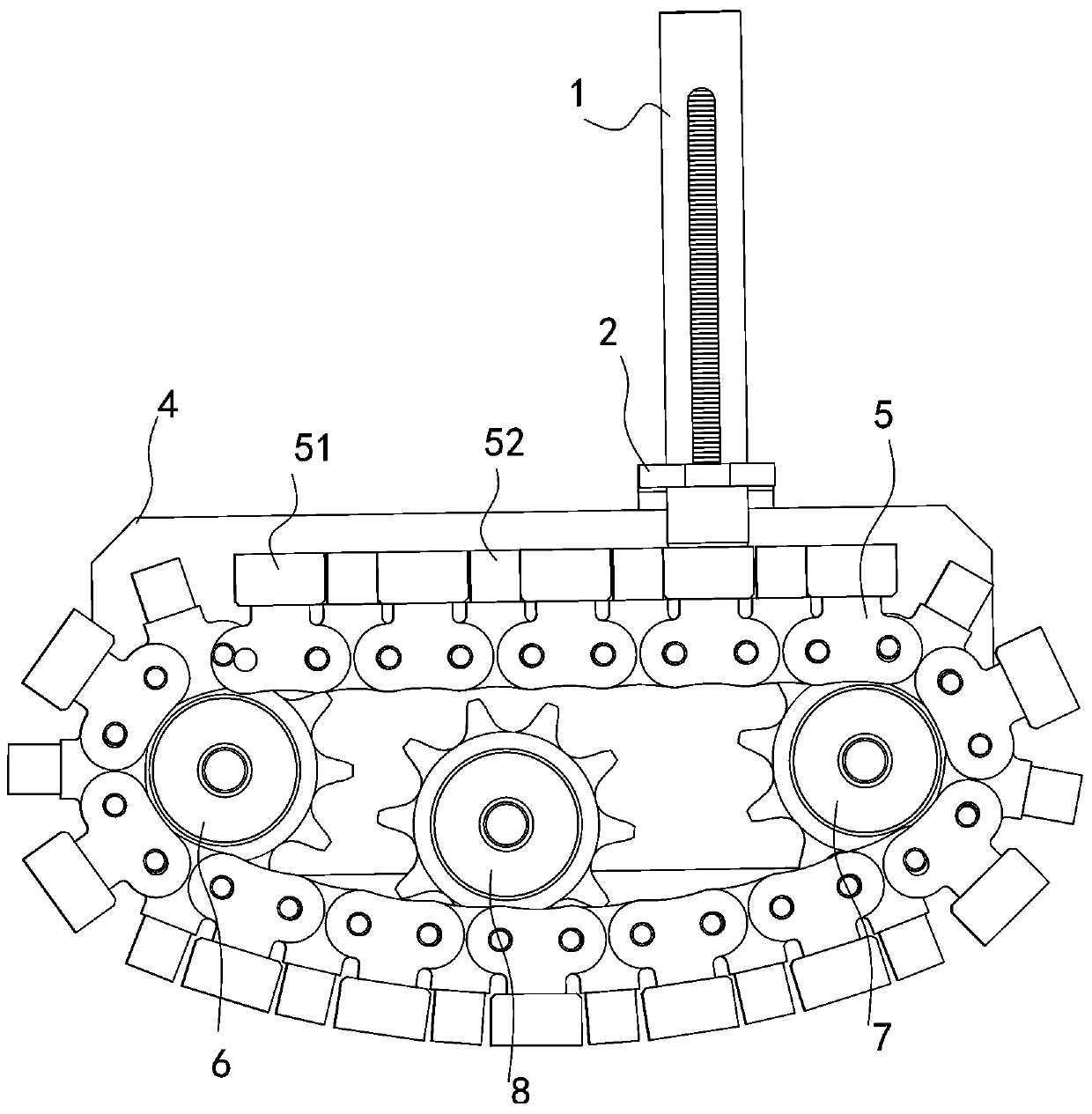

Chain type spacer quantitative feeding and assembling robot

ActiveCN109227073AGuaranteed surface qualityRealize quantitative captureMetal working apparatusSprocketEngineering

The invention discloses a chain type spacer quantitative feeding and assembling robot, which comprises a material barrel, an L-shaped bracket, a servo motor, a fixing plate and a chain, wherein the material barrel is arranged on the bracket; the bracket is arranged on the fixing plate; the servo motor is arranged on the fixing plate; a driving chain wheel is connected with the output end of the servo motor; the fixing plate is connected with a first driven chain wheel; the chain is meshed with the driving chain wheel and the first driven chain wheel; the chain is provided with grabbing blocks;each grabbing block is internally provided with an electromagnet; each grabbing block is provided with a circular groove; the depth of the circular groove is equal to the thickness of the spacer, a partition block is also fixed on the chain, the partition block is positioned between the grabbing blocks, the material barrel is at a certain distance from the upper surface of the grabbing blocks orthe partition block, and the distance is smaller than the thickness of the spacer; according to the invention, the quantitative feeding and assembling of the spacer are combined together, the efficiency is higher, the abrasion caused by friction between the spacer and other objects is reduced, and the stability of the spacer is more durable.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

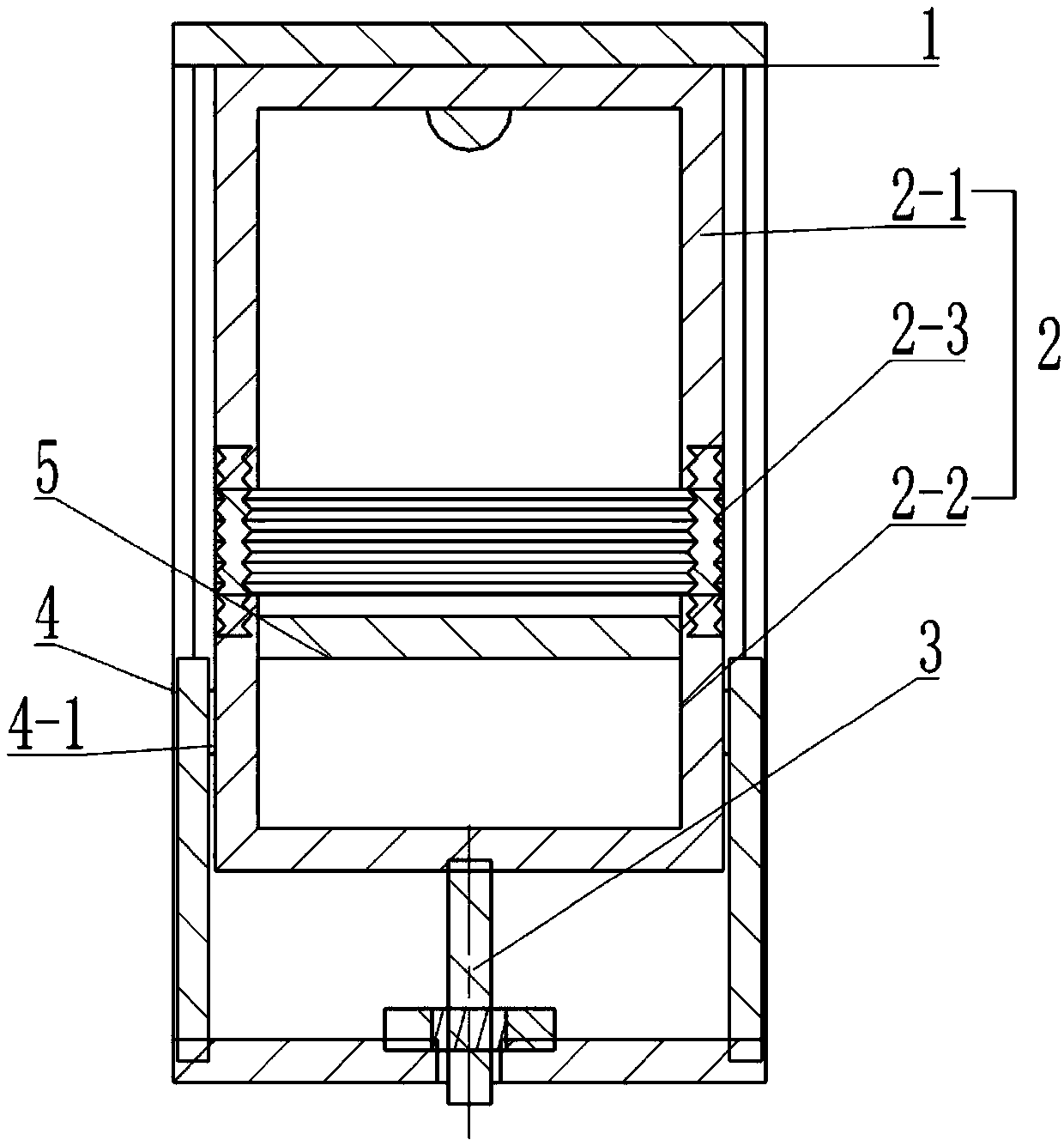

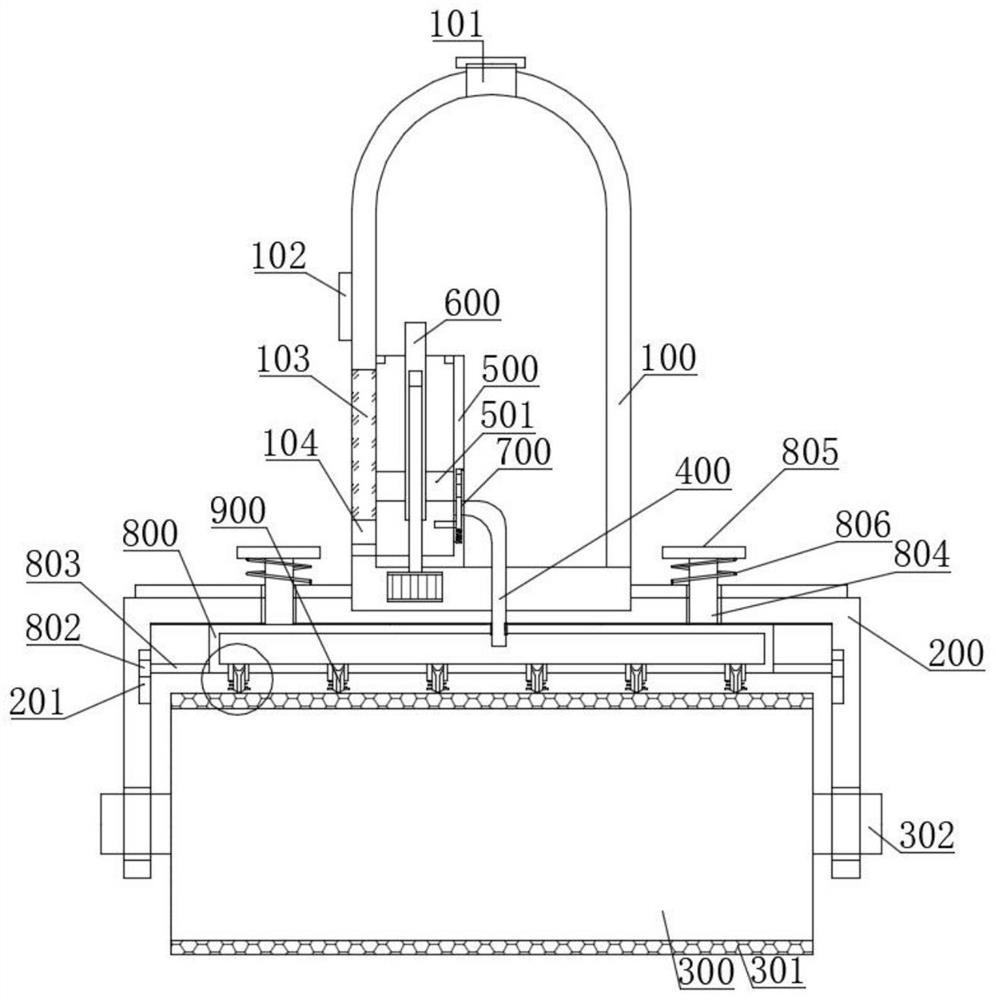

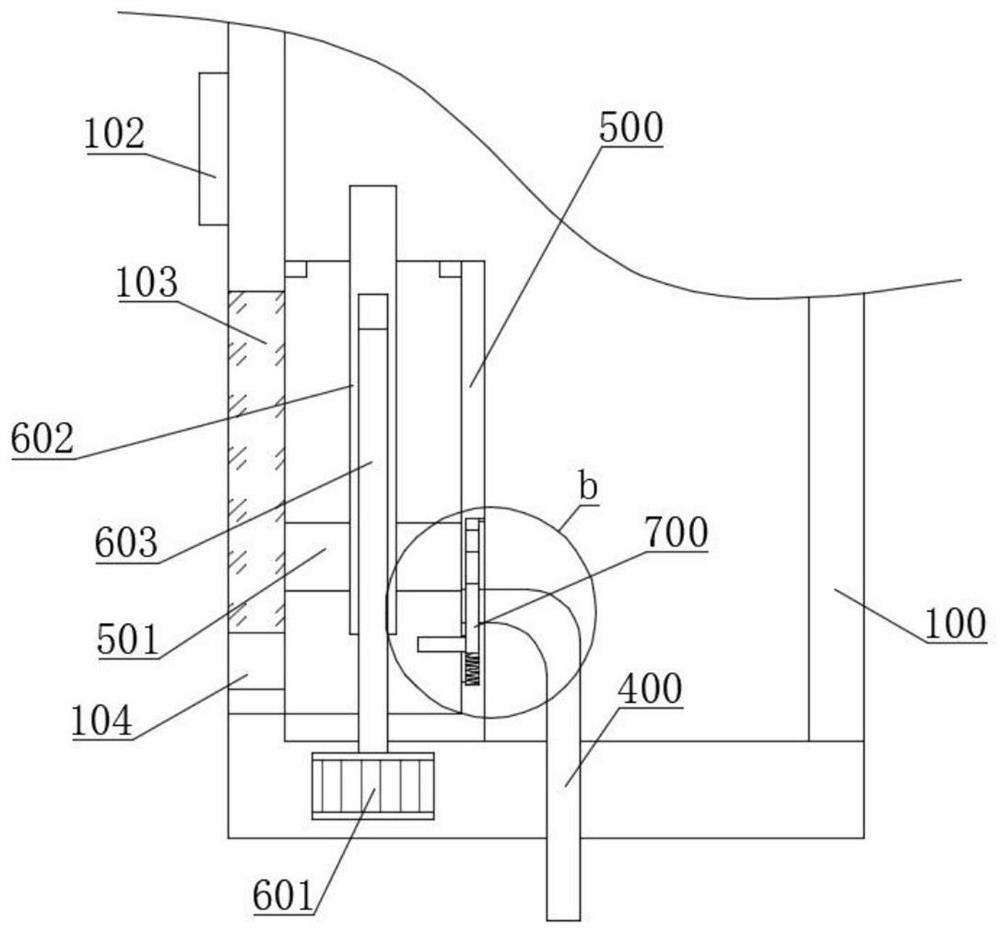

Laser sintering 3D printing machine

ActiveCN110549602ARealize quantitative supplyAvoid accumulationManufacturing platforms/substrates3D object support structuresEngineering3D printing

The invention provides a laser sintering 3D printing machine comprising a telescopic forming cylinder capable of solving the sealing and washing problems and a powder supplying and laying mechanism. The telescopic forming cylinder is connected with an upper cylinder body and a lower cylinder body through telescopic structures, the whole device is in a closed state, and the quality of formed partscan also be improved while the sealing problem is solved; and furthermore, because a working table and the forming cylinder are connected in a seamless manner, the washing problem can be well solved.The laser sintering 3D printing machine further comprises the powder supplying and laying device. Quantitative supplying of powder is achieved through a quantitative powder laying mechanism, surplus powder stacking is prevented, the device is simple, and cost is low.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

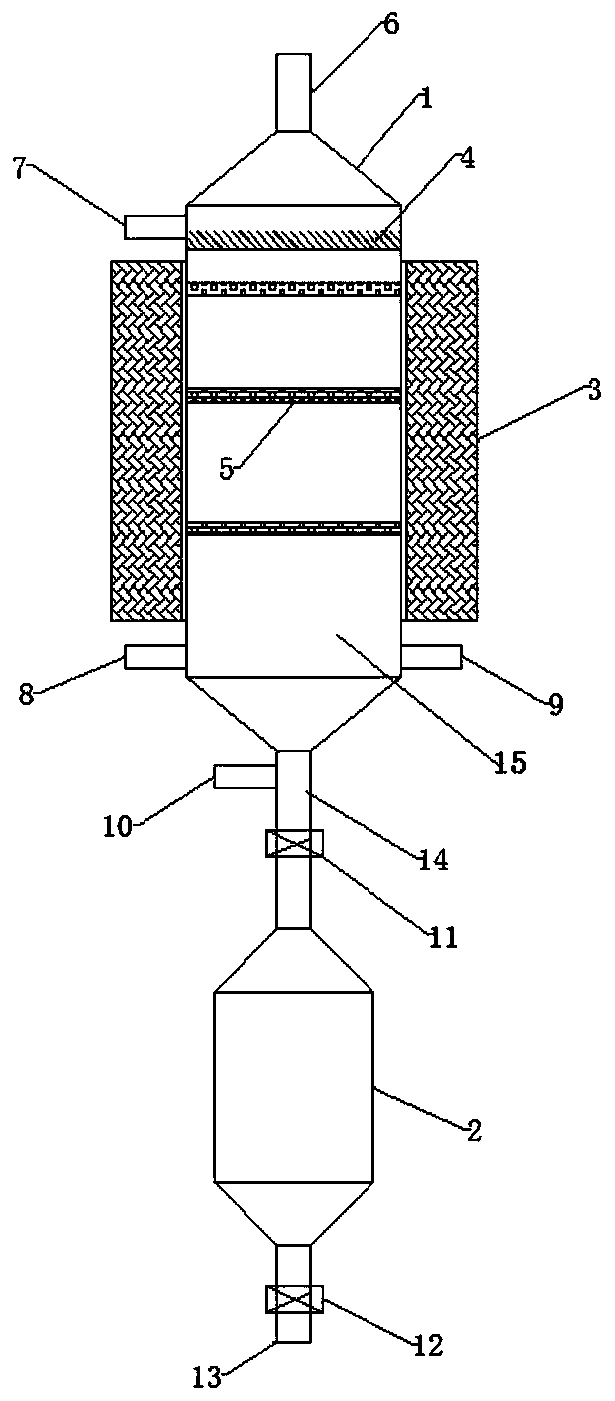

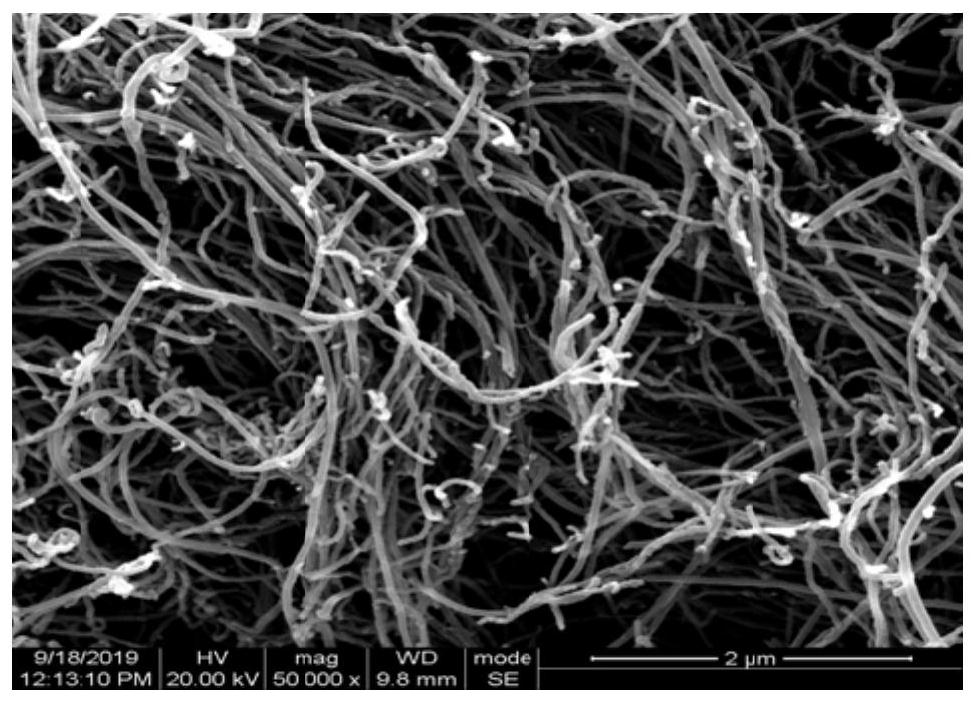

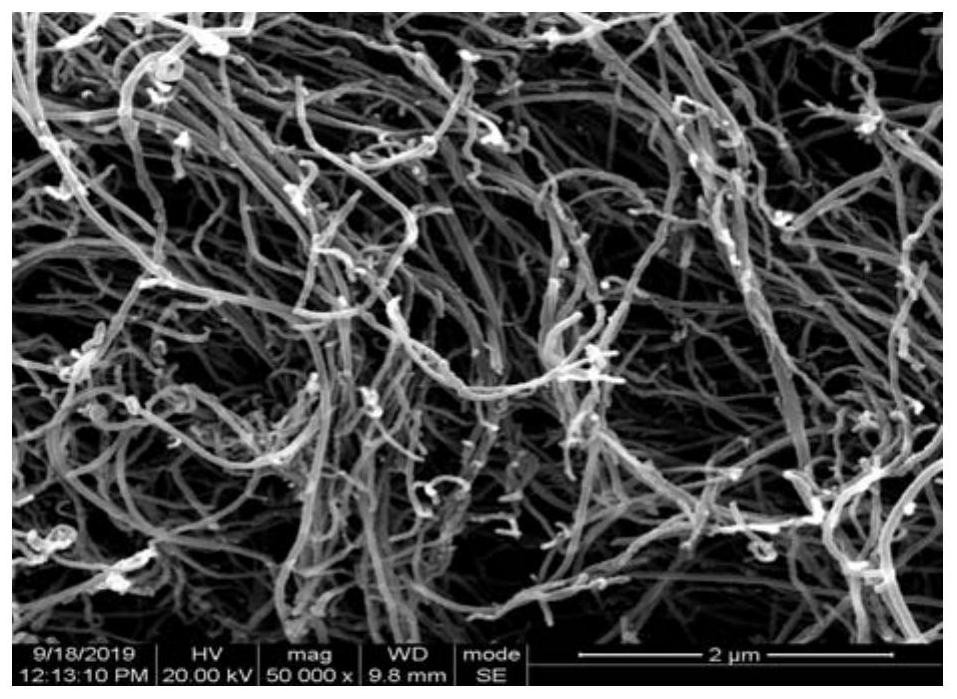

Carbon nanotubes purified by gas phase damping method, device and purification method

The invention relates to the technical field of carbon nanotube purification, and in particular, relates to a carbon nanotubes purified by a gas phase damping method, a device and a purification method. The method disclosed by the invention comprises three steps of feeding the carbon nanotubes, purifying, cooling and collecting. According to the invention, a high-temperature corrosion-resistant ultrasonic vibrating screen is used for feeding carbon nanotubes, so that quantitative feeding can be realized, and the screen can be prevented from being blocked; a gas-phase damping ring is utilized to increase the resistance of the carbon nanotubes in the descending process of a purification chamber and prolong the contact time of the carbon nanotubes and chlorine, and a residual metal catalyst in the carbon nanotubes reacts under the heating condition to generate chloride, the metal catalyst and the carbon nanotubes are separated, and the purpose of purifying the carbon nanotubes is achieved. The method disclosed by the invention is simple, easy to amplify in productivity, small in pollution, easy to engineer, good in purification effect and suitable for removing various residual metalsin various carbon nanotubes. The purity of the carbon nanotubes is high, and the content of single metal impurities in the carbon nanotubes is less than 20 ppm.

Owner:成都莱尔纳米科技有限公司

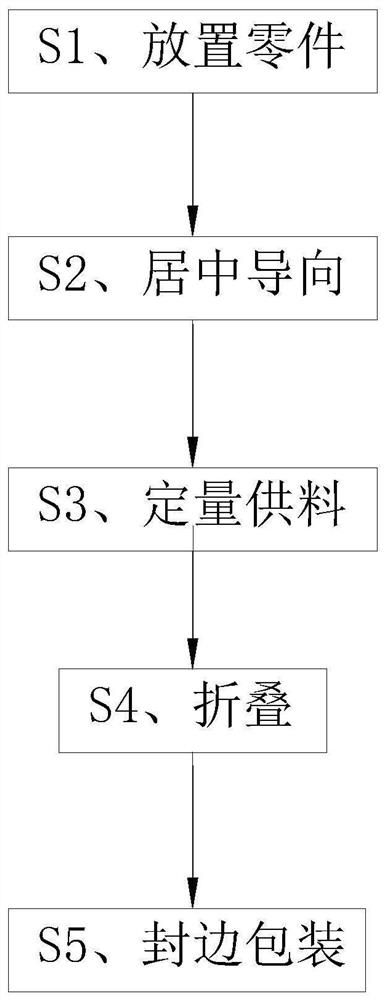

Part packaging method

InactiveCN112141420AAvoid cloggingControl work processWrapper twisting/gatheringSolid materialStructural engineeringMechanical engineering

The invention discloses a part packaging method, and particularly relates to a part packaging device. The device comprises a workbench, a vibratory feeding mechanism for conveying, a vibratory discharging mechanism for discharging, a shaft ring part centering pushing mechanism, a quantitative supply mechanism, an edge-sealing folding mechanism and a sealing mechanism. According to the device involved in the process, an opening of a packaging box is covered through rotation of a bent plate of a folding locating frame, so that pre-packaging is realized; and a sealing adhesive tape is attached tothe opening gap of the packaging box through a front pressing wheel and a rear pressing wheel along with synchronous movement of a conveying belt, and after the packaging box is disengaged from the sealing mechanism, the sealing adhesive tape is cut off through descending of a driving cutter. Therefore, automatic sealing is realized, and labor cost is reduced.

Owner:李伦中

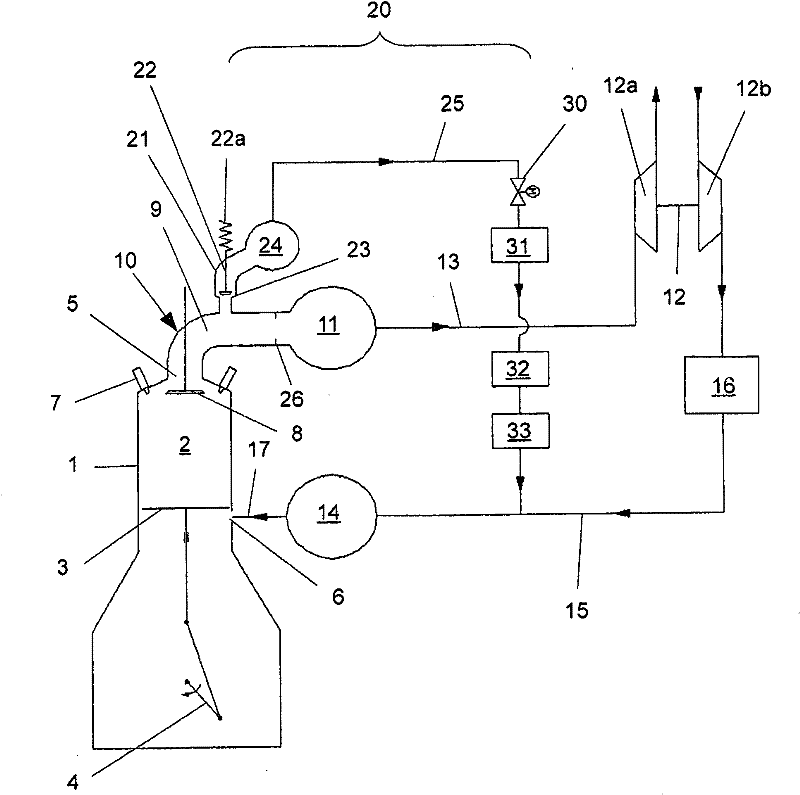

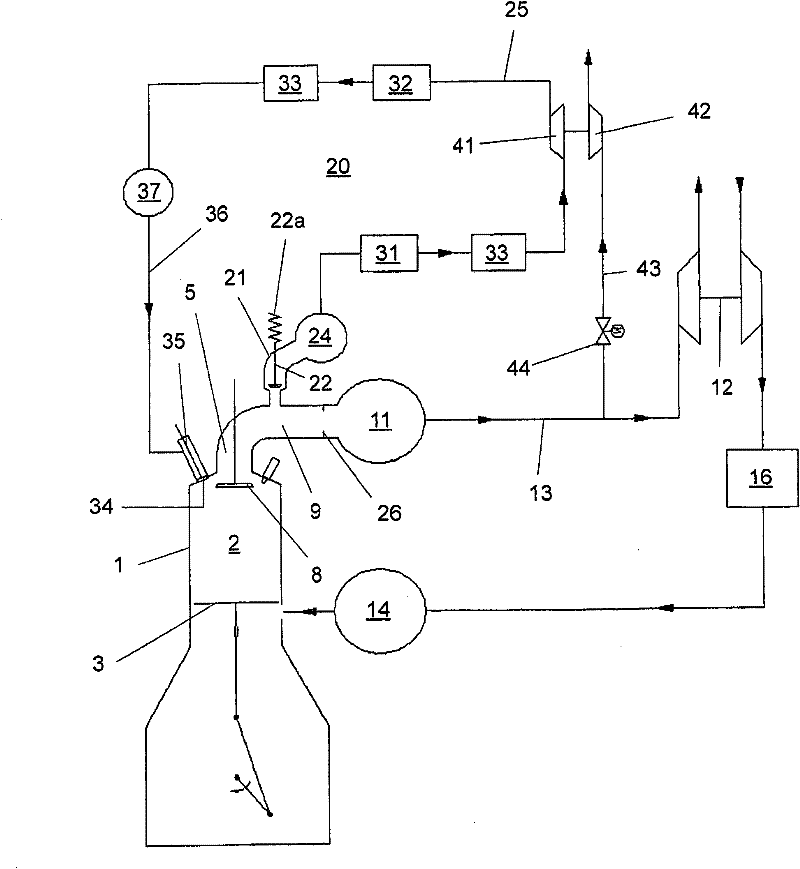

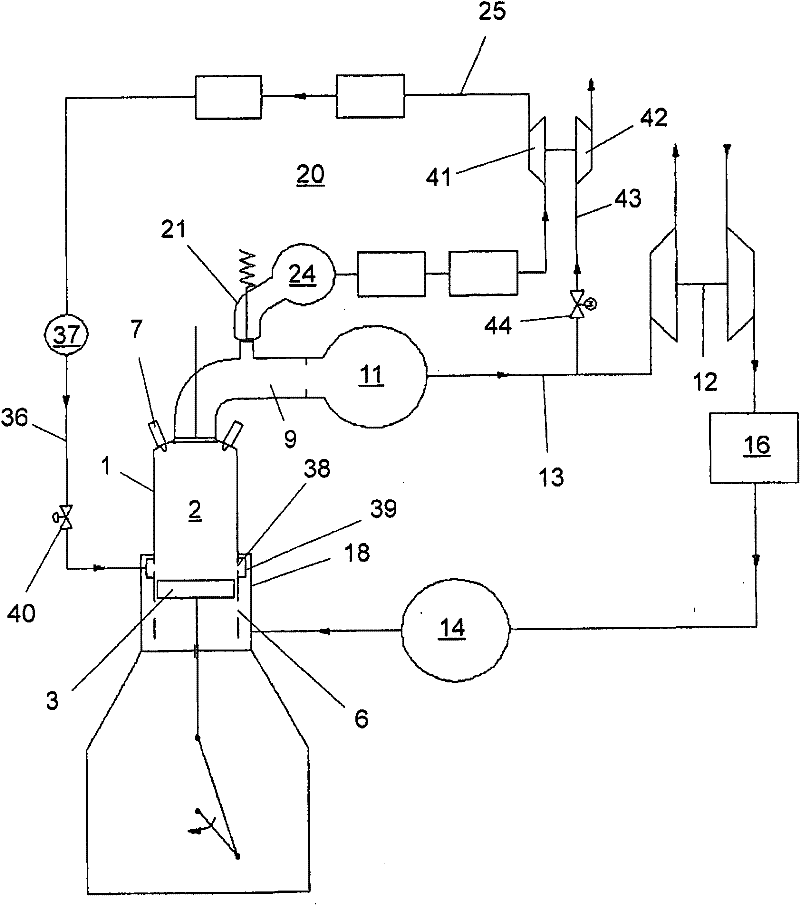

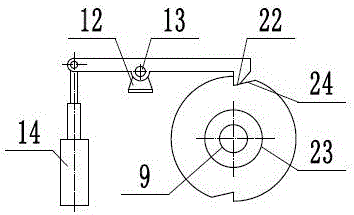

Internal combustion engine

ActiveCN101737204BEmission reductionReduce direct connectionNon-fuel substance addition to fuelInternal combustion piston enginesReciprocating motionEngineering

The invention relates to an internal combustion engine which is provided with at least one cylinder (1) and a device used for recycling the exhaust gas. The cylinder is provided with an working chamber (2) which is limited by a reciprocating piston (3) and is loaded by the scavenging gas comprising compressed gas and fuel. The working chamber is provided with at least one scavenging gas inlet (6), at least one fuel inlet and at least one exhaust gas outlet (5). An exhaust duct (9) is connected with the exhaust gas outlet. A pressure impact (19) is generated in the exhaust duct (9) through theexhaust flowed out from the opened exhaust outlet (5). Through a device used for exhaust recirculation, one part of the exhaust can be used as the recirculation gas for being directly or indirectly guiding into the working chamber (2). Thus the dilution of the recirculation gas by the scavenging gas is prevented and a simple structure is realized. A recirculation gas outlet (21) is leaded out from the exhaust duct (9) connected with the exhaust outlet (5). The recirculation gas outlet can be closed through an attaching valve (22). The valve opens the attaching recirculation gas outlet (21) inan area between increasing and reducing the pressure impact (19) generated in the exhaust duct (9).

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

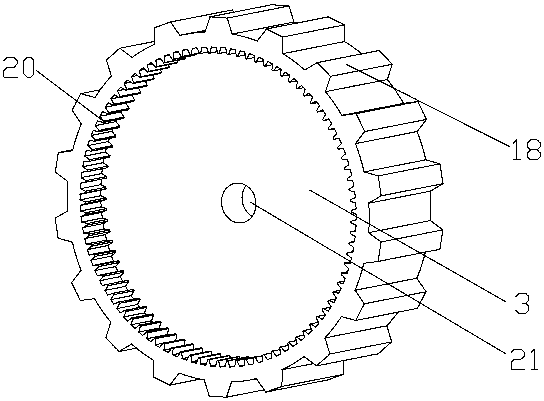

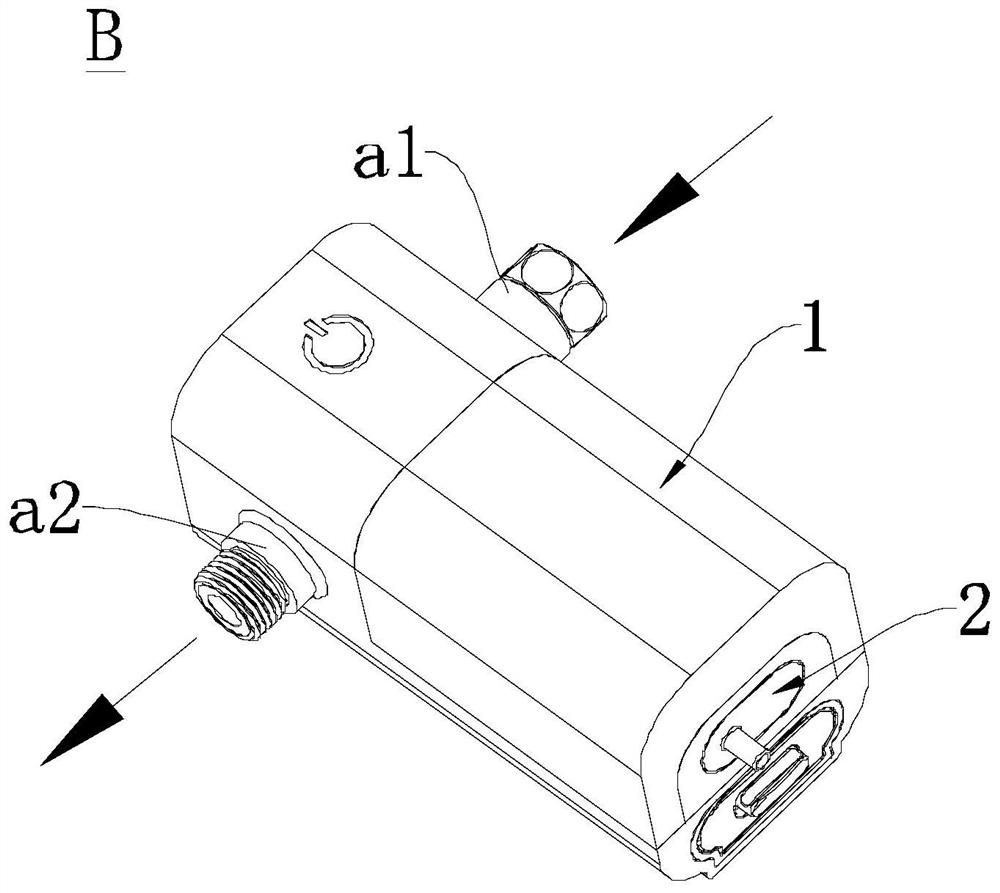

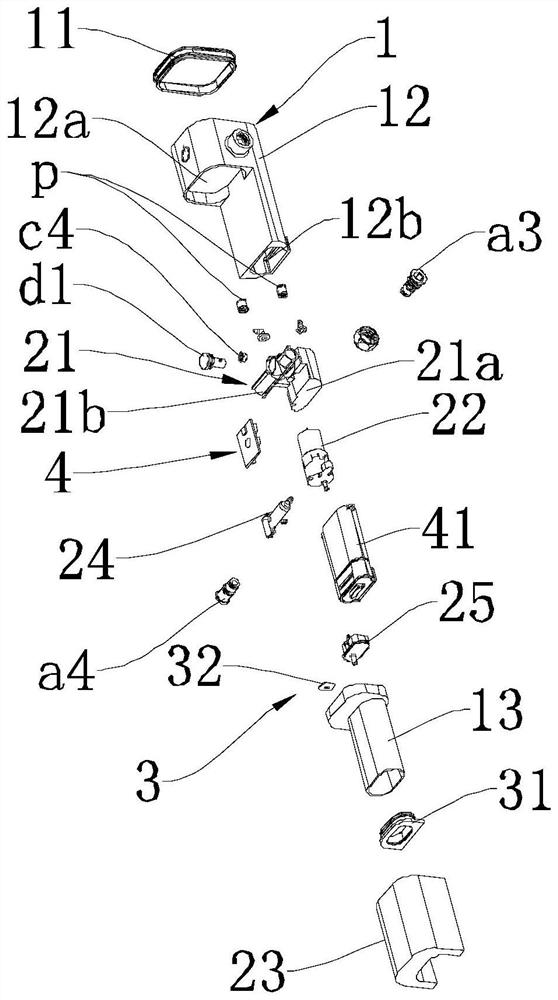

A non-contact access box for disposable water cups

ActiveCN109319310BRealize quantitative supplyCompact designDispensing apparatusGear wheelEngineering

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

Automatic device for preparing oil into fuel gas

InactiveCN109794177AKeep a safe distanceRatio is easy to controlFlow mixersTransportation and packagingAutomatic controlProduct gas

The invention discloses an automatic device for preparing oil into fuel gas. The automatic device comprises a high-pressure fan, a pressure relief flow divider valve, a flow dividing feedback tube, anoil storage tank, an oil conveying pipe, a flow adjustor, a pressure automatic control switch and a temperature automatic control switch, the pressure relief flow divider valve is installed at an outlet of the high-pressure fan, overpressure overflowing gas returns into a suction port of the high-pressure fan through the flow dividing feedback tube, the oil conveying pipe is connected with an outlet of the oil storage tank and the suction port of the high-pressure fan, and the flow adjustor, the pressure automatic control switch and the temperature automatic control switch control the flow, pressure and temperature in a gas-preparing technological process respectively. In this way, an oil conveying pump, a reaction kettle and a heating device are omitted, the manufacturing cost for the device is lowered, the oil with the specific gravity being 0.62-0.69 can be prepared into the fuel gas, energy saving and emission reduction are realized for an enterprise, and funds are saved for the enterprise.

Owner:山东中沃石油天然气有限公司

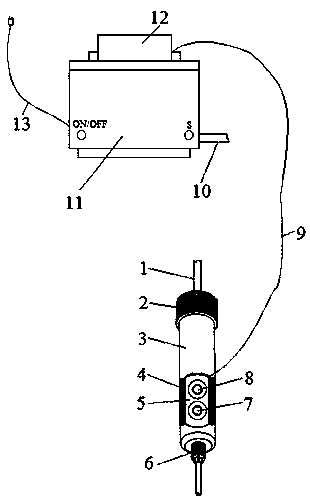

Soldering tin propelling and sucking multi-purpose device based on single chip microcomputer

PendingCN109794664ASolve unmanageable problemsEasy to operate manuallyWelding/cutting auxillary devicesAuxillary welding devicesMicrocomputerMicrocontroller

The invention discloses a soldering tin propelling and sucking multi-purpose device based on a single chip microcomputer. The soldering tin propelling and sucking multi-purpose device comprises a tubebody, an air pump and a single chip microcomputer control unit; one end of the tube body communicates with the air pump, and the other end of the tube body is provided with a needle holder; and a control mechanism sleeves the tube body, and the control mechanism and a driver on the air pump are both connected with the single chip microcomputer control unit. When the multi-purpose device is used as a soldering tin propelling device, a needle head is mounted on the tube body; and the multi-purpose device solves the problems that in the manual soldering process of printed circuit boards (pcbs),tin feeding of solder joints and solder pads is difficult to control, and cold solder joints are generated well, the time of manual soldering of the pcbs can be effectively shortened, the soldering efficiency is improved, and a lot of convenience is provided for small-batch soldering.

Owner:NORTHWEST NORMAL UNIVERSITY

Spring-shaped environment-friendly coating silver solder ring

ActiveCN104907724BNo pollution in the processEasy to useWelding/cutting media/materialsSoldering mediaMeth-Polyvinyl alcohol

The invention discloses a spring-shaped environment-friendly coating silver brazing material ring, which consists of at least two rings of spring-shaped silver brazing material cores with a median diameter of 2.0 mm to 56.0 mm wound by filaments or thin narrow strips of silver brazing material It is composed of silver brazing flux coating coated on the outside of the spring-shaped silver solder core. The silver brazing flux includes at least one of inorganic fluoride, potassium fluoroborate, boric anhydride, borate, and elemental boron. The silver brazing flux , polyvinyl alcohol, methyl cellulose and water according to a certain ratio to prepare flux solution, directly coated on the outer surface of the spring-shaped silver solder core, after drying, you can get a spring-shaped environment-friendly coating silver solder Finished material ring. The spring-shaped environment-friendly coating silver solder ring of the present invention, because it does not contain organic binders, complies with ROHS standards, greatly reduces environmental pollution during brazing and combustion, thereby protecting the health of operators, and greatly reducing the risk of environmental pollution. Reduced the labor intensity of the brazing process.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Defected skin cleaning device for dermatological treatment

PendingCN114177508AApply evenlyRealize quantitative supplyMedical devicesMedical applicatorsBiomedical engineeringDermatology department

The invention is applicable to the field of medical instruments, and provides a rotten skin cleaning device for dermatological treatment, which comprises a liquid medicine supply assembly, the liquid medicine supply assembly comprises a liquid medicine tank fixedly mounted on a frame, a liquid medicine cylinder is fixedly mounted on one side in the liquid medicine tank, and a piston is arranged in the liquid medicine cylinder in a lifting manner. The height position of the piston in the liquid medicine cylinder is adjusted through a height adjusting assembly; one side of the liquid medicine cylinder is provided with an on-off valve matched with the piston, and the piston moves downwards in the liquid medicine cylinder to push the on-off valve to be in an open state. According to the rotten skin cleaning device for dermatological treatment, by adjusting the height of the piston in the liquid medicine barrel, when the liquid medicine tank is turned over, the amount of liquid medicine contained in the liquid medicine barrel in the one-time reversing process can be fixed, and then when the liquid medicine in the liquid medicine barrel is supplied to the liquid medicine dripping assembly, the liquid medicine in the liquid medicine barrel can be conveniently and rapidly removed. Quantitative supply can be achieved, and extra accurate quantity control is not needed.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV

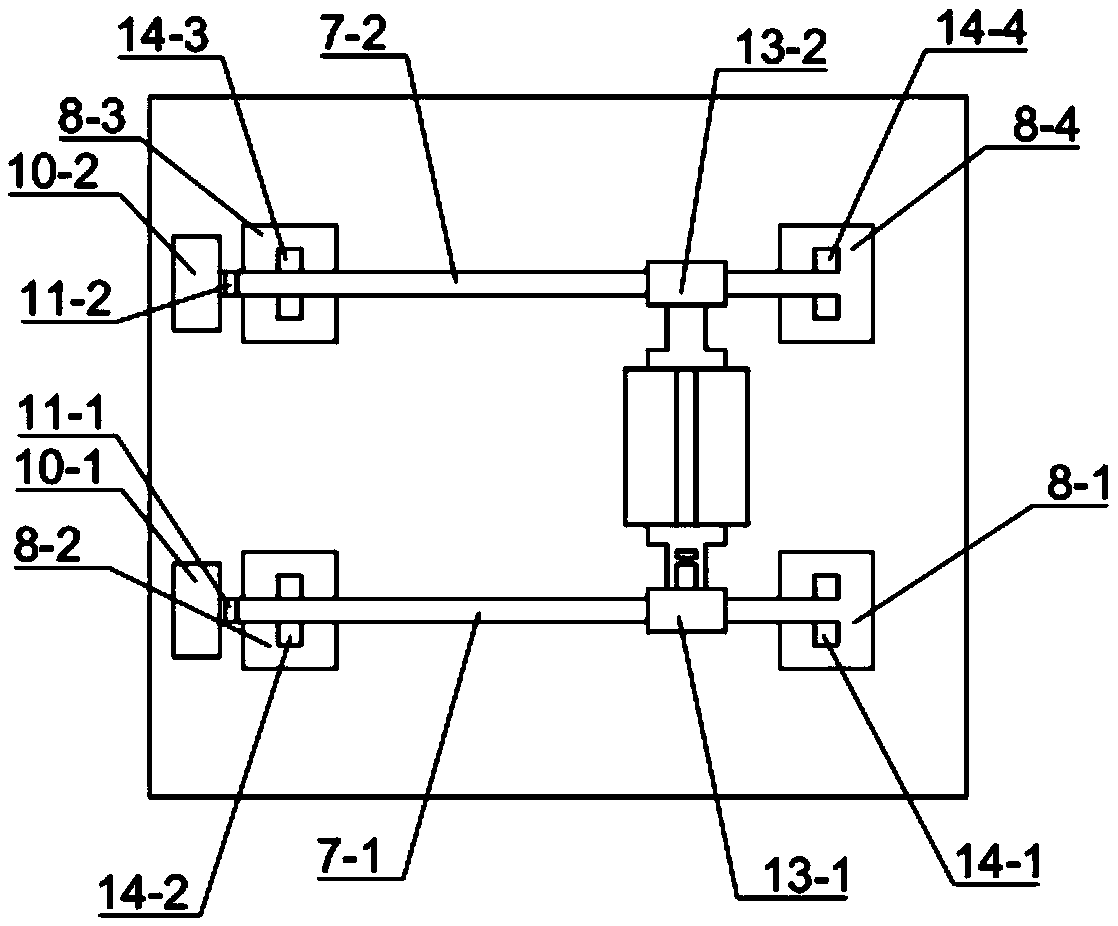

Chain-type gasket quantitative supply and assembly equipment

ActiveCN109227075AGuaranteed surface qualityRealize quantitative captureMetal working apparatusChain typeEngineering

The invention discloses chain-type gasket quantitative supply and assembly equipment. The equipment comprises a material barrel, an L-shaped bracket, a servo motor, a fixing plate and a chain; the material barrel is arranged on the bracket, the bracket is arranged on the fixing plate, the servo motor is disposed on the fixing plate, an output end of the servo motor is connected with a driving chain wheel, the fixing plate is connected with a first driven chain wheel, and the chain is separately meshed with the driving chain wheel and the first driven chain wheel and provided with gripping blocks; electromagnets are arranged in the gripping blocks, the gripping blocks are provided with circular grooves, the depth of the circular grooves is equal to the thickness of each gasket, and each partition block is also fixedly arranged on the chain and located between every two gripping blocks; a certain distance between the material barrel and each gripping block or between the material barreland the upper surface of each partition block is smaller than the thickness of one gasket. According to the equipment, the quantitative supply and assembly of the gaskets are combined, the efficiencyis higher, wearing caused by friction between the gaskets and other objects is reduced, and the stability of the gaskets lasts for a longer time.

Owner:江苏先博区块链科技有限公司

Decoction pot for manufacturing brown sugar

InactiveCN110250309AShorten the timeImprove production efficiencyTableware washing/rinsing machine detailsConfectioneryMotor drivePulp and paper industry

The invention discloses a decoction pot for manufacturing brown sugar. The decoction pot comprises a chamber which is internally provides with a storage cavity, decoction solid sugar can be put in the storage cavity, the lower side of the storage cavity is provided with a compounding cavity, and a communication hole is formed between the storage cavity and the compounding cavity in a communicated manner. After a stirring motor is started, the stirring motor drives a stirring blade shaft to rotate, the stirring blade shaft drives stirring blades to stir solid brown sugar in the storage cavity, and the brown sugar in the storage cavity is stirred into the compounding cavity, so that brown sugar decoction time is sharply shortened, manpower input can be reduced, and manufacturing efficiency in brown sugar decoction can be improved. In brown sugar decoction, quantitative supply of raw materials can be realized, a brown sugar ratio can be controlled, automatic pouring and cleaning can be realized after brown sugar decoction is completed, and after-cleaning products can be recovered, so that resource waste is reduced.

Owner:YONGKANG KEKA AUTOMATION EQUIP CO LTD

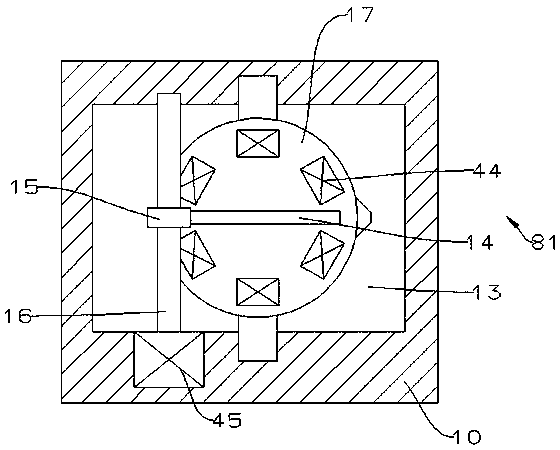

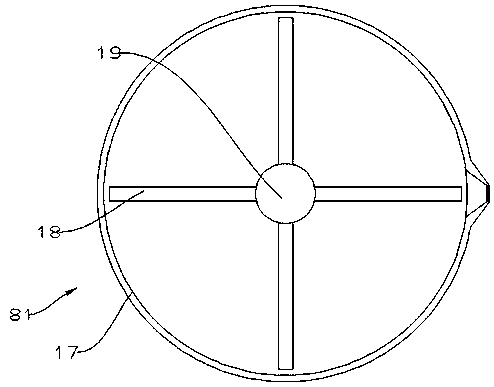

Crushed garbage quantitative feeding device

InactiveCN103979225ASimple and reliable structureRealize quantitative supplyLarge containersDrive shaftEngineering

The invention relates to a crushed garbage quantitative feeding device, which comprises a support frame, a storage cabin, a discharge opening and a pulling unit, wherein the storage cabin is arranged on the support fame and is used for storing crushed garbage, the discharging opening is formed in a horizontal bottom plate of the storage cabin and is used for quantitatively discharging the garbage, the pulling unit is arranged at the discharging opening part and is used for quantitative discharging supply, the upper part of the storage cabin is provided with a feeding opening, the pulling unit comprises a plate-shaped pulling plate, a driving shaft and a driving motor, a fixing hole is formed in the middle of the pulling plate, the driving motor drives the driving shaft to rotate, a rotating hole is formed in the bottom plate and is in a position near the discharging opening, the driving shaft and the rotating hole are mutually and rotationally connected, the puling plate is fixedly connected with the driving shaft on the upper surface of the bottom plate through the fixing hole, in addition, the lower surface of the pulling plate and the upper surface of the bottom plate are mutually pasted, the driving motor is arranged under the bottom plate, and the driving motor and the driving shaft are in mutual driving connection. The crushed garbage quantitative feeding device has the advantages that the structure is simple, convenient and reliable, various kinds of crushed garbage can be conveniently stored and quantitatively supplied, in addition, the work process is stable, the cost is low, and the work is reliable.

Owner:陈化学

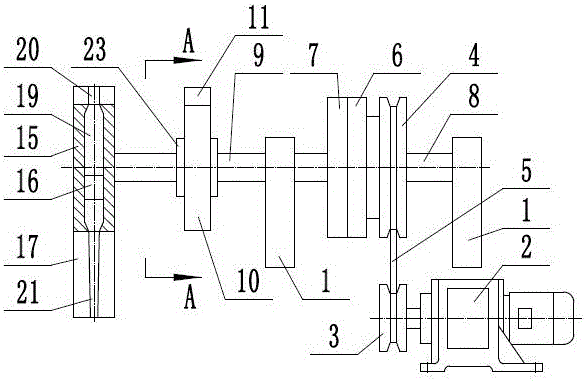

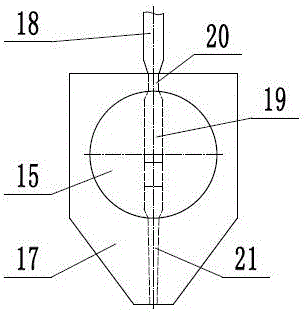

Powdery material supply device

ActiveCN105923333ARealize quantitative supplyGuaranteed rateRotary conveyorsBiochemical engineeringMaterial supply

The invention provides a powdery material supply device and belongs to the technical field of supply machines. The device comprises a first friction disk, a second friction disk, a positioning disk, a positioning rod, a round plate and a plunger, wherein a first supporting shaft and a second supporting shaft are coaxial; the first friction disk is arranged on one side of the first supporting shaft; the second friction disk is arranged on one side of the second supporting shaft; the first friction disk and the second friction disk are attached to each other; the round plate is coaxially fixed on the other side of the second supporting shaft and is rotationally arranged in a round plate support; a radial through hole is formed in the round plate, and opening diameters of the two ends of the through hole are smaller than that the opening diameter of the middle part of the through hole; the plunger is vertically glidingly arranged in the through hole; a material injection pipe is arranged above an inlet; the positioning disk is coaxially fixed on the second supporting shaft; the middle end of the positioning rod is hinged to a positioning supporting seat by the aid of a hinge pin; a positioning jaw is arranged at one end of the positioning rod; and the other end of the positioning rod is connected with an electromagnet. Quantitative supply of powdery materials is realized, and the device is reasonable in structure and good in stability.

Owner:CHONGQING HENGYUAN POWDER METALLURGICAL PROD CO LTD

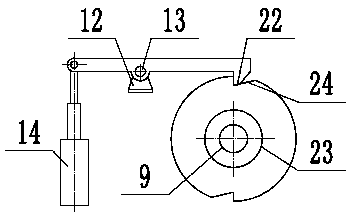

Seasoning adding full-automatic robot

InactiveCN110693334ARealize quantitative supplyGuaranteed standardizationGearingCooking vesselsEngineeringProcess engineering

The invention provides a full-automatic robot for adding seasonings. The full-automatic robot comprises a batching tank, a batching driving mechanism, a discharging mechanism and a circulating mechanism. The full-automatic robot for adding the seasonings has the advantages that the seasonings can be automatically added, the types of the seasonings needed when different dishes are cooked can be metby arranging the multiple ingredient tanks, and the actual cooking requirement is fully met. Besides, by controlling the burdening amount of the burdening tank, quantitative supply of the seasoningscan be achieved, and standardization of the taste of cooked dishes can be guaranteed.

Owner:SUZHOU SHENYUN ROBOT

A laser sintering 3D printer

ActiveCN110549608BAchieve sealingGuarantee molding qualityAdditive manufacturing apparatusManufacturing recyclingComputer printing3d printer

The invention provides a laser sintering 3D printer, which includes a telescopic molding cylinder and a powder supply and spreading mechanism that can solve the problems of sealing and cleaning. The telescopic molding cylinder is connected to the upper and lower cylinder bodies by a telescopic structure, and the entire device is in a closed state. While solving the sealing problem, it can also improve the quality of the formed parts. In addition, because the workbench and the forming cylinder are seamlessly connected, the cleaning problem can be well solved. Including the powder supply and spreading device, the quantitative supply of powder is realized by the quantitative powder spreading mechanism, the equipment is simple and the cost is low. Including setting a powder outlet on the workbench to collect the sintered powder, avoiding adding a collection box in the molding room, and reducing the volume of the molding room.

Owner:武汉斑鹿科技股份有限公司

a biomass burner

ActiveCN104791770BSmall granularitySolve not working properlySolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberEngineering

The invention relates to a biomass burner, comprising a frame (1), a combustion chamber (2), a position air chamber (3) and a storage bin (4), the air chamber (3) and the combustion chamber (2) passing through the The air passage (31) is communicated, one end of the air induction passage (31) is provided with a fan (32), and the other end is passed into the combustion chamber (2); the biomass particles enter the combustion chamber (2) from the storage bin (4) For combustion, the combustion chamber (2) is also provided with a flaming port (21) and an ash outlet (22), and also includes a feeding module (5), which includes a feeding channel (51) and a screw shaft (53) ), the screw shaft (53) is provided with a helical gear (54); the helical gear (541) of the helical gear (54) and the wall (42) of the discharge port (41) form an oblique notch (43), The biomass particles need to enter the channel inlet (5a) through the oblique notches (43); the present invention solves the problem that the equipment cannot operate normally because the biomass particles easily block the discharge port, and realizes quantitative feeding and continuously adjustable firepower , Automatic control, good shearing effect, preventing material blocking and tempering.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Induction foam outlet device and shower device

The invention discloses an induction foam outlet device and a shower device. The induction foam outlet device comprises a shell, a foam outlet body, an induction assembly and a control assembly, and awater inlet opening and a water outlet opening are formed in the shell; the foam outlet body comprises a water tank body, a pump body, a liquid soap box and a liquid mixing cavity, water flows through the water inlet and then flows to the water outlet and the water tank body, the sensing assembly and the pump body are connected with the control assembly, the liquid mixing cavity comprises a liquid inlet channel, a water inlet channel and a mixing channel, the liquid inlet channel is communicated with the liquid soap box, the water inlet channel is communicated with the water tank body, and the mixing channel is connected to the pump body. According to the induction foam outlet device and the shower device, a user does not need to make direct contact with the device, quantitative supply can be achieved, operation is easy, convenient and rapid, meanwhile, the induction foam outlet device can automatically supplement water, and time cost is further saved.

Owner:XIAMEN RUNNER IND CORP

A powder feeding device

ActiveCN105923333BRealize quantitative supplyGuaranteed rateRotary conveyorsBiochemical engineeringMaterial supply

The invention provides a powdery material supply device and belongs to the technical field of supply machines. The device comprises a first friction disk, a second friction disk, a positioning disk, a positioning rod, a round plate and a plunger, wherein a first supporting shaft and a second supporting shaft are coaxial; the first friction disk is arranged on one side of the first supporting shaft; the second friction disk is arranged on one side of the second supporting shaft; the first friction disk and the second friction disk are attached to each other; the round plate is coaxially fixed on the other side of the second supporting shaft and is rotationally arranged in a round plate support; a radial through hole is formed in the round plate, and opening diameters of the two ends of the through hole are smaller than that the opening diameter of the middle part of the through hole; the plunger is vertically glidingly arranged in the through hole; a material injection pipe is arranged above an inlet; the positioning disk is coaxially fixed on the second supporting shaft; the middle end of the positioning rod is hinged to a positioning supporting seat by the aid of a hinge pin; a positioning jaw is arranged at one end of the positioning rod; and the other end of the positioning rod is connected with an electromagnet. Quantitative supply of powdery materials is realized, and the device is reasonable in structure and good in stability.

Owner:CHONGQING HENGYUAN POWDER METALLURGICAL PROD CO LTD

Chain Gasket Quantitative Supply and Assembly Robot

ActiveCN109227073BGuaranteed surface qualityRealize quantitative captureMetal working apparatusAgricultural engineeringChain type

Owner:ZHEJIANG CANYUAN HOME TEXTILE

Carbon nanotube, device and purification method purified by gas phase damping method

ActiveCN111348643BRealize quantitative supplyAchieve separationCarbon nanotubesPtru catalystMetal impurities

The invention relates to the technical field of carbon nanotube purification, in particular to a carbon nanotube purified by a gas phase damping method, a device and a purification method. The method of the invention comprises three steps of carbon nanotube feeding, purification and cooling collection. The present invention uses a high-temperature corrosion-resistant ultrasonic vibrating screen to feed carbon nanotubes, which can not only realize quantitative feeding, but also prevent screen blockage; use a gas phase damping ring to increase the resistance of carbon nanotubes in the process of descending the purification chamber and increase the carbon The contact time between the nanotubes and chlorine gas reacts the metal catalyst remaining in the carbon nanotubes to generate chloride under heating conditions, and realizes the separation of the metal catalysts from the carbon nanotubes, thereby achieving the purpose of purifying the carbon nanotubes. The method of the invention is simple, the production capacity is easy to enlarge, the pollution is small, the engineering is easy, the purification effect is good, and it is suitable for removing various residual metals in various carbon nanotubes. The carbon nanotubes have high purity, and the single metal impurity content is less than 20ppm.

Owner:成都莱尔纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com