Patents

Literature

61results about How to "Solve not working properly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computerized process to, for example, automate the home sale, mortgage loan financing and settlement process, and the home mortgage loan refinancing and settlement processes

ActiveUS7548884B1Saving expenseShorten the timeFinanceCommerceInformation deliveryInformation transfer

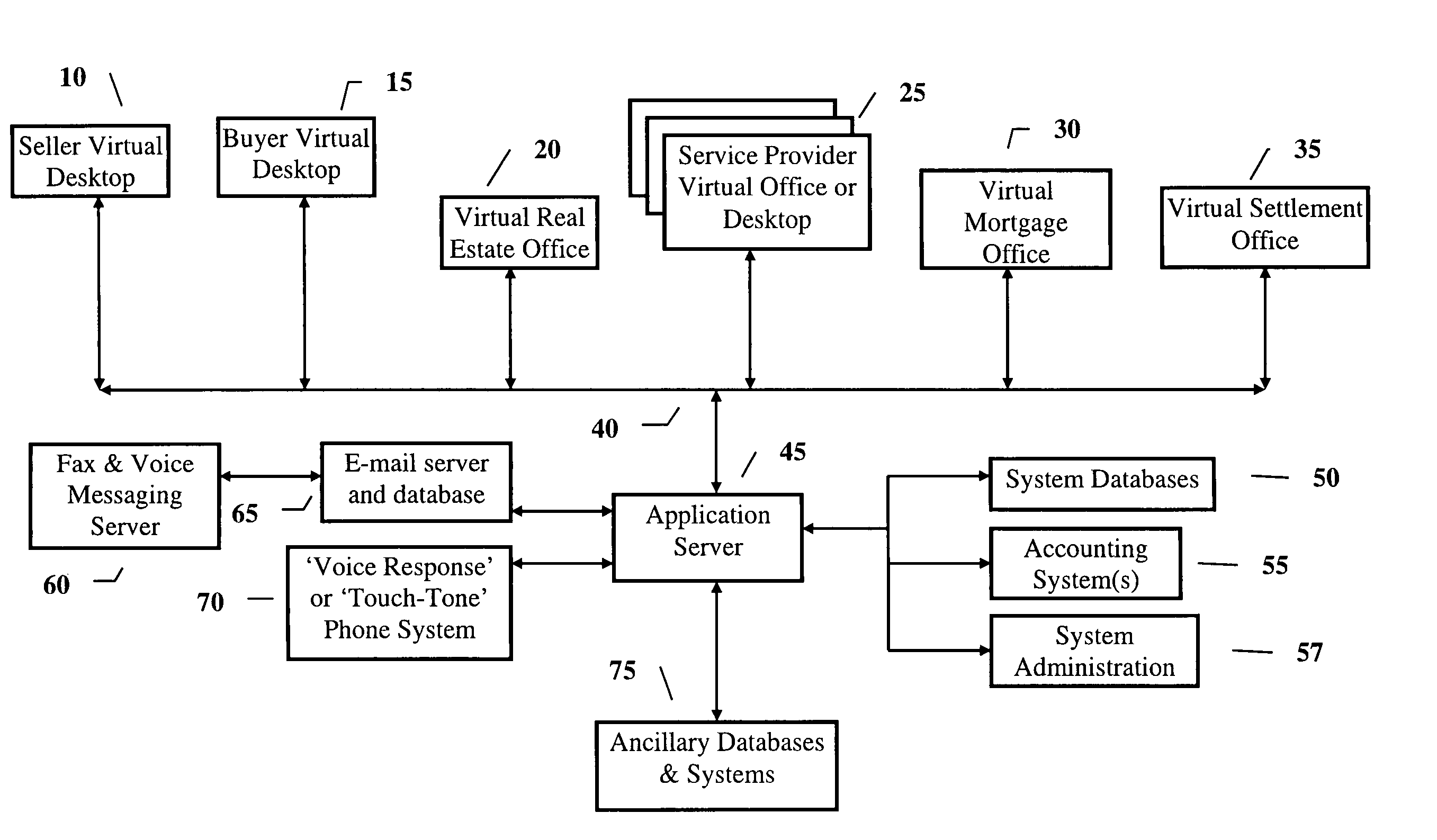

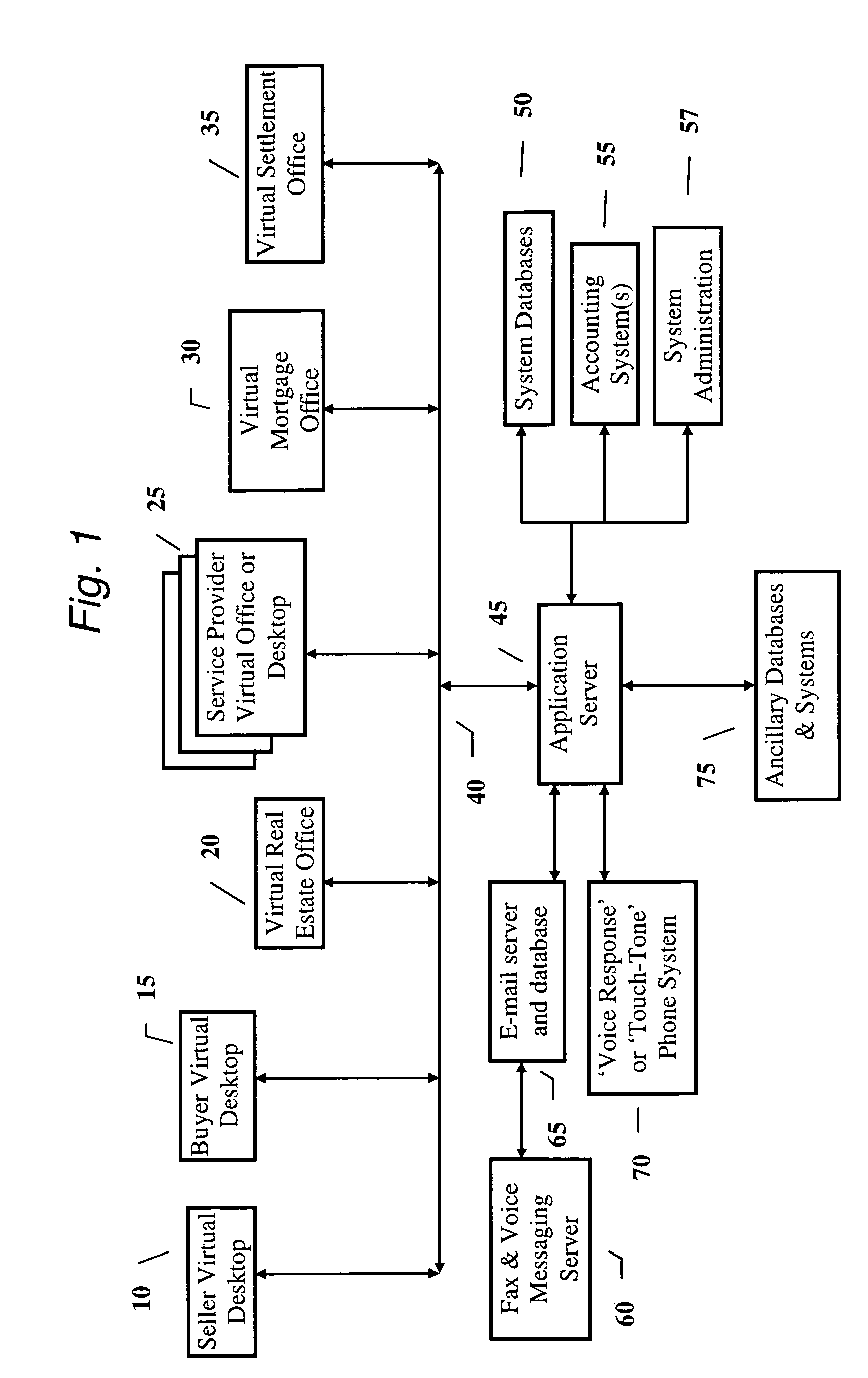

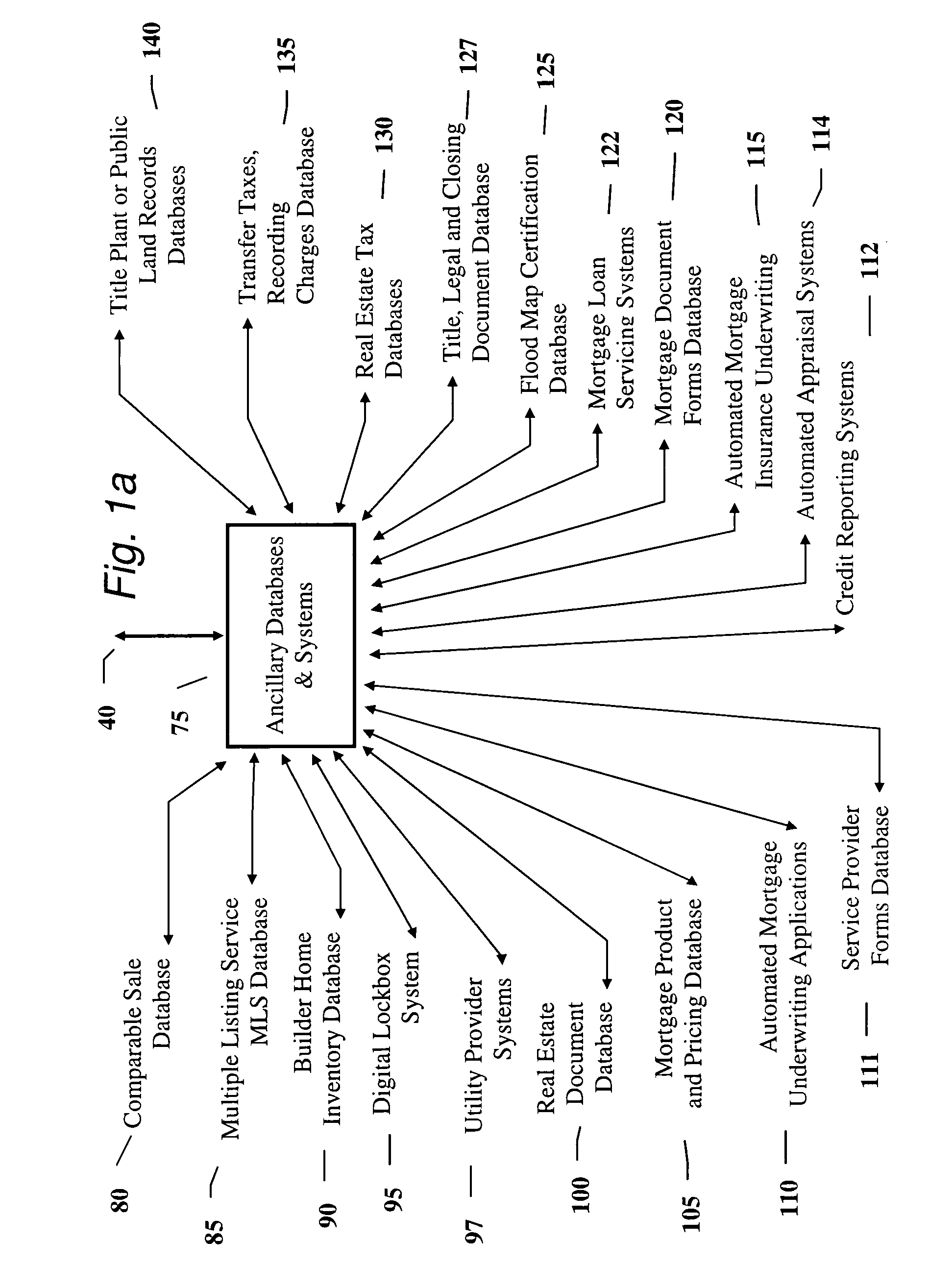

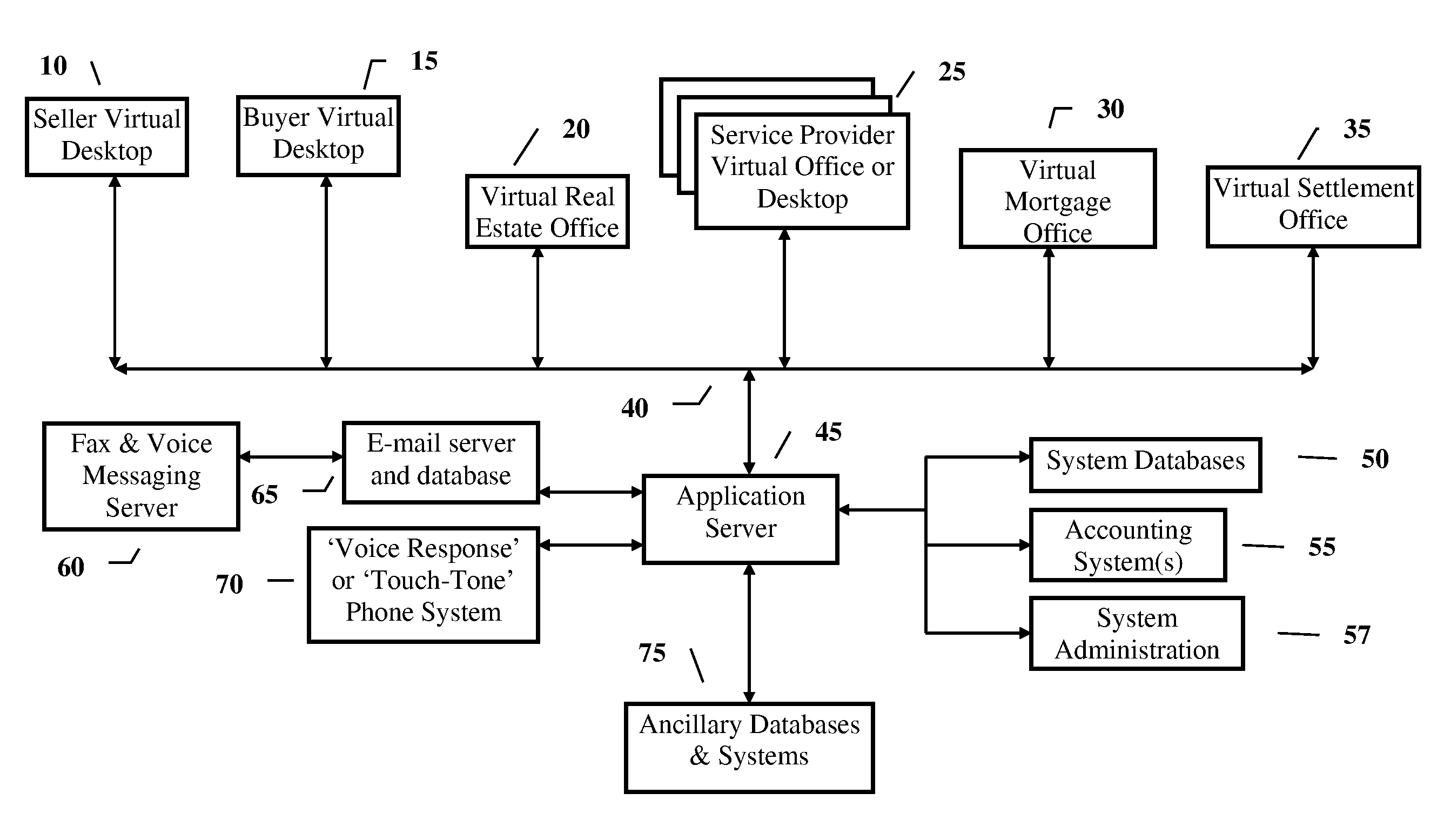

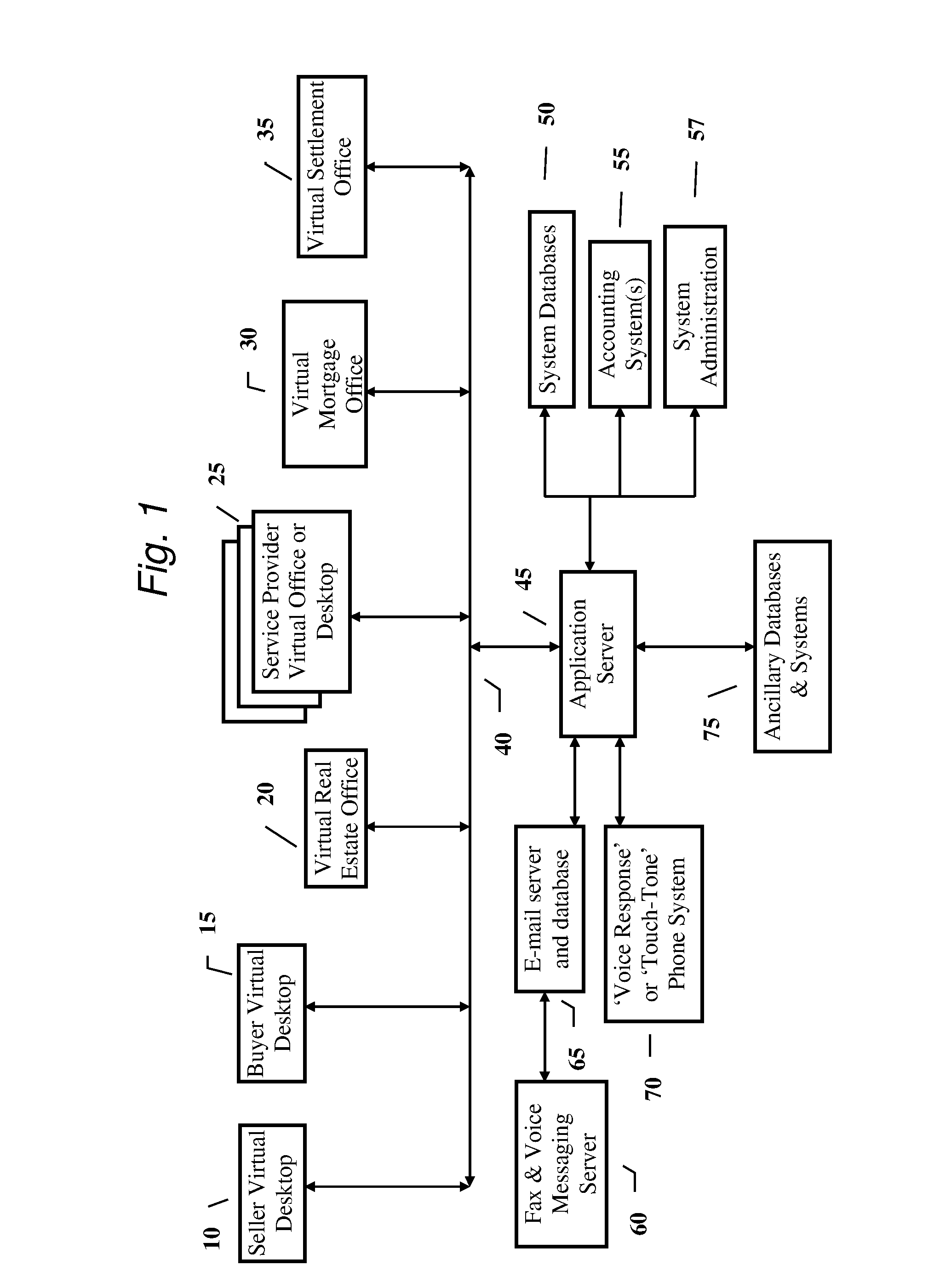

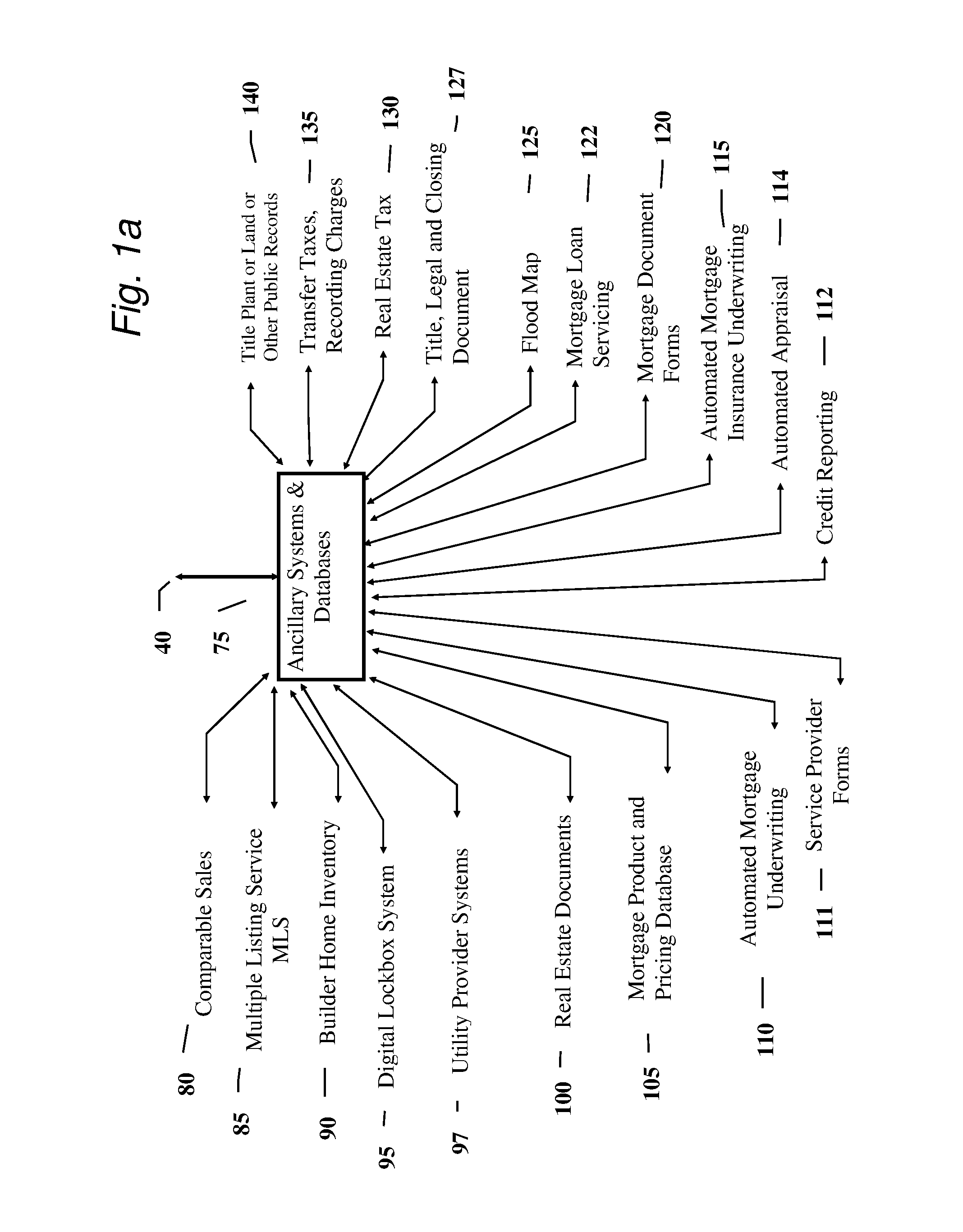

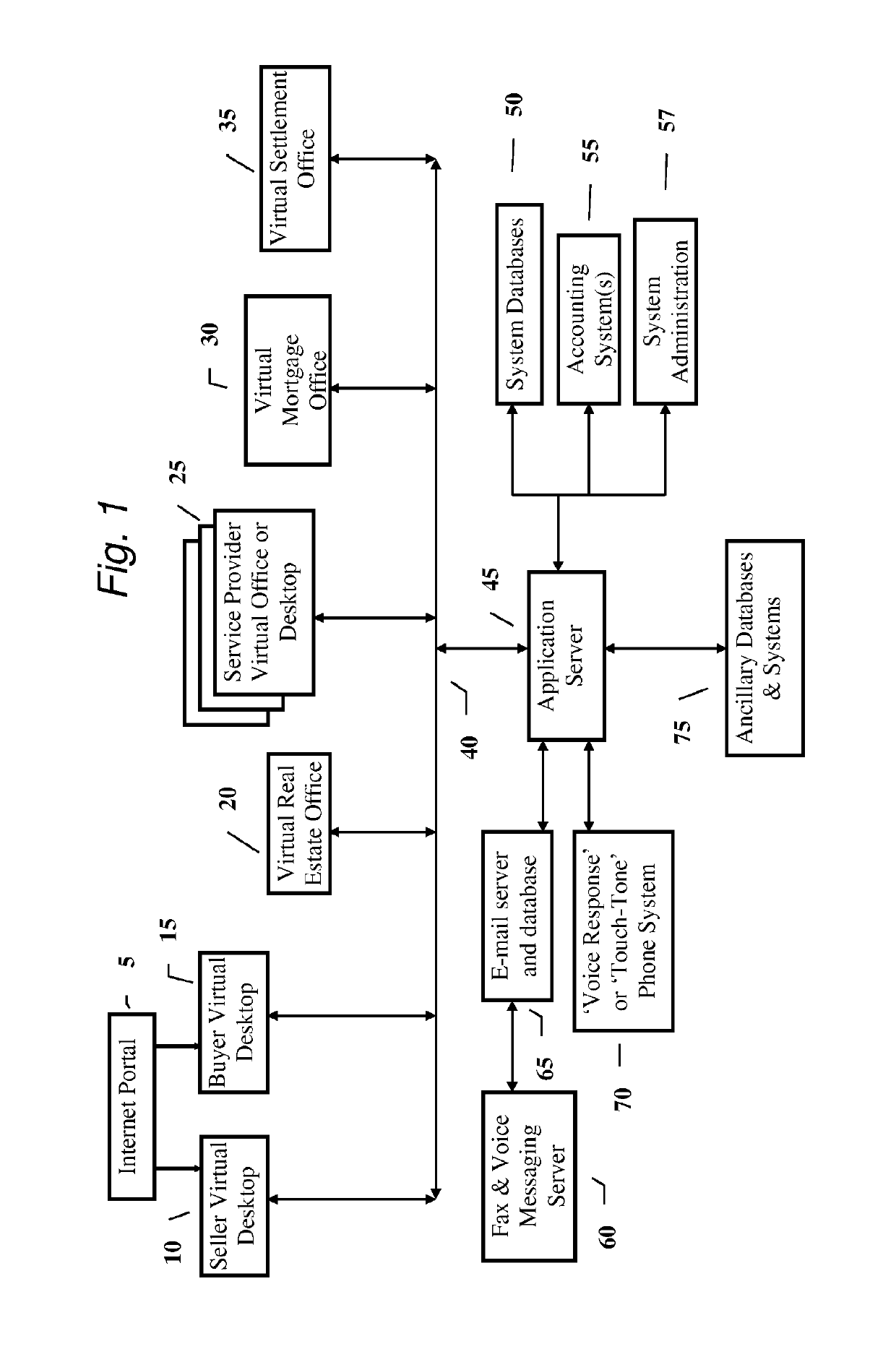

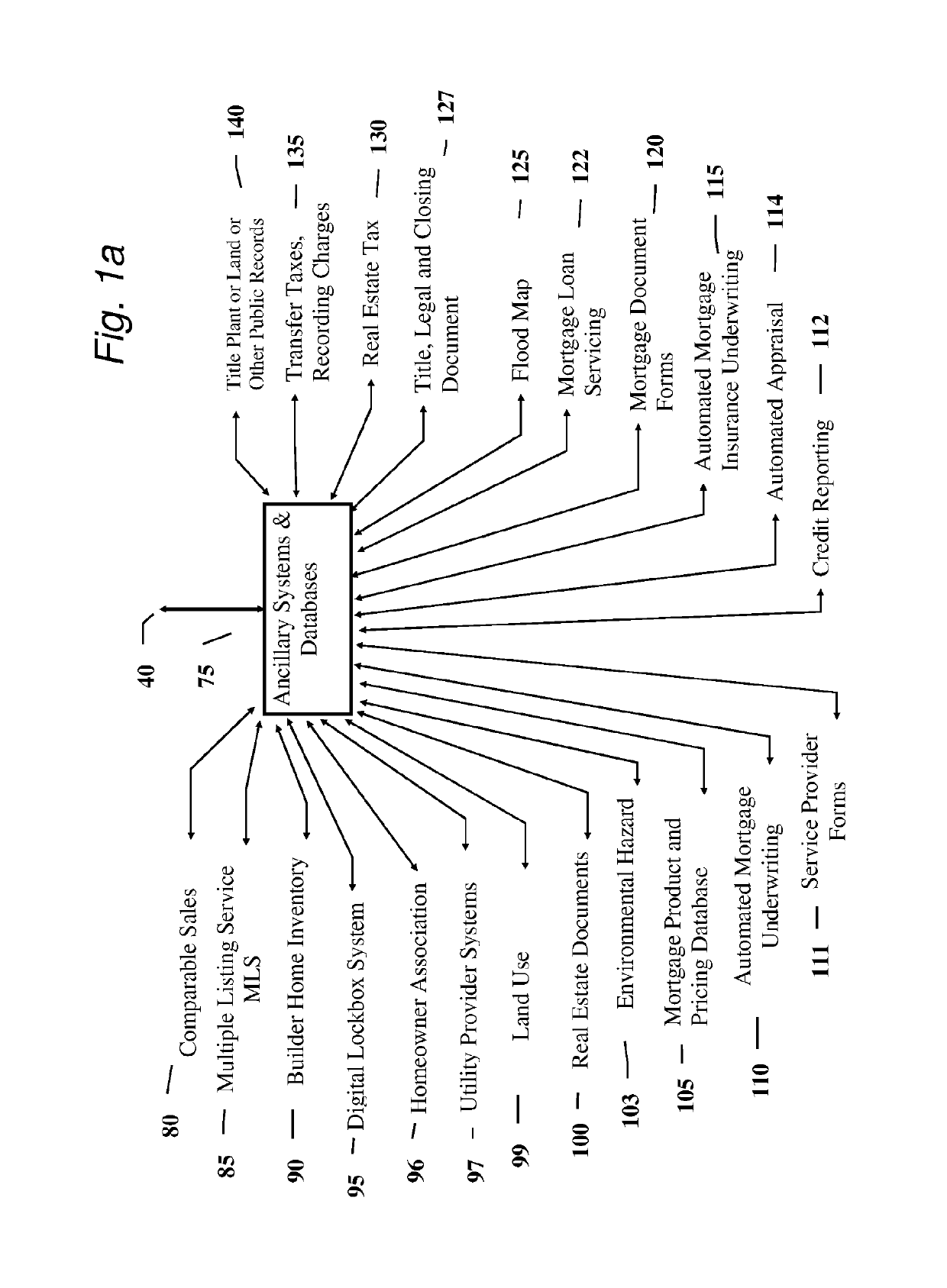

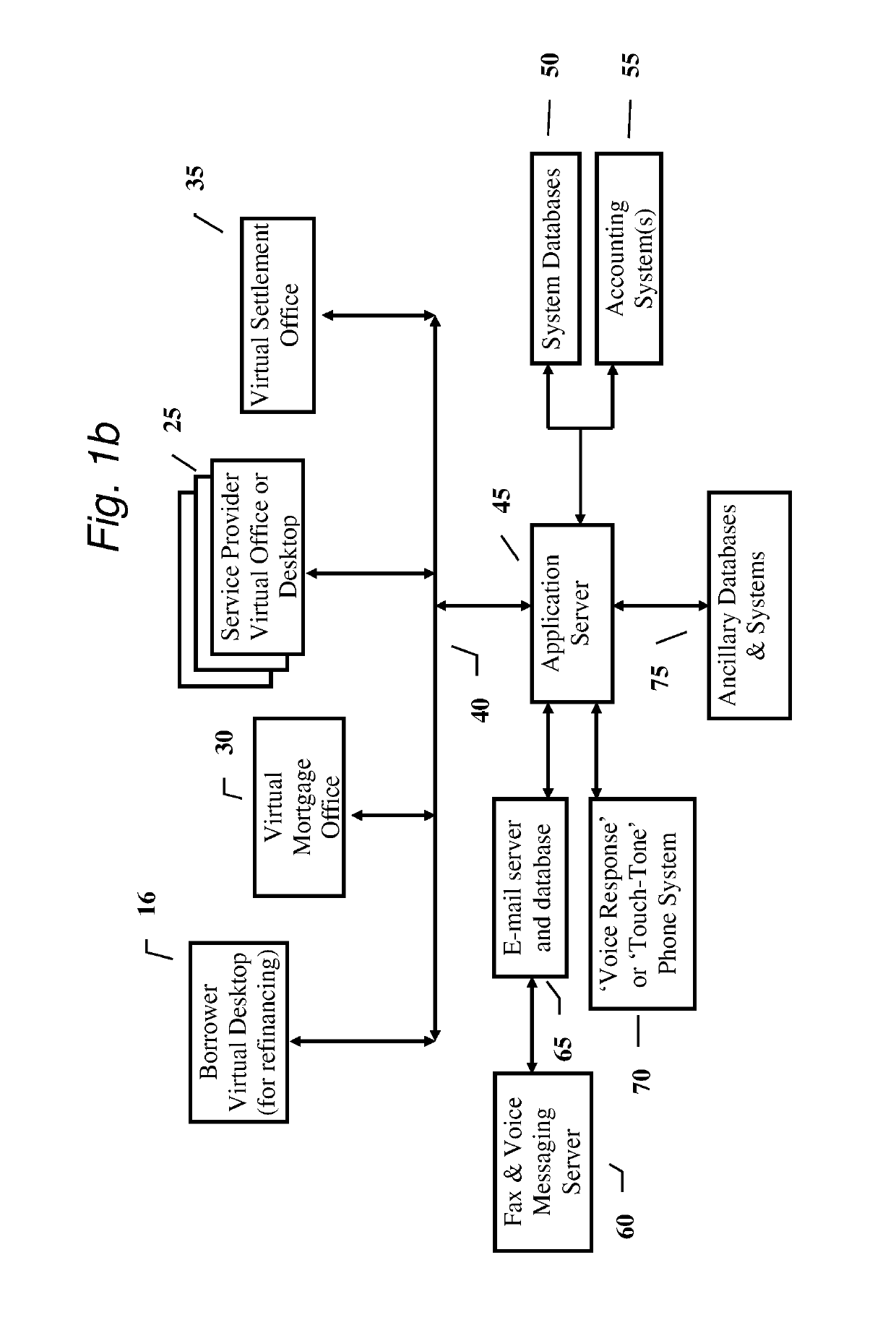

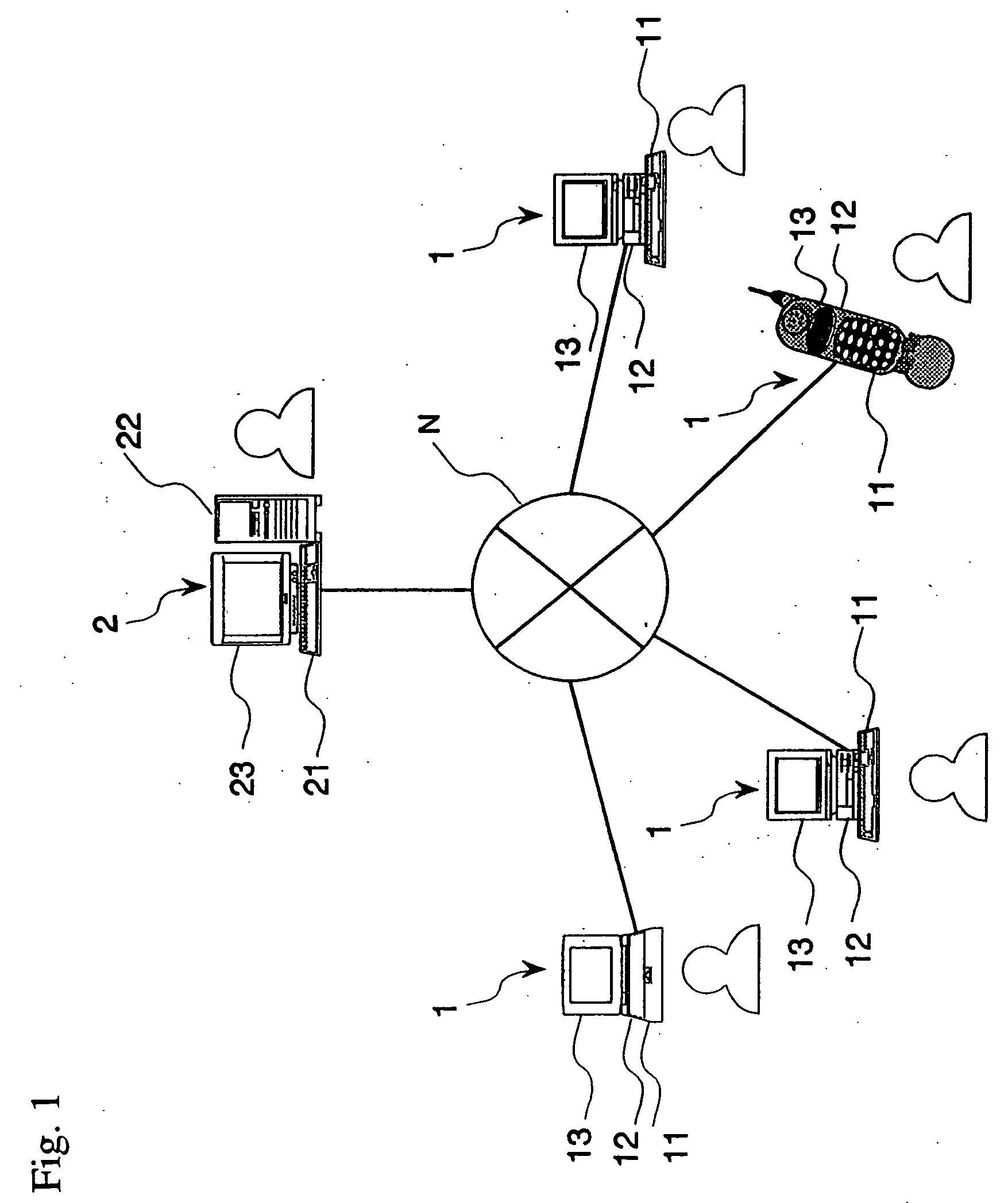

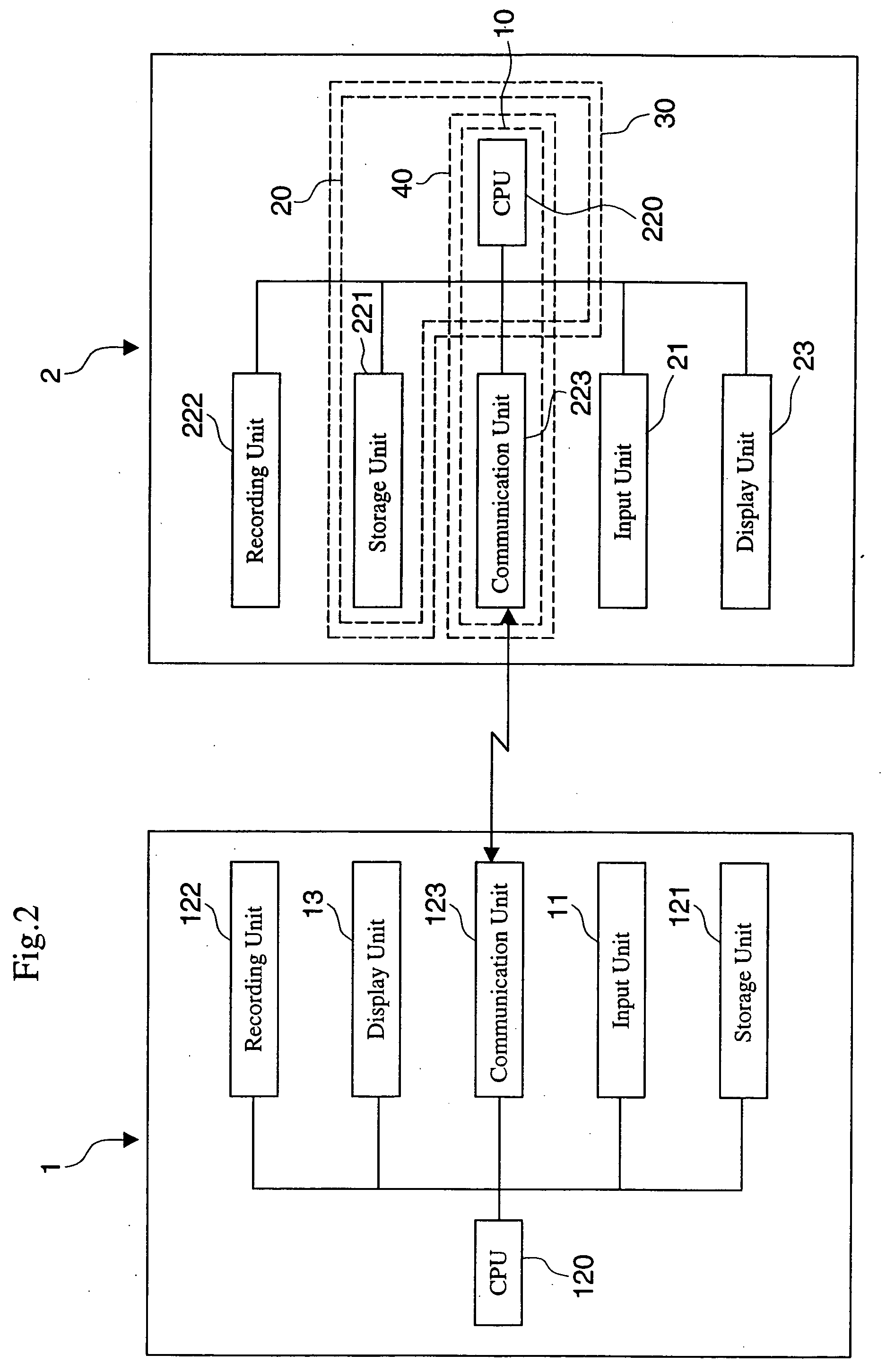

In some embodiments, a comprehensive computer system and method (See FIGS. 1, 1a, 2) for automating and facilitating the performing and processing of tasks, information transfer, and information storage associated with the home sale (See FIG. 3a), mortgage origination (See FIG. 3b), and settlement process (See FIG. 3c), and the home mortgage refinancing origination and settlement process (See FIGS. 1b, 1c, 2a) (or performing other business processes), over a distributed computing network are disclosed.

Owner:THOMAS NEIL

Computerized process to, for example, automate the home sale, mortgage loan financing and settlement process, and the home mortgage loan refinancing and settlement processes

In some embodiments, a comprehensive computer system and method (See FIGS. 1, 1a, 2) for automating and facilitating the performing and processing of tasks, information transfer, and information storage associated with the home sale (See FIG. 3a), mortgage origination (See FIG. 3b), and settlement process (See FIG. 3c), and the home mortgage refinancing origination and settlement process (See FIGS. 1b, 1c, 2a) (or performing other business processes), over a distributed computing network are disclosed.

Owner:THOMAS NEIL

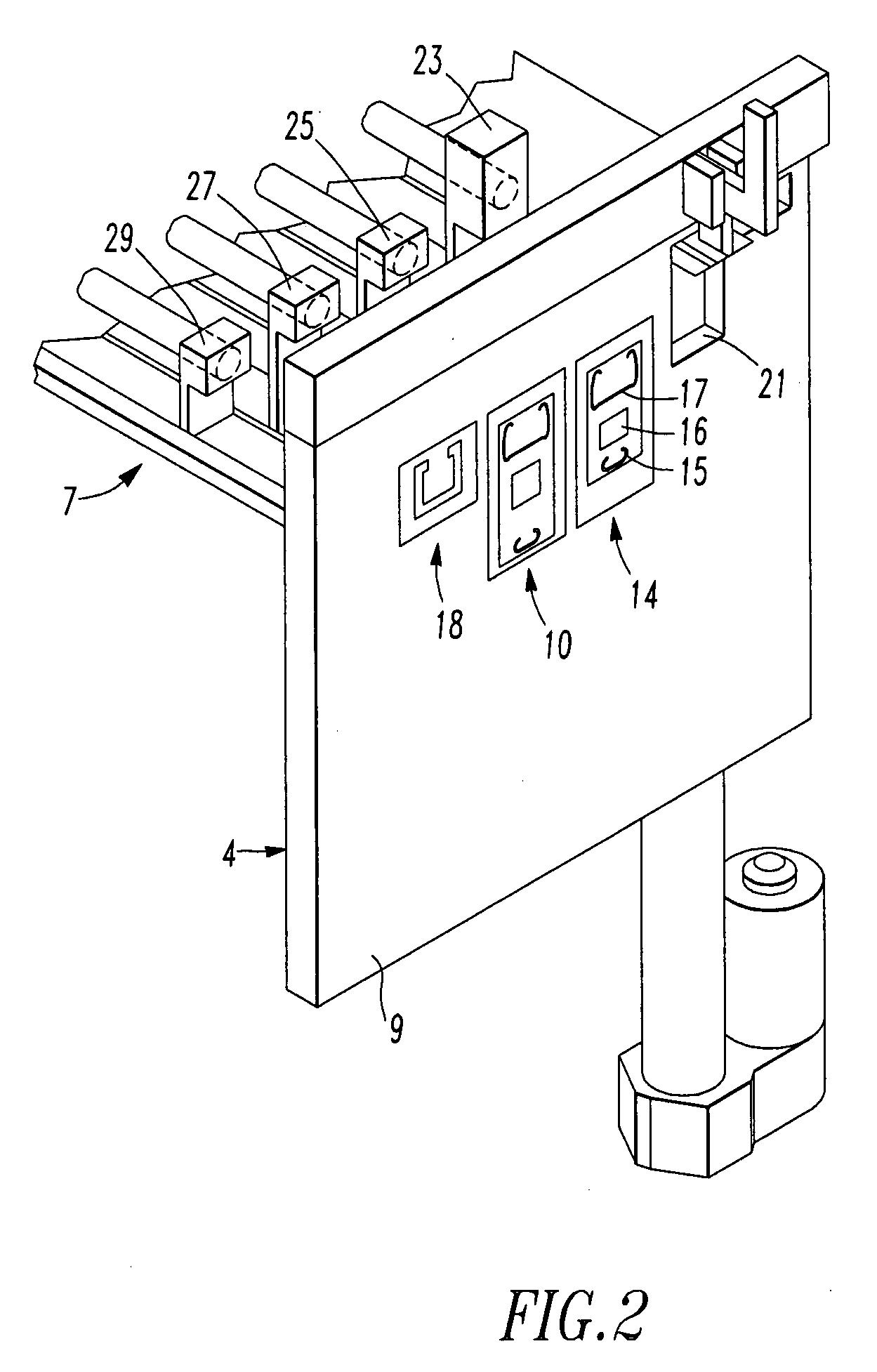

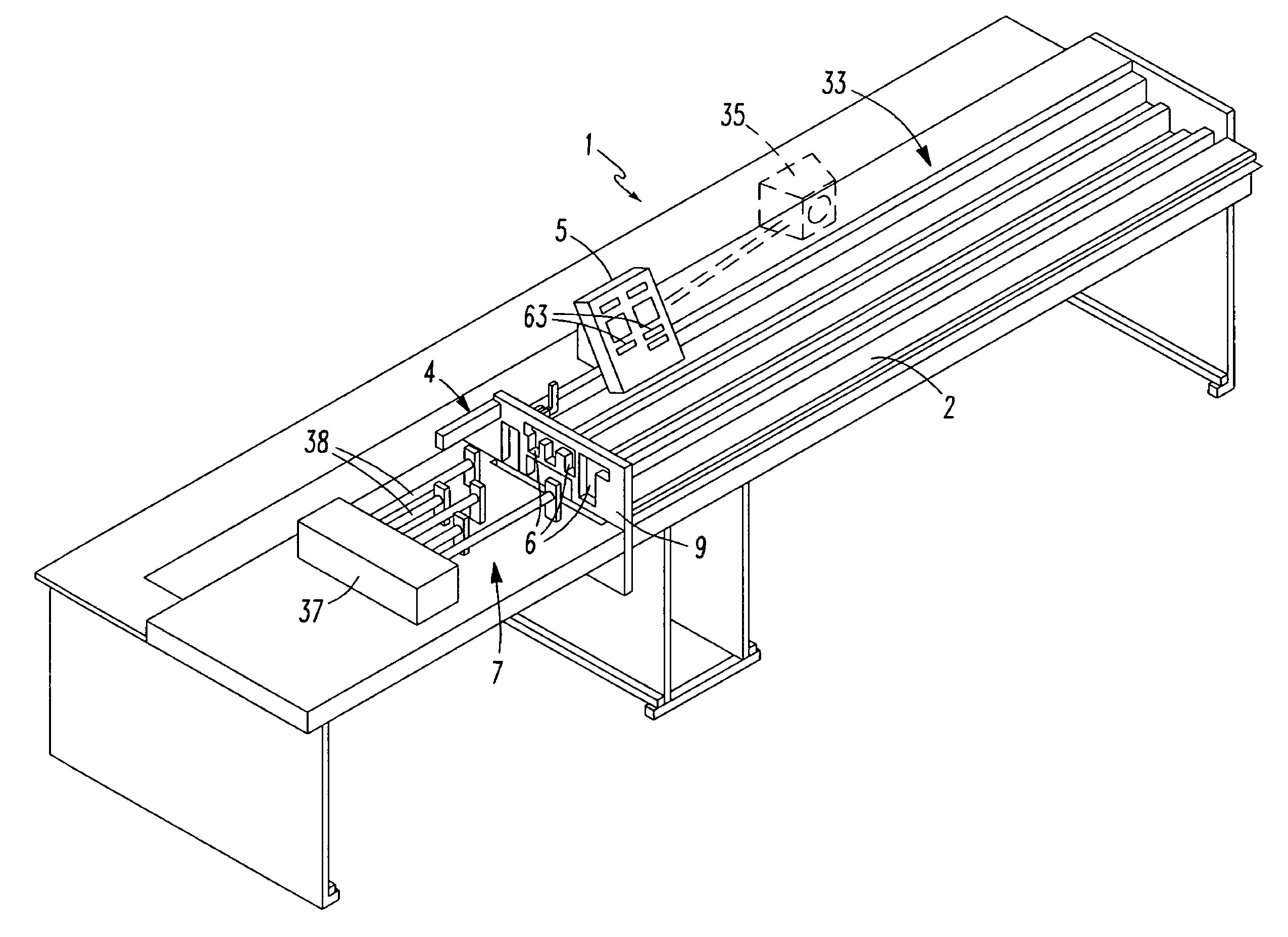

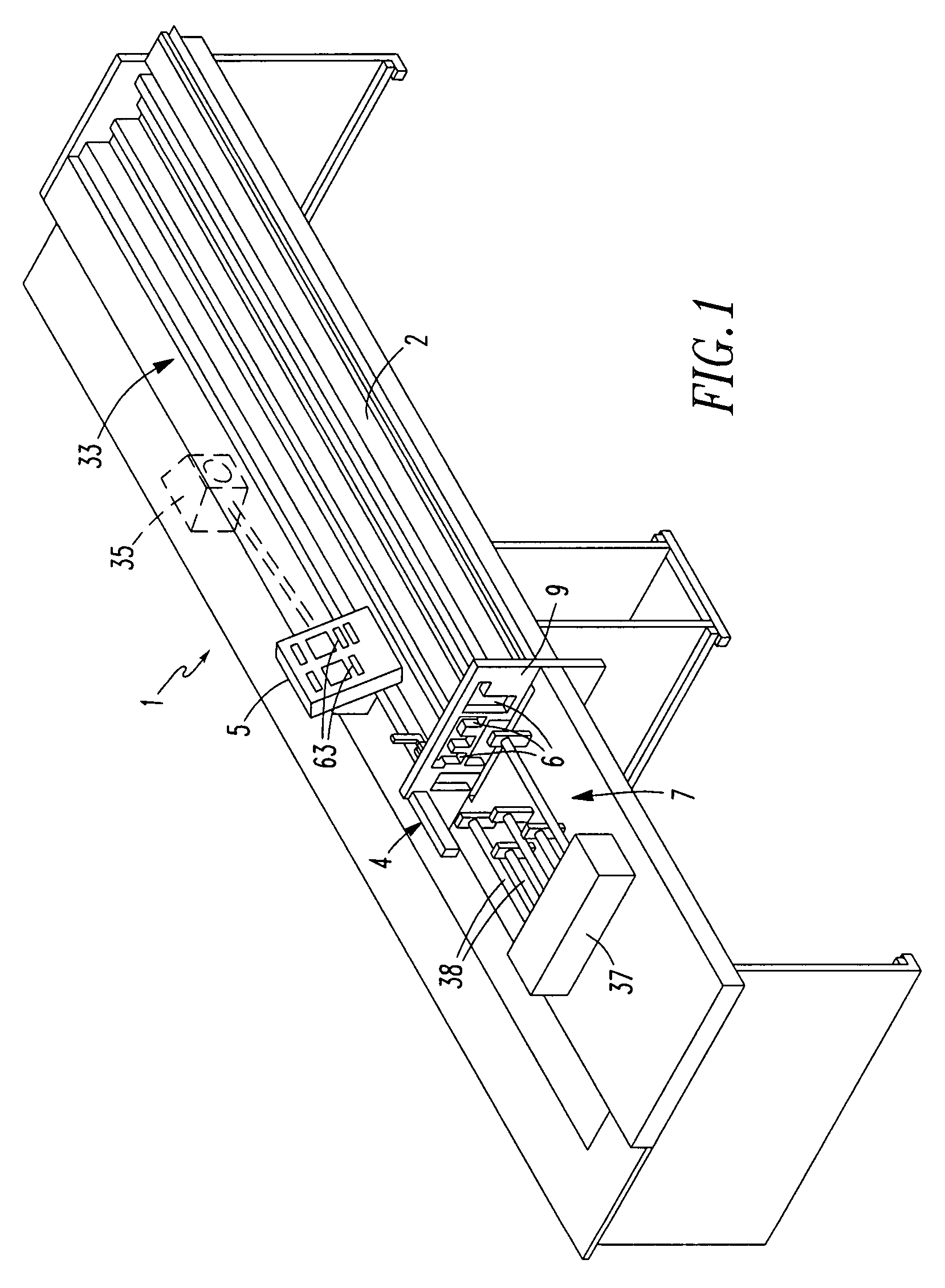

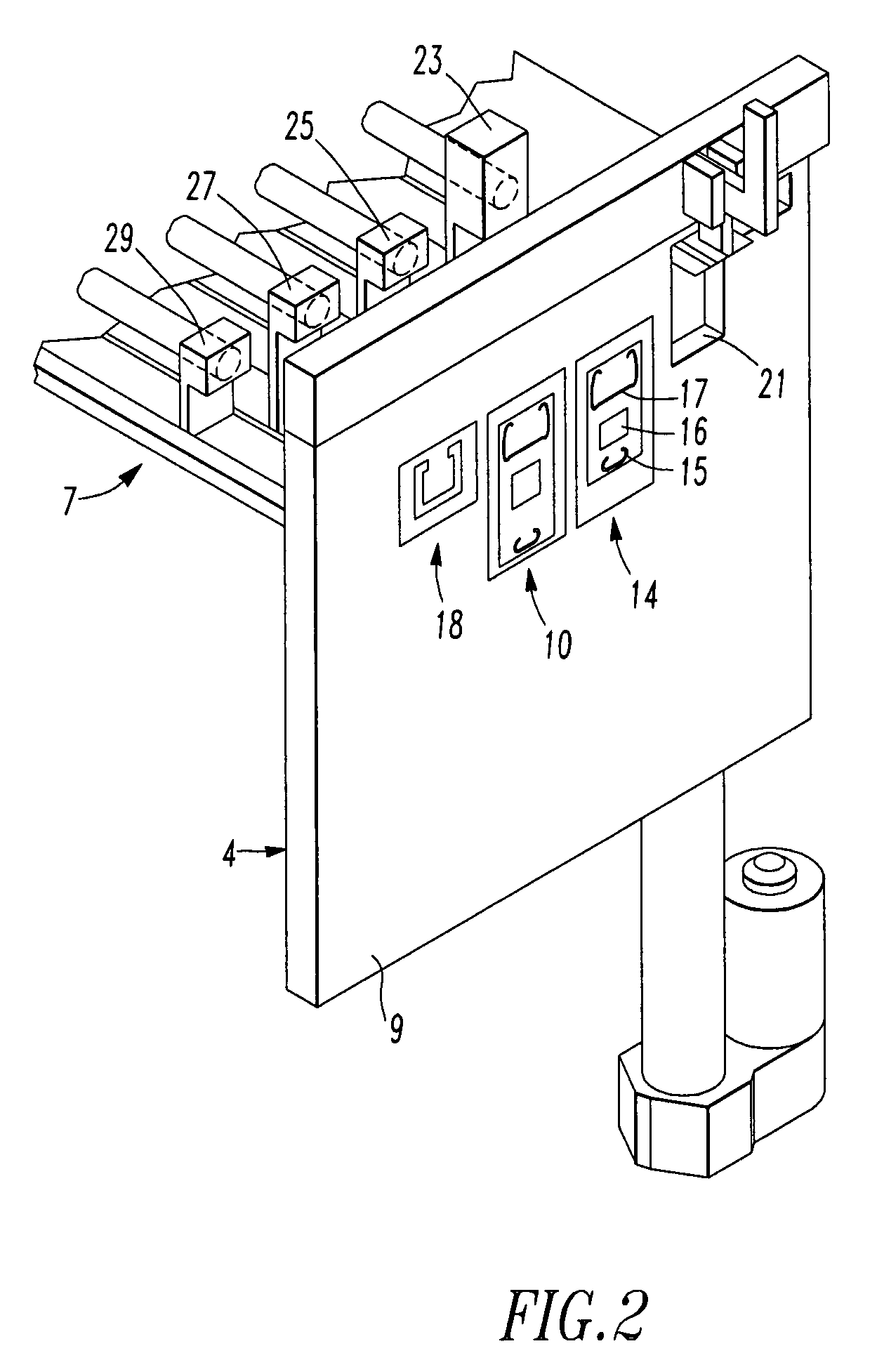

Window covering cutting machine

ActiveUS20090071307A1Solve not working properlySufficient informationDoor/window protective devicesStock shearing machinesEngineeringMechanical engineering

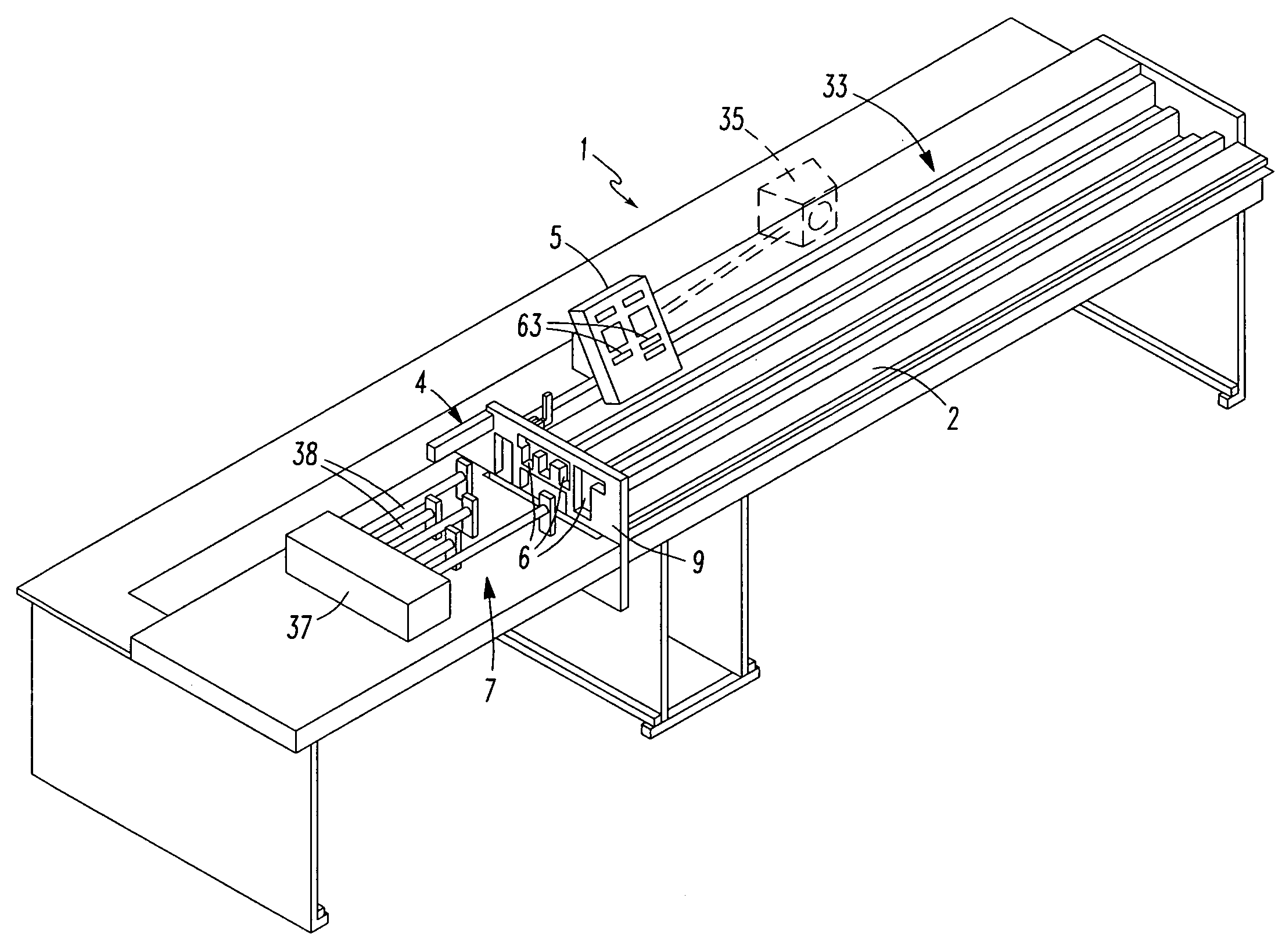

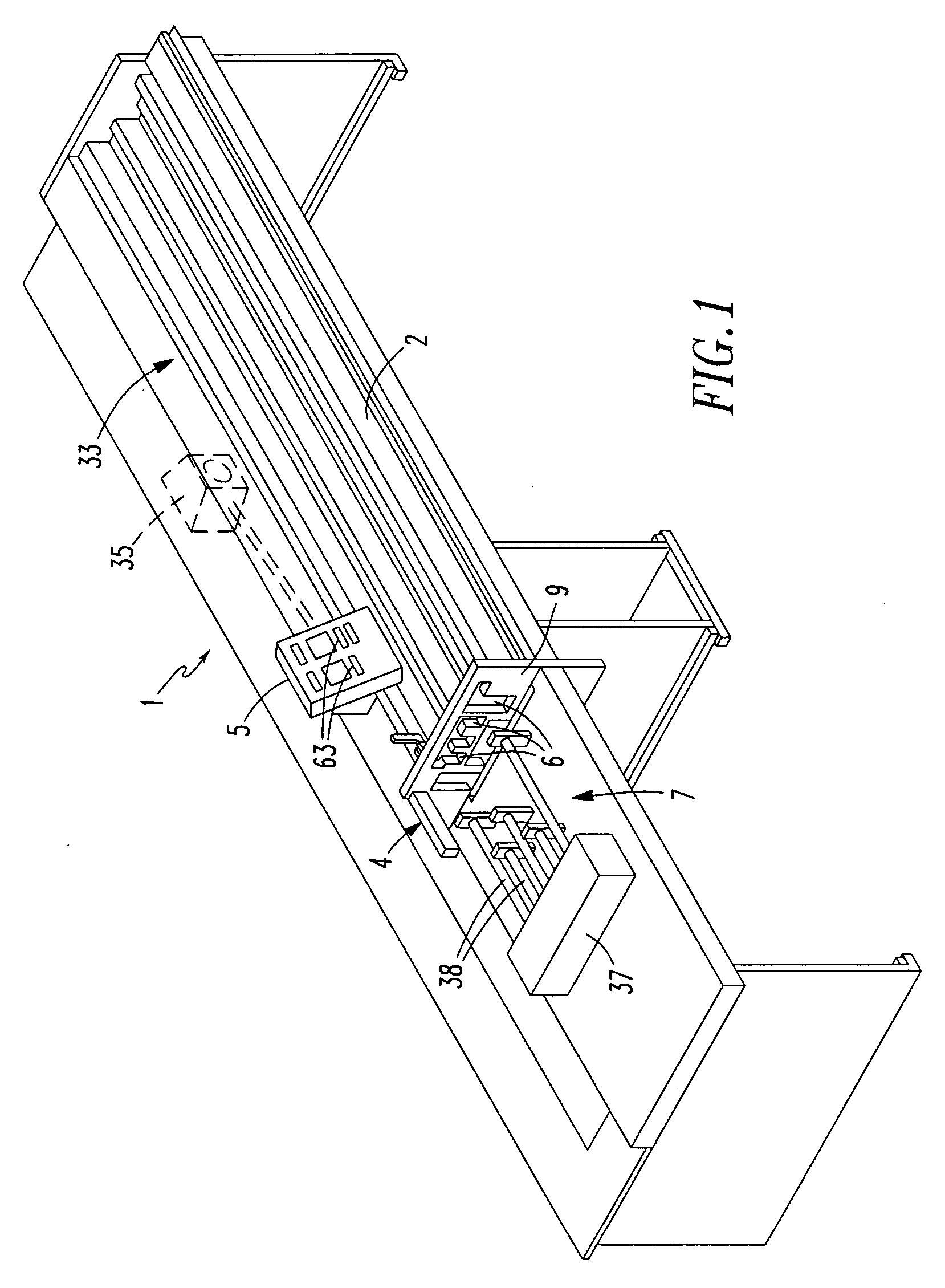

A window covering cutting machine is disclosed that has a support table, a cutting mechanism adjacent the support table and a plurality of moveable stops moveably connected to at least one of the cutting mechanism and the support table. The support table has a surface on which at least a portion of a window covering work piece can be placed. The cutting mechanism has a housing with a plurality of openings sized to receive at least a portion of a window covering work piece. The cutting mechanism also has at least one cutting device configured to cut portions of a window covering that extend through any of the openings. One stop is aligned with each opening and is independently moveable relative to the housing and the other stops.

Owner:LUMINO

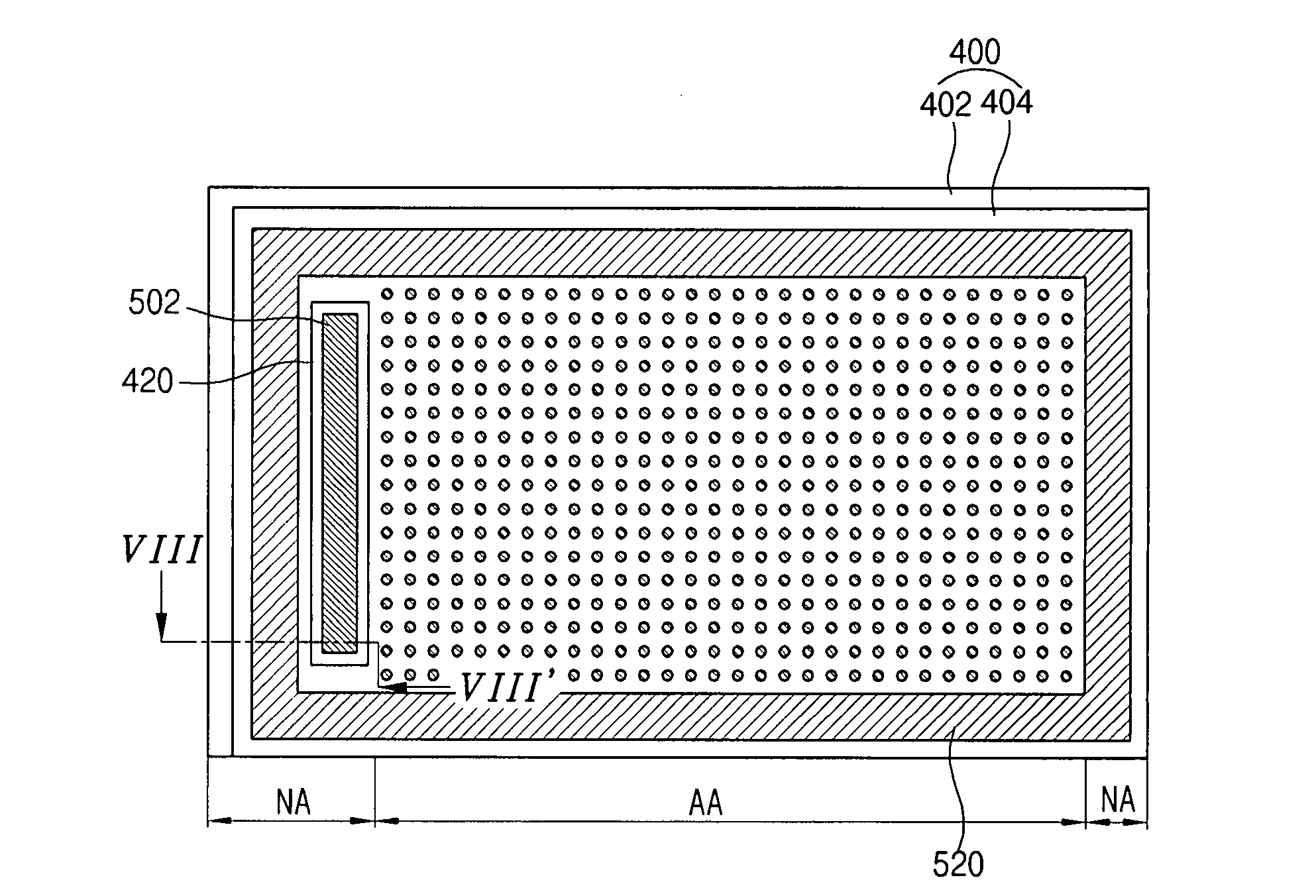

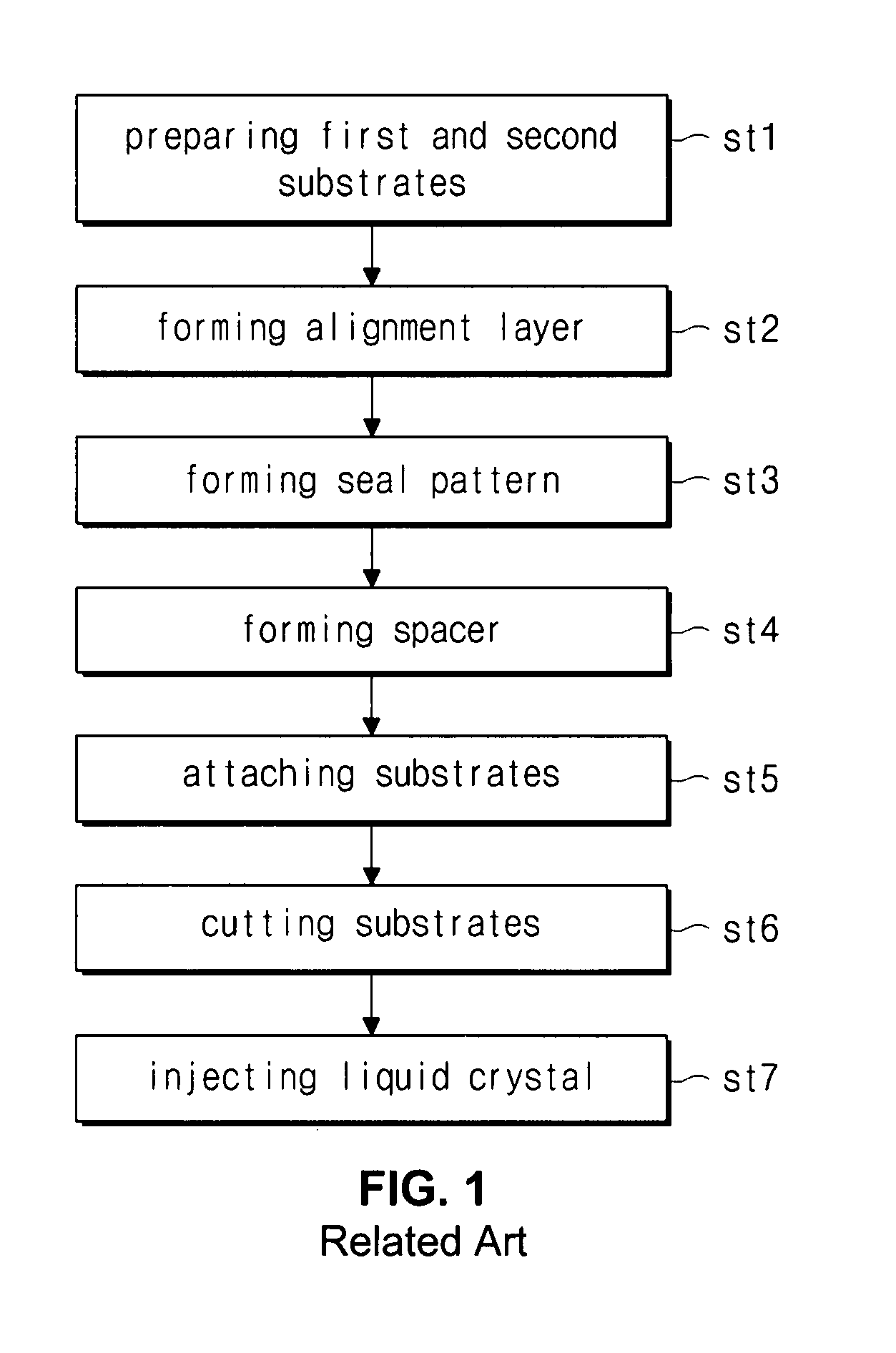

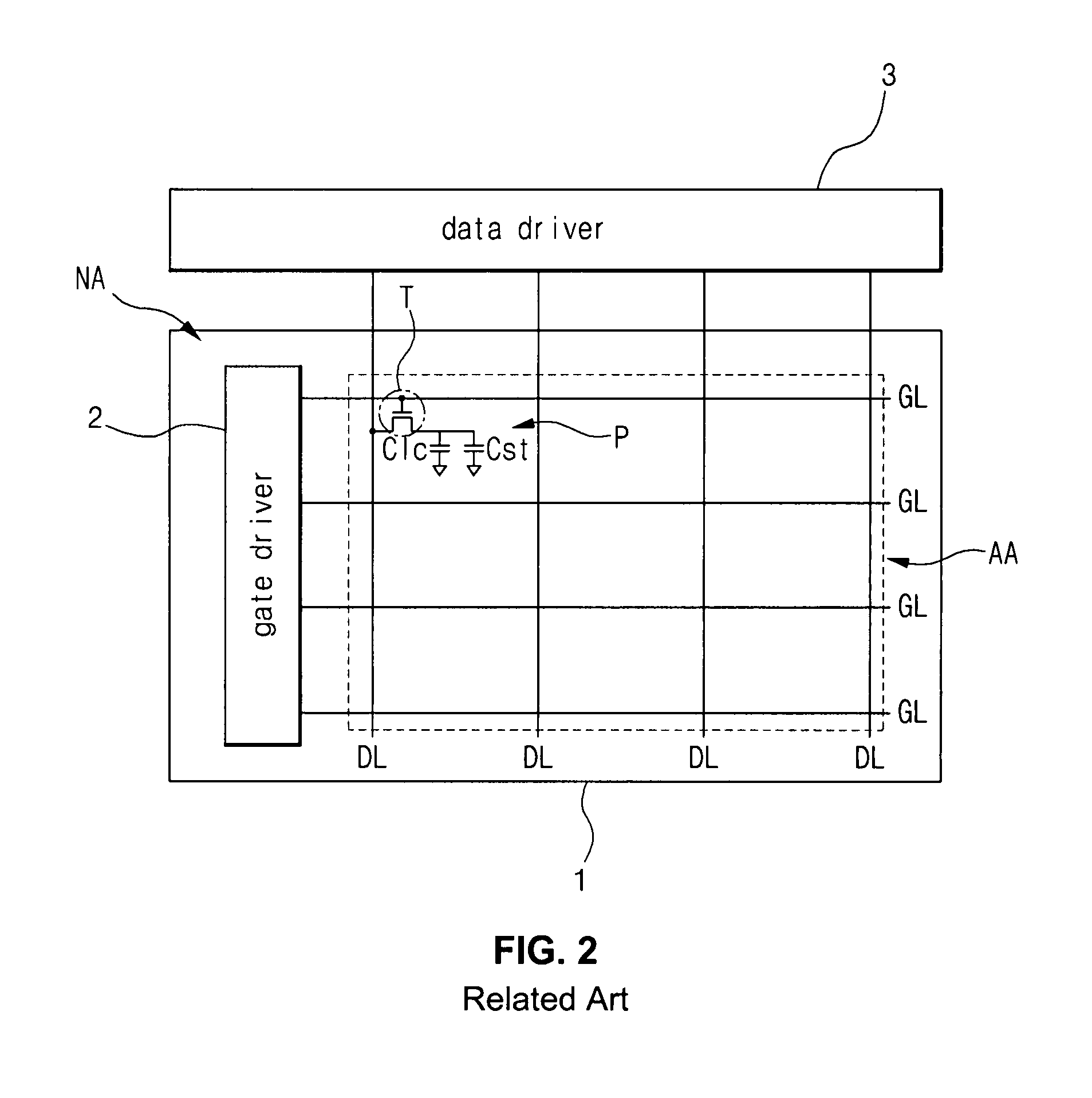

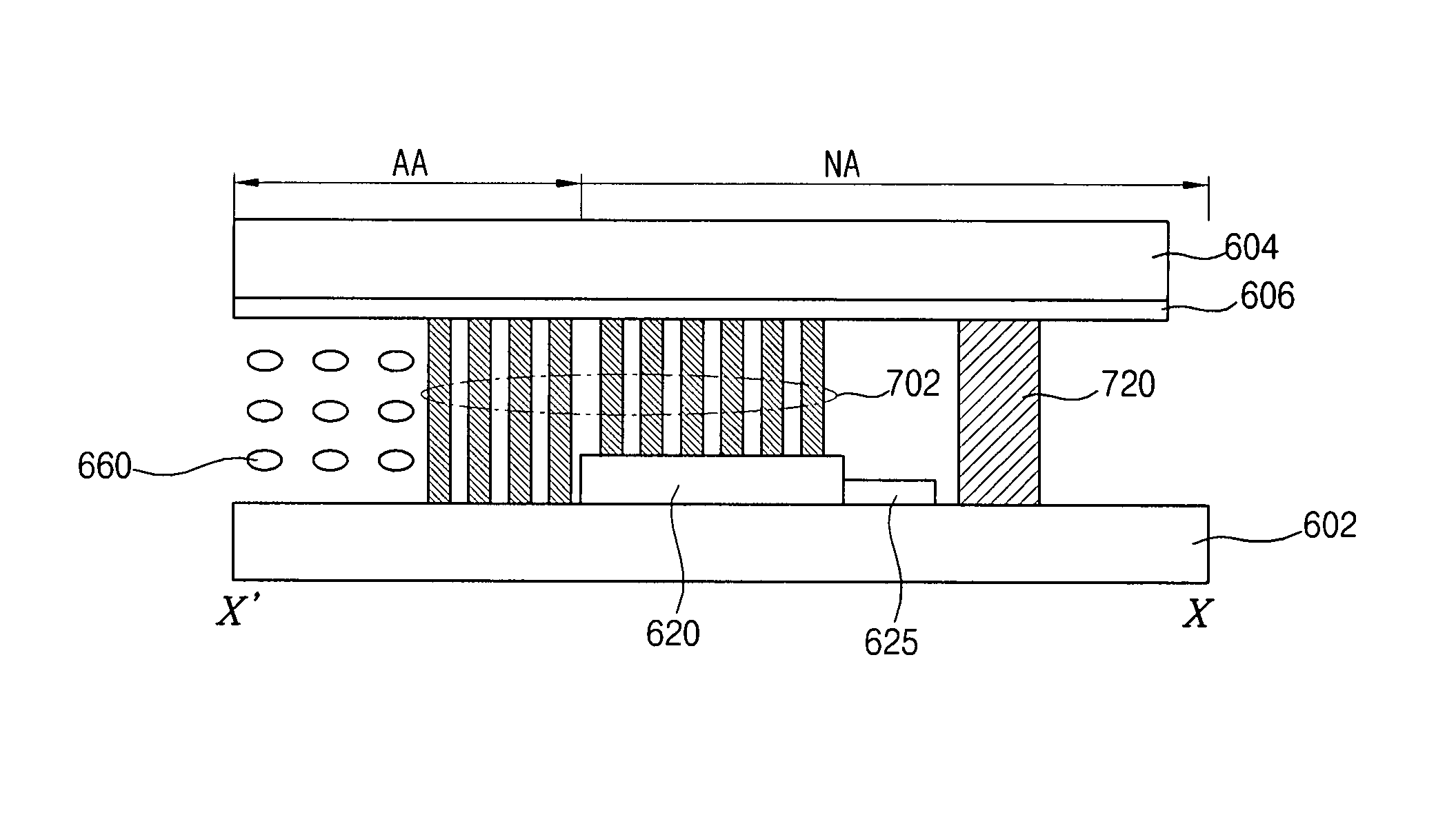

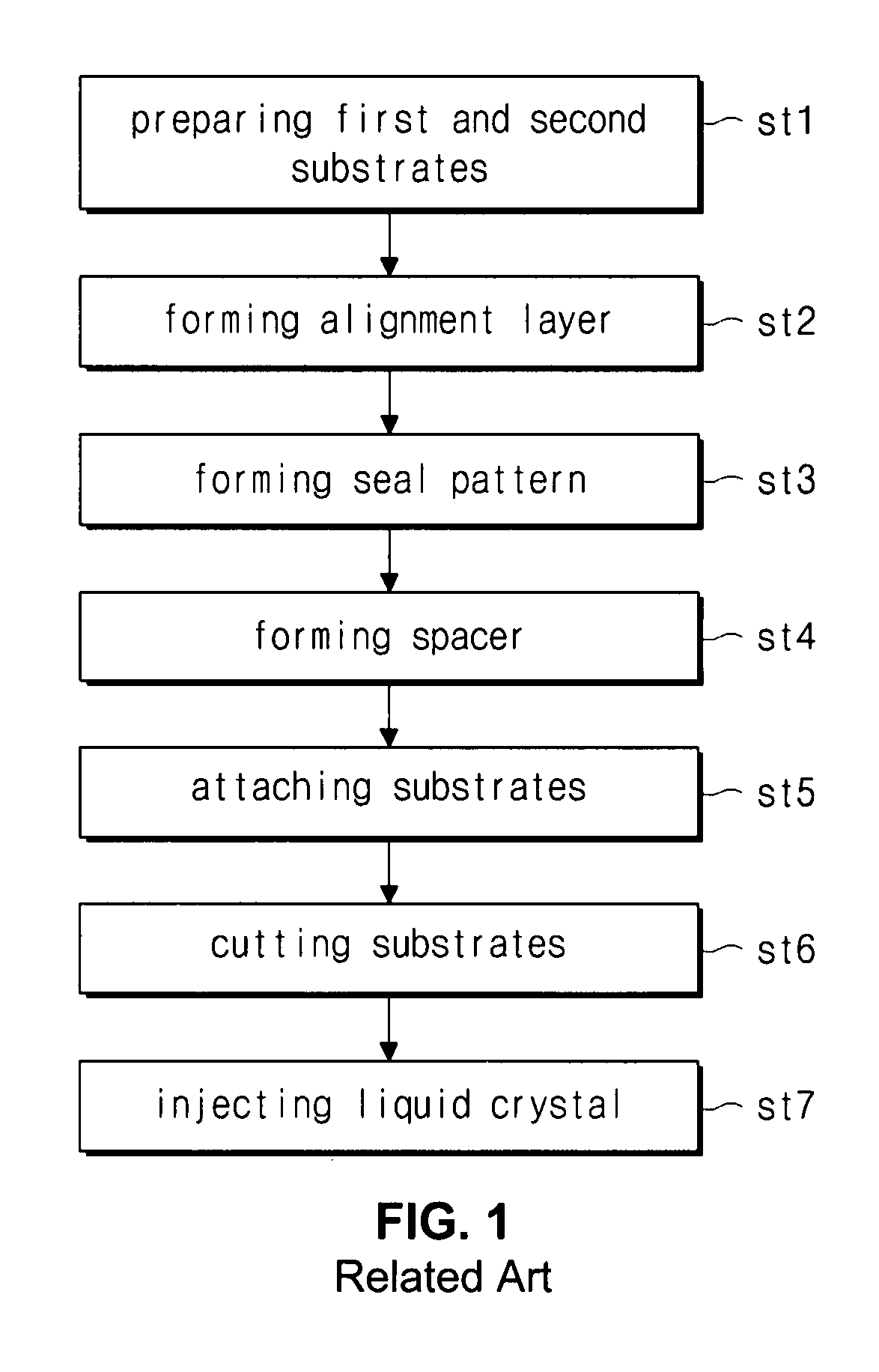

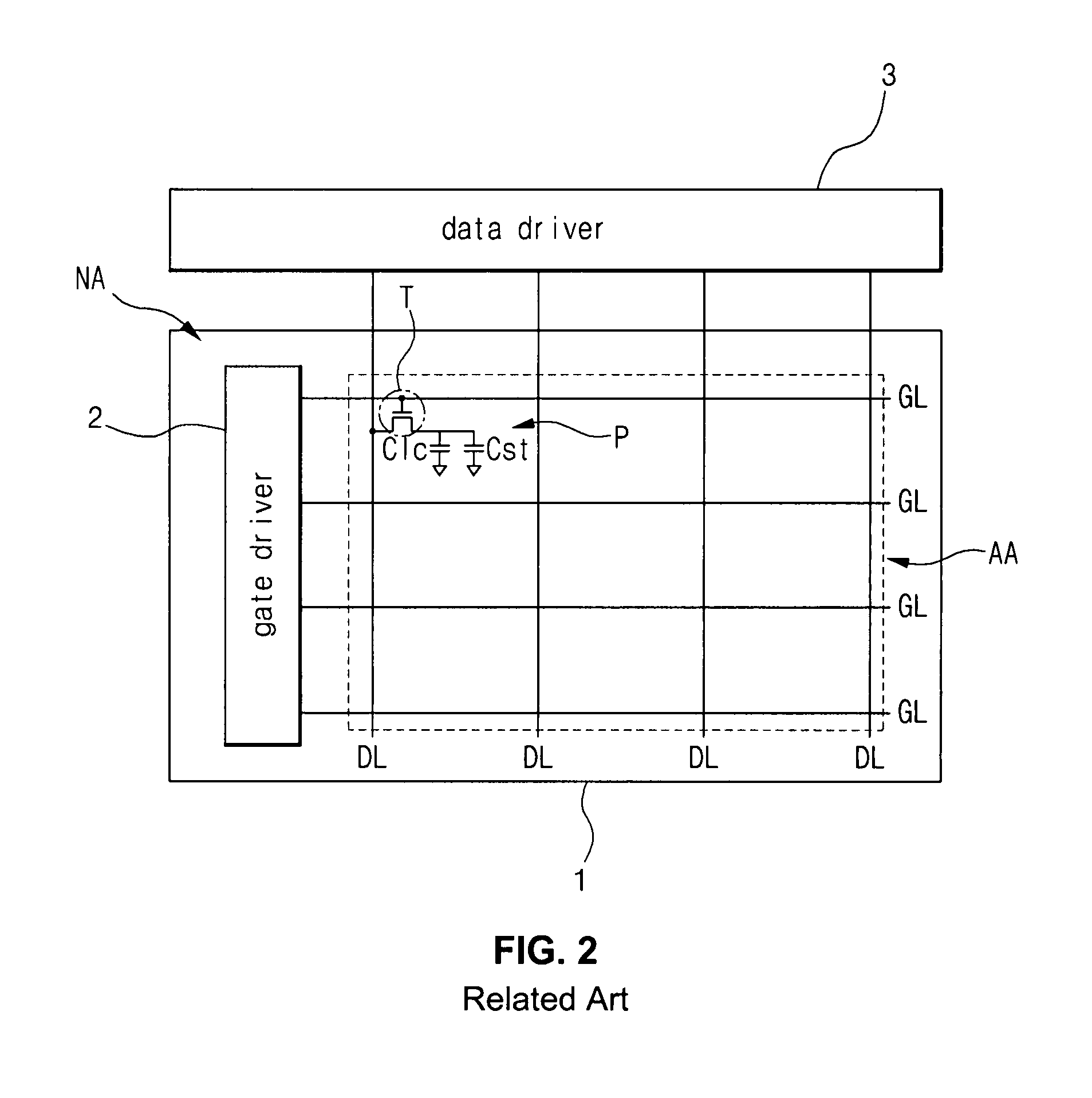

Liquid crystal display device and method of manufacturing the same

ActiveUS20080158496A1Guaranteed to workPrevent electrical shortNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes first and second substrates spaced apart from each other, on which a display area and a non-display area are defined, a liquid crystal layer interposed between the first and second substrates, a seal pattern in the non-display area between the first and second substrates, a driver in the non-display area on the first substrate, column spacers in the display area between the first and second substrates, and a first auxiliary spacer between the driver and the second substrate.

Owner:LG DISPLAY CO LTD

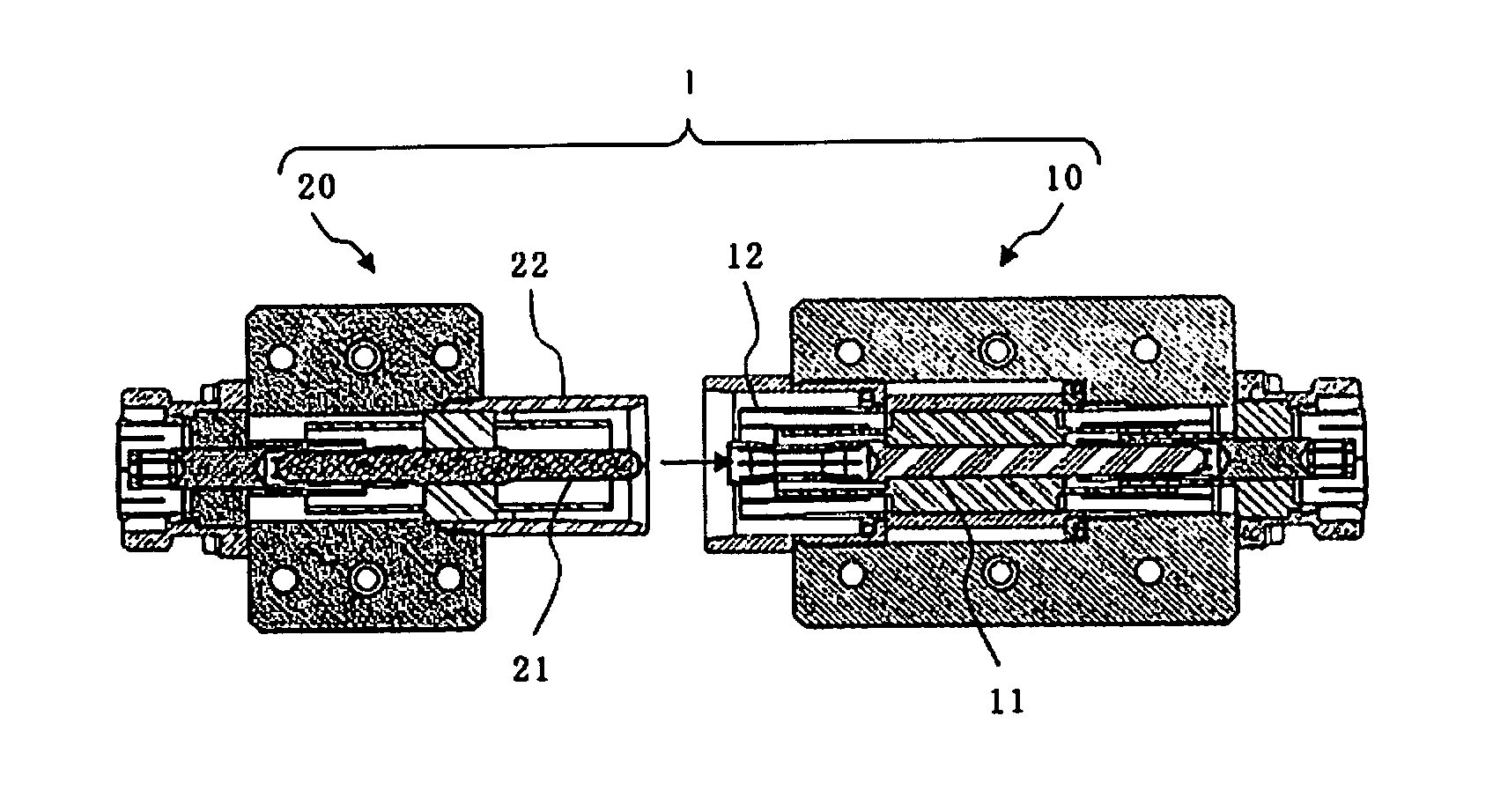

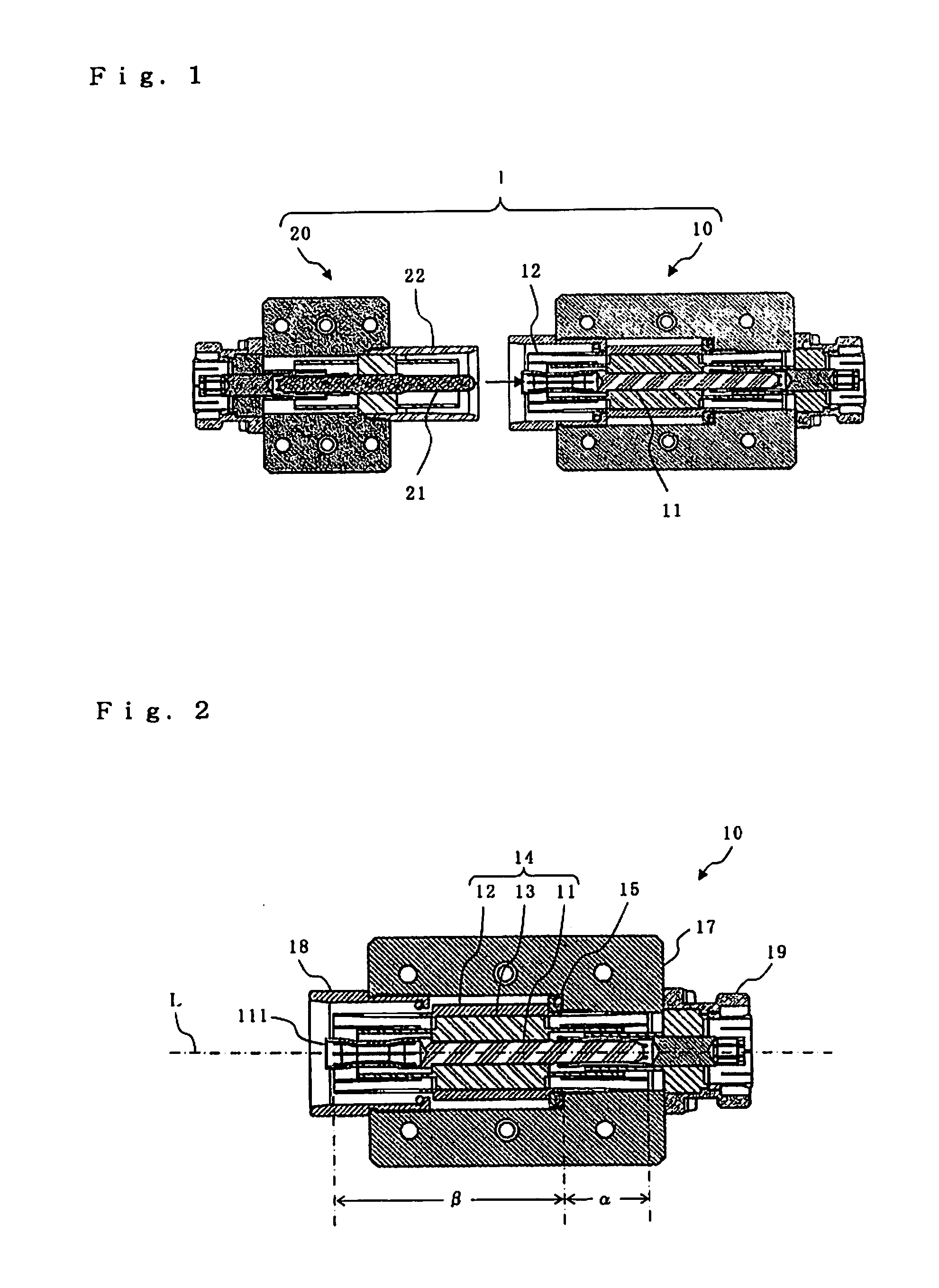

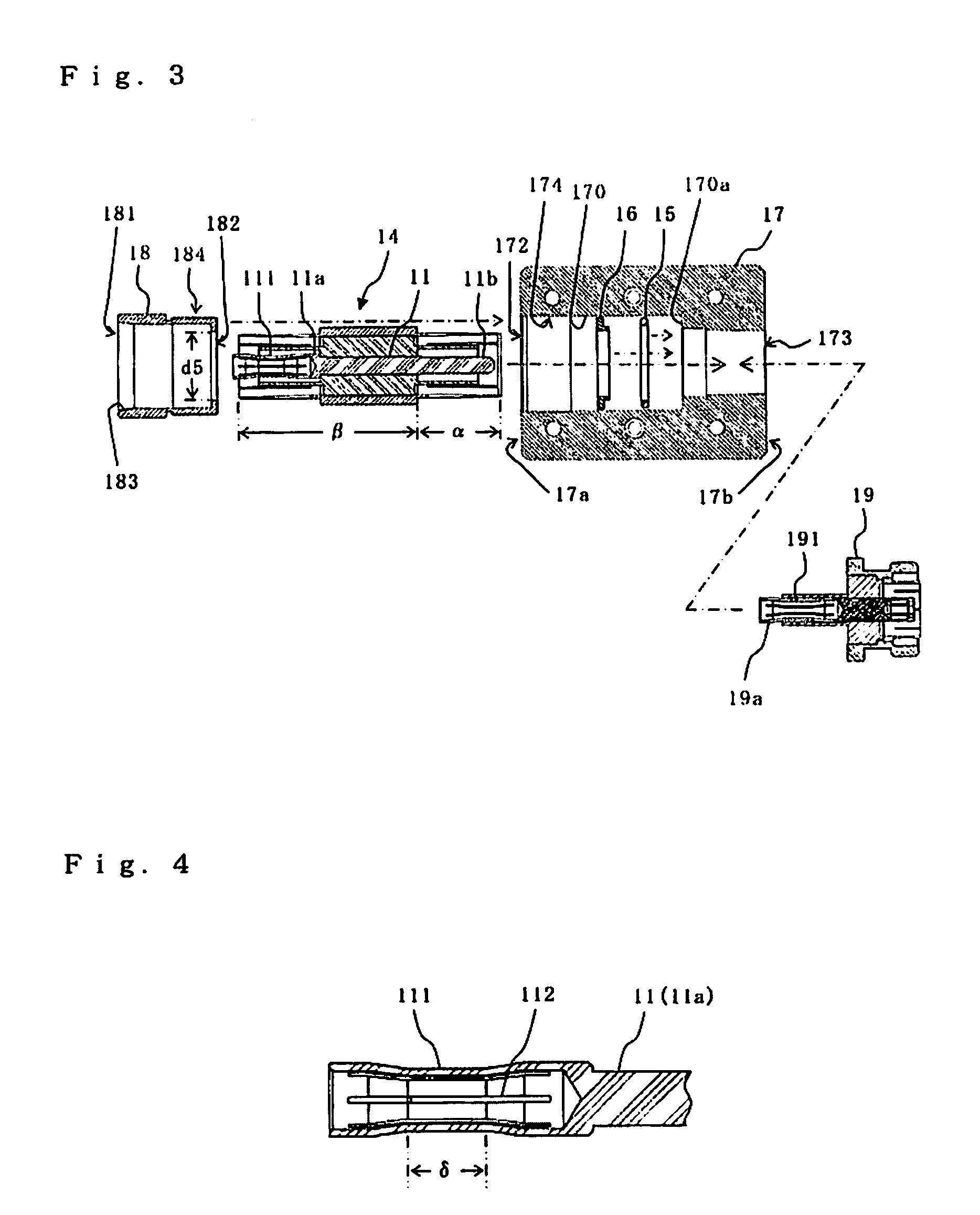

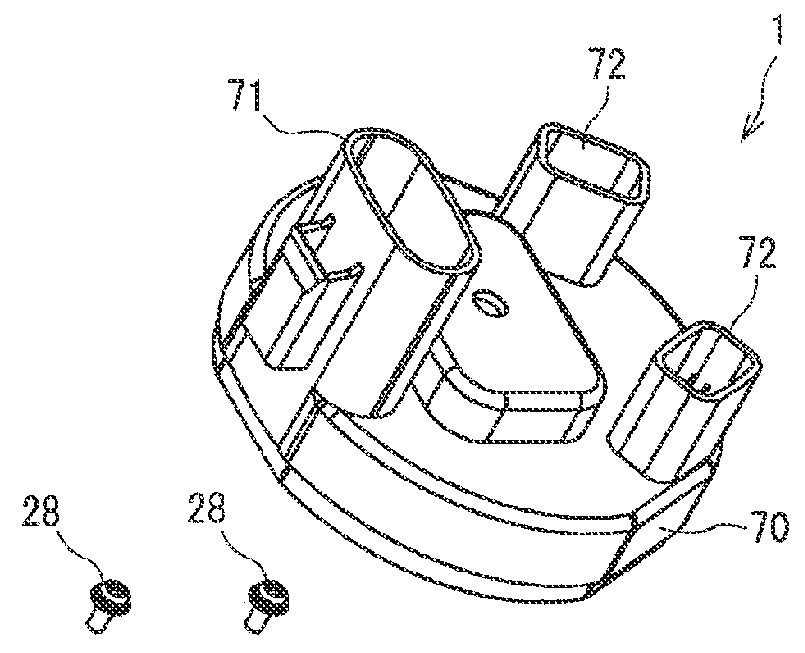

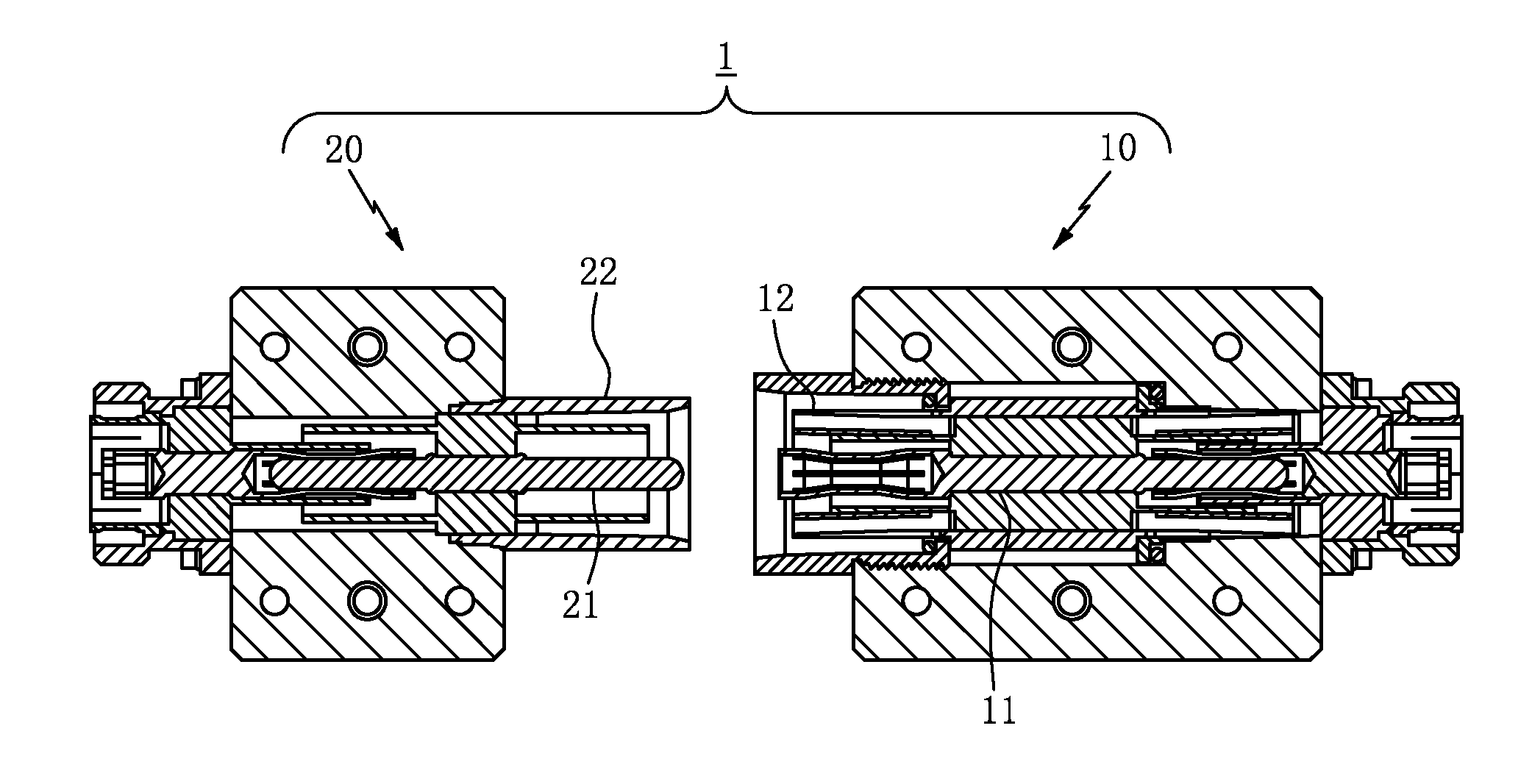

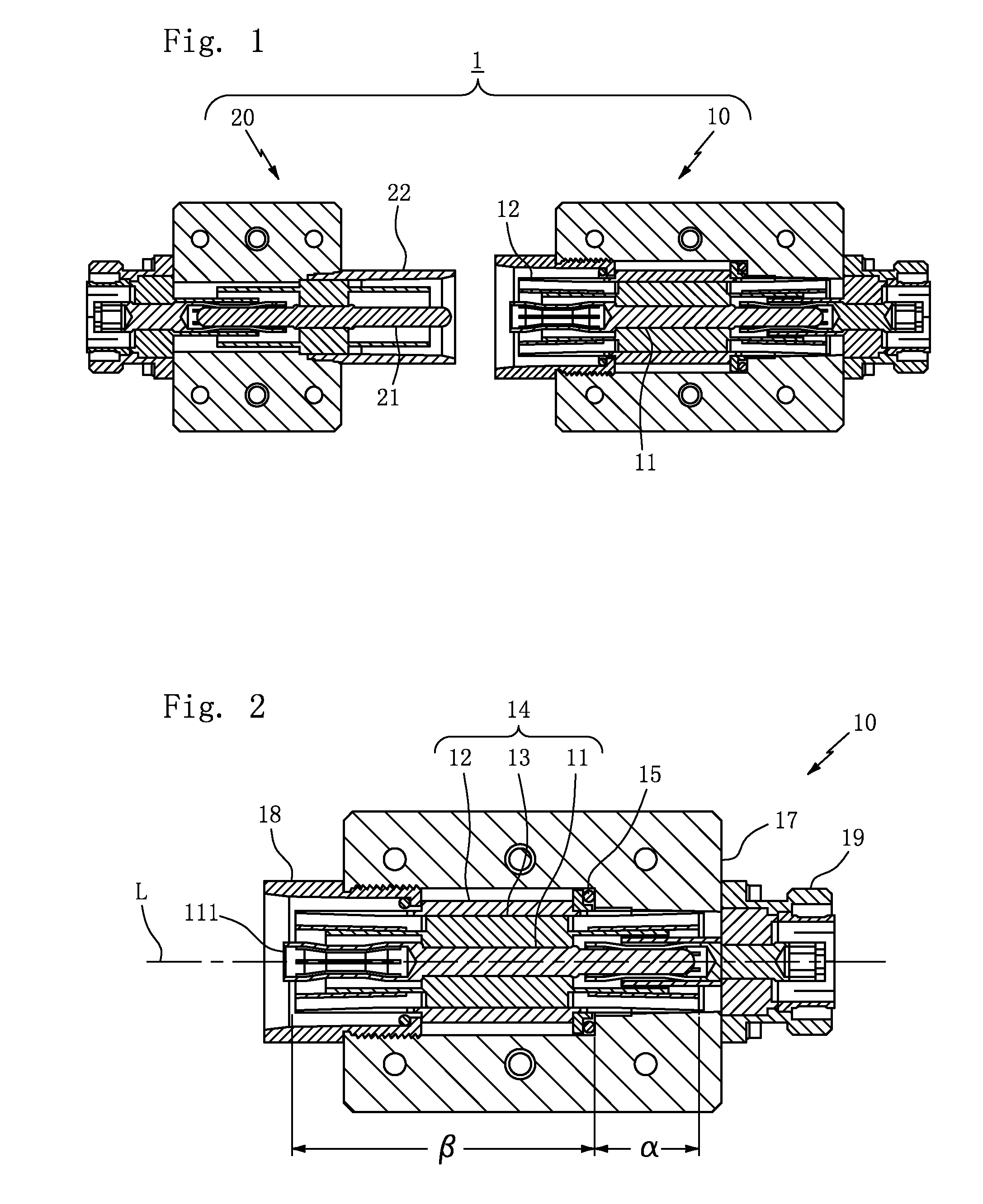

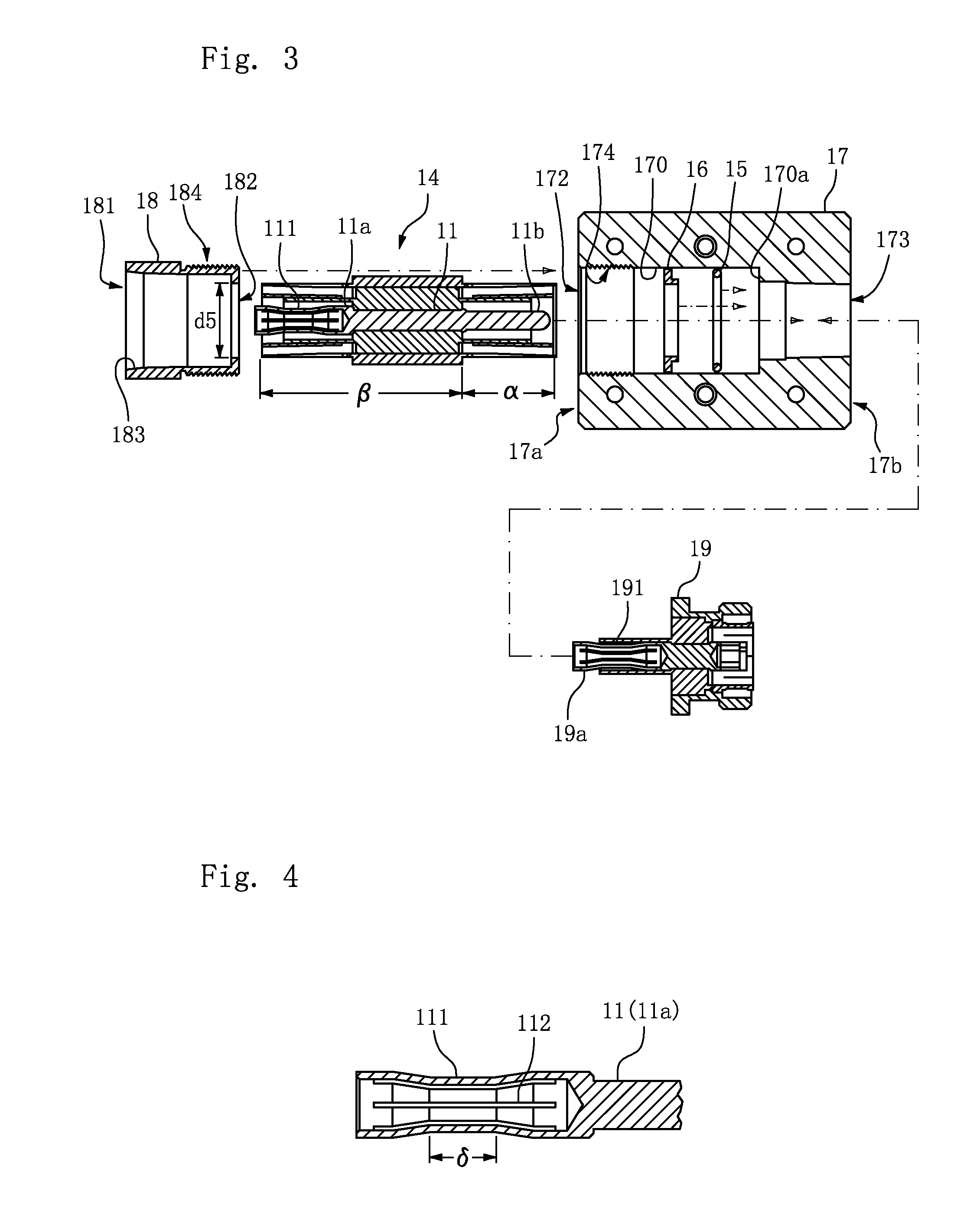

Coaxial connector

ActiveUS20110256760A1Reduce errorsImprove work efficiencyElectrically conductive connectionsCoupling device detailsElectrical conductorCoaxial cable

Owner:GV TECH

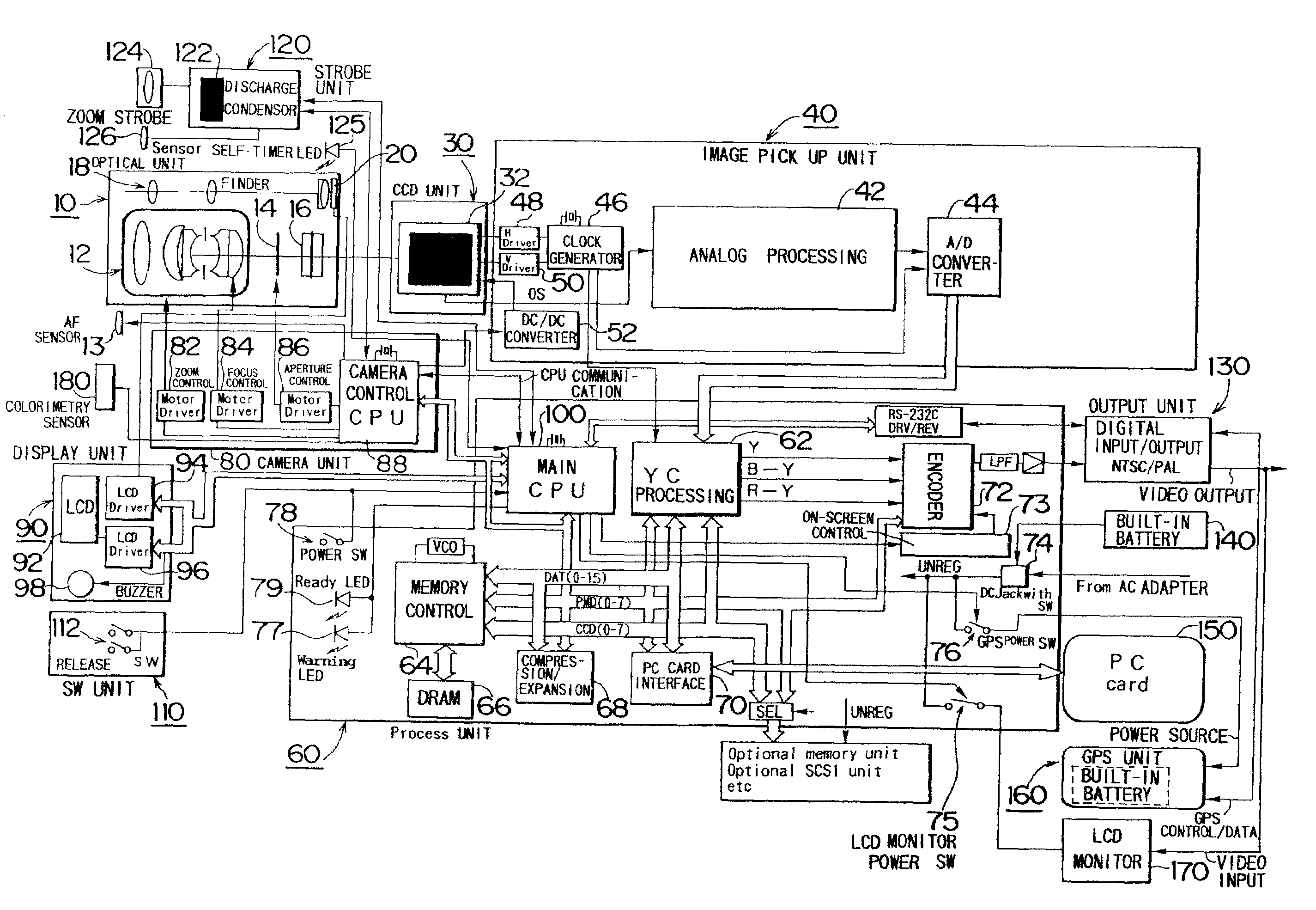

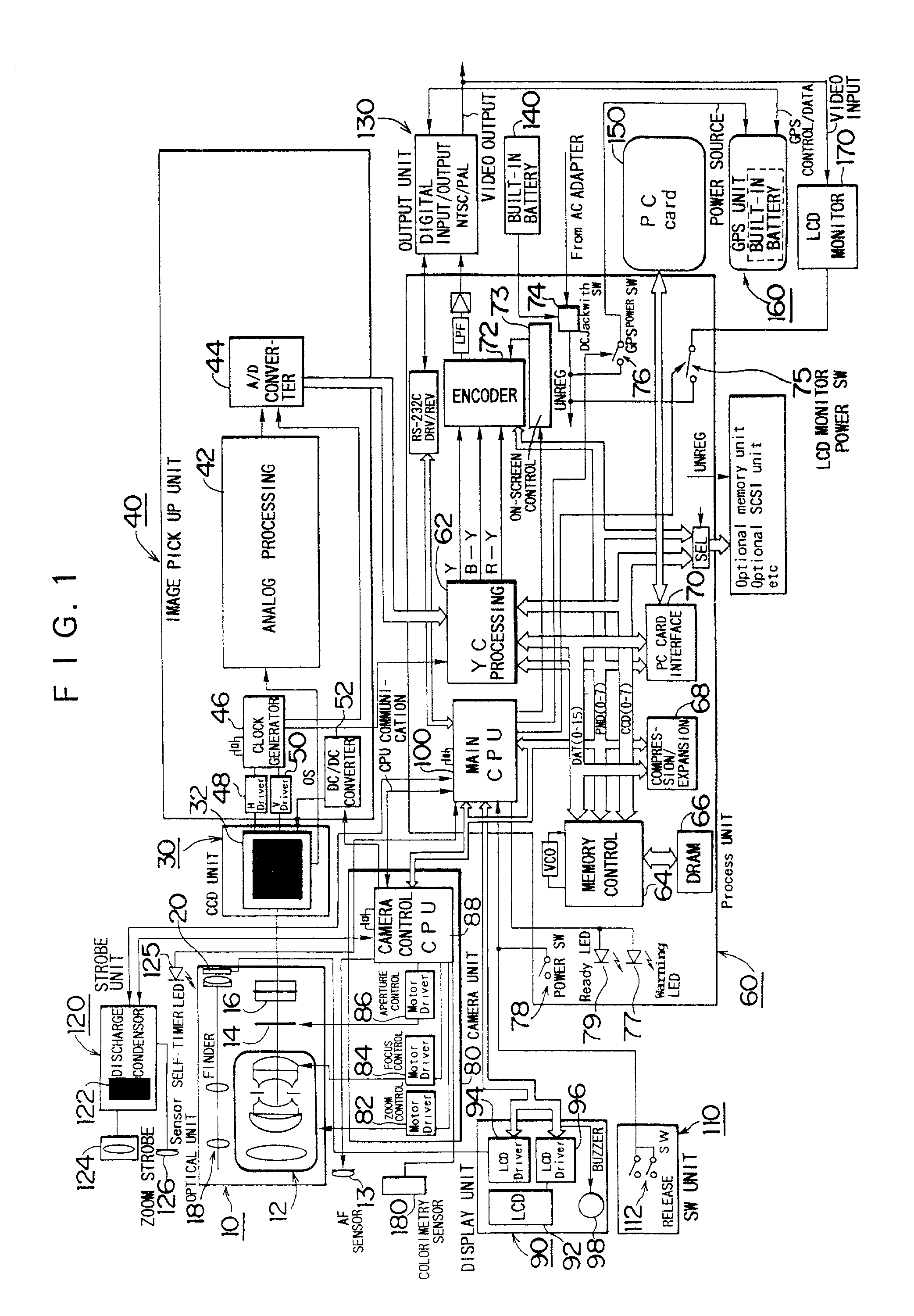

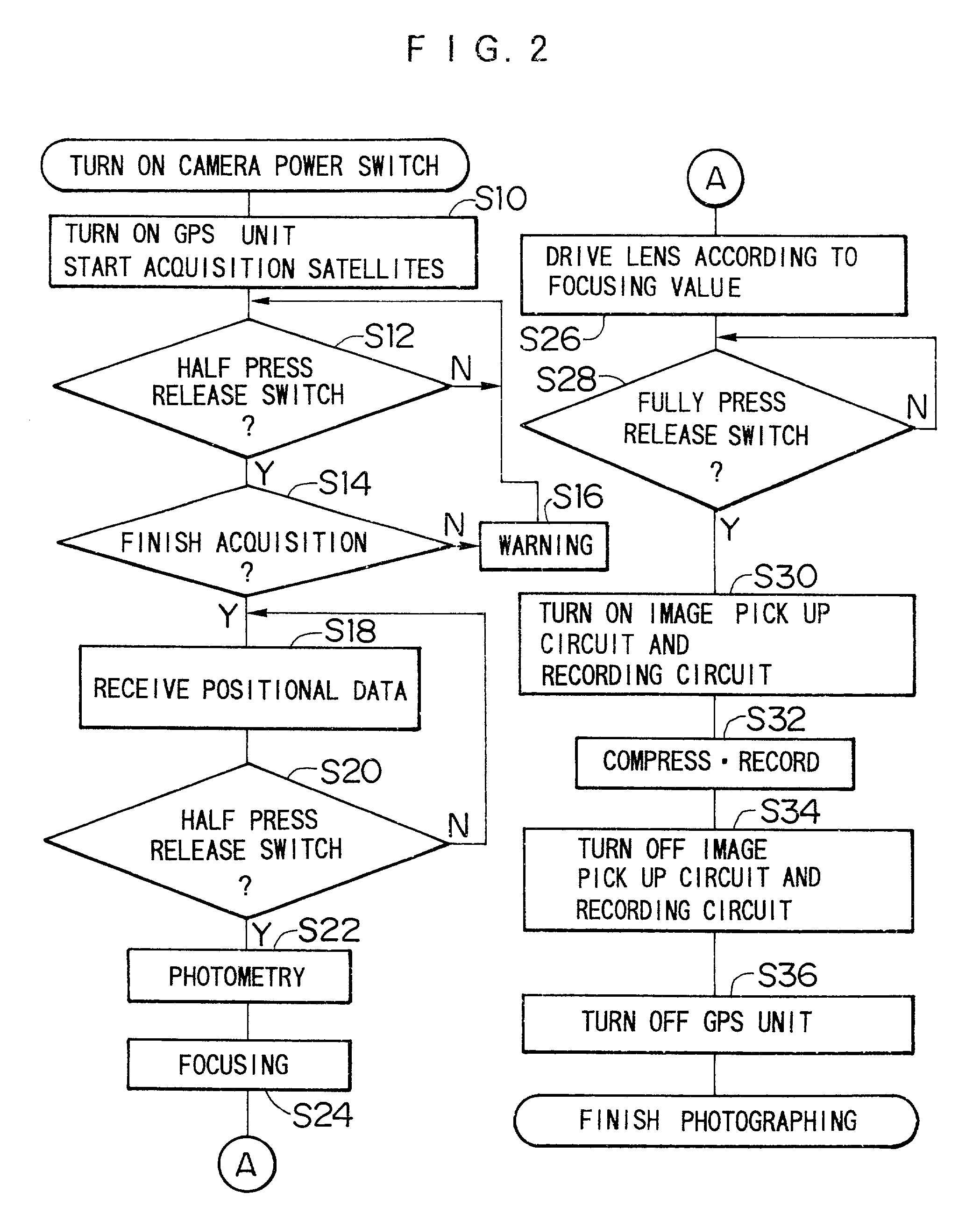

Camera which records positional data of GPS unit

InactiveUS7103267B2Prevent image pickupBad influence on the position measuring accuracyTelevision system detailsColor television signals processingImage signalImaging Signal

A camera which records positional data, which is obtained by a GPS unit during photographing, and image data on a memory card. The camera receives the positional data representing the photographing place from the GPS unit, and records the positional data and the image data on the memory card. While the GPS unit is measuring the position to obtain the positional data to be recorded, an image pickup circuit including a CCD sensor, etc. which converts image light into an image signal, a recording circuit for recording the image signal on the memory card, an LCD monitor which is used as a view finder, a strobe unit and a printer are halted.

Owner:FUJIFILM CORP

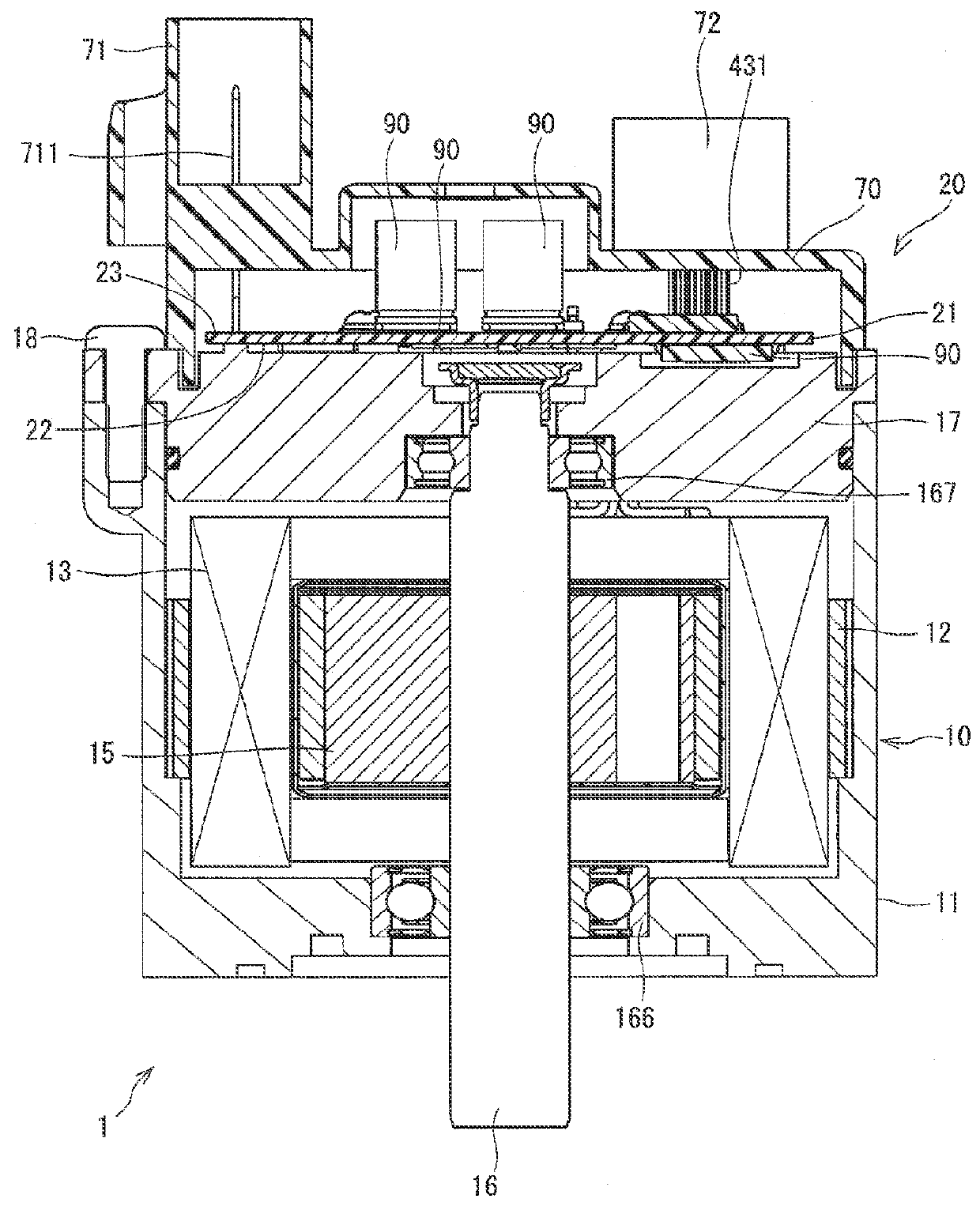

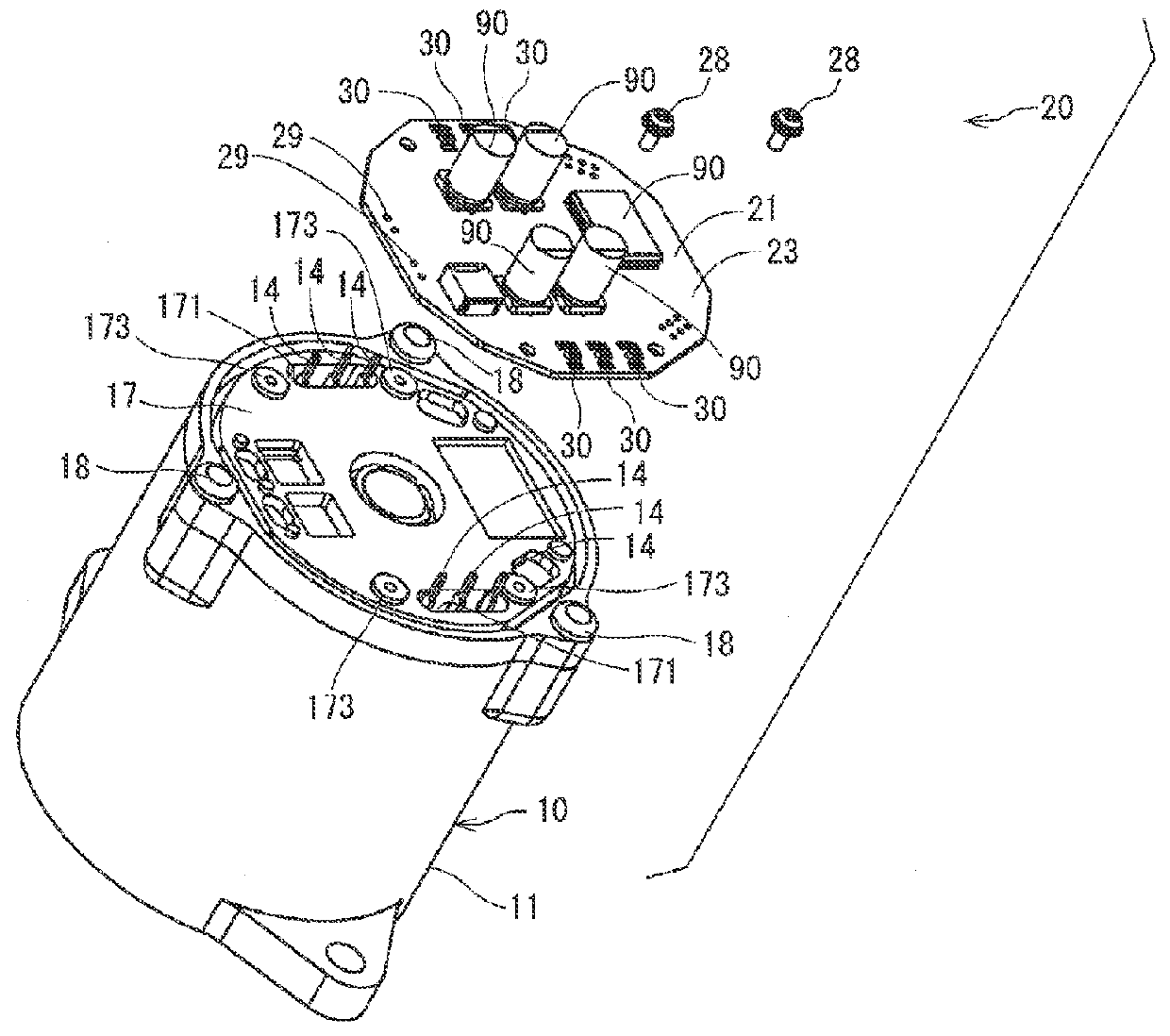

Drive unit including terminals in resiliant contact with each other

ActiveUS20160036306A1Improve assembly accuracyGuaranteed ease of connectionAssociation with control/drive circuitsFixed connectionsElectric machineElectronic component

A drive unit that includes a rotating electric machine, and a controller having a substrate with electronic components mounted on the substrate, and controlling a drive of the rotating electric machine. The drive unit also includes a first terminal electrically connected to the rotating electric machine or to a power supply, and a second terminal disposed on the substrate. The second terminal has an insertion hole into which the first terminal is inserted, and has a protruding shape protruding in parallel with an insertion direction or an anti-insertion direction of the first terminal. Also, the first terminal and the second terminal are in a resilient contact with each other.

Owner:DENSO CORP

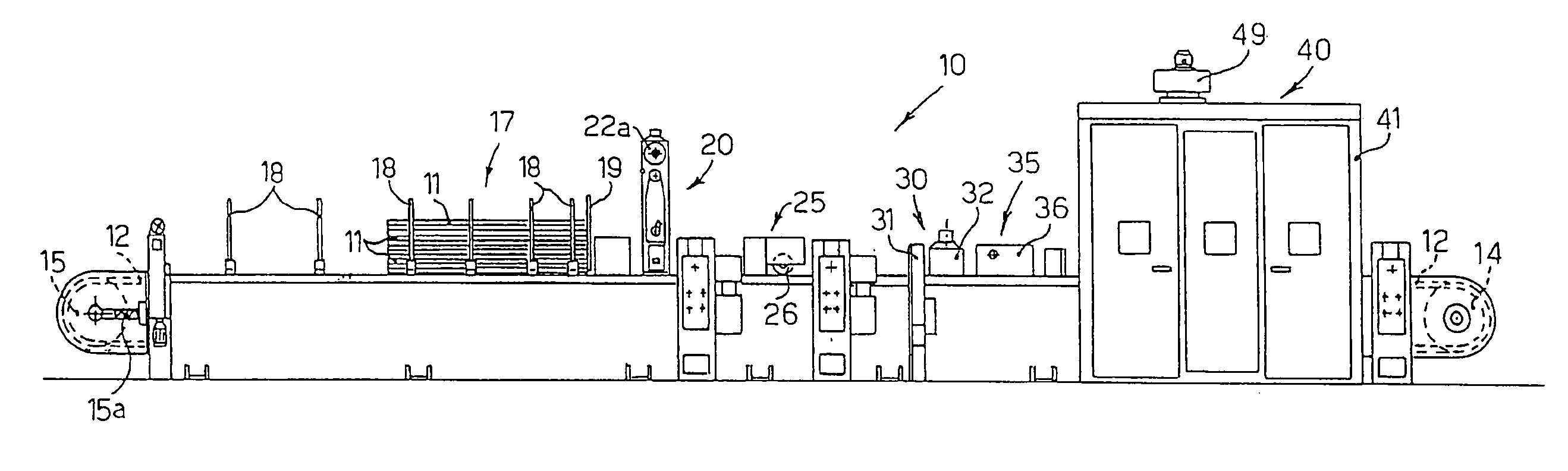

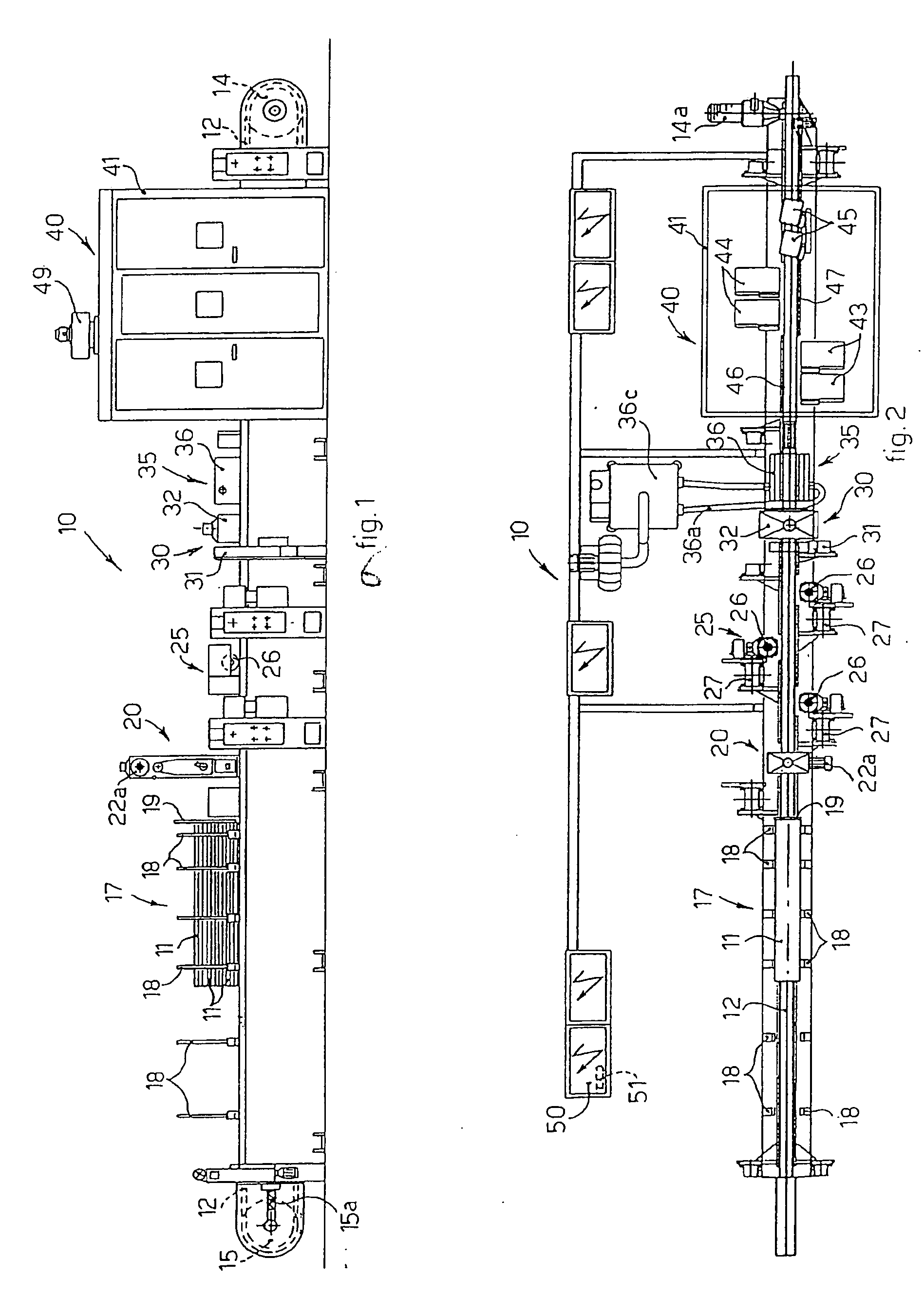

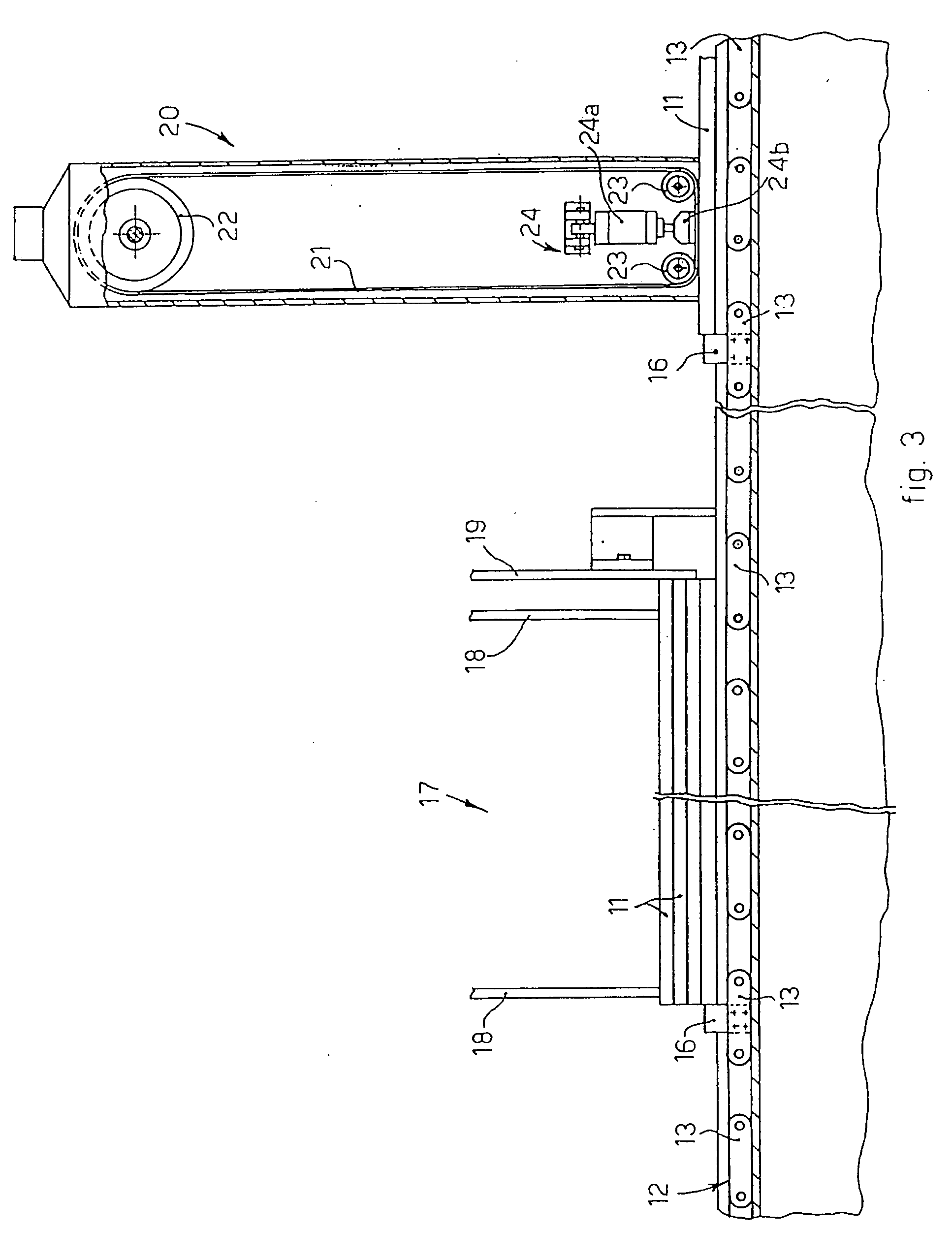

Apparatus and method for painting objects such as profiles, panels or suchlike

InactiveUS20050223972A1Work has been limitedSolve not working properlyLiquid surface applicatorsBelt grinding machinesHead partsManufacturing engineering

Apparatus and method for painting objects equipped with a painting head to paint the objects, and a movement member to move the objects through the painting head. The apparatus comprises working members arranged upstream and in line with the painting head to perform a treatment on the objects before they are introduced into the painting head, and a drying member arranged downstream and in line with the painting head in order to dry other objects after they have been painted.

Owner:DELLE VEDOVE LEVIGATRICI

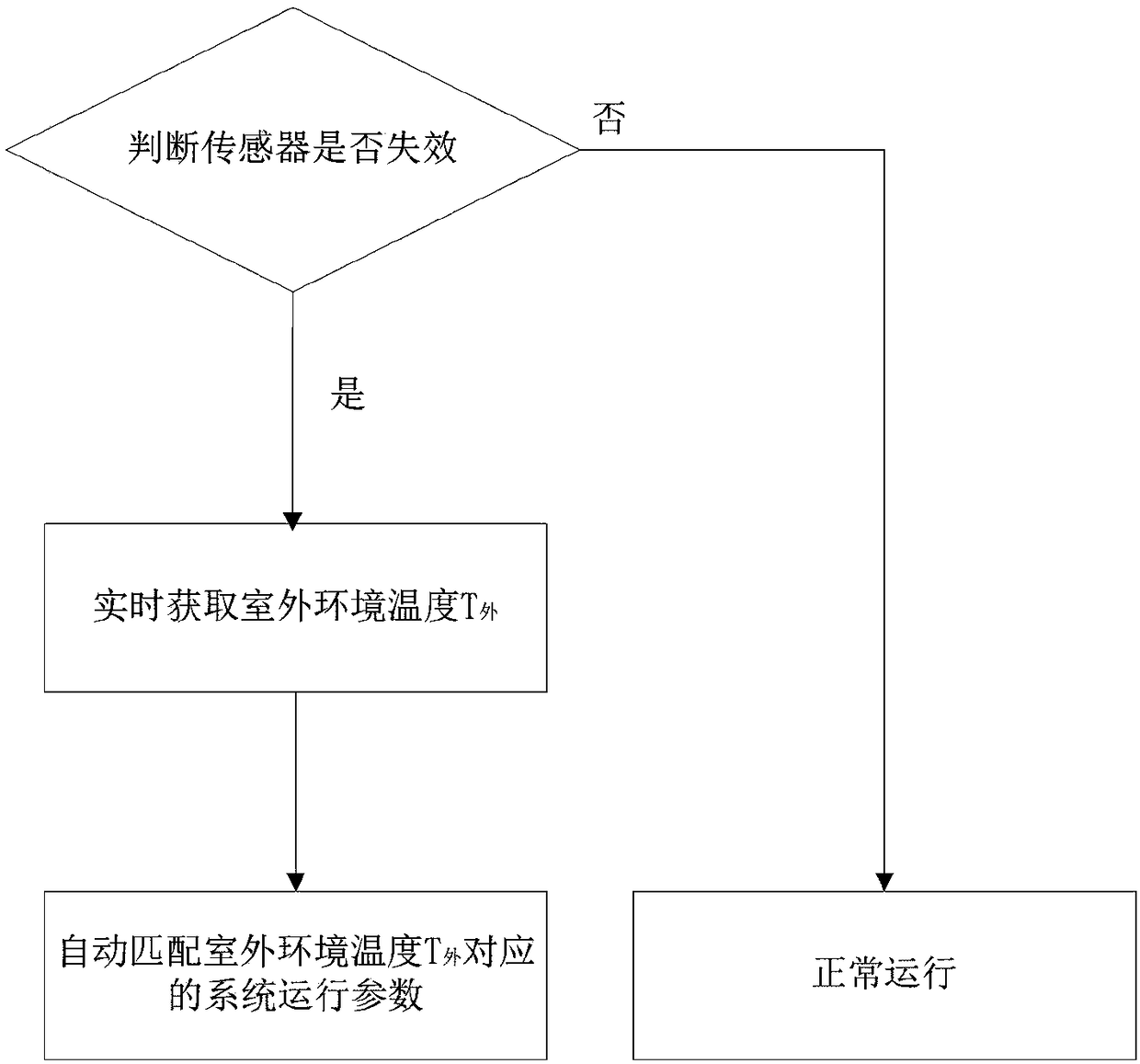

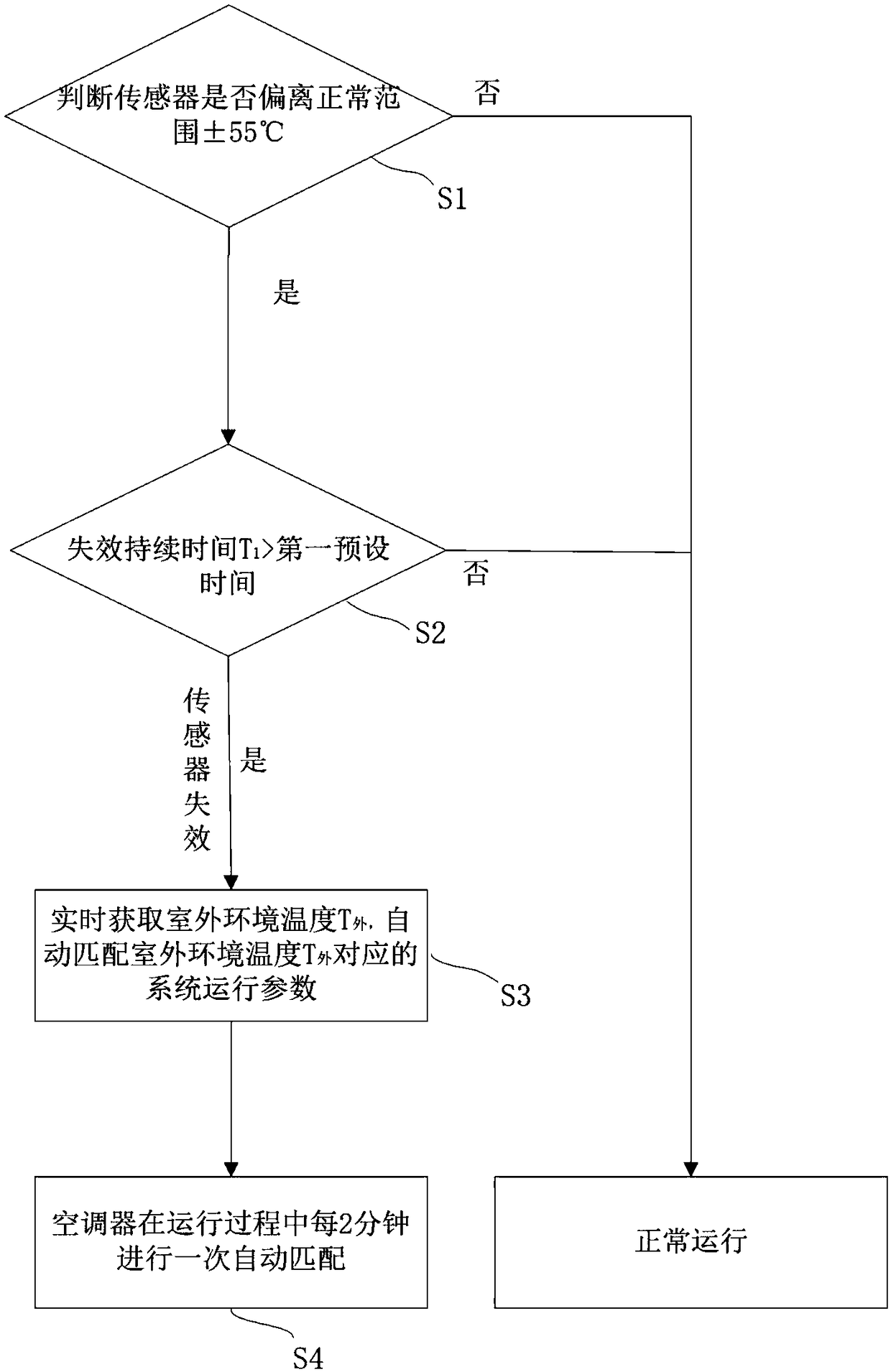

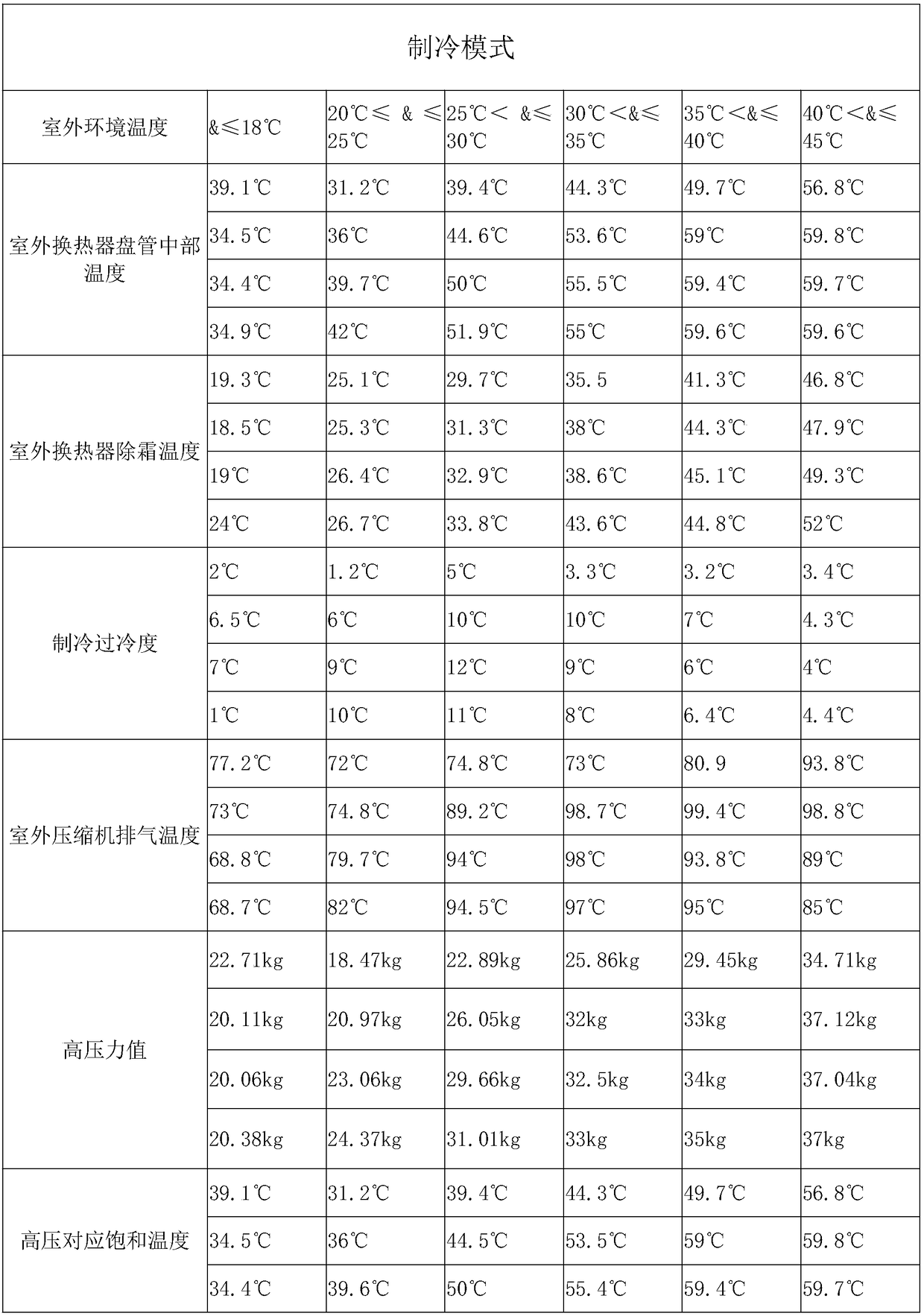

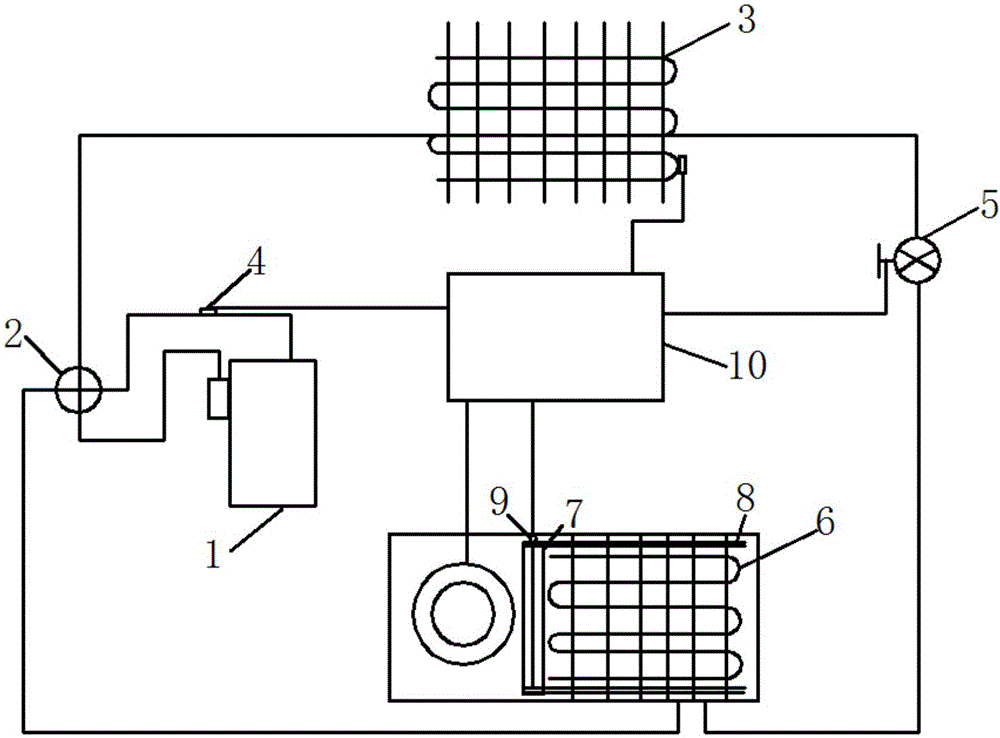

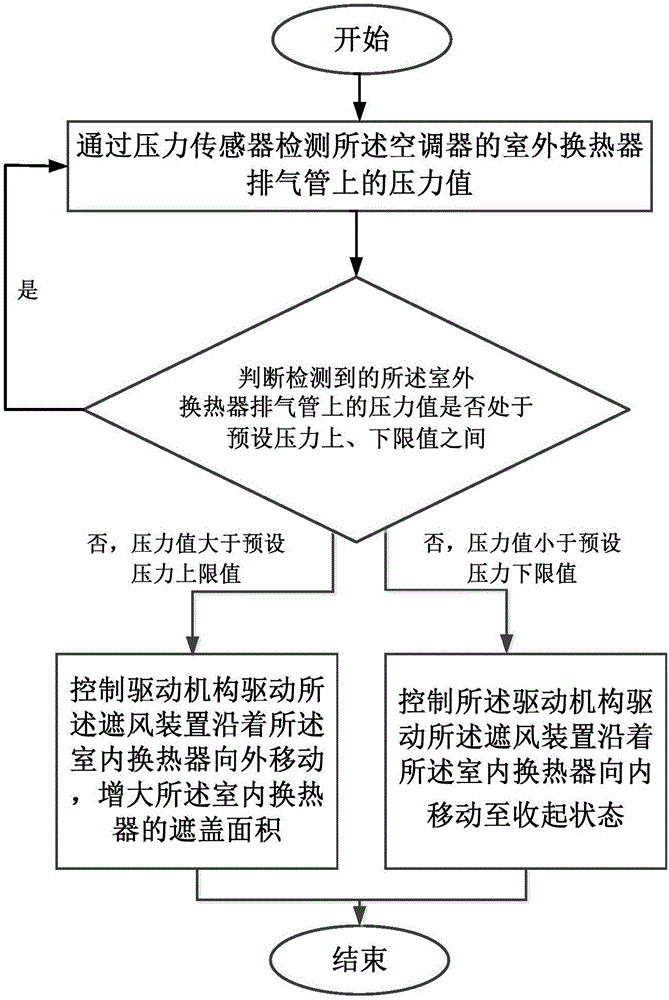

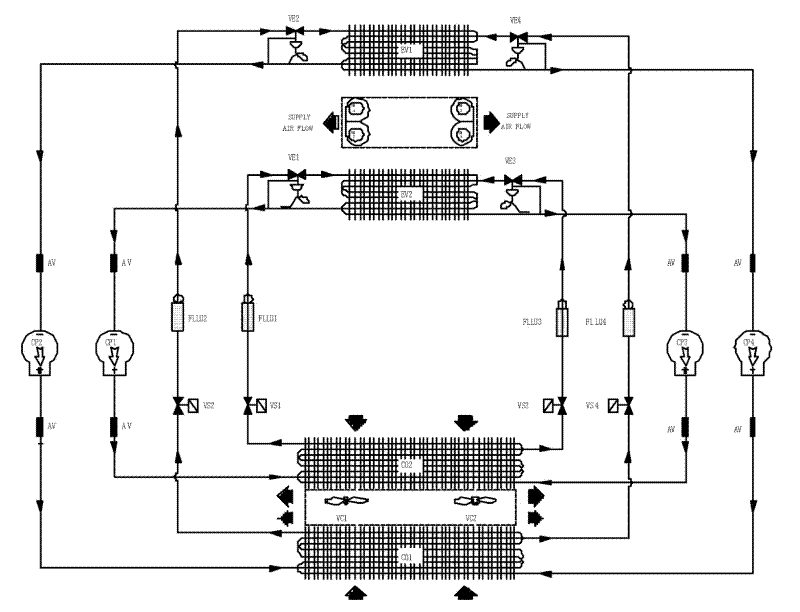

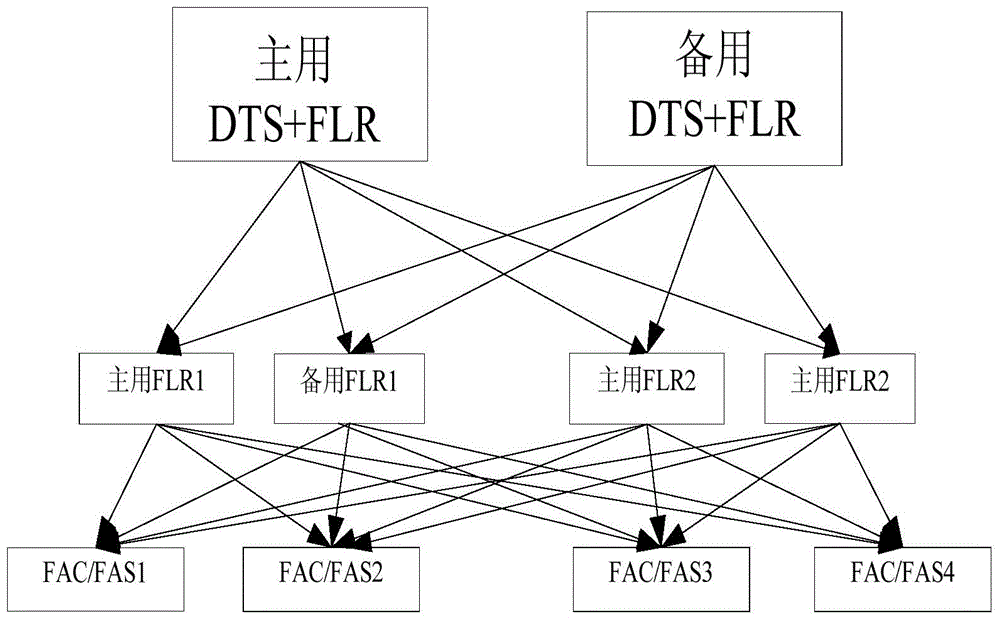

Operation method for controlling reliability of air conditioner, control system and air conditioner

ActiveCN109340992AControl normal operationSatisfy normal useMechanical apparatusControl systemNormal mode

The invention provides an operation method for controlling the reliability of an air conditioner, a control system and the air conditioner. The operation method for controlling the reliability of theair conditioner comprises the following steps that whether a temperature sensor fails or not is judged according to a temperature signal sent by the temperature sensor, if the temperature sensor fails, the air conditioner continues to acquire real-time outdoor environment temperature, the air conditioner automatically matches each operation parameter of the system corresponding to the outdoor temperature according to the real-time outdoor temperature, and continues to operate according to each operation parameter of the system after automatic matching; and otherwise, normal mode operation is continued. The operation method for controlling the reliability of the air conditioner can continuously control normal operation of the air conditioner after the temperature sensor fails, so that the normal use of people is met.

Owner:NINGBO AUX ELECTRIC +1

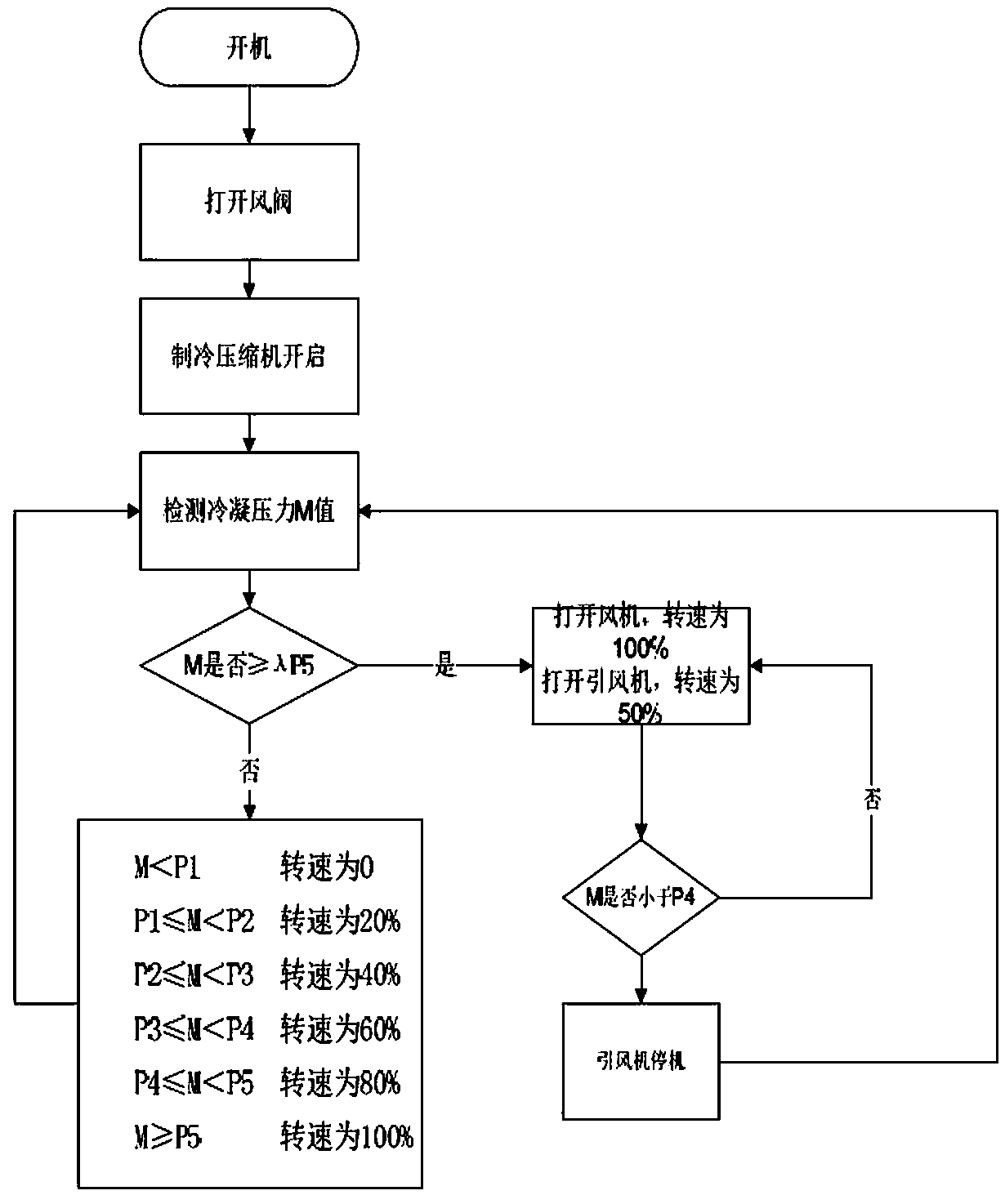

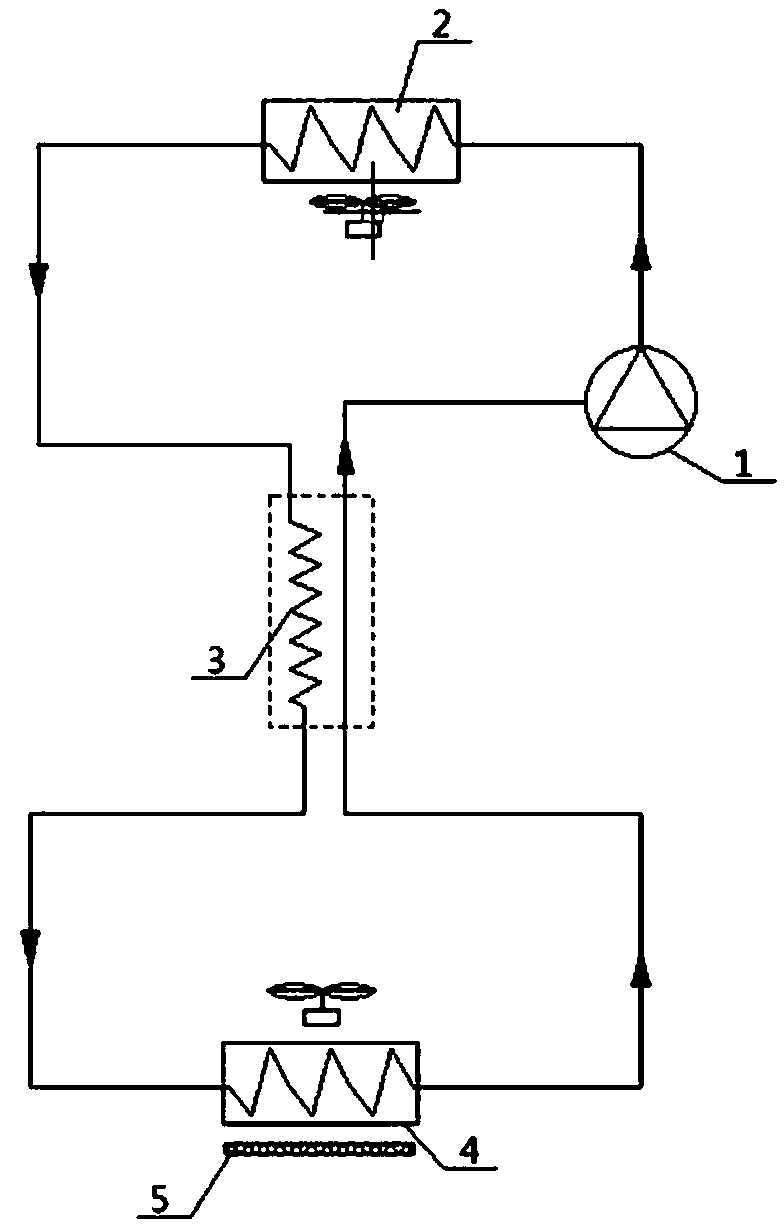

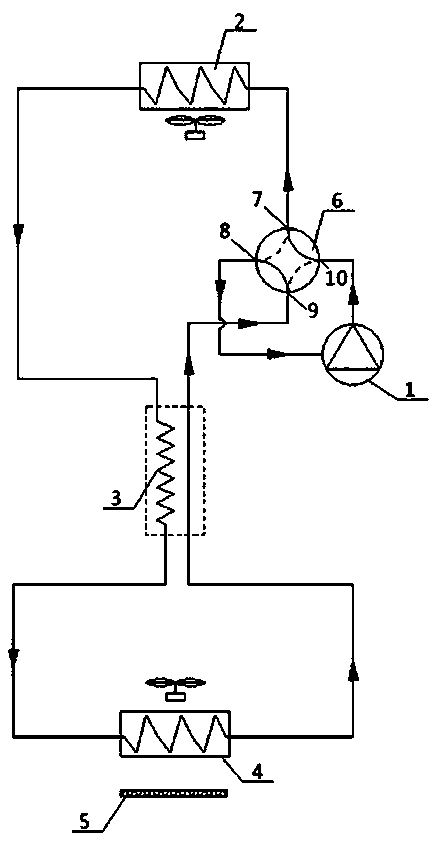

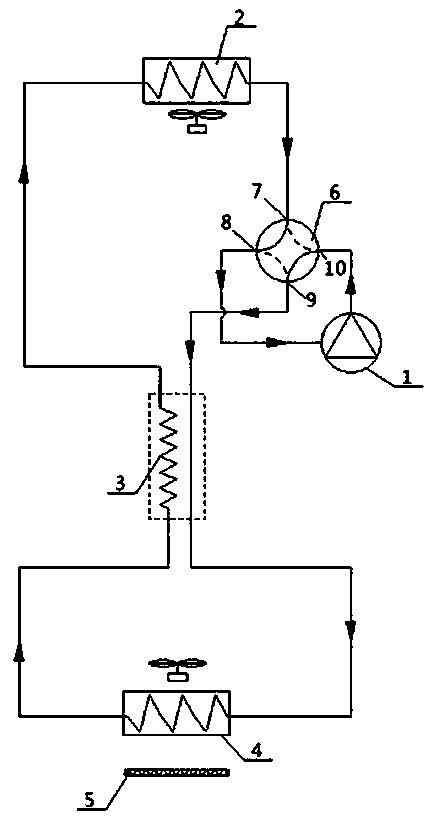

High-temperature refrigeration air conditioner and high-temperature refrigeration control method

PendingCN106440067ASolve the problem that the pressure is too high to runSolve not working properlyMechanical apparatusSpace heating and ventilation safety systemsEngineeringHigh pressure

The invention relates to the technical field of air conditioners, in particular to a high-temperature refrigeration air conditioner and a high-temperature refrigeration control method. The high-temperature refrigeration air conditioner comprises a compressor, an outdoor heat exchanger, a throttling device and an indoor heat exchanger which are connected to form a refrigeration loop or a heating loop. The high-temperature refrigeration air conditioner further comprises a wind shielding device for shielding the indoor heat exchanger, a driving mechanism connected with the wind shielding device, and a control module for controlling the driving mechanism. A pressure sensor connected with the control module is arranged on a pipeline between the outdoor heat exchanger and the compressor, and the control module adjusts the shielding area, shielded by the wind shielding device, of the indoor heat exchanger through the driving mechanism according to data of the pressure sensor. According to the high-temperature refrigeration air conditioner, it is achieved that pressure can be kept within a proper range during refrigeration in the outdoor high-temperature environment, the problem that an air conditioning system cannot run in severe working conditions due to too high pressure is solved, and the running reliability and comfort in the high-temperature environment are greatly improved.

Owner:GUANGZHOU HUALING REFRIGERATION EQUIP +1

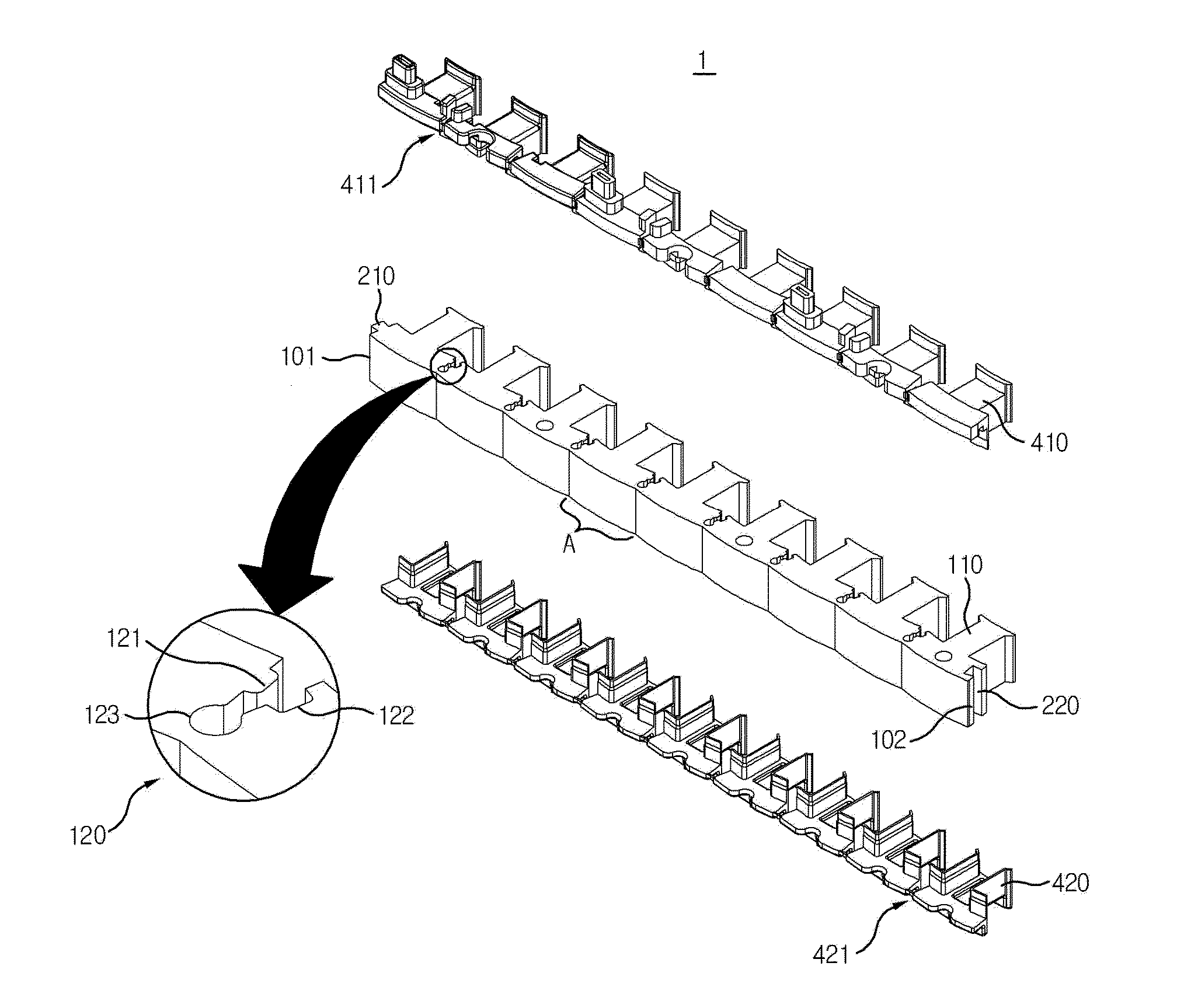

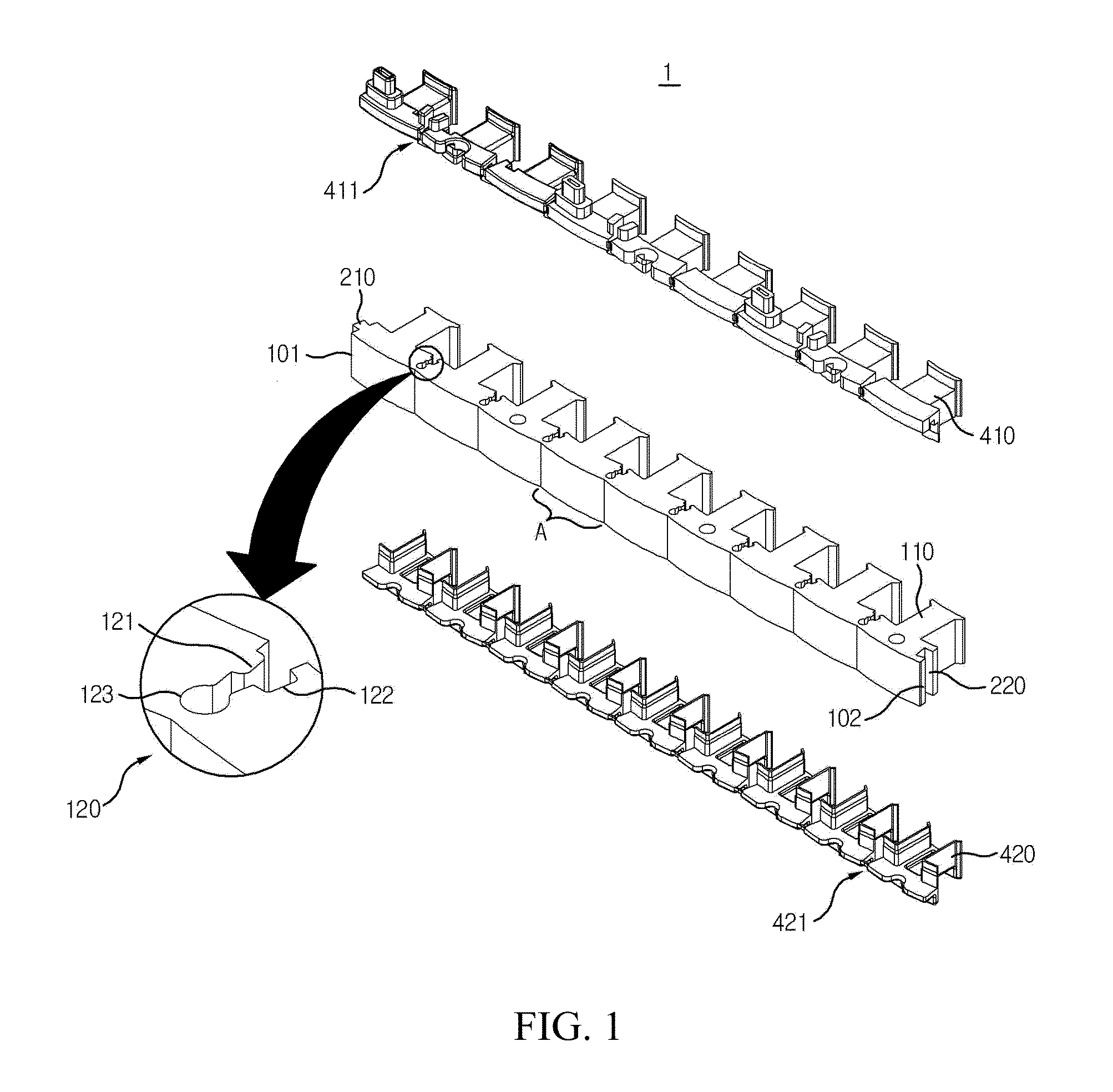

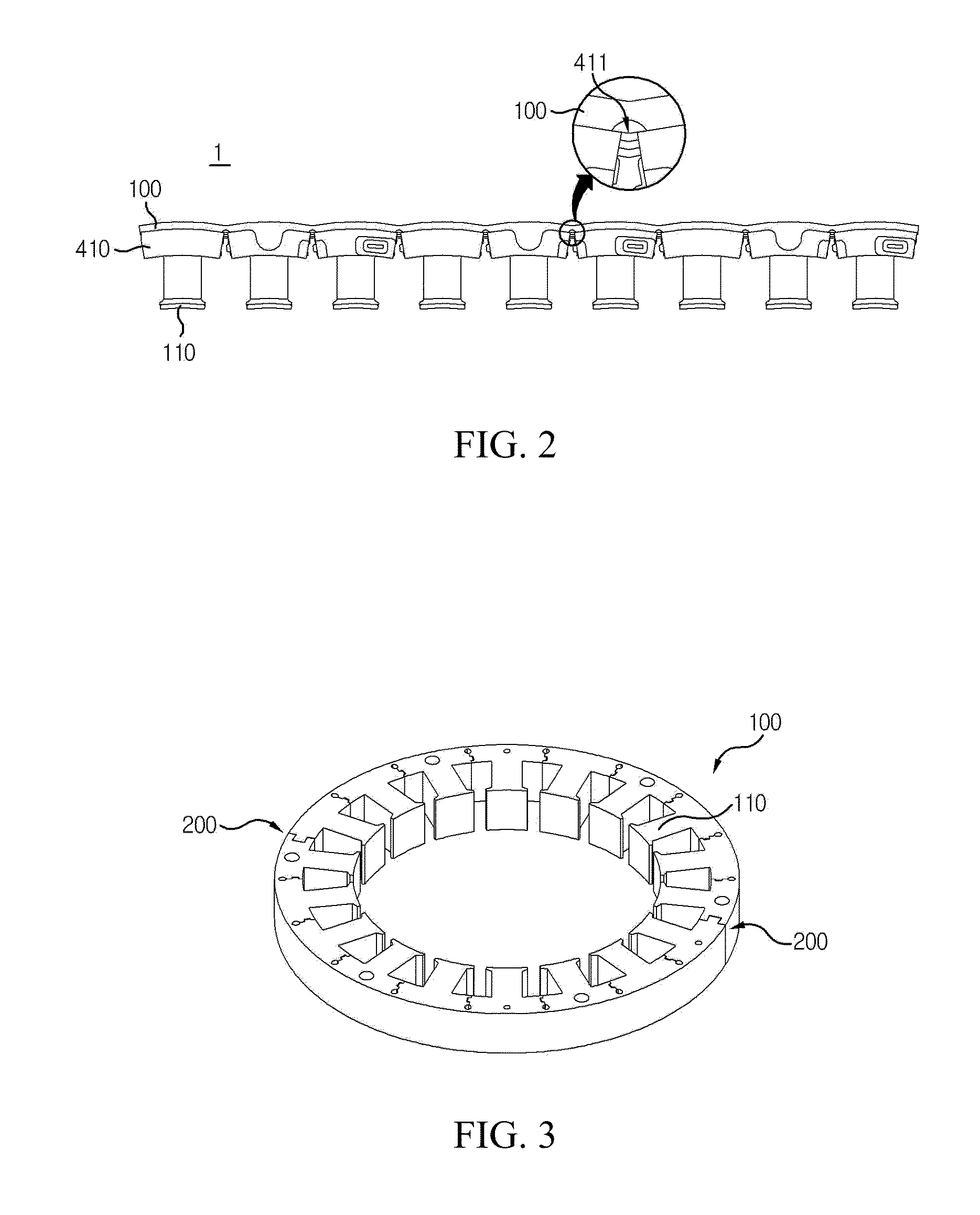

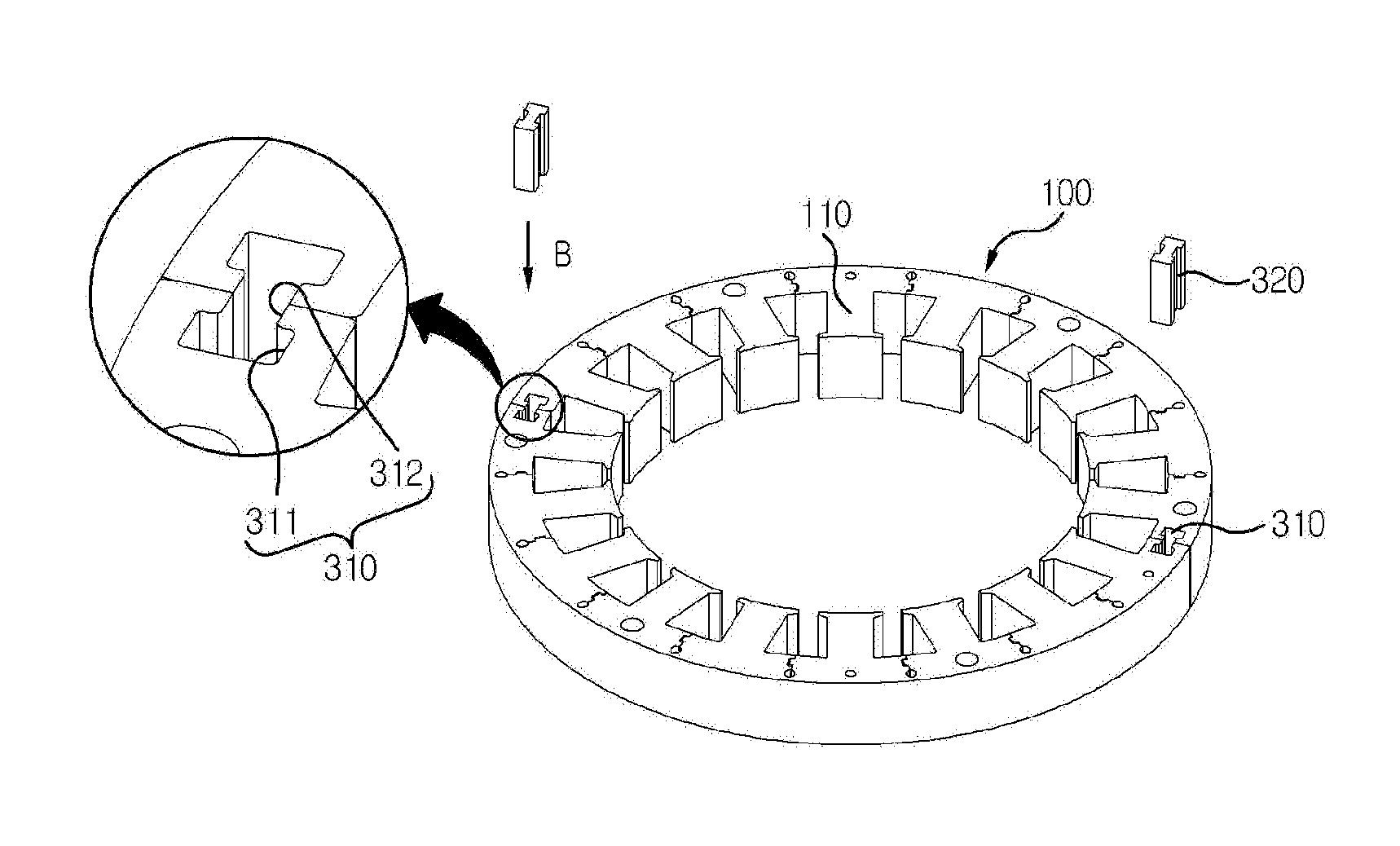

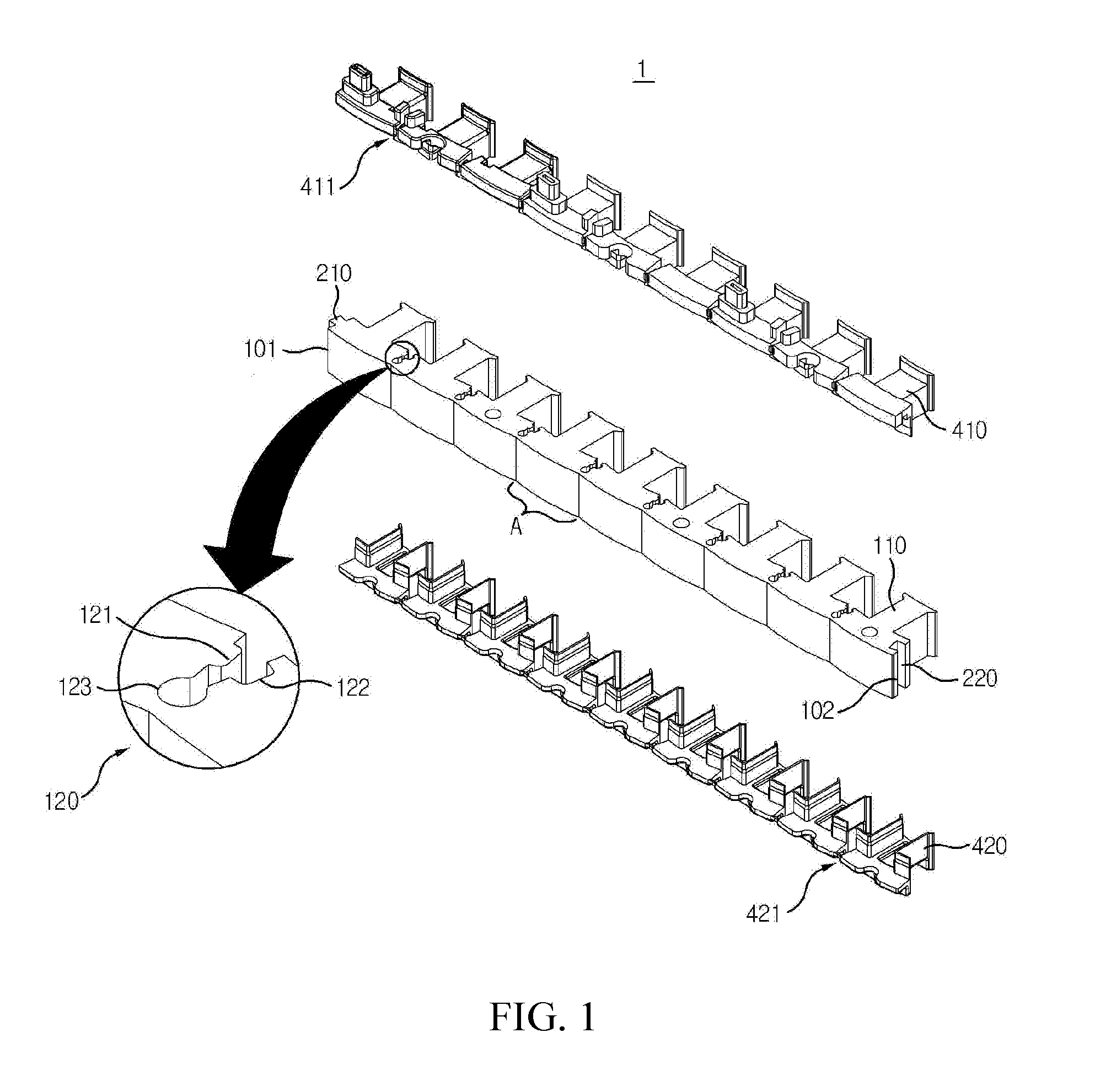

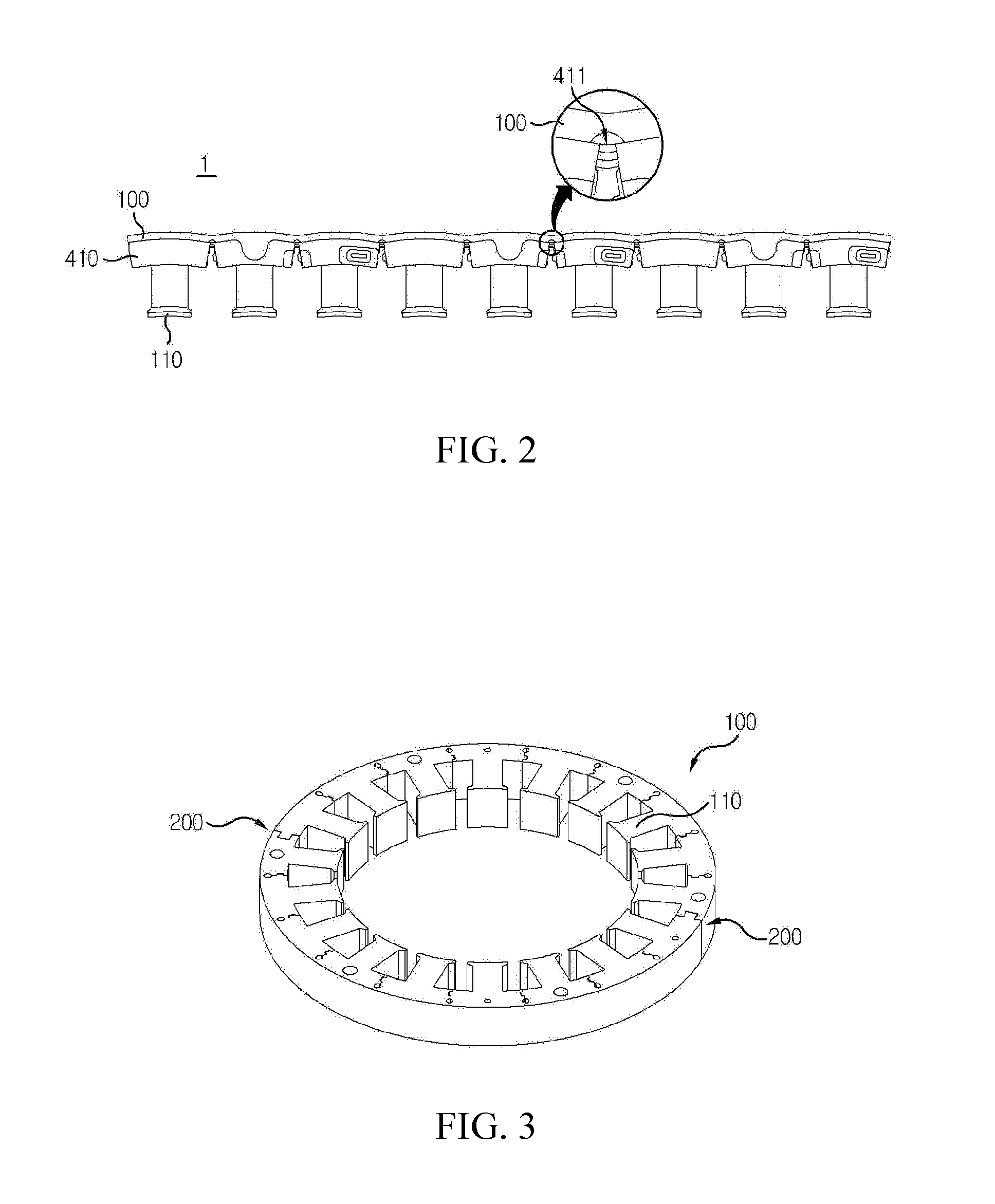

Stator Core For Motor and Manufacturing Method Thereof

ActiveUS20130099604A1Simple structureReduce the impact of interferenceWindings insulation shape/form/constructionMagnetic circuit stationary partsEngineeringElectric motor

Disclosed stator core for motor is comprising: more than one stator core body; a fixing unit, which is arranged at both ends of the stator core body and fixes the stator core body to be a cylindrical shape; a first insulator, which is integrally formed by mold in order to wrap a part of the stator core body and a side surface of plural teeth simultaneously; and a second insulator, which is arranged to have a form corresponding to the first insulator, and which is integrally formed by mold in order to wrap a part of the stator core body and a side surface of plural teeth simultaneously through the assembly with the first insulator, wherein the first simulator and the second simulator are separated from each other by the section wrapping the teeth during the bending process of the stator core body.

Owner:LG INNOTEK CO LTD

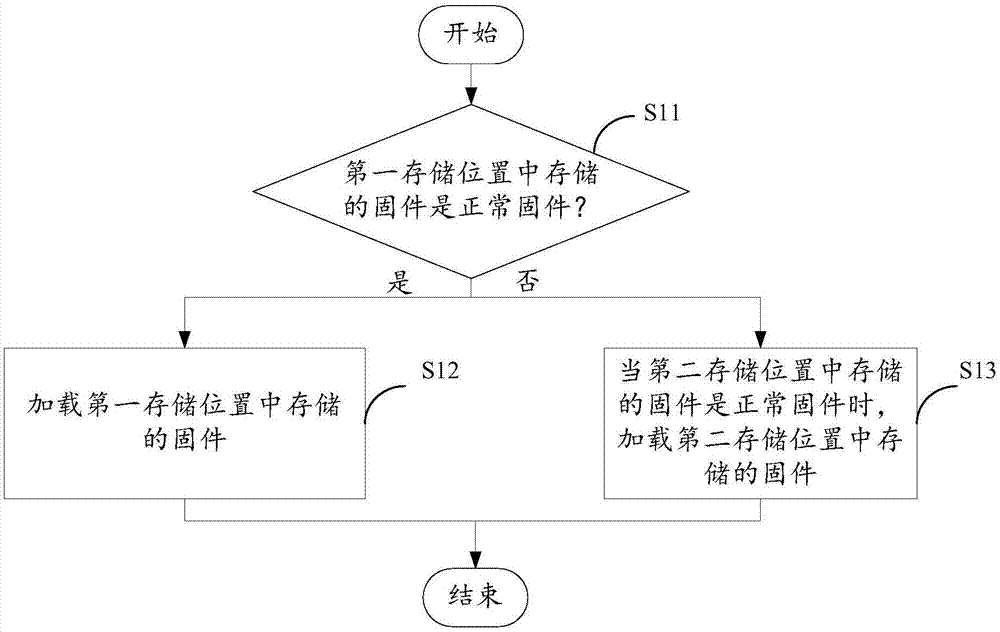

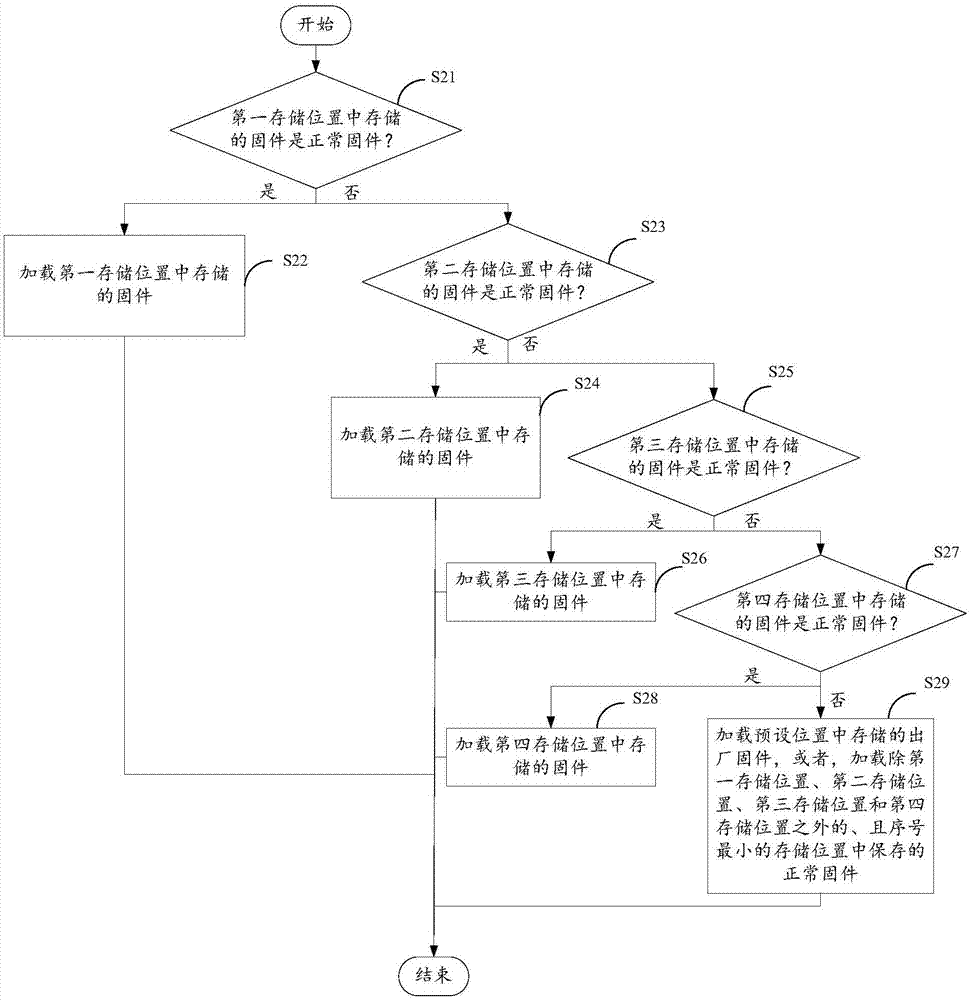

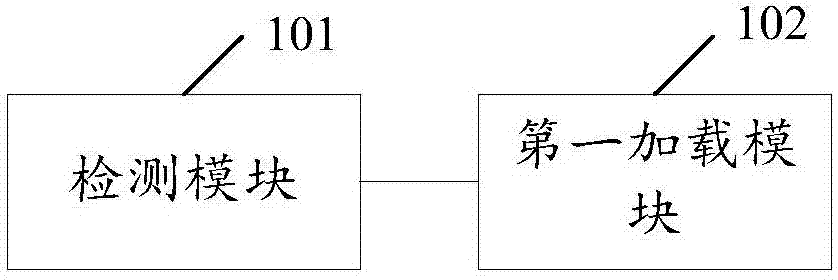

Firmware loading method and apparatus, and electronic device

ActiveCN107315616ASolve not working properlyProgram loading/initiatingSolid-state driveElectric equipment

The invention provides a firmware loading method and apparatus, and an electronic device. Firmware are stored in a first storage position and a second storage position; and when the firmware in the first storage position or the second storage position is damaged, the firmware in the other storage position can be used. The problem that a solid state disk cannot run normally when the firmware is damaged in the prior art is solved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Stator Core with a Structure to Improve Assembly Characteristics

ActiveUS20160365778A1Simple structureReduce the impact of interferenceWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric motorStator

Disclosed stator core for motor is comprising: more than one stator core body; a fixing unit, which is arranged at both ends of the stator core body and fixes the stator core body to be a cylindrical shape; a first insulator, which is integrally formed by mold in order to wrap a part of the stator core body and a side surface of plural teeth simultaneously; and a second insulator, which is arranged to have a form corresponding to the first insulator, and which is integrally formed by mold in order to wrap a part of the stator core body and a side surface of plural teeth simultaneously through the assembly with the first insulator, wherein the first simulator and the second simulator are separated from each other by the section wrapping the teeth during the bending process of the stator core body.

Owner:LG INNOTEK CO LTD

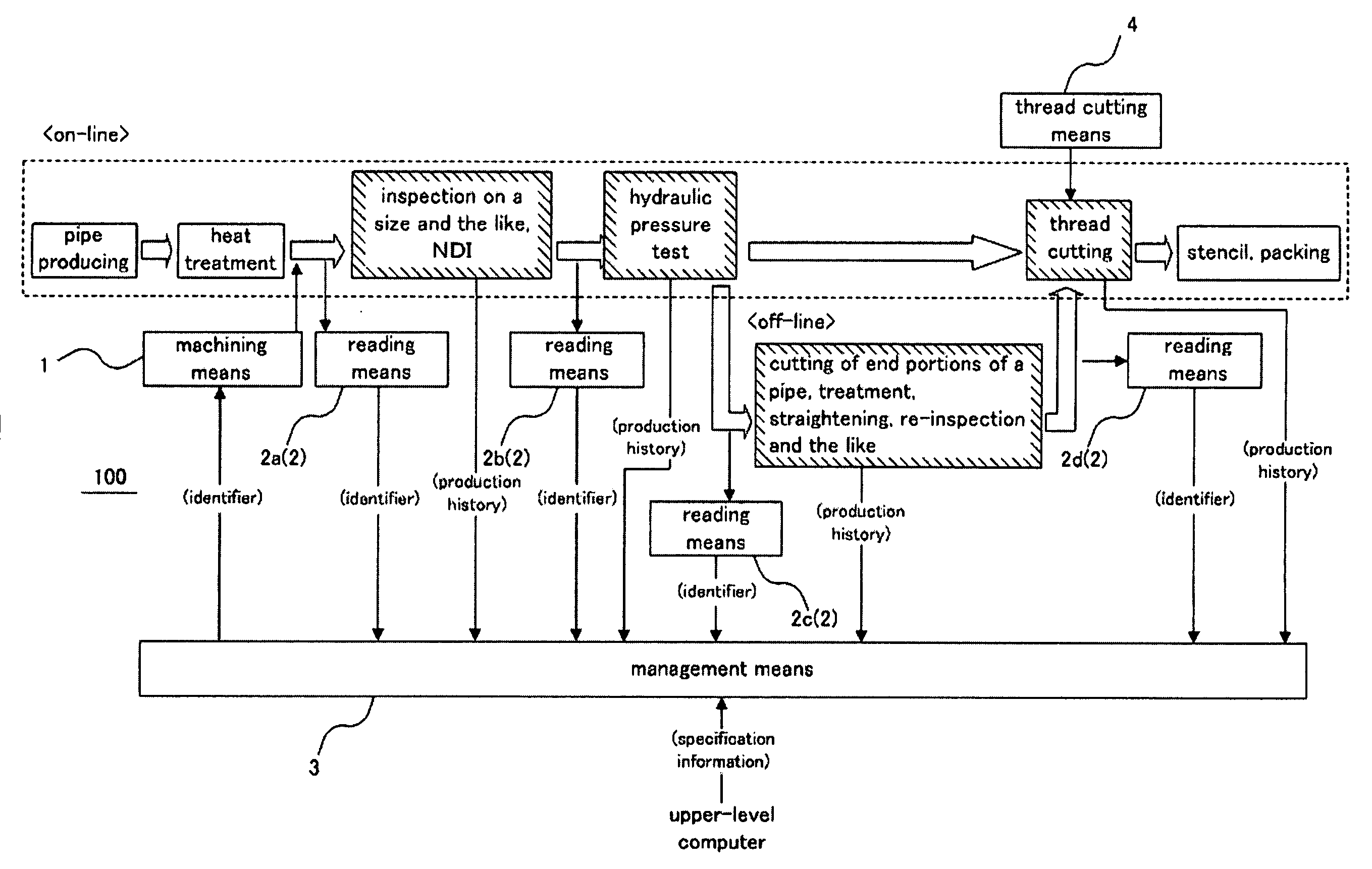

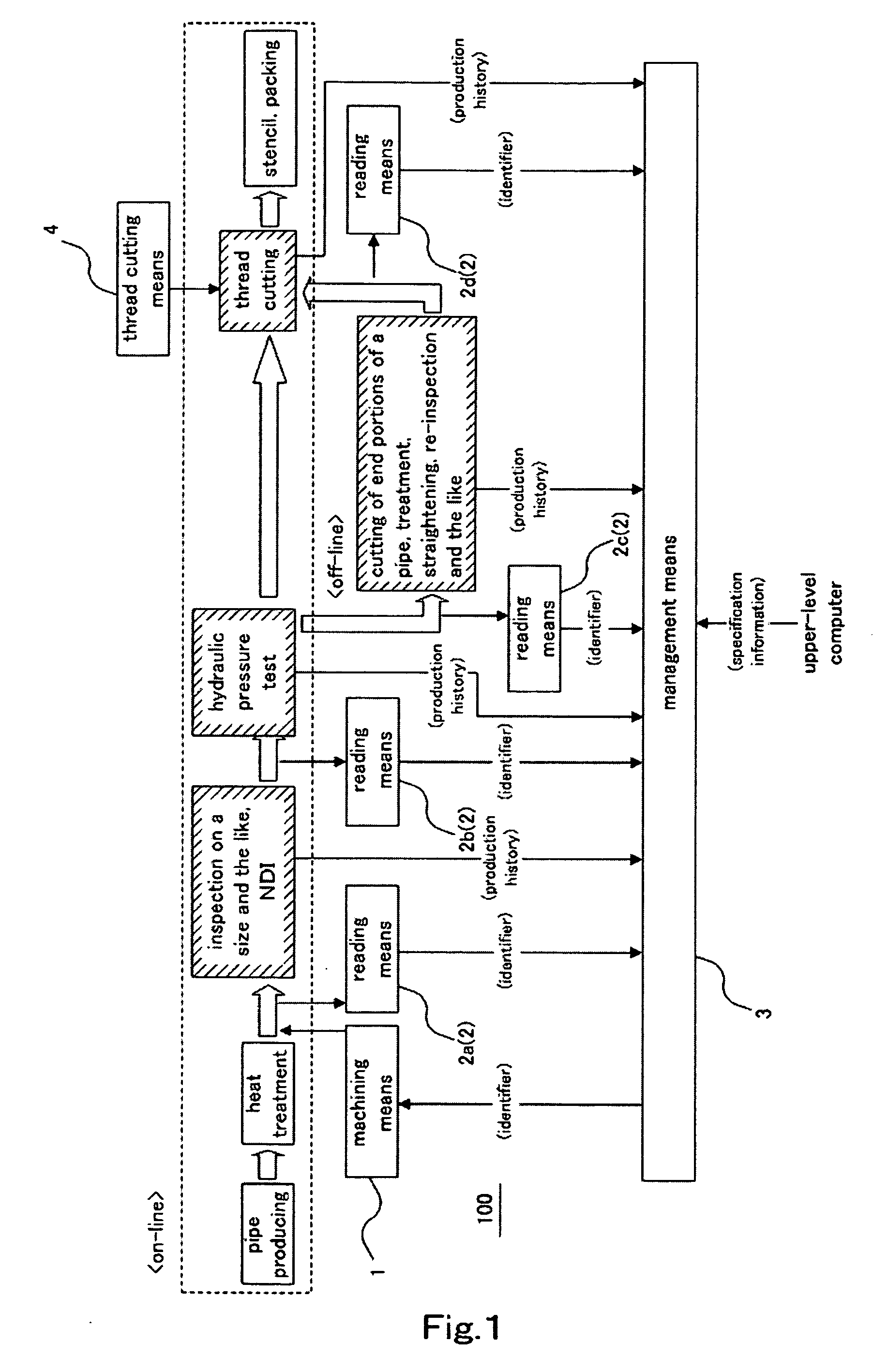

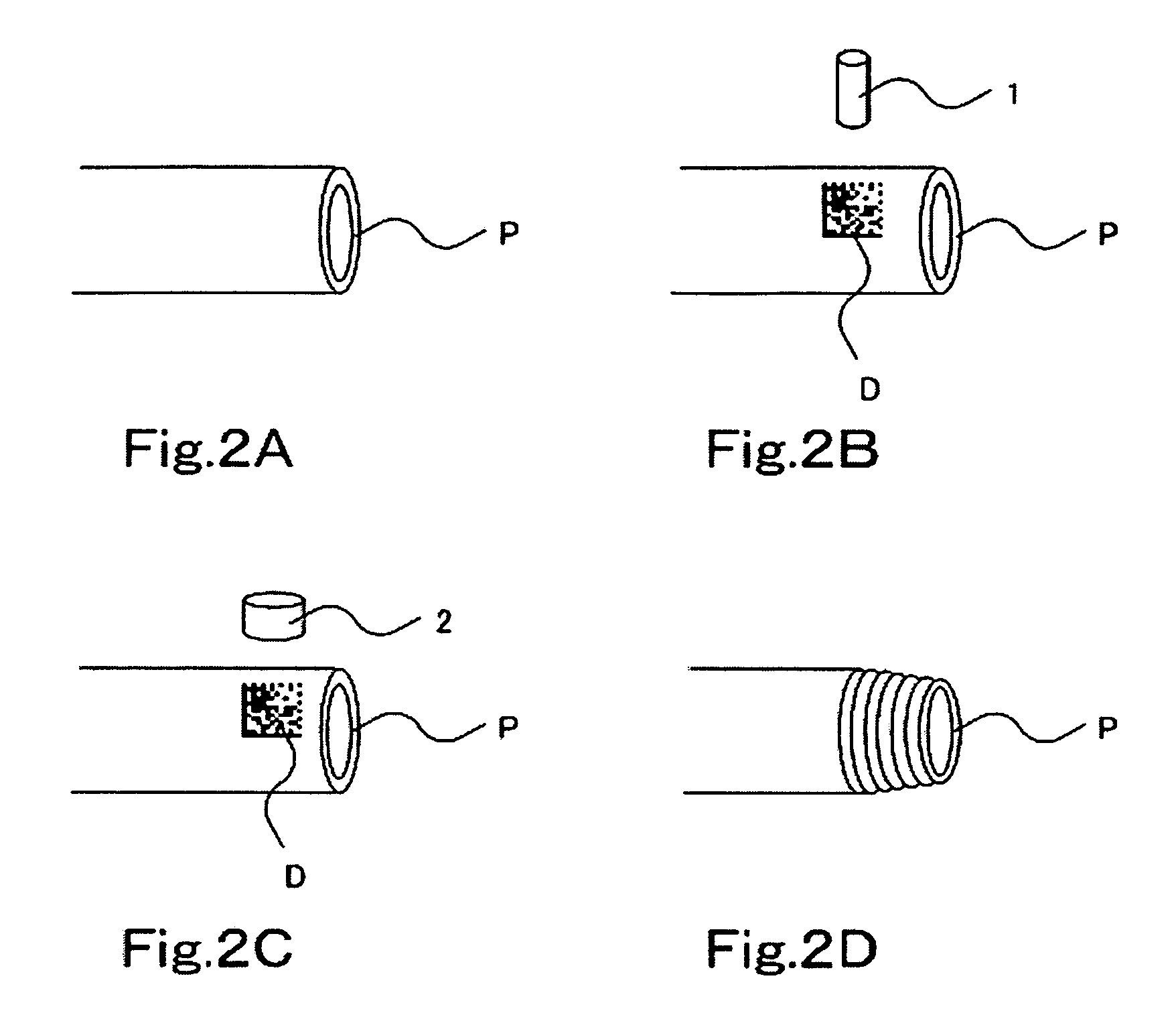

Method and Apparatus for Managing Production History Information of Pipe or Tube and Method for Producing Pipe or Tube Therewith

ActiveUS20090216361A1Risk of errorSolve not working properlyProgramme controlWood turning toolsMachiningInformation management

The production history information management apparatus 100 comprises: machining means 1 for machining an identifier for identifying a pipe or tube in a region of the pipe or tube on which thread cutting is to be performed before an initial production process is performed among production processes which are management targets of the production history information; reading means 2 for reading the identifier machined on the pipe or tube before each of the production processes is performed or while each of the production processes is performed; management means 3 for storing the production history information of the pipe or tube obtained in each of the production processes and the identifier read with the reading means from the pipe or tube while the production history information and the identifier are associated with each other; and thread cutting means 4 for removing the identifier machined on the pipe or tube in the process of performing the thread cutting on the end portions of the pipe or tube among the production processes which are management targets of the production history information.

Owner:NIPPON STEEL CORP

Computerized process to, for example, automate the home sale, mortgage loan financing and settlement process, and the home mortgage loan refinancing and settlement processes

ActiveUSRE47762E1Generate priceFair priceDiscounts/incentivesFinanceService provisionBusiness process

In some embodiments, a comprehensive computer system and method (See FIGS. 1, 1a, 2) for automating and facilitating the performing and processing of tasks, information transfer, and information storage associated with the home sale (See FIG. 3a), mortgage origination (See FIG. 3b), and settlement process (See FIG. 3c), and the home mortgage refinancing origination and settlement process (See FIGS. 1b, 1c, 2a) (or performing other business processes), over a distributed computing network are disclosed. One aspect of the invention is a greatly simplified process for a home buyer to search for a home and simultaneously receive accurate and competitive bids for mortgages and services from multiple lenders and service providers. The process includes an automated under-writing process which generates complete, accurate information on the costs of buying and owning a home at very beginning of the home buying process. Another aspect of the invention is greatly automating the entire sale, loan and settlement process.

Owner:THOMAS NEIL

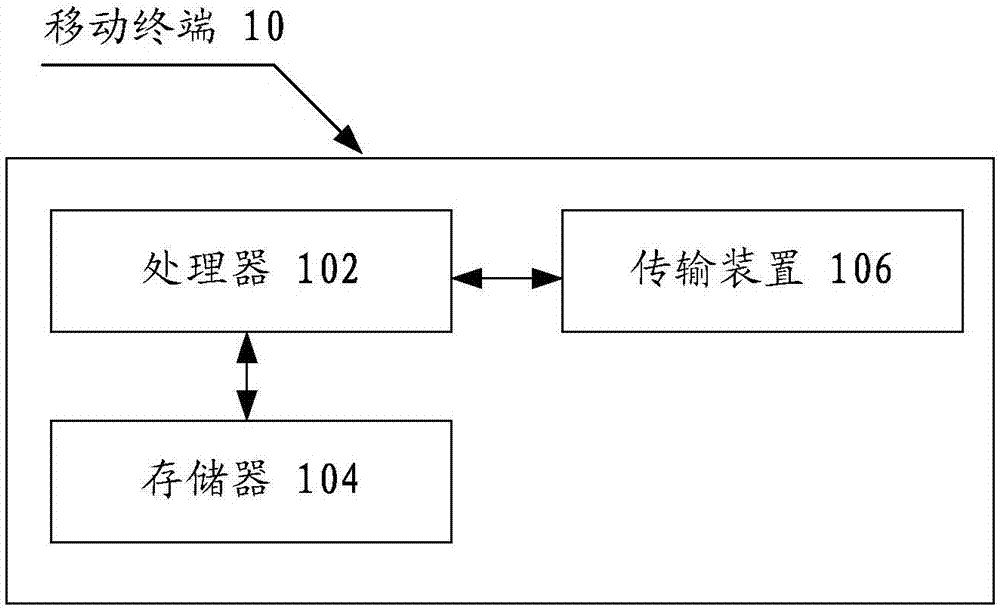

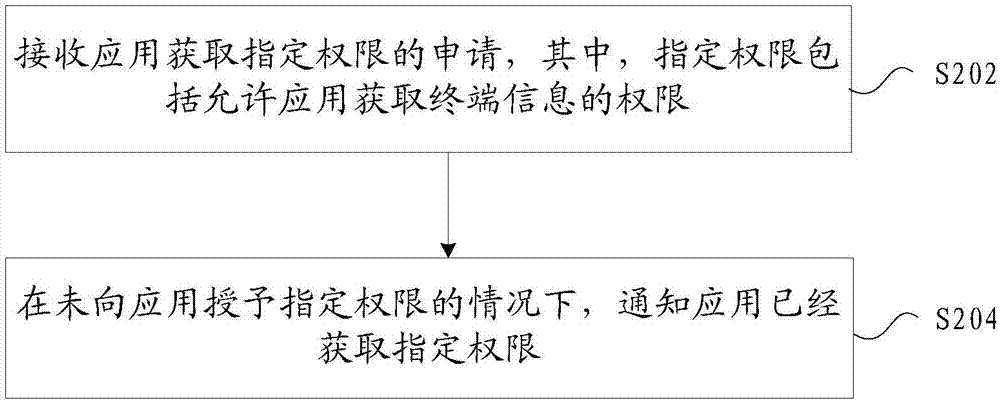

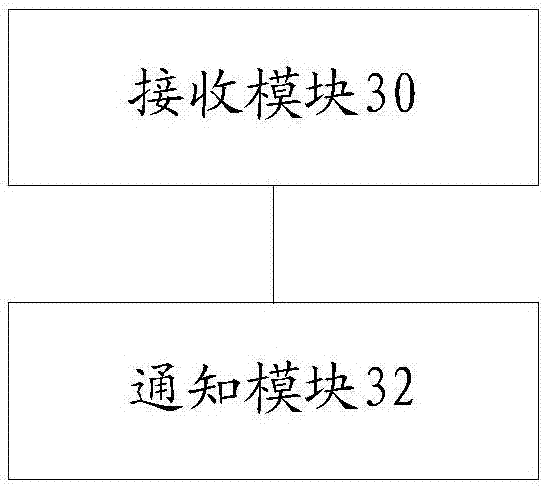

Authority management method and apparatus, and terminal

Owner:ZTE CORP

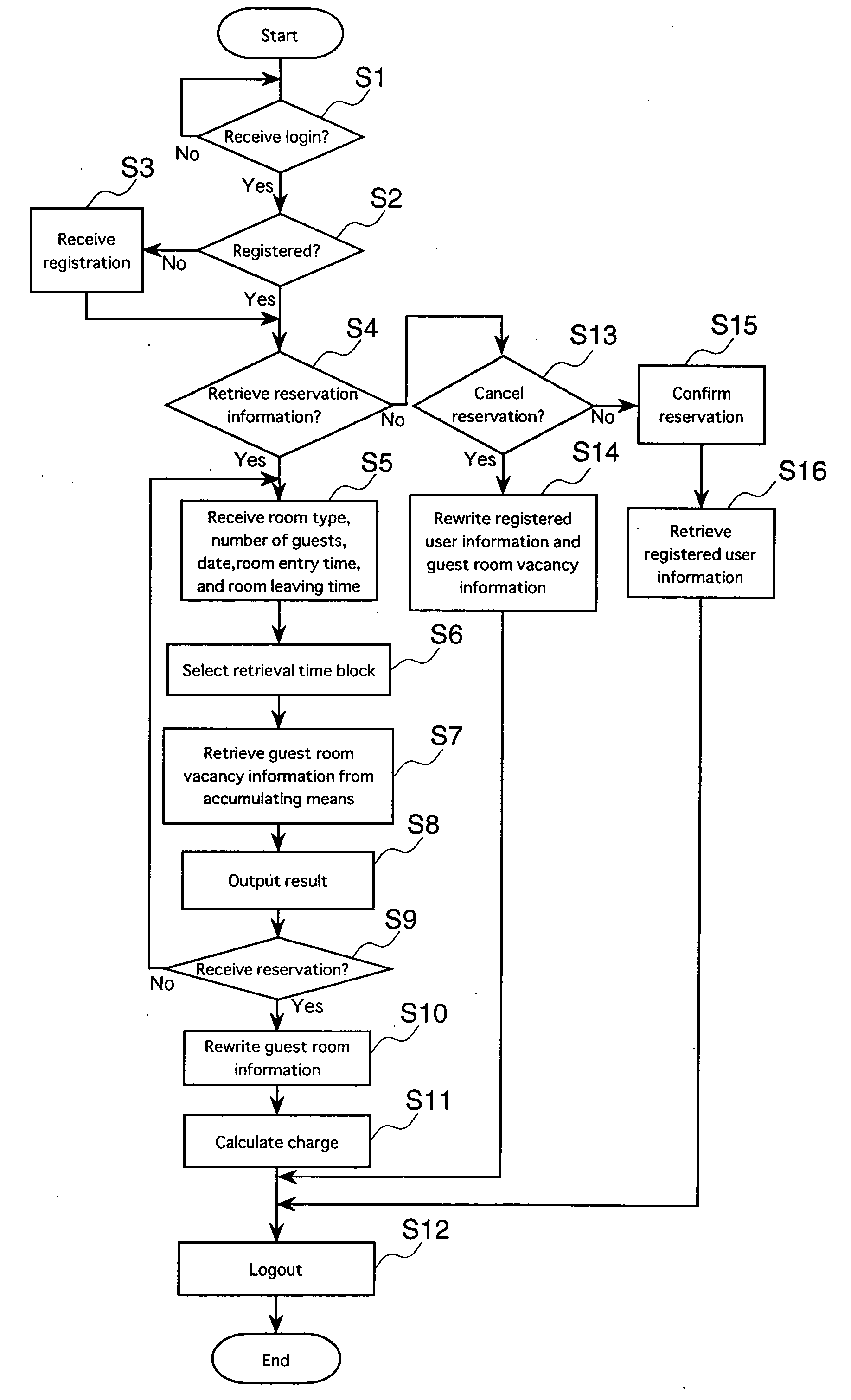

Hotel facility reservation status retrieving device and method and recording medium

InactiveUS20050021379A1Obtain sense of easeSolve not working properlyReservationsBuying/selling/leasing transactionsEntry timeComputer science

Guest room vacancy information 221d is stored by guest room information storing means 30, corresponding to respective time blocks 221c obtained by dividing 24 hours, and an input of a room entry time and a room leaving time which an accommodation user desires is received by input receiving means 10. Then, using vacancy information retrieving means 20, the guest room vacancy information 221d corresponding to a room entry time block including the room entry time received by the input receiving means 10, and the guest room vacancy information 221d corresponding to a room leaving time block including the room leaving time received by the input receiving means 10 are retrieved from the guest room information storing means 30 to output a retrieval result obtained by the retrieval, by output means 40.

Owner:ISHIBASHI

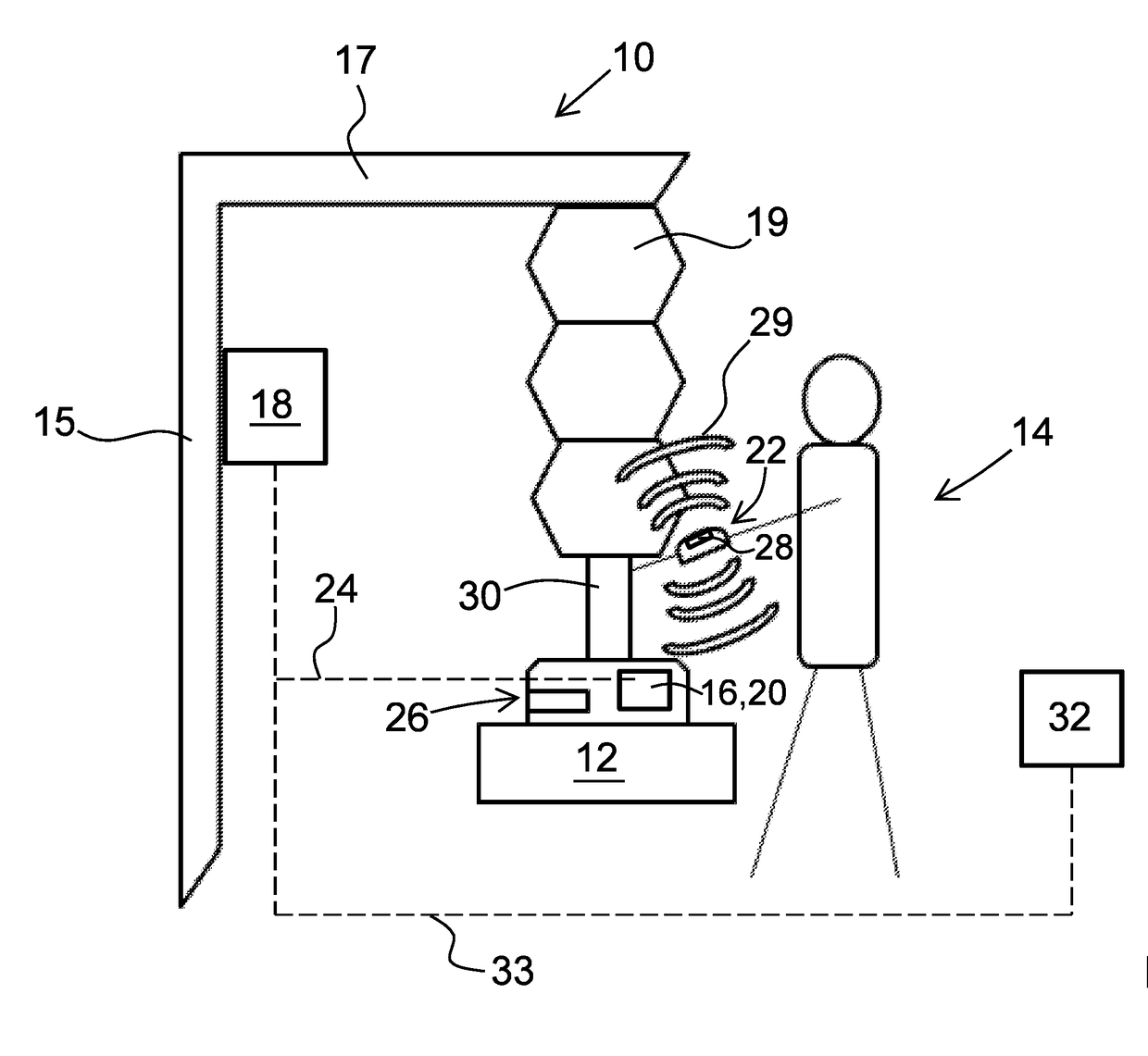

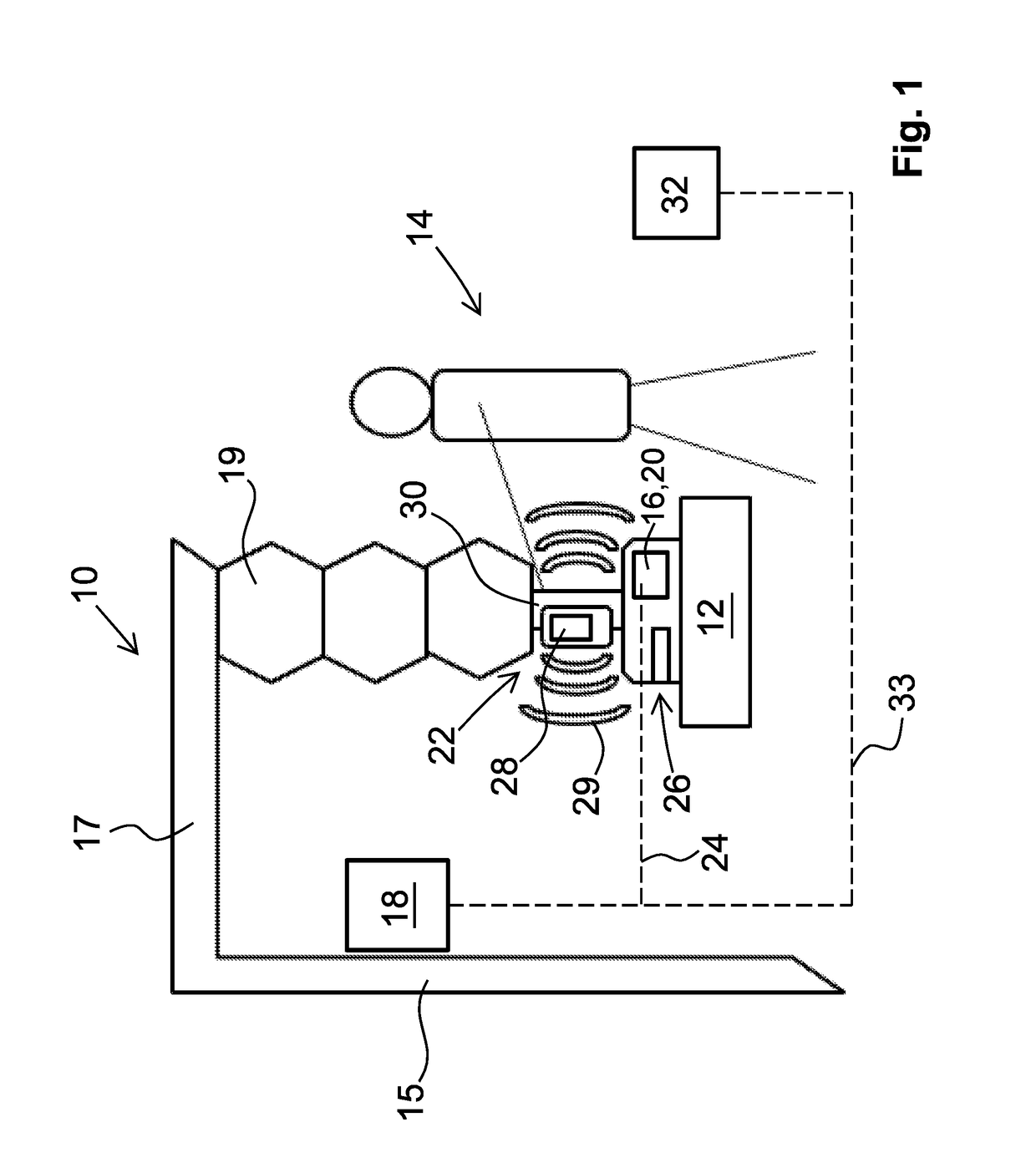

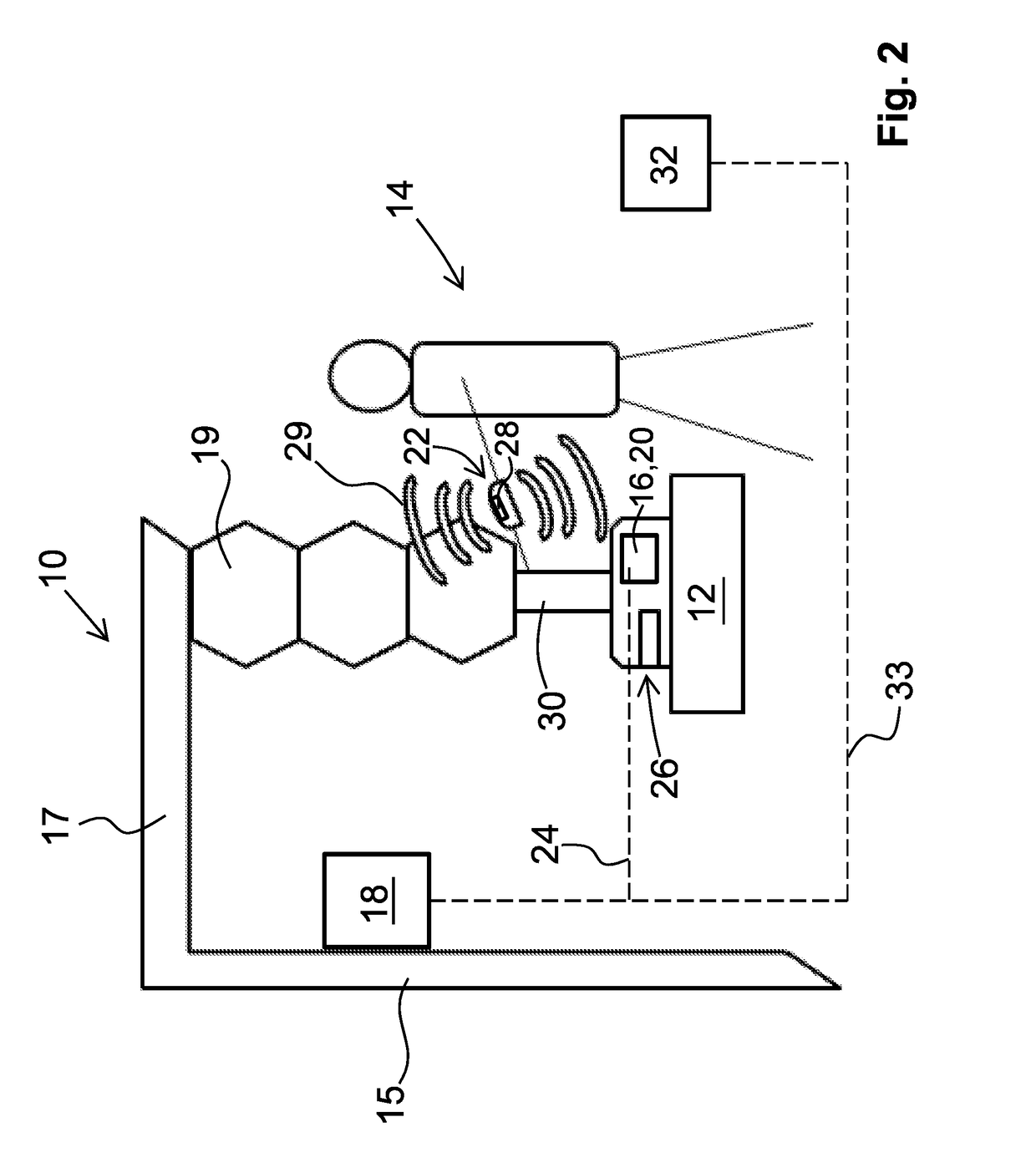

Handling Device And Method For Operating A Handling Device

InactiveUS20180218585A1Easy to handleAccurate processingProgramme-controlled manipulatorPortable liftingEngineering

Owner:J SCHMALZ GMBH

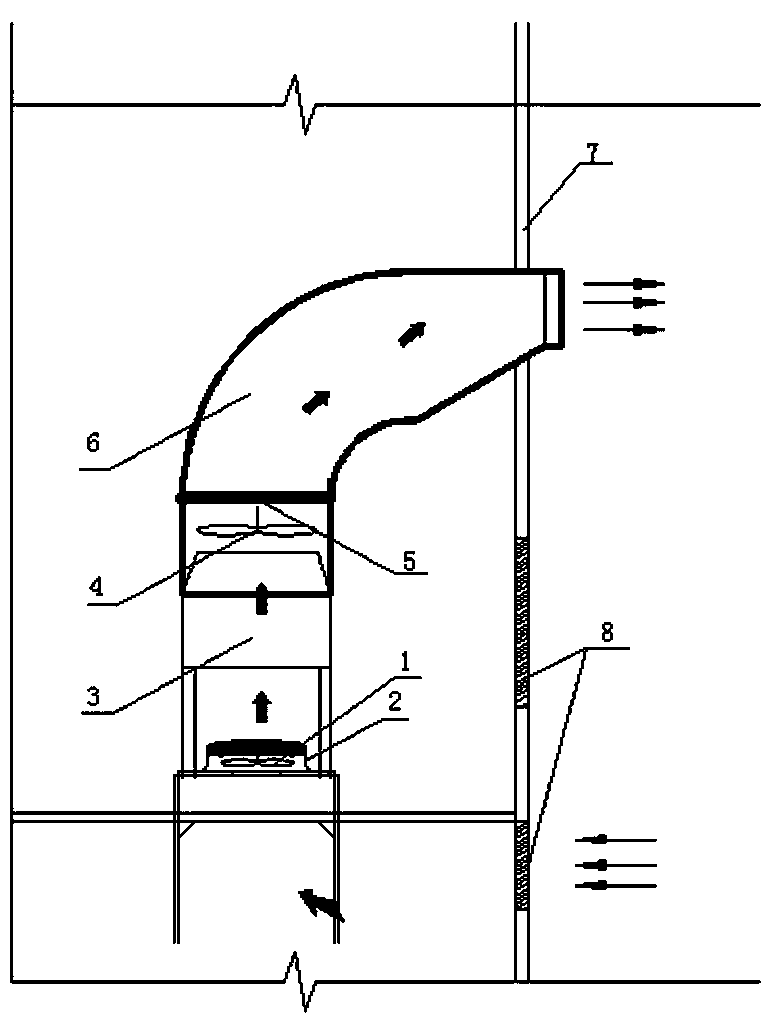

Control method for heat dissipation device of outdoor unit mounted indoors and air conditioner

InactiveCN109812876ASolve not working properlyImprove year-round energy efficiencyMechanical apparatusSpace heating and ventilation safety systemsEngineeringGuide tube

The invention discloses a control method for a heat dissipation device of an outdoor unit mounted indoors and an air conditioner. According to the control method for the heat dissipation device of theoutdoor unit, the heat dissipation device comprises an air guide tube connected with a fan of the outdoor unit, and an induced draft fan. The control method comprises the following steps: obtaining values of operation parameters of the outdoor unit, and comparing the values with corresponding preset values; and controlling the operation of the induced draft fan according to the compared results.The control method can effectively solve the heat dissipation problem when the outdoor unit is mounted indoors.

Owner:GREE ELECTRIC APPLIANCES INC

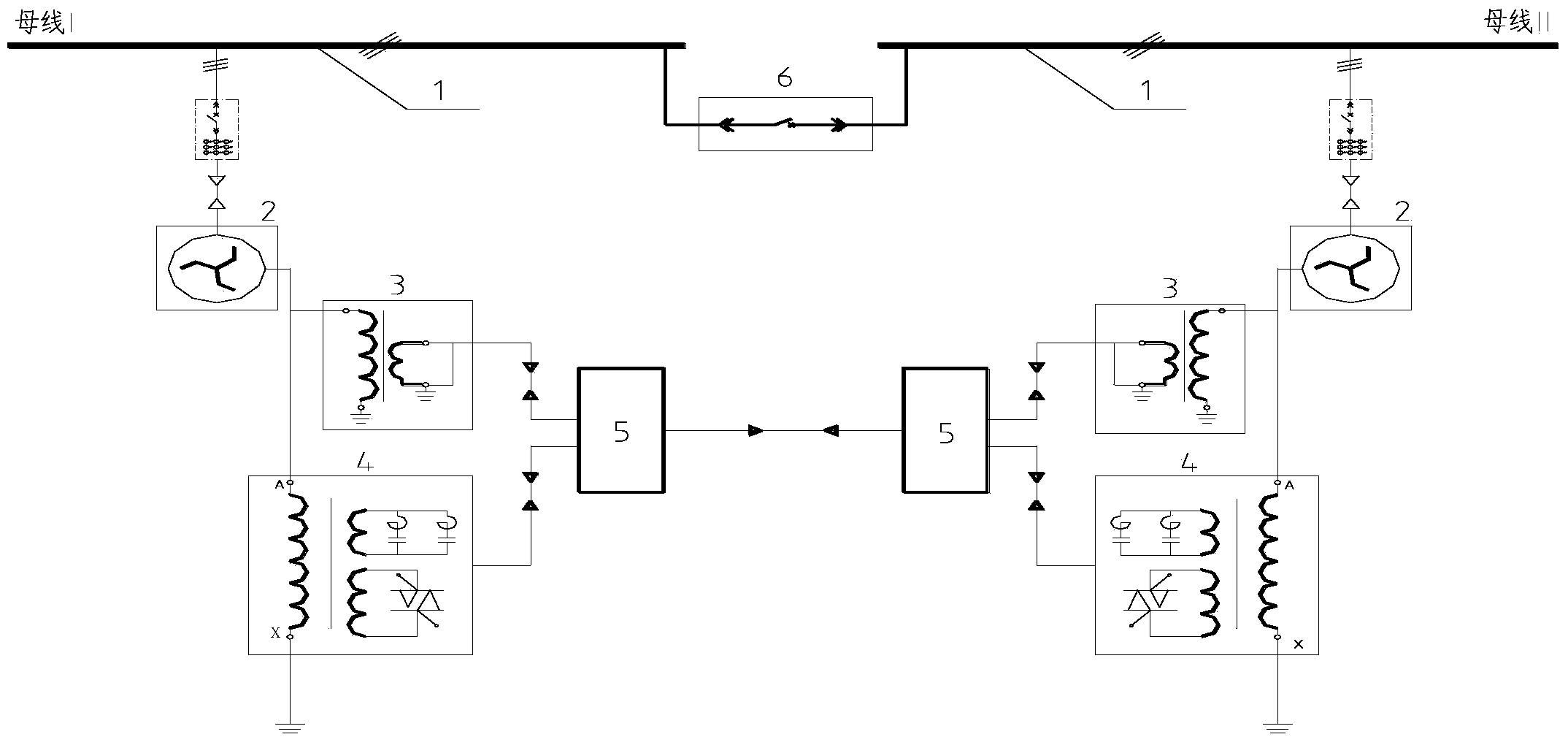

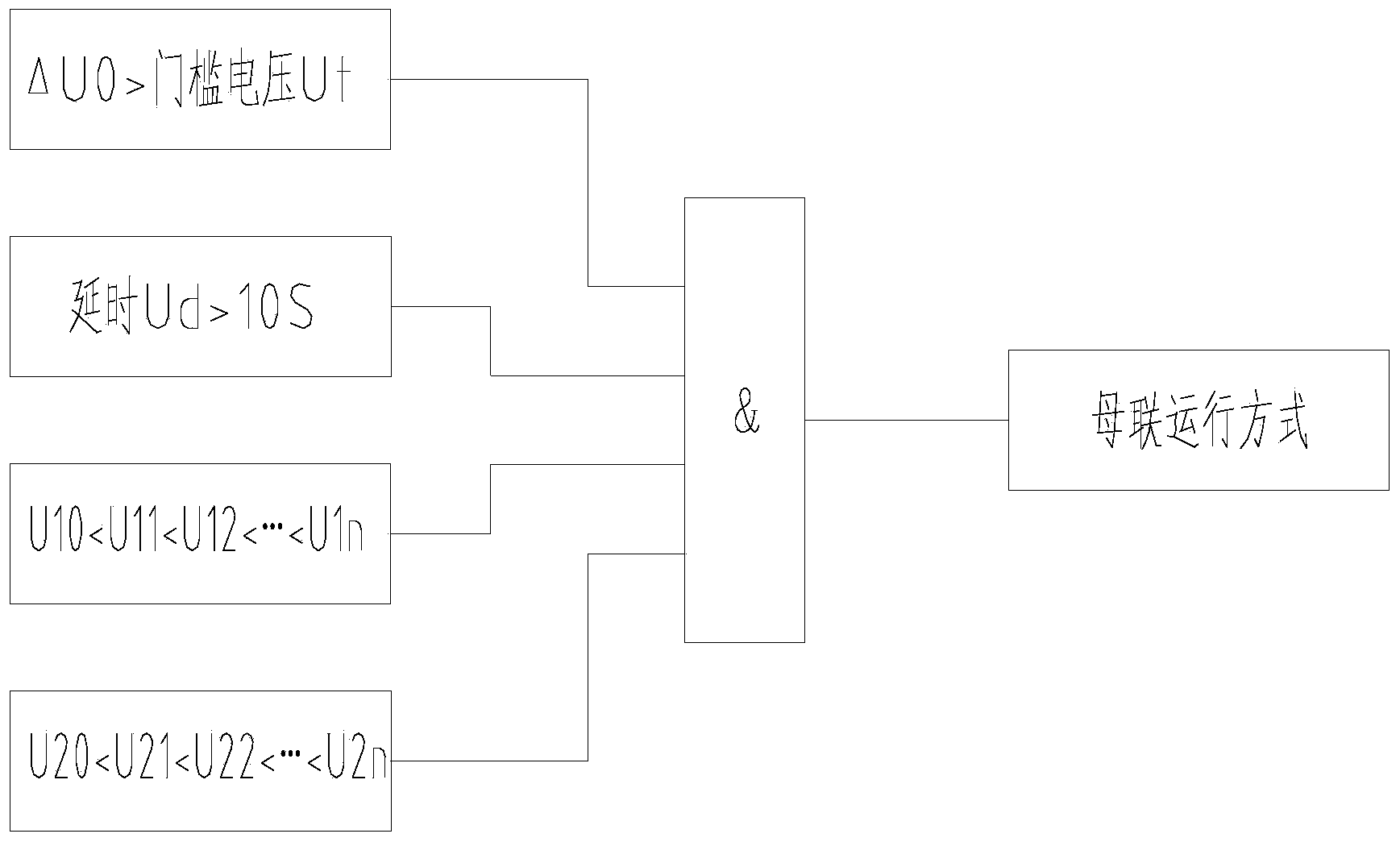

Method for automatically and parallelly operating phase-control arc suppression coils

ActiveCN104362609AAvoid misjudgmentReduce manufacturing costEmergency protective arrangements for limiting excess voltage/currentCapacitive currentCapacitance

The invention relates to a method for automatically and parallelly operating phase-control arc suppression coils. Software functional modules are arranged in an arc suppression coil controller, so that the method can be implemented. The method includes implementation steps of continuously adjusting an angle of a silicon-controlled rectifier of a phase-control arc suppression coil; synchronously detecting change of zero-sequence voltages of neutral points of the other arc suppression coil and identifying operating states of the two arc suppression coils by the aid of the software functional modules of the controller; distributing compensating capacitive currents for the various arc suppression coils by the aid of set distributing principles according to the operating states. The method has the advantages that the requirement that bus tie contact signals need to be acquired from bus tie switch cabinets when the traditional arc suppression coils are parallelly operated can be omitted, electric characteristics of the phase-control arc suppression coils are sufficiently utilized and are combined with software analysis and computation, and accordingly automatic parallel operating functions can be realized.

Owner:XUJI GRP +2

Coaxial connector

ActiveUS8323054B2Increase powerSolve not working properlyElectrically conductive connectionsCoupling device detailsCoaxial cableElectrical conductor

Owner:GV TECH

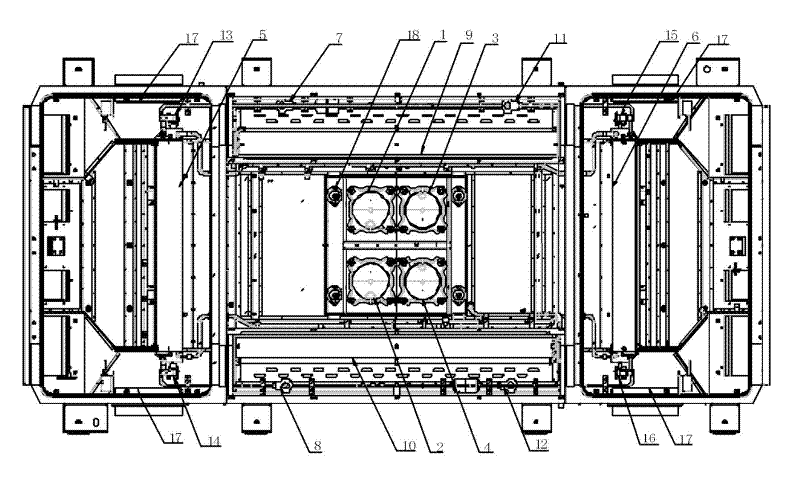

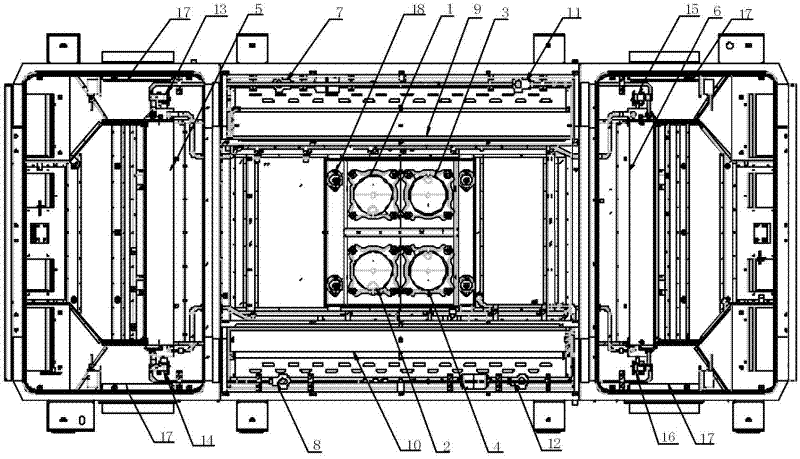

Energy-saving high-temperature-resistant subway train air conditioning

InactiveCN102211591AReduce the number of starts and stopsImprove protectionRailway heating/coolingCompression machines with several condensersSolenoid valveEngineering

The invention discloses an energy-saving high-temperature-resistant subway train air conditioning. The energy-saving high-temperature-resistant subway train air conditioning is structurally characterized in that: under the condition of not changing the size of the subway train air conditioning, four scroll compressors, an R134a refrigeration agent, two sets of double-loop evaporators, two sets ofdouble-loop condensers, four expansion valves, four solenoid valves and related refrigeration accessories are adopted; the four scroll compressors are rigidly connected with a base plate; then the four scroll compressors and the base plate are arranged on a bottom plate of the air conditioning through four shock absorber assemblies; and the four scroll compressors are set to be four independent loops, and can be subjected to temperature adjustment according to 25 percent, 50 percent, 75 percent and 100 percent of the load of a coach; and a new ventilation door structure under infinitely variable control is arranged on a new air inlet. The invention has the advantages that: the energy-saving high-temperature-resistant subway train air conditioning has low using cost, and can perform four-gear temperature adjustment, the compressors are protected, the power consumption is reduced, the problem that the subway train air conditioning cannot run at the high temperature of more than 46 DEG Cis solved, new air is adjusted effectively to save energy, and the whole shock absorption effect is good.

Owner:上海松芝轨道车辆空调有限公司 +1

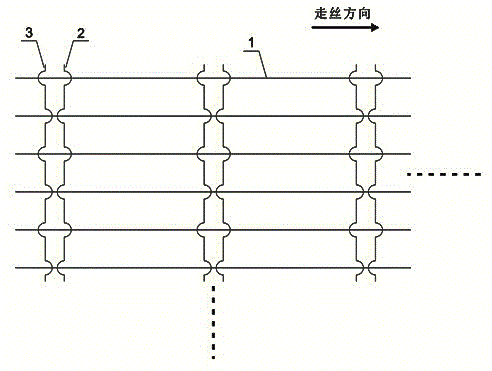

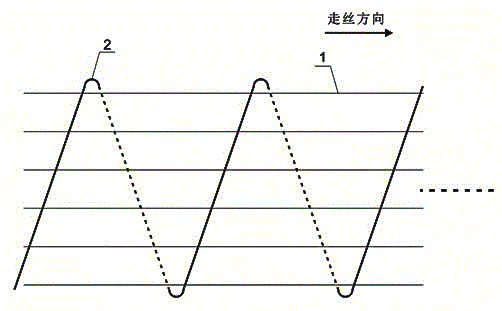

Production technology of carbon filament beating-up

InactiveCN105483896AImprove operabilityReduce lossesLoomsFibre chemical featuresPolymer chemistryEngineering

The invention relates to a production technology of carbon filament beating-up. The production technology comprises the following steps that 1, PAN protofilaments are divided into an upper layer and a lower layer, namely, the PAN protofilament layer containing singular numbers of the protofilaments and the PAN protofilament layer containing even numbers of the protofilaments according to the singular numbers and even numbers through a beating-up machine heald frame; 2, carbon fiber filaments or a weft storage mechanism with the carbon fiber filaments penetrates through openings of the upper layer and lower layer of the PAN protofilaments to make the carbon fiber filaments and the PAN protofilaments woven together; 3, the upper position and the lower position of the heald frame are exchanged, and then the positions of the upper layer PAN protofilaments and the lower layer PAN protofilaments are exchanged; 4, the carbon fiber filaments penetrate through the opening to be woven together with the PAN protofilaments. According to the production technology of carbon filament beating-up, the carbon fiber filaments and the PAN protofilaments are woven together, the problems that due to the fact that the property of the protofilaments is unstable and operation of equipment is unstable, when partial PAN protofilaments are broken, the PAN protofilaments are scattered in the equipment, or due to the fact that the manufacturing precision of the equipment is insufficient, the PAN protofilaments are overlapped, a fire or even an explosion is caused, and the carbon fiber filaments cannot operate normally are solved, the operability during filament breaking is improved, losses are reduced, and personnel safety is improved.

Owner:ZHEJIANG JINGGONG SCI & TECH

Liquid crystal display device having column spacers and first auxiliary spacers that include a plurality of spaced apart patterns

A liquid crystal display device includes first and second substrates spaced apart from each other, on which a display area and a non-display area are defined, a liquid crystal layer interposed between the first and second substrates, a seal pattern in the non-display area between the first and second substrates, a driver in the non-display area on the first substrate, column spacers in the display area between the first and second substrates, and a first auxiliary spacer between the driver and the second substrate.

Owner:LG DISPLAY CO LTD

Window covering cutting machine

ActiveUS8720313B2Solve not working properlyDoor/window protective devicesStock shearing machinesMechanical engineeringWindow covering

A window covering cutting machine is disclosed that has a support table, a cutting mechanism adjacent the support table and a plurality of moveable stops moveably connected to at least one of the cutting mechanism and the support table. The support table has a surface on which at least a portion of a window covering work piece can be placed. The cutting mechanism has a housing with a plurality of openings sized to receive at least a portion of a window covering work piece. The cutting mechanism also has at least one cutting device configured to cut portions of a window covering that extend through any of the openings. One stop is aligned with each opening and is independently moveable relative to the housing and the other stops.

Owner:LUMINO

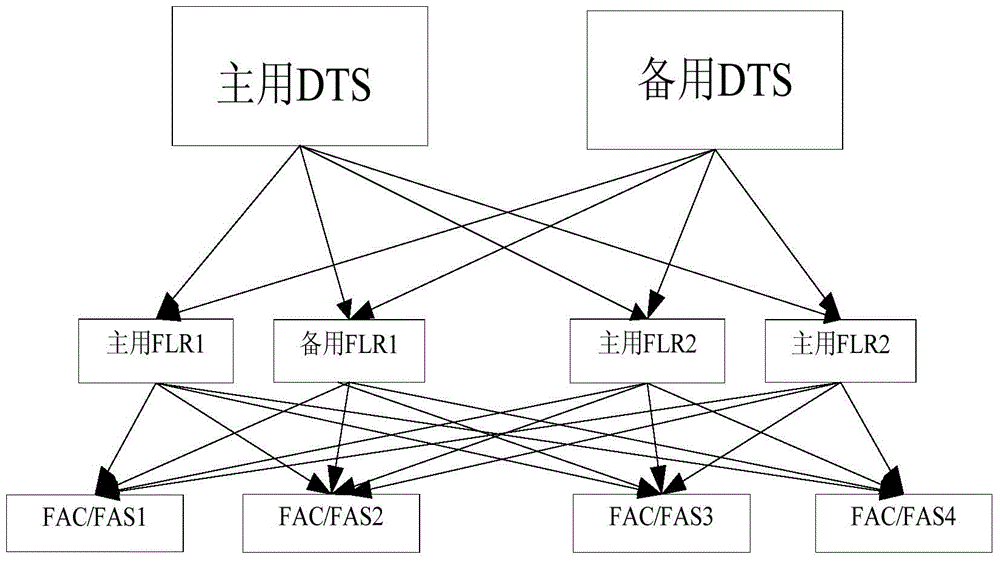

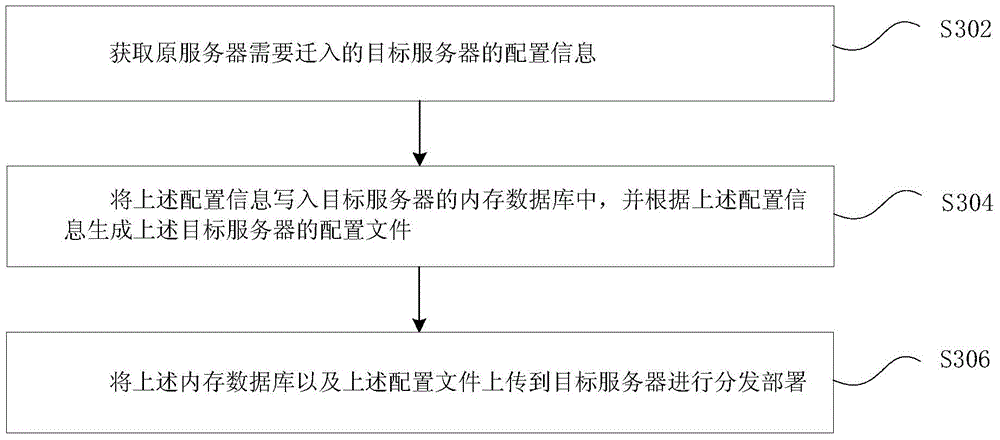

Migration processing method and device of metadata server

ActiveCN104615598ASolve not working properlyReduce mistakesProgram controlTransmissionIn-memory databaseData library

Provided are a metadata server migration processing method and device, the method comprising: obtaining the configuration information of a target server that an original server is to be migrated to; writing the configuration information into an in-memory database of the target server, and generating a configuration file of the target server according to the configuration information; uploading the in-memory database and the configuration file to the target server for distributed deployment. The technical solution of the present invention prevents abnormal service operation caused by the damage to or the location change of the metadata server, significantly reduces manual operation errors and decreases the time for migration, thus improving migration efficiency.

Owner:NANJING ZHONGXING XIN SOFTWARE CO LTD

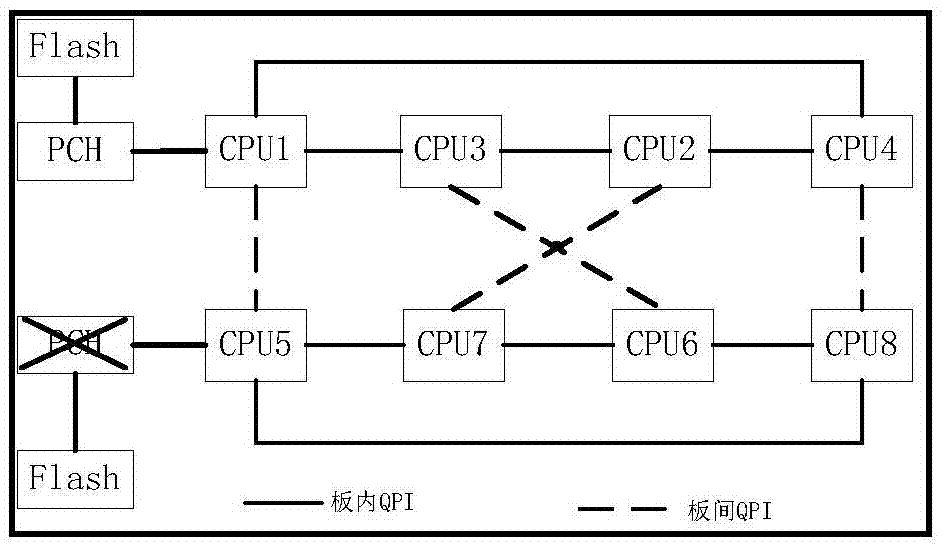

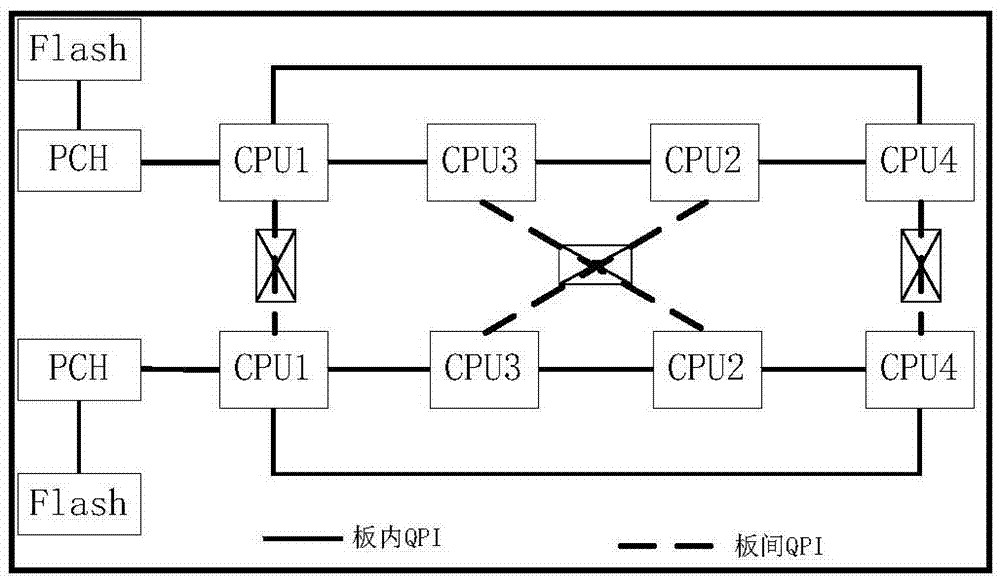

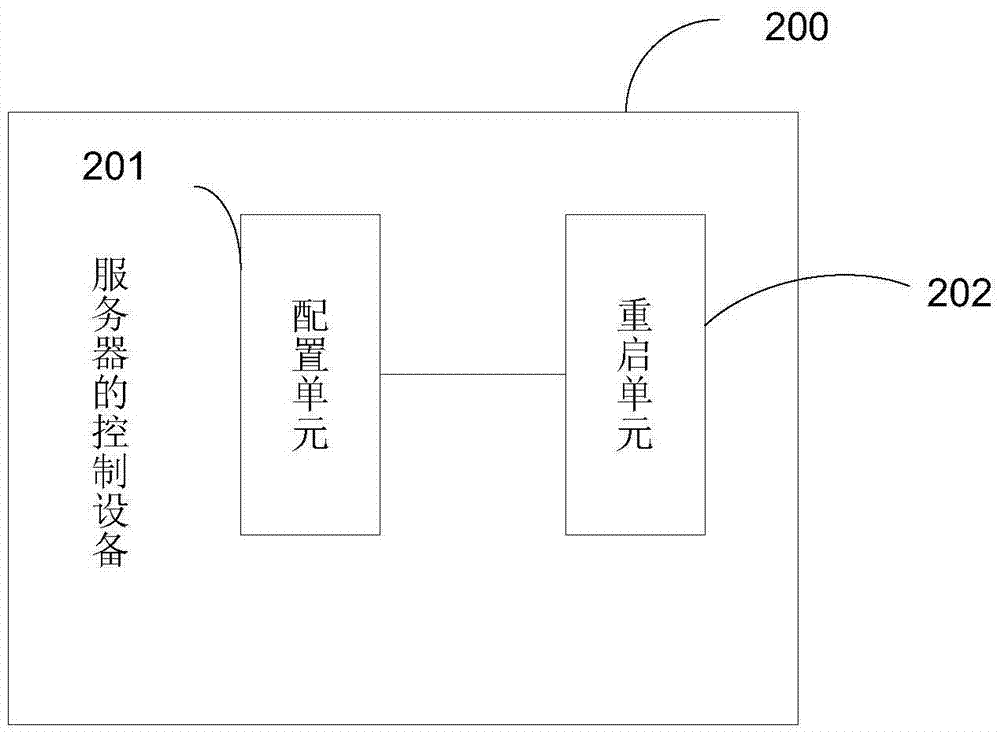

Control method and control equipment of server

ActiveCN105446833ACPU boostGuaranteed uptimeRedundant operation error correctionPlatform Controller HubDependability

The embodiment of the invention provides a control method and control equipment of a server so as to solve the problem in the prior art that service interruption is caused due to the exceptional startup of the server. The control method and the control equipment of the server of the embodiment are characterized in that a master CPU (Central Processing Unit) is reconfigured when the server is subjected to the exceptional startup due to the exception of the master CPU, PCH (Platform Controller Hub) connected with the CPU or Flash connected with the PCH connected with the master CPU. When the exceptional startup is in the presence in the server which supports hard partitioning, the server still can be guaranteed to be normally started and operated so as to improve the reliability and the stability of the server, the RAS (Reliability, Availability and Serviceability) of the whole server is improved, meanwhile, the problem that the system can not operate due to Flash exception can be solved, an original BIOS (Basic Input / Output System) design way is not used, and the cost of the Flash chip of the server is saved.

Owner:XFUSION DIGITAL TECH CO LTD

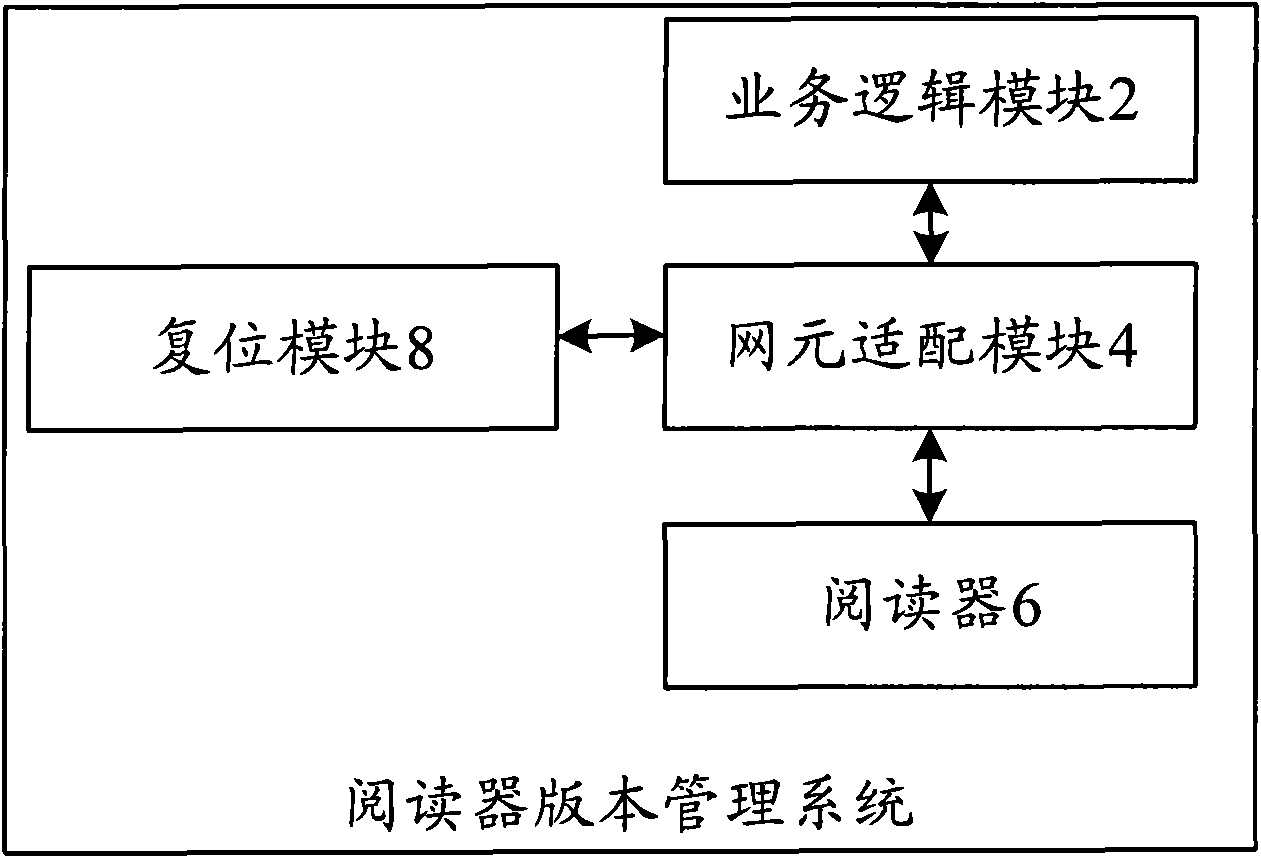

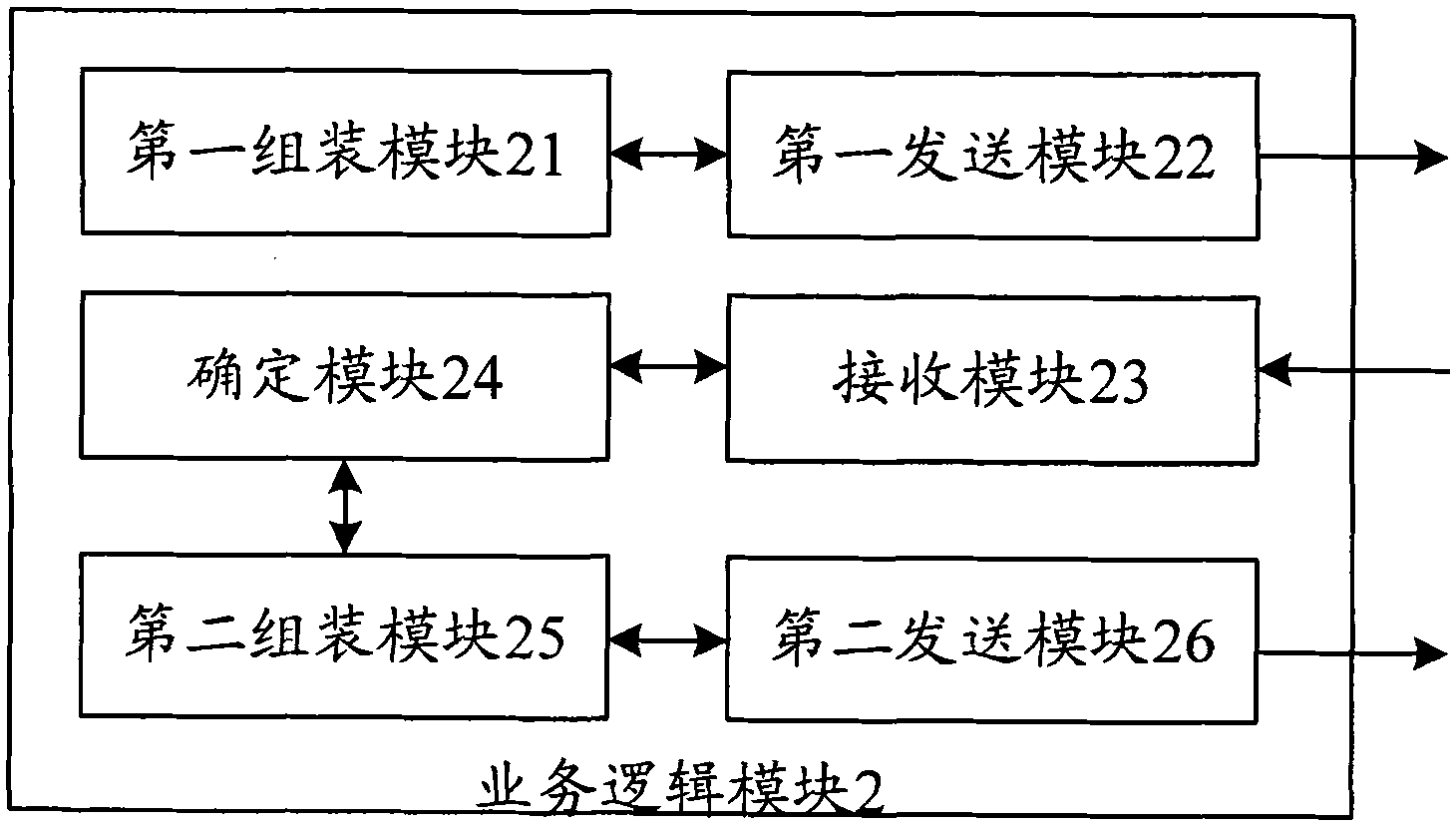

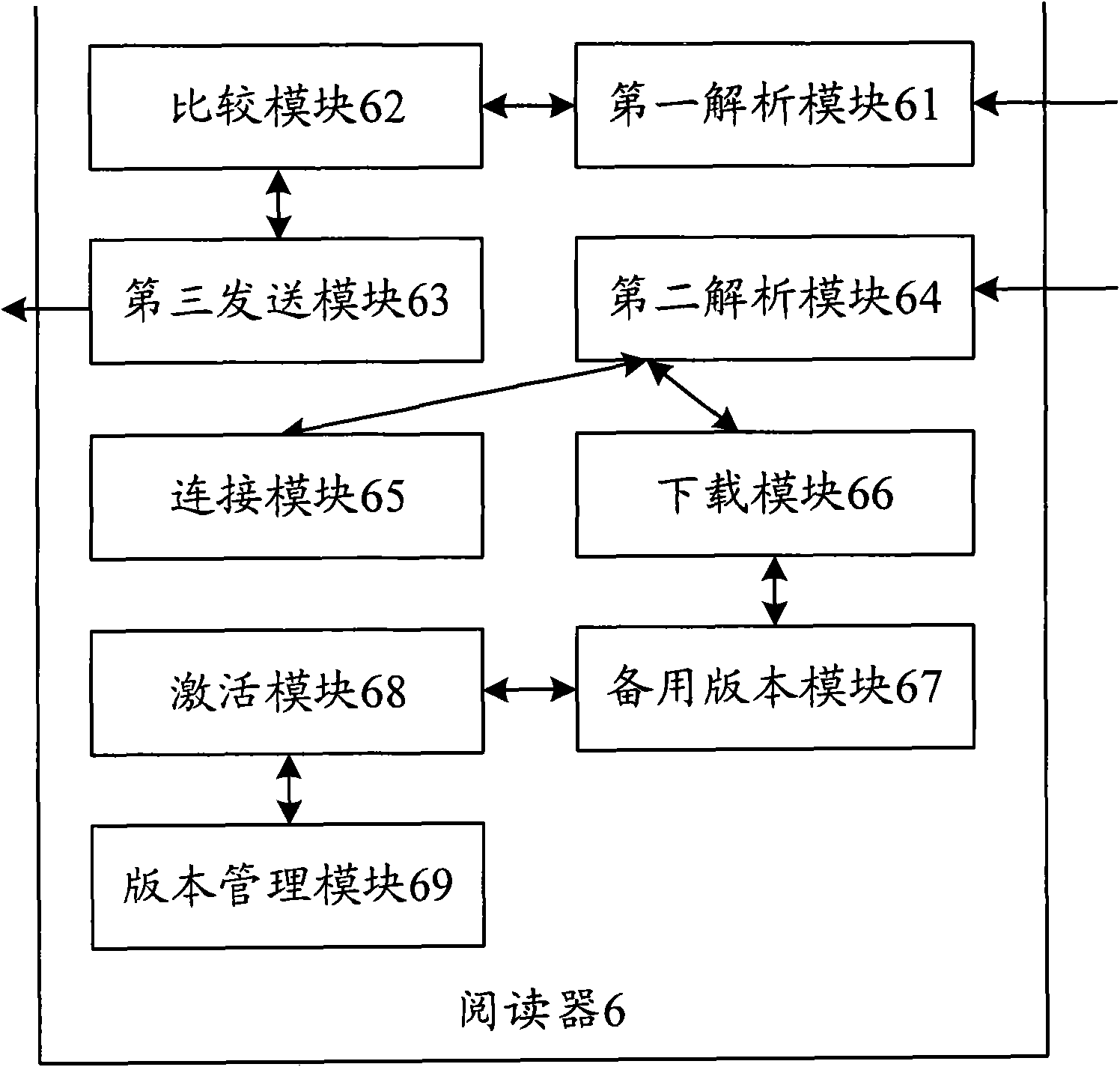

Version management system, returning system, returning method and upgrading method of reader

InactiveCN101826019ASolve not working properlyImprove stabilitySensing record carriersProgram loading/initiatingBusiness logicNetwork element

The invention discloses a version management system, a returning system, a returning method and an upgrading method of a reader. The version management system of the reader comprises a service logic module, a network element adaptive module and a reader, wherein the service logic module is used for assembling a download message according to interface information and transmitting the assembled download message; the network element adaptive module is used for converting the assembled download message transmitted by the service logic module, transmitting the assembled download message to the reader, converting a byte stream transmitted by the reader and transmitting the converted byte stream to the service logic module; and the reader is used for downloading a version file of an upgradind version according to the download message and storing the downloaded version file of the upgrading version in a standby version module as a standby version. With the treatment, the equipment can be automatically switched to another version when the version has the problems and can normally work, thereby improving the stability of the system, the overall performance of the system and the easy maintenance.

Owner:ZTE CORP

Refrigerator defrosting control method and refrigerator

ActiveCN110940138ASolve efficiency problemsResolution timeCorrosion preventionRefrigeration componentsFour-way valveIcebox

The invention discloses a refrigerator defrosting control method and a refrigerator adopting the defrosting control method. According to the defrosting control method, when the refrigerator enters a defrosting mode, the difference value between condensation pressure and evaporation pressure is judged, and when the difference value is larger than or equal to a preset pressure value, a hot air defrosting mode is adopted; and when the difference value is smaller than the preset pressure value, an electric heating defrosting mode is adopted. The problems that a single electric heater defrosting manner is adopted by a traditional air cooling refrigerator, consequently, the defrosting efficiency is low, and the temperature of a freezing chamber is increased again to be high during defrosting aresolved; and meanwhile, the problems that a single hot air defrosting manner is adopted, consequently, when the environment temperature is low, a four-way valve cannot be started, and consequently hotair defrosting cannot run normally are solved.

Owner:GREE ELECTRIC APPLIANCES INC

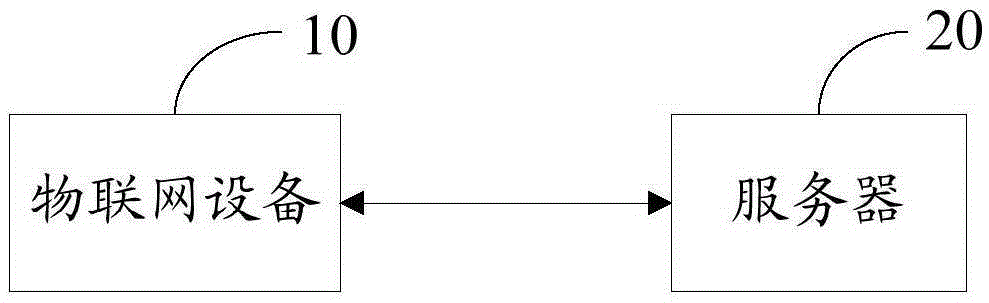

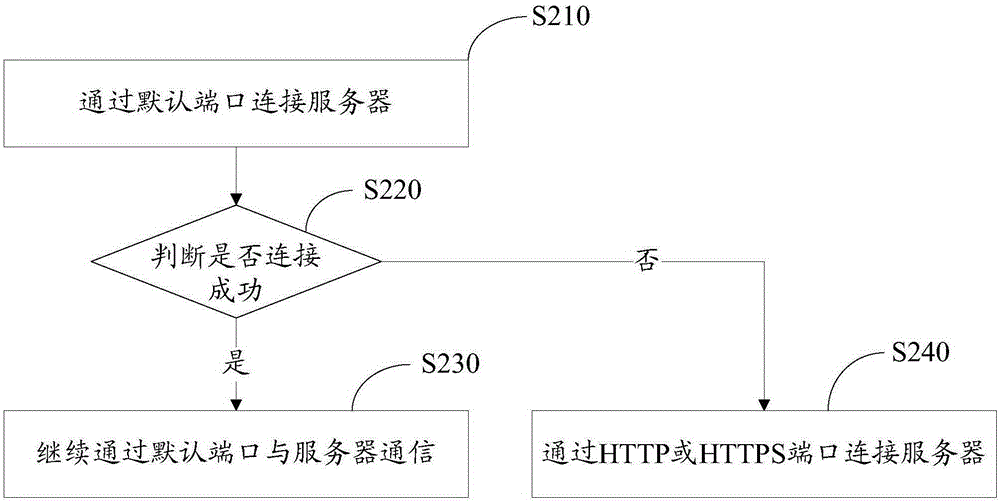

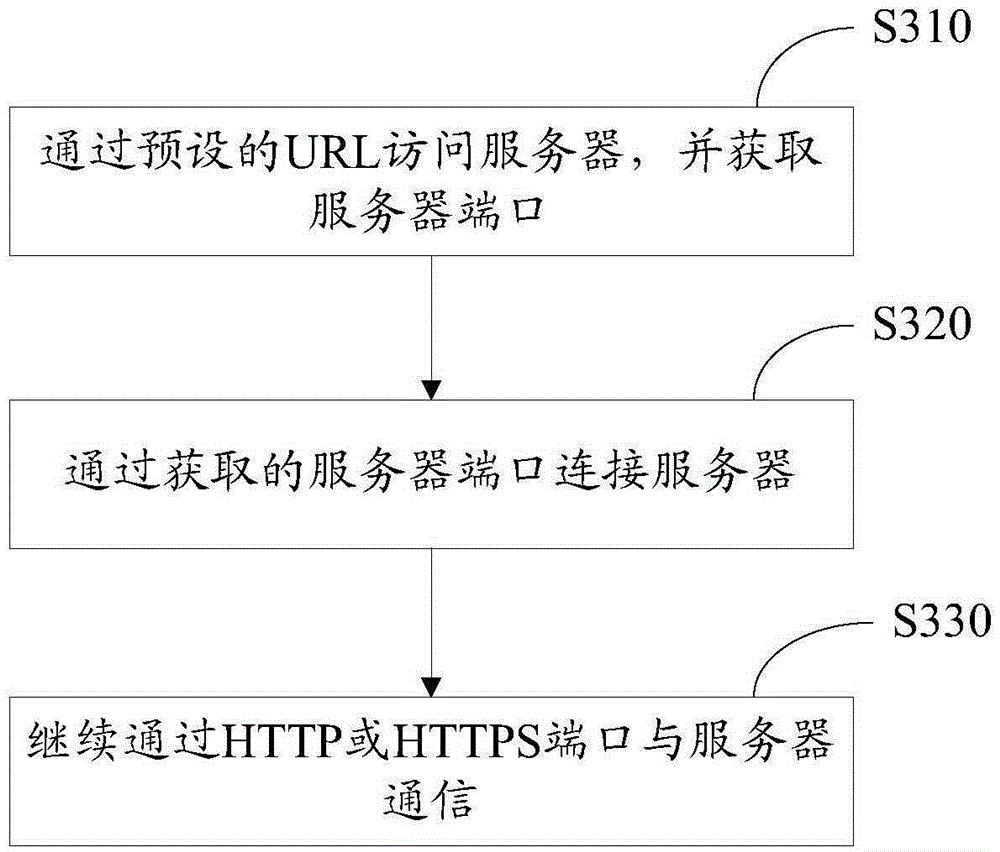

Communication method and system for IOT equipment

InactiveCN105323319ASolve not working properlySolve resource consumptionTransmissionComputer scienceEmbedded system

The invention relates to a communication method and system for IOT equipment. The method comprises the following steps: connecting to a server through a default port; judging whether the connection is successful or not; if so, continuously communicating with the server through the default port; and otherwise, connecting to the server through an HTTP or HTTPS port. The communication method and system for the IOT equipment disclosed by the invention can solve the problem that the IOT equipment cannot be operated normally while being not successfully connected to the server due to the fact that some inactive ports of the server are closed.

Owner:深圳市白泽图腾科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com