Patents

Literature

55results about How to "Satisfy normal use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

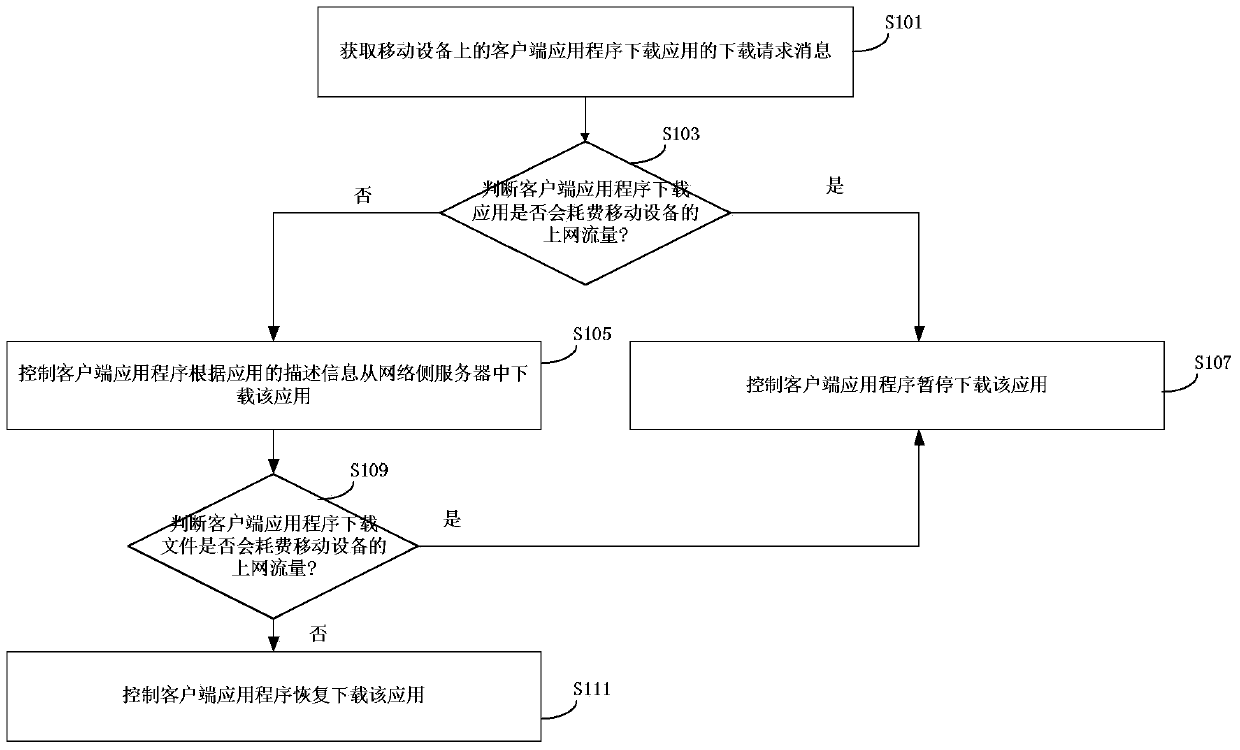

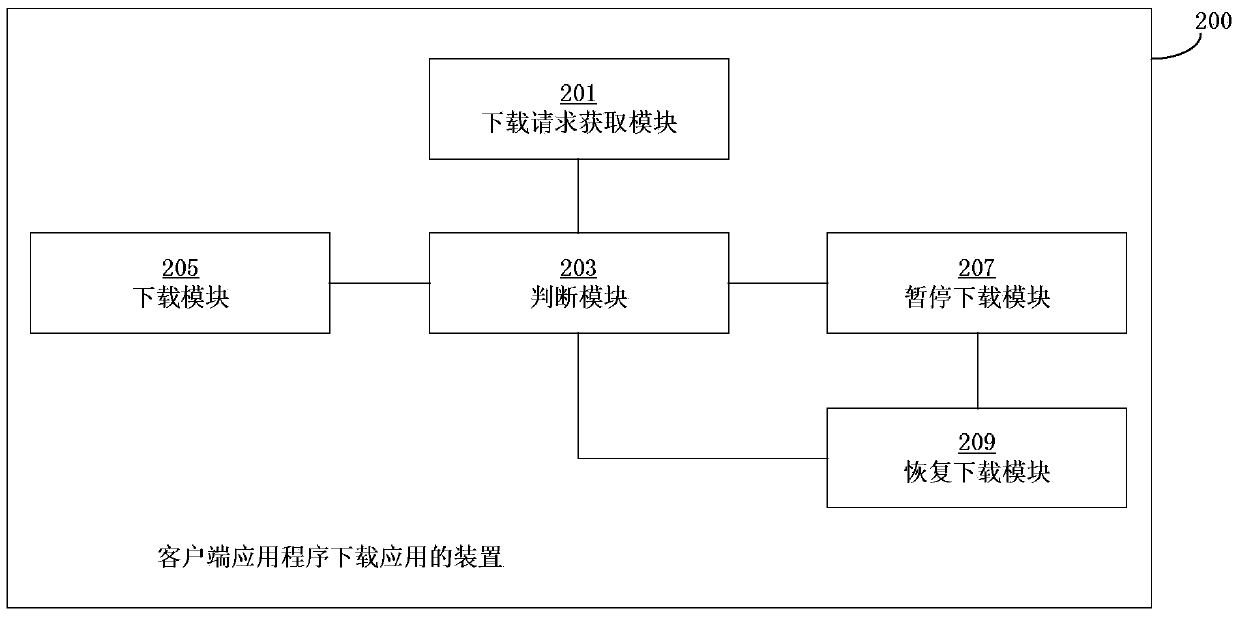

Method and device for downloading application by client end application program

The invention discloses a method and a device for downloading an application by a client end application program. The method comprises the steps of acquiring the downloading request information for downloading the application by the client end application program on mobile equipment, wherein the downloading request information comprises the description information of the application; judging whether the downloading of the application by the client end application program consumes internet flow of the mobile equipment or not; if the downloading of the application by the client end application program does not consume the internet flow of the mobile equipment, downloading the application from a network side server by the client end application program according to the description information of the application; if the downloading of the application by the client end application program consumes the internet flow of the mobile equipment, controlling the client end application program to stop the application downloading temporarily. The internet flow of a user can be effectively saved by the embodiment of the invention.

Owner:BEIJING QIHOO TECH CO LTD +1

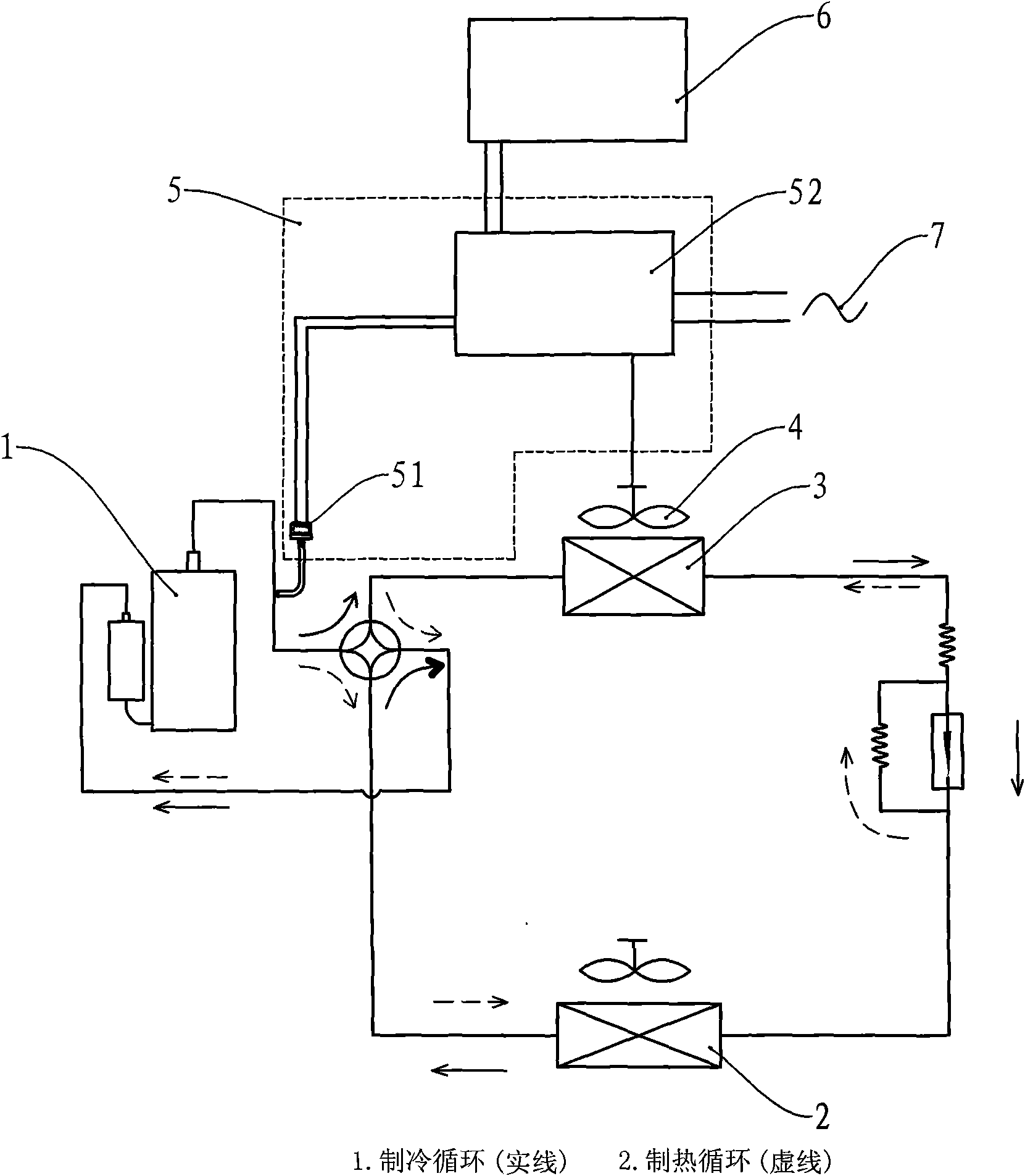

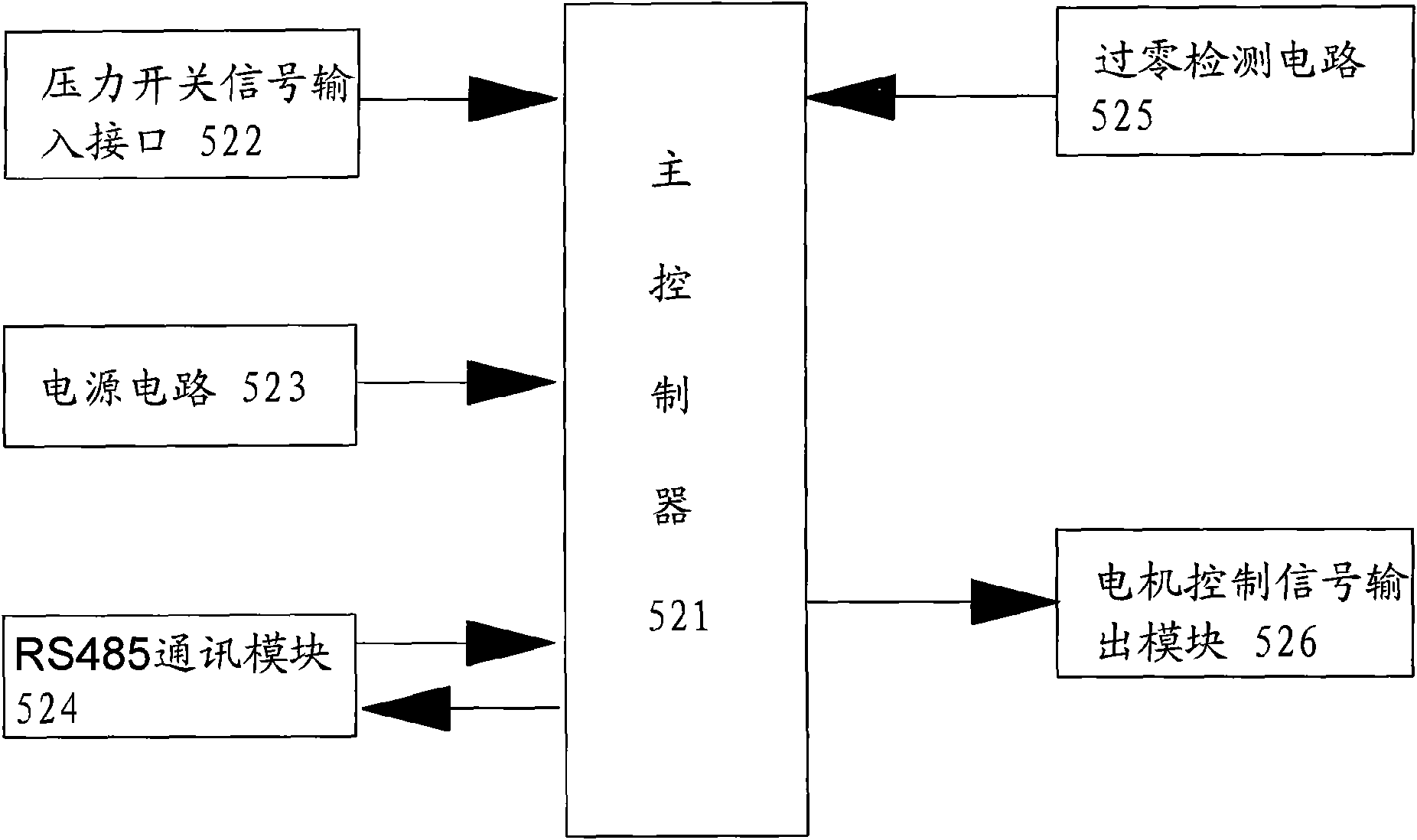

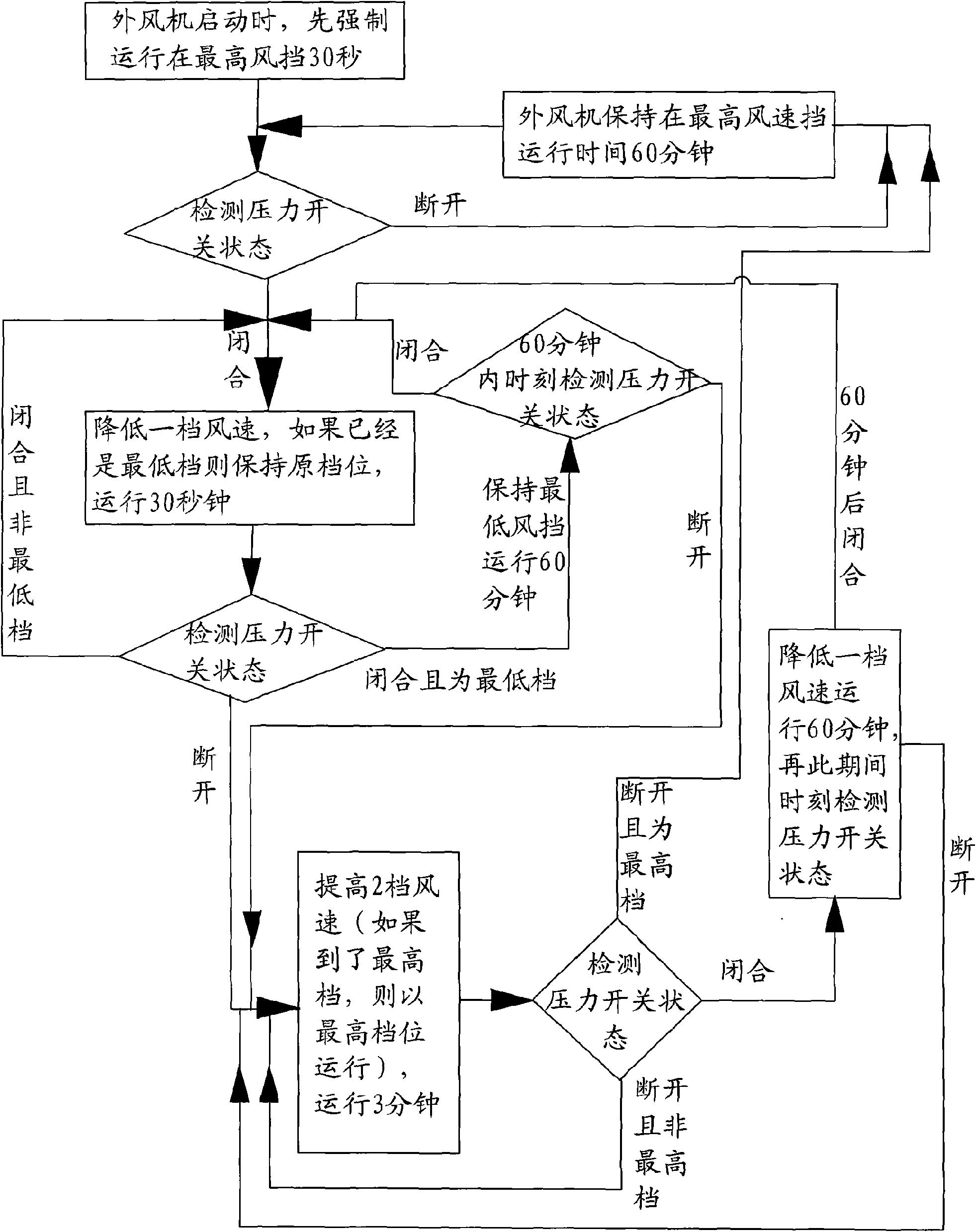

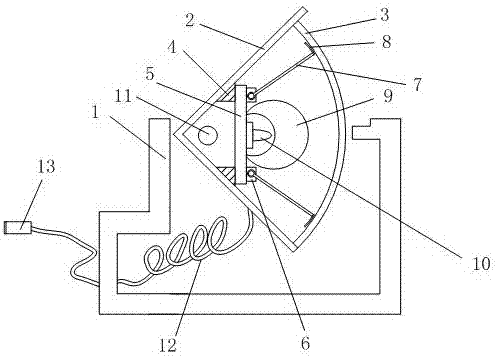

Speed adjusting device, air-conditioning system and speed adjusting method for air-conditioning system

ActiveCN101556069ASpeed reduction or maintenanceLow failure rateSpace heating and ventilation safety systemsLighting and heating apparatusFailure rateElectric machine

The invention relates to a low-temperature speed adjusting device applied to an air-conditioning system and a speed adjusting method for the air-conditioning system, and also relates to the air-conditioning system using the speed adjusting device. The speed adjusting device comprises a pressure switch and a chopped wave speed adjusting plate, wherein the pressure switch is arranged on a gas exhaust pipe of a compressor of the air-conditioning system; the chopped wave speed adjusting plate further comprises a main controller, and a pressure switch signal input interface, a power supply circuit, a 485 communication module, a zero crossing detection circuit and a motor control signal output module, which are connected with the main controller; the chopped wave speed adjusting plate is communicated with an outer machine main board of the air-conditioning system through the 485 communication module and receives state information of the pressure switch through the pressure switch signal input interface; a logical program is stored in the main controller, and controls the rotating speed of an outer blower according to pressure switch signals and running time and running modes of the air-conditioning system; and the power supply circuit is connected with the outer machine main board of the air-conditioning system. The novel low-temperature refrigerating and speed adjusting device has the characteristics of low cost and low failure rate.

Owner:GREE ELECTRIC APPLIANCES INC

Novel phosphorus and magnesium based cement grouting material and preparation method

The invention discloses a novel phosphorus and magnesium based cement grouting material and a preparation method and belongs to the field of technical application of grouting materials. The grouting material is prepared from the following raw materials in parts by weight: a component A: 30 to 90 parts of a compound magnesium compound, 0.5 to 5 parts of a compound retarder, 0.2 to 0.7 part of a water reducer, 0.2 to 1.5 parts of an acid-alkali buffering agent, 1 to 5 parts of a compound stabilizer and 0.5 to 1.5 parts of a compound surfactant; a component B: 20 to 50 parts of phosphate and 0.2to 2 parts of a de-foaming agent. The preparation method comprises the following steps: accurately weighing materials of the component A and the component B according to the ratio and uniformly stirring; mixing with water according to the weight ratio of 100 to (20 to 50) and stirring to form slurry; after uniformly mixing, pressing a mixture into gaps or cracks and curing. The novel phosphorus and magnesium based cement grouting material disclosed by the invention has the beneficial effects of controllable coagulation time, large adjustable range, high early age strength, high bonding strength, good permeability, simplicity and convenience for construction, greenness and environment protection and low cost, and meets the requirements on three properties including injectability, controllability and permeability resistance.

Owner:山东塔罗斯智能装备有限公司

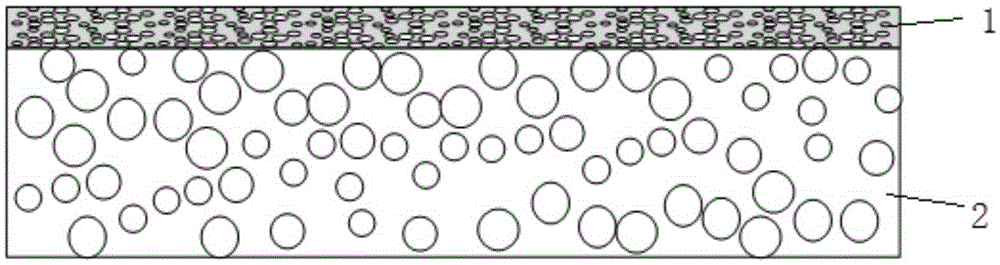

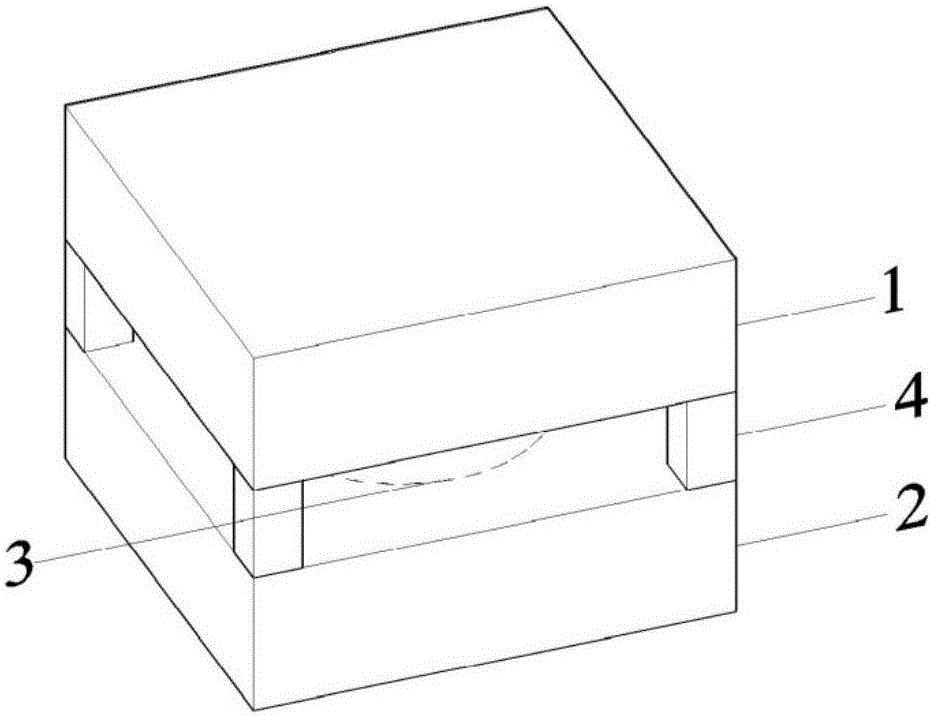

Plugging-resistant freeze-resistant pervious concrete pavement brick and manufacturing method

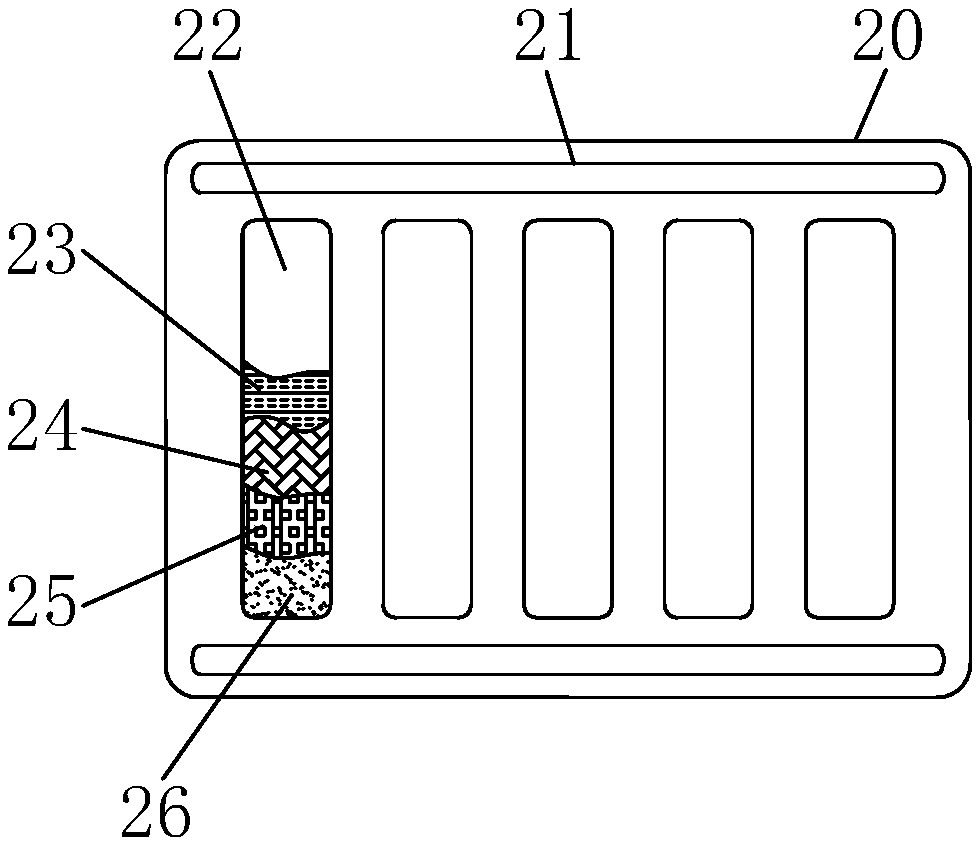

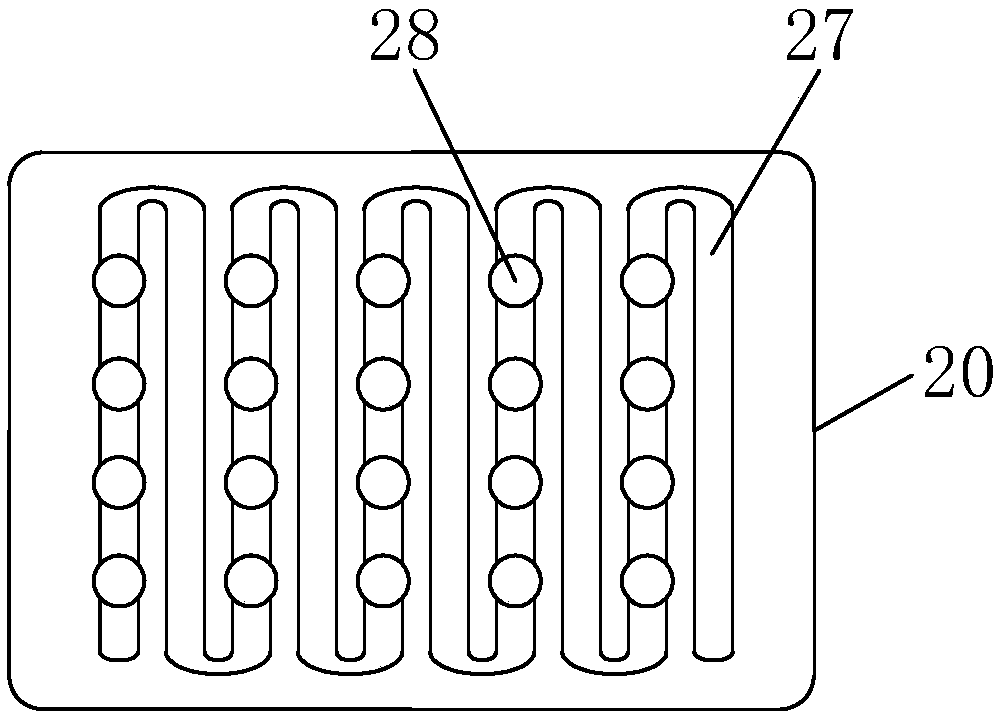

InactiveCN105386379AHigh strengthSatisfy normal useSolid waste managementSingle unit pavingsFreeze thawingFiber

The invention relates to a plugging-resistant freeze-resistant pervious concrete pavement brick. The plugging-resistant freeze-resistant pervious concrete pavement brick mainly comprises a plugging-resistant surface layer and a base layer, wherein the plugging-resistant surface layer is positioned on the base layer and consists of the following materials components in a compounding ratio and in parts by weight: 80-100 parts of cement, 310-360 parts of coarse sand, 7-11 parts of silica fume, 6-10 parts of VAE emulsion, 25-35 parts of water and 0.8-1.2 parts of a water reducing agent; the base layer consists of the following material components in the compounding ratio and in parts by weight: 90-110 parts of cement, 220-260 parts of pebbles, 70-110 parts of coarse sand, 8-12 parts of silica fume, 8-12 parts of VAE emulsion, 0.1-0.4 of polyethylene fibers, 25-35 parts of water and 0.8-1.2 parts of a water reducing agent. New material components are designed, so that the concrete brick provided by the invention has good pervious freeze-thaw resistant effects and is not easy to plug.

Owner:SHANDONG UNIV

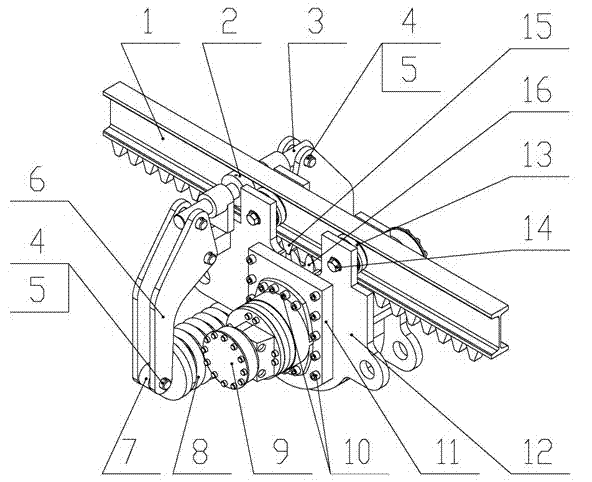

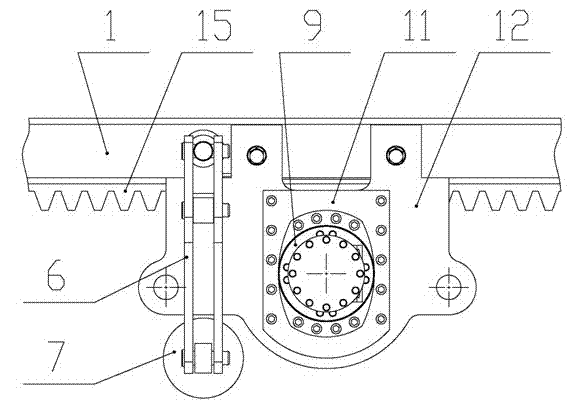

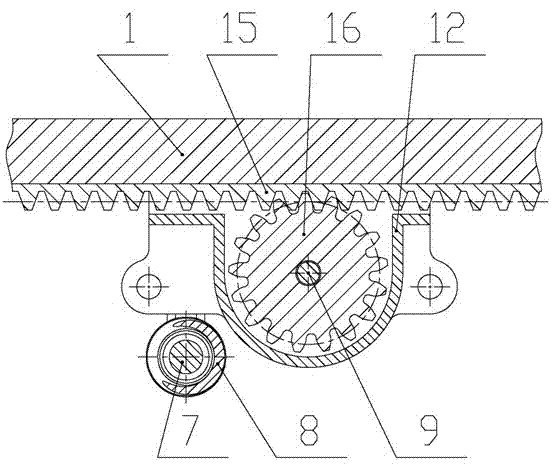

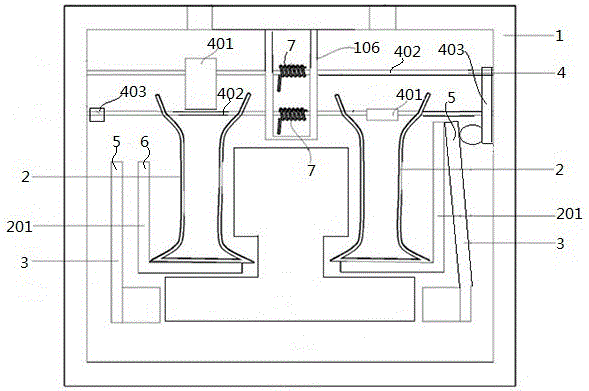

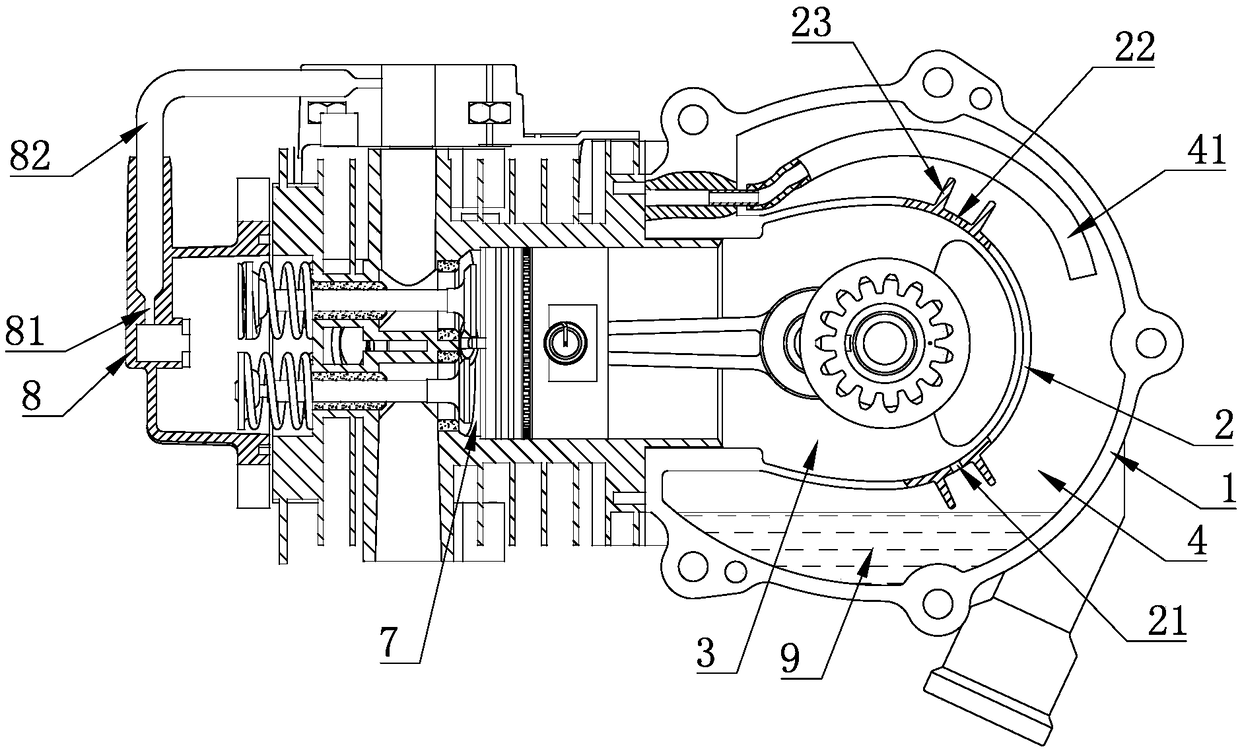

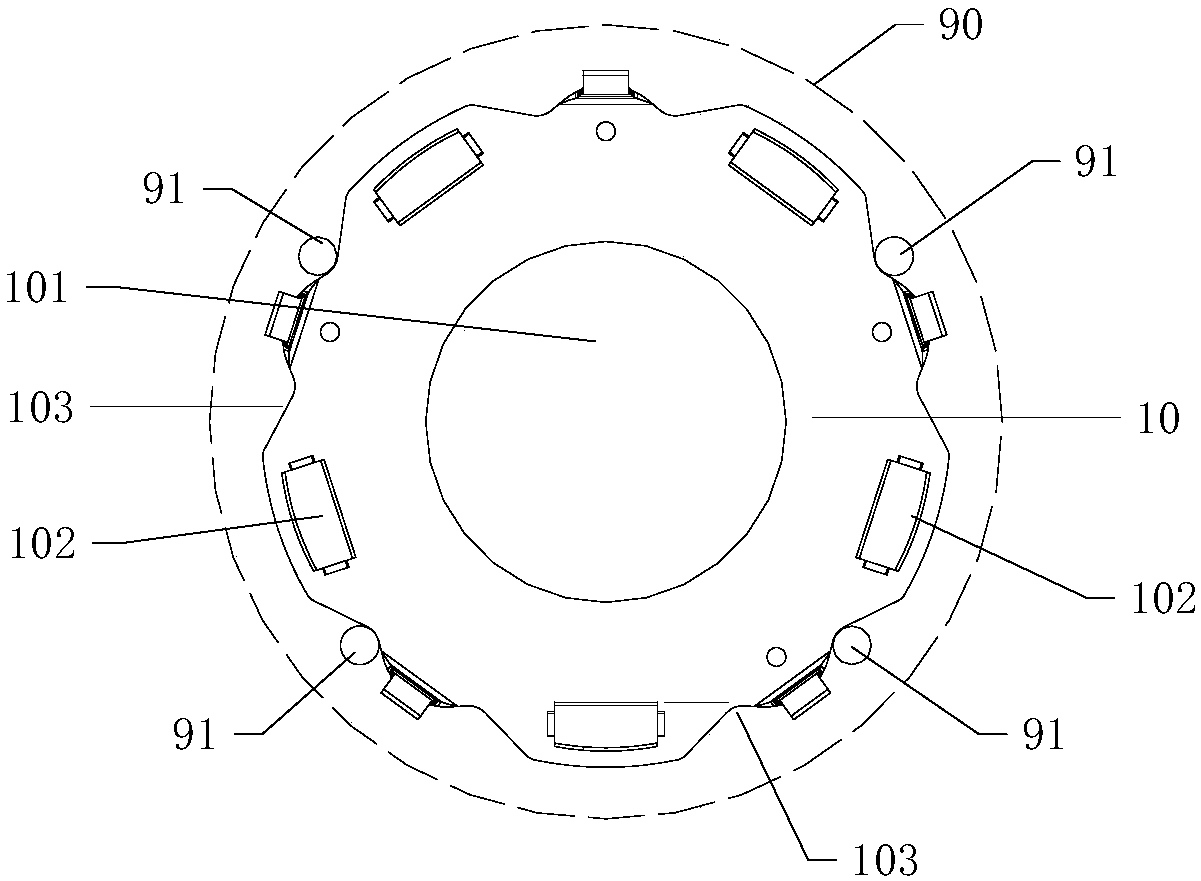

Mining monorail crane rack rail driving device

The invention which discloses a mining monorail crane rack rail driving device belongs to the technical field of mine machines. The device comprises a rack rail driving unit and a rail portion, wherein the rack rail driving unit comprises a frame supporting portion, a braking portion, a bearing wheel assembly portion and a driving portion; the frame supporting portion comprises a frame and connection plates; the braking portion comprises damper brake blocks, a damper brake rod, braking swing arms, a braking oil cylinder and a braking spring; the bearing wheel assembly portion comprises bearing wheels and bearing wheel mounting pins; the driving portion comprises driving motors and driving gears; and the rail portion comprises a rail and rack rails. The device has the following beneficial effects: when a locomotive runs to a wet and slippery road or a large ramp road, the device allows driving combination to be realized through the rack rail driving unit and a rubber cover driving wheel driving unit, and provides large traction force through utilizing the gears and the high efficiency characteristic of rack rail transmission, so a skidding phenomenon is avoided, thereby normal use is satisfied, and the working efficiency is improved.

Owner:徐州苏煤矿山设备制造有限公司

Special steel for hardware tool and preparation method thereof

The invention discloses a special steel for a hardware tool and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.50-0.60% of C, 0.17-0.37% of Si, 0.20-0.50% of Mn, 0.008-0.020% of P, 0.001-0.005% of S, 0.25-0.60% of Cr, 0.20-0.35% of Ni, 0.07-0.25% of Cu, 0.010-0.030% of Ti, and the rest amount of iron and inevitable impurities. The preparation method is performed by a general clean steel process, and comprises the steps of steel smelting, LF furnace refining, continuous casting, casting blank heating, rolling, cooling and reeling. All alloy element components in the steel are designed to properly increase the carbon content and decrease the content of such noble metals as Ni and Cr; the process of smelting and rolling is controlled to obtain the special steel for the hardware tool with high-hardness surface and low-hardness-toughness heart material matrix; and the steel can satisfy the performance needed by the hardware tool and the target of optical economic benefit.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

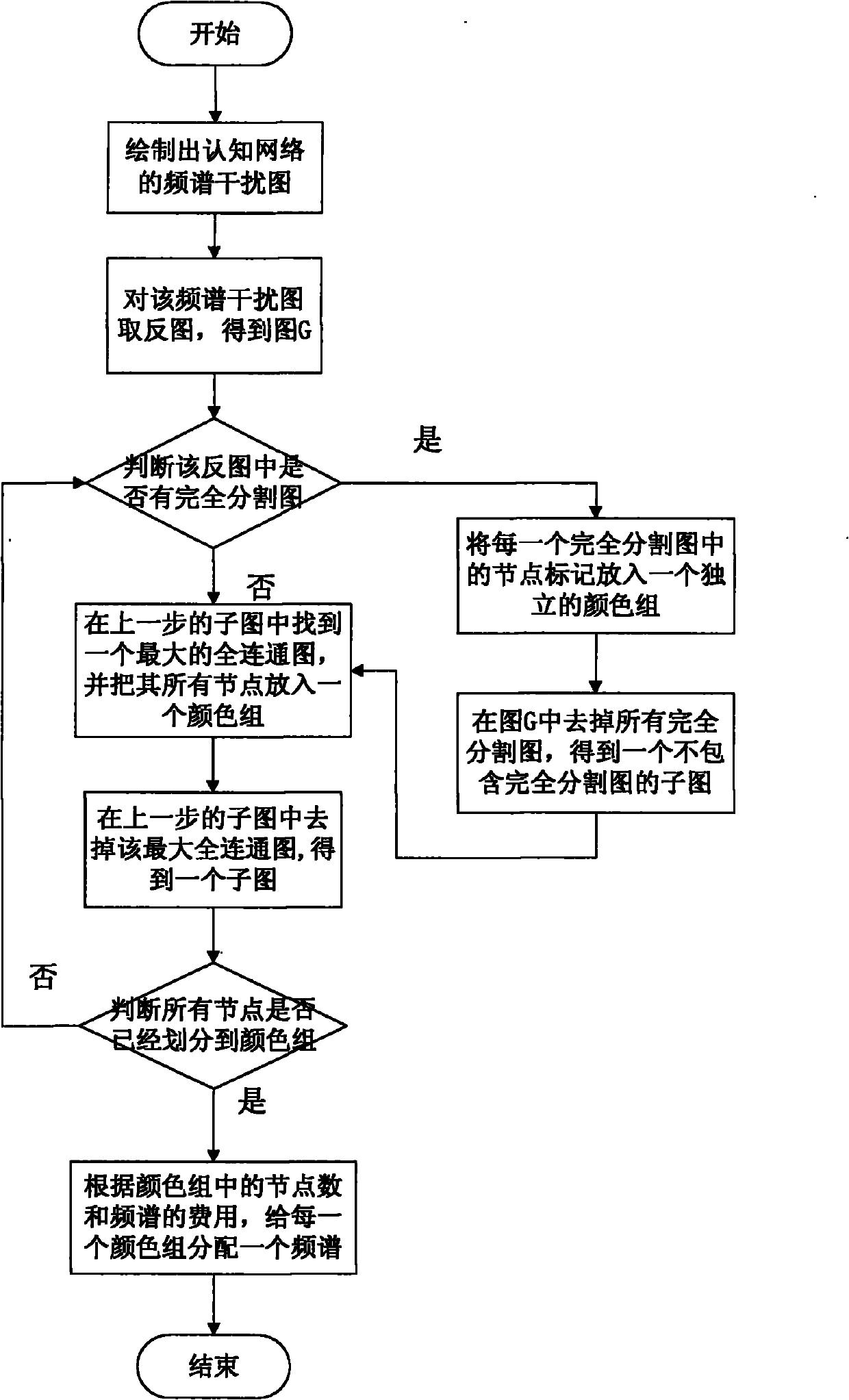

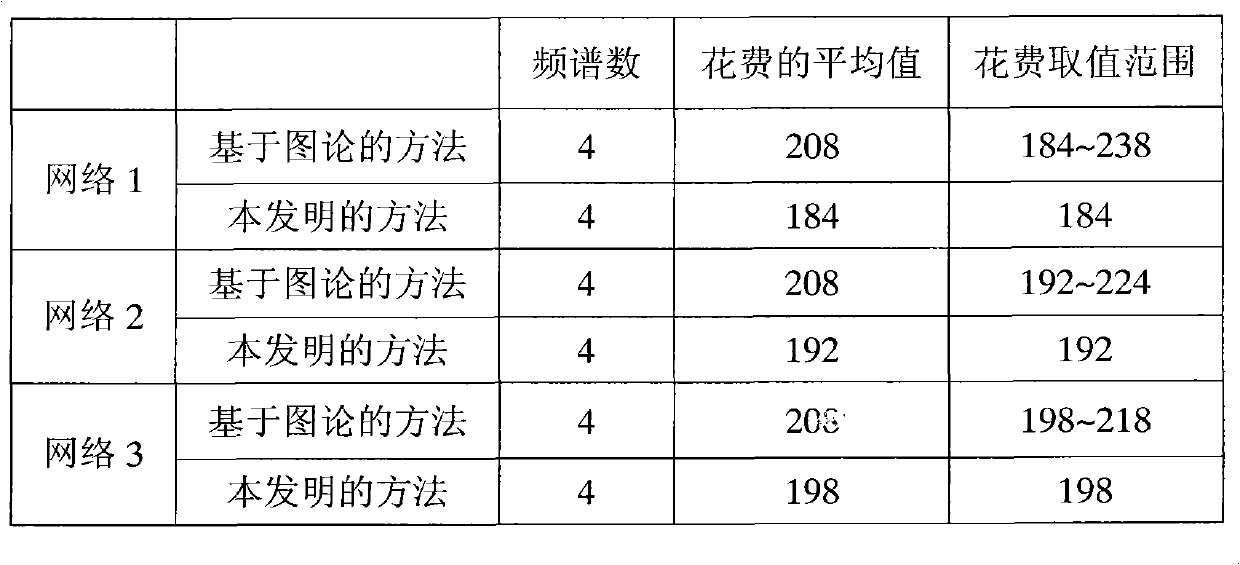

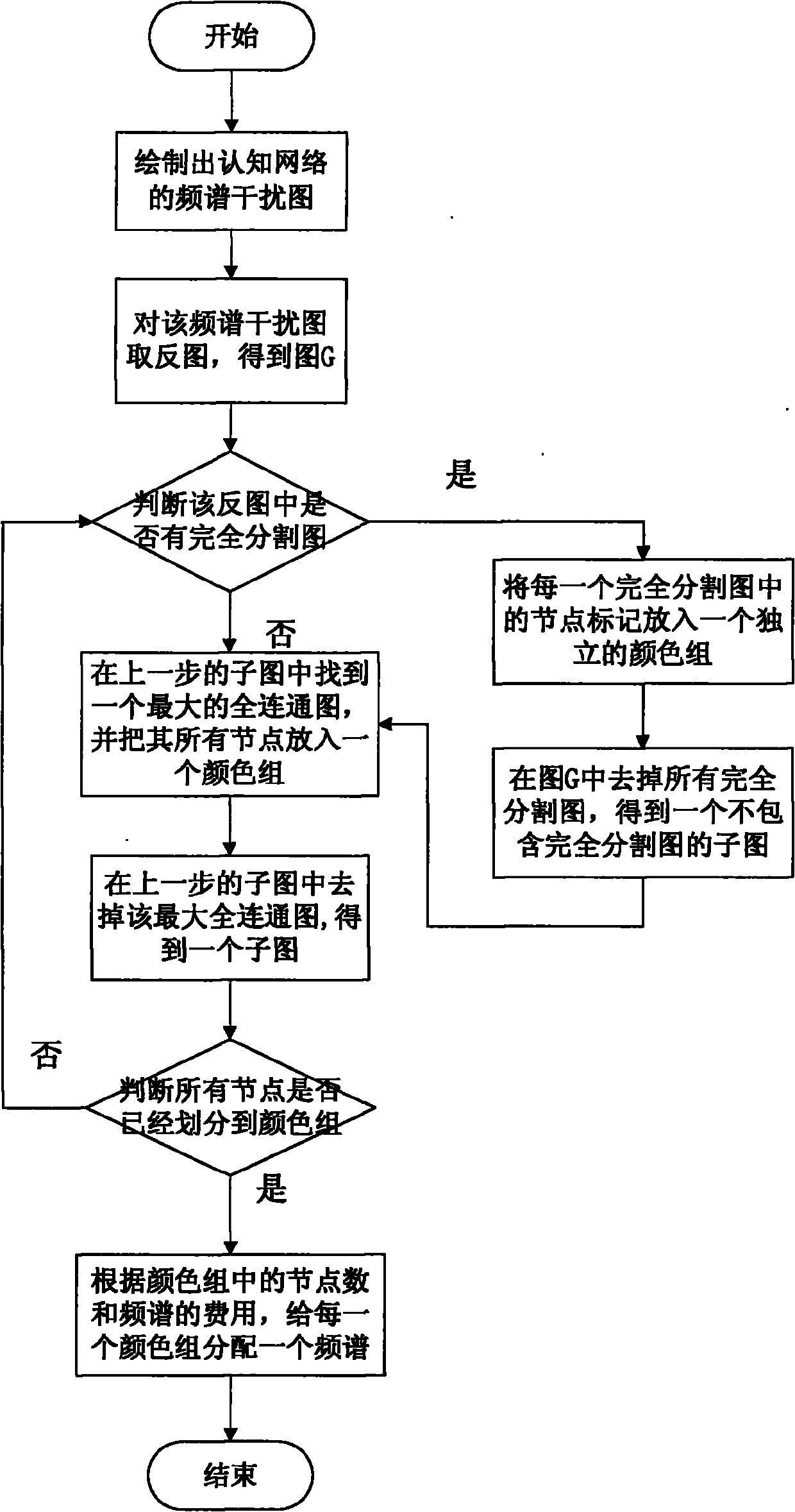

Method for allocating dynamic frequency spectrums of cognitive network based on inverse image description

InactiveCN101951609AImprove efficiencyCutting costsNetwork planningFrequency spectrumGraph theoretic

The invention provides a method for allocating dynamic frequency spectrums of a cognitive network based on inverse image description, mainly solving the problems of higher user cost and lower frequency spectrum service efficiency in the traditional awareness network. The method comprises the following steps of: (1) extracting an inverse image from a frequency spectrum interference pattern of the cognitive network to obtain an inverse image model G, and allocating m frequency spectrums to N users by the model G through using color groups; (2) allocating the N users in the inverse image model Gto m color groups by a graph theory method; and (3) sequentially arranging the m color groups according to the descending order of node numbers, sequentially allocating the m frequency spectrums to the arranged color groups according to the increasing order of costs, wherein one color group corresponds to one frequency spectrum to make users represented by nodes of the same one color group shareone frequency spectrum, and the shared frequency spectrum is the frequency spectrum allocated to the located color group, and then the frequency spectrum allocation of the cognitive network is finished. The invention can efficiently reduce the total cost of user for buying the frequency spectrums in the cognitive network and improve the service efficiency of the frequency spectrums.

Owner:XIDIAN UNIV

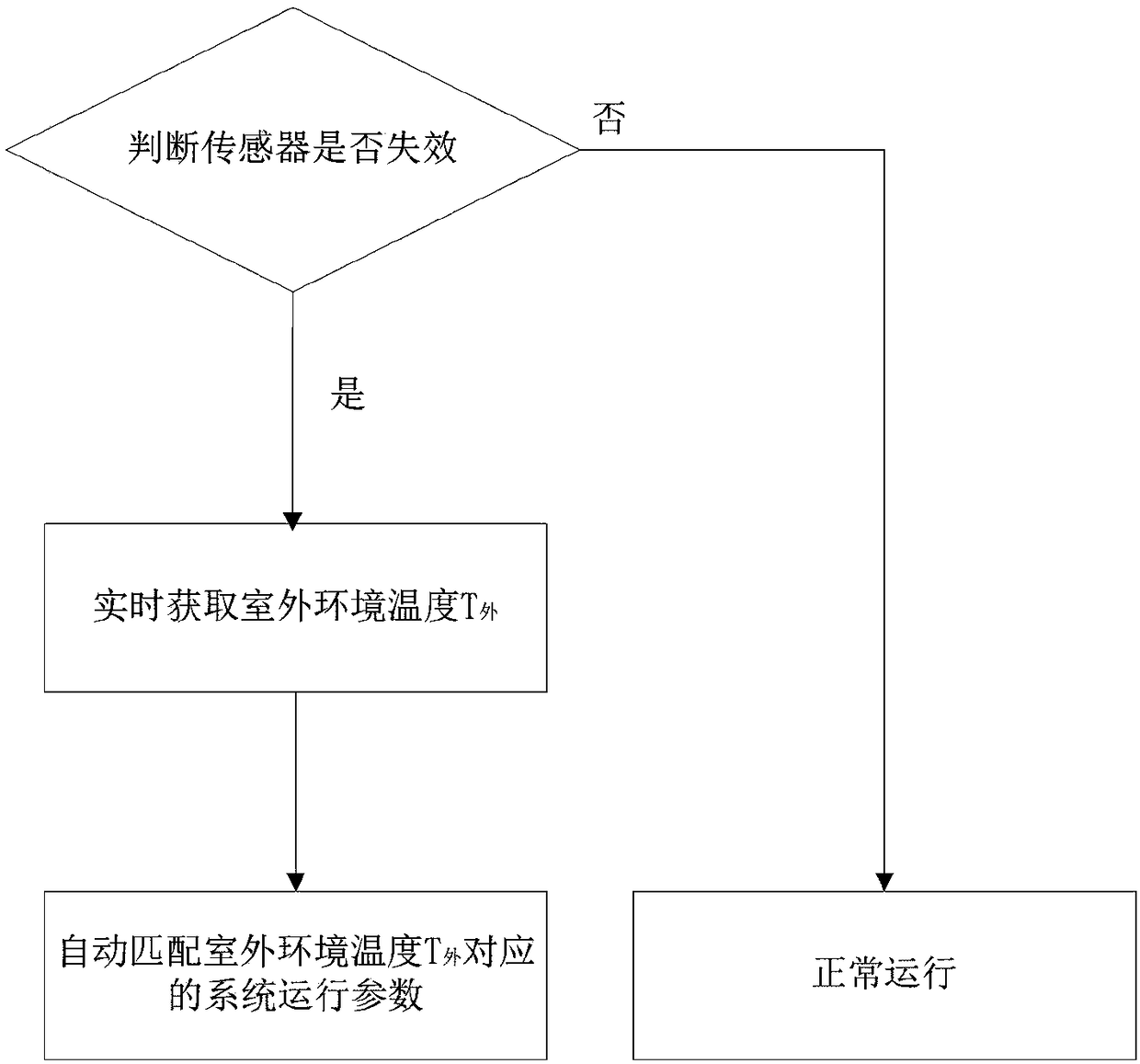

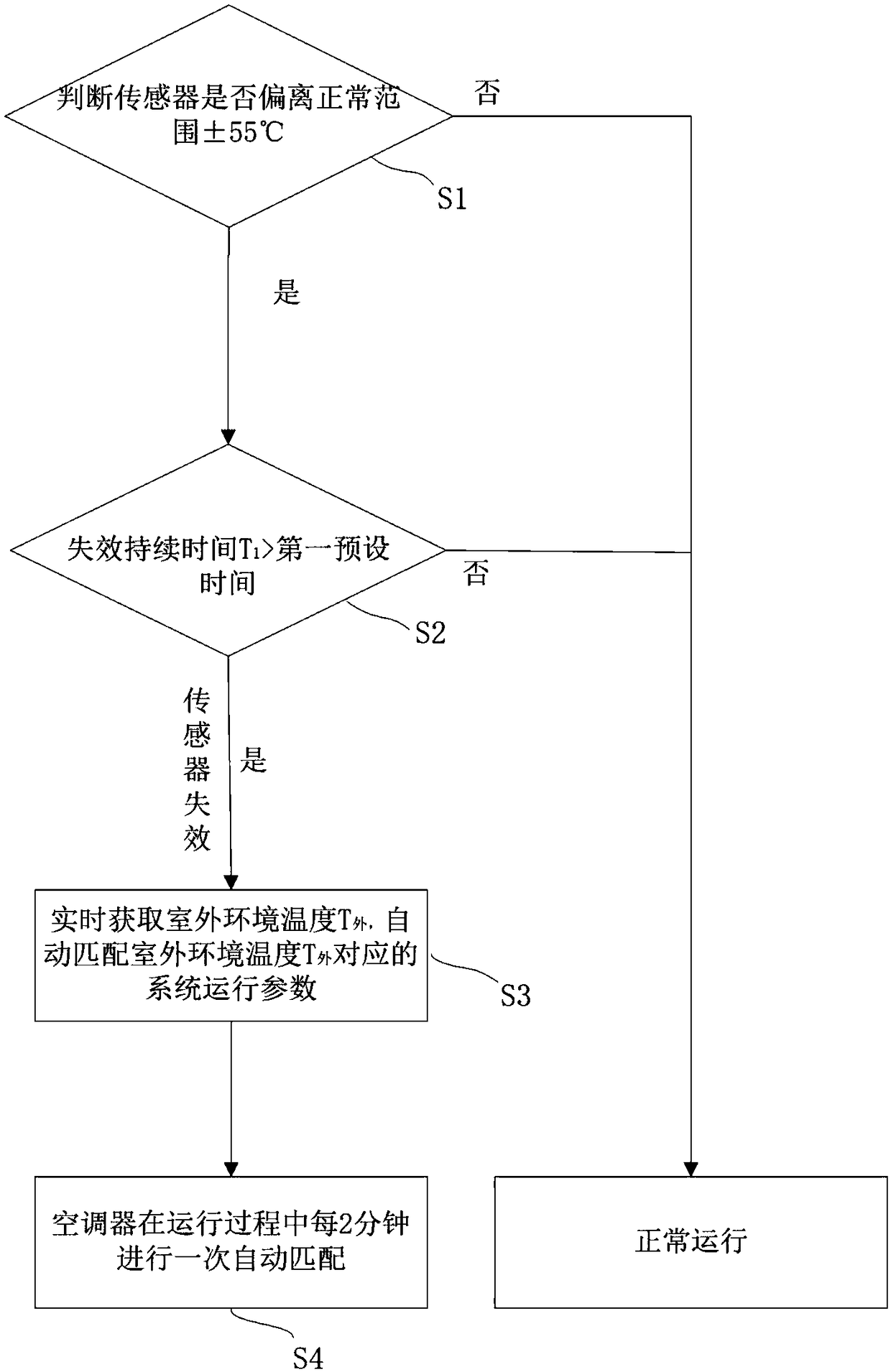

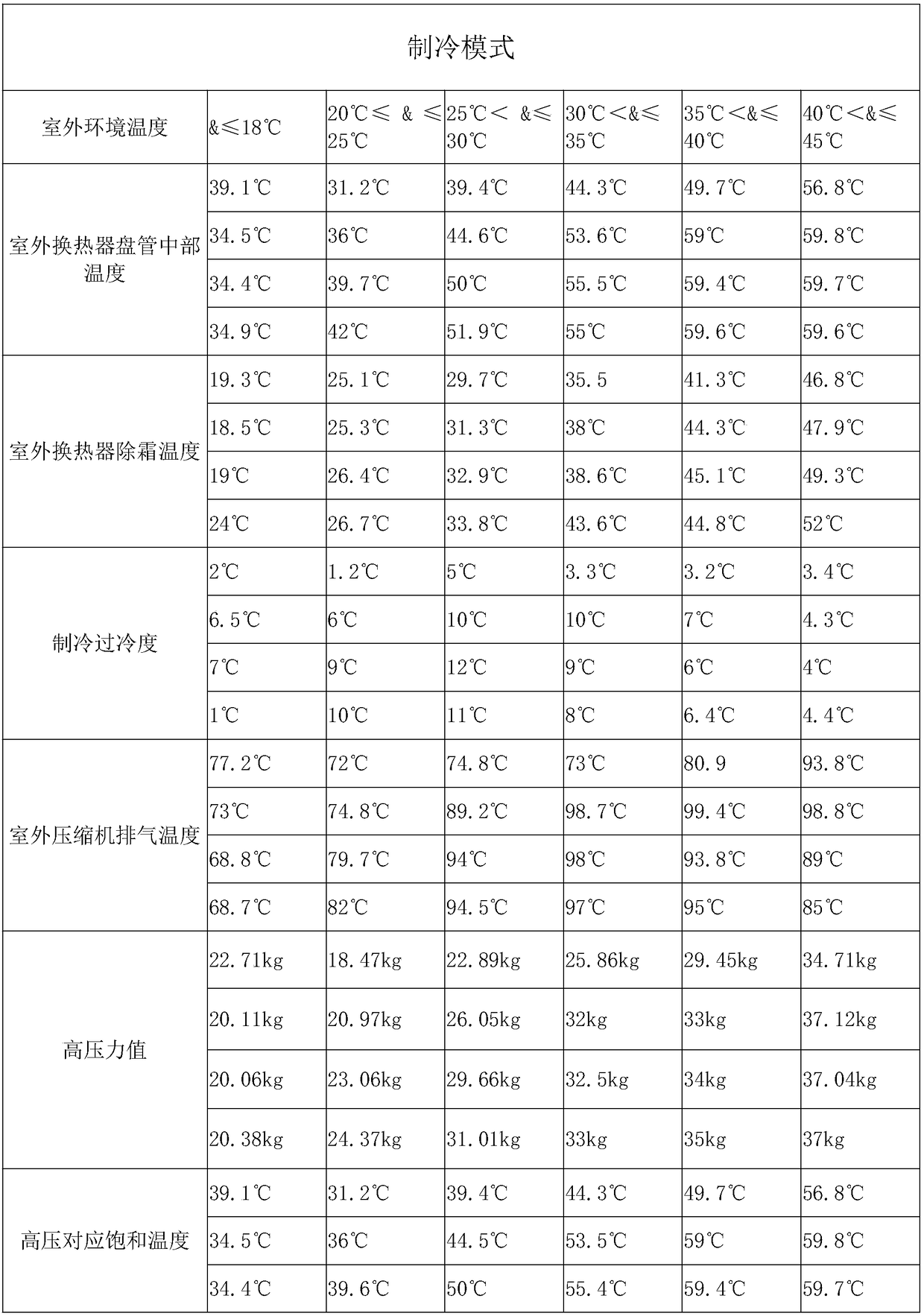

Operation method for controlling reliability of air conditioner, control system and air conditioner

ActiveCN109340992AControl normal operationSatisfy normal useMechanical apparatusControl systemNormal mode

The invention provides an operation method for controlling the reliability of an air conditioner, a control system and the air conditioner. The operation method for controlling the reliability of theair conditioner comprises the following steps that whether a temperature sensor fails or not is judged according to a temperature signal sent by the temperature sensor, if the temperature sensor fails, the air conditioner continues to acquire real-time outdoor environment temperature, the air conditioner automatically matches each operation parameter of the system corresponding to the outdoor temperature according to the real-time outdoor temperature, and continues to operate according to each operation parameter of the system after automatic matching; and otherwise, normal mode operation is continued. The operation method for controlling the reliability of the air conditioner can continuously control normal operation of the air conditioner after the temperature sensor fails, so that the normal use of people is met.

Owner:NINGBO AUX ELECTRIC +1

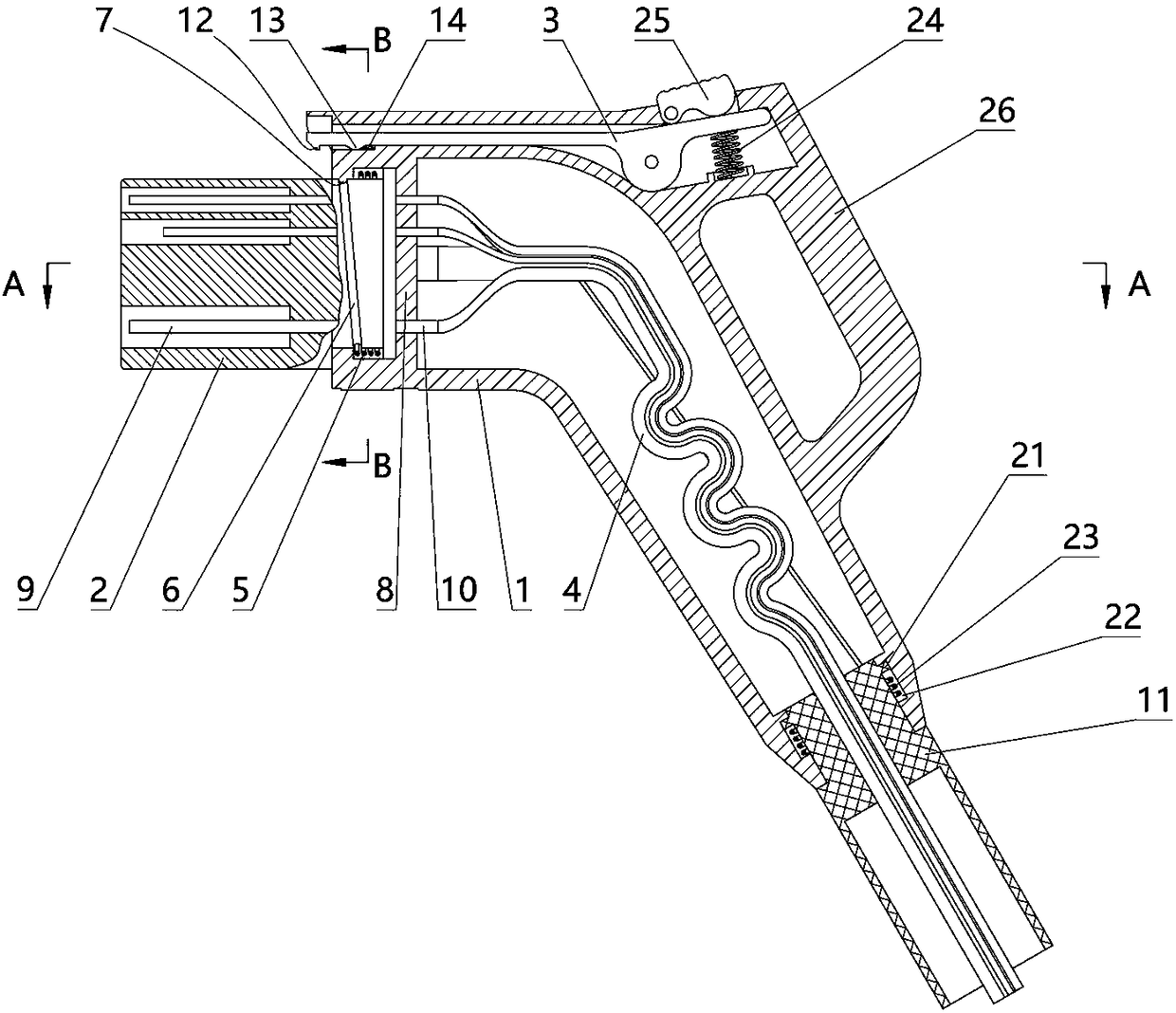

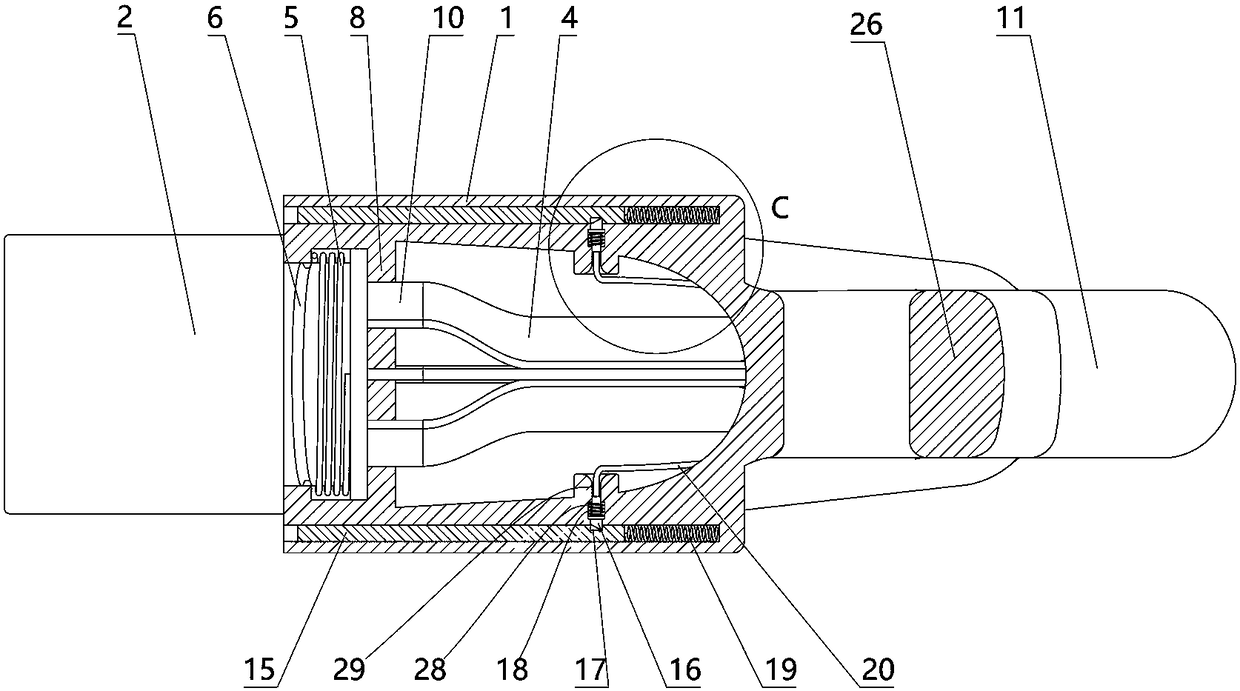

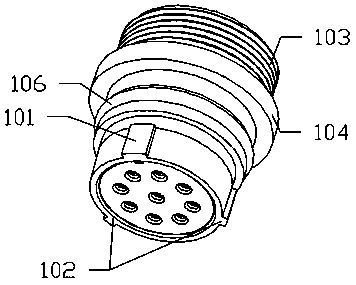

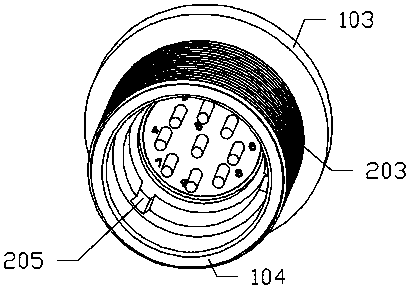

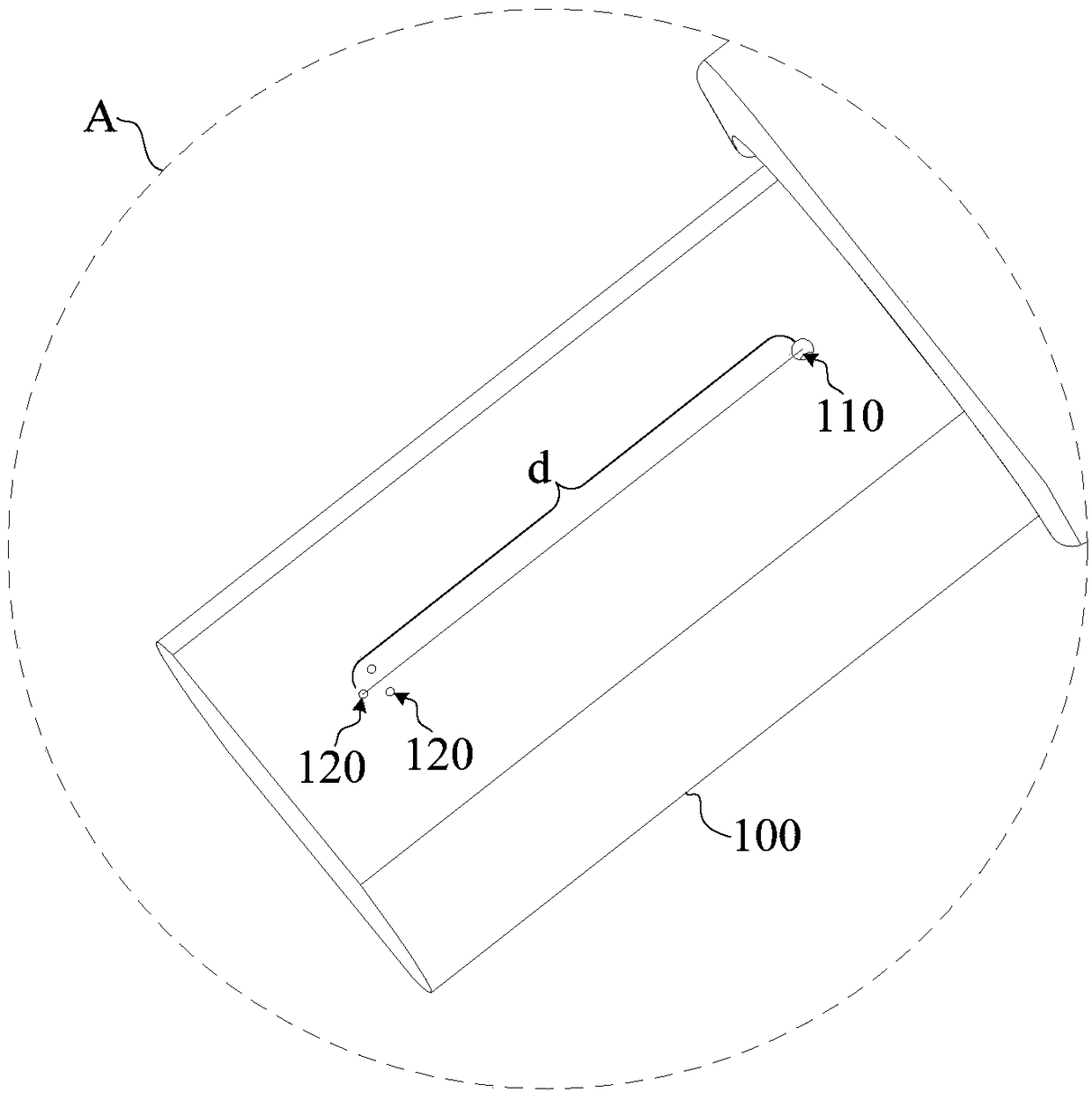

Charging gun with dragging protection function

The invention relates to a charging gun with a dragging protection function. The charging gun comprises a gun body with an inner cavity, a plug, a locking part and a wiring harness; the plug is rotationally connected with the gun body; the plug is sleeved with a torsional spring; the two ends of the torsional spring are connected with the gun body and the plug respectively; a circumferential cam groove, which is closed and inclined along the rotary axis of the plug, is formed in the plug; a cam push rod matched with the circumferential cam groove is arranged on the gun body; the cam push rod is arranged in the circumferential cam groove; a terminal placed in the inner cavity is arranged on the gun body; a plurality of horizontally arranged ejector pins are arranged on the plug, multiple contact conductors are mounted on the terminal, and the contact conductors are in contact with the ejector pins in a one-to-one correspondence manner; an inserting-connecting sleeve is glidingly inserted and mounted on the gun body; the wiring harness is fixedly connected with the inserting-connecting sleeve; and one end of the wiring harness is placed in the inner cavity and connected with the terminal. By virtue of the charging gun, the normal charging use of a vehicle can be satisfied while it is ensured that the charging gun can be in a power-down state quickly in suffering from pulling force so as to be separated from the vehicle elastically and safely in an emergency condition.

Owner:乐清市荣盛引进电器有限公司

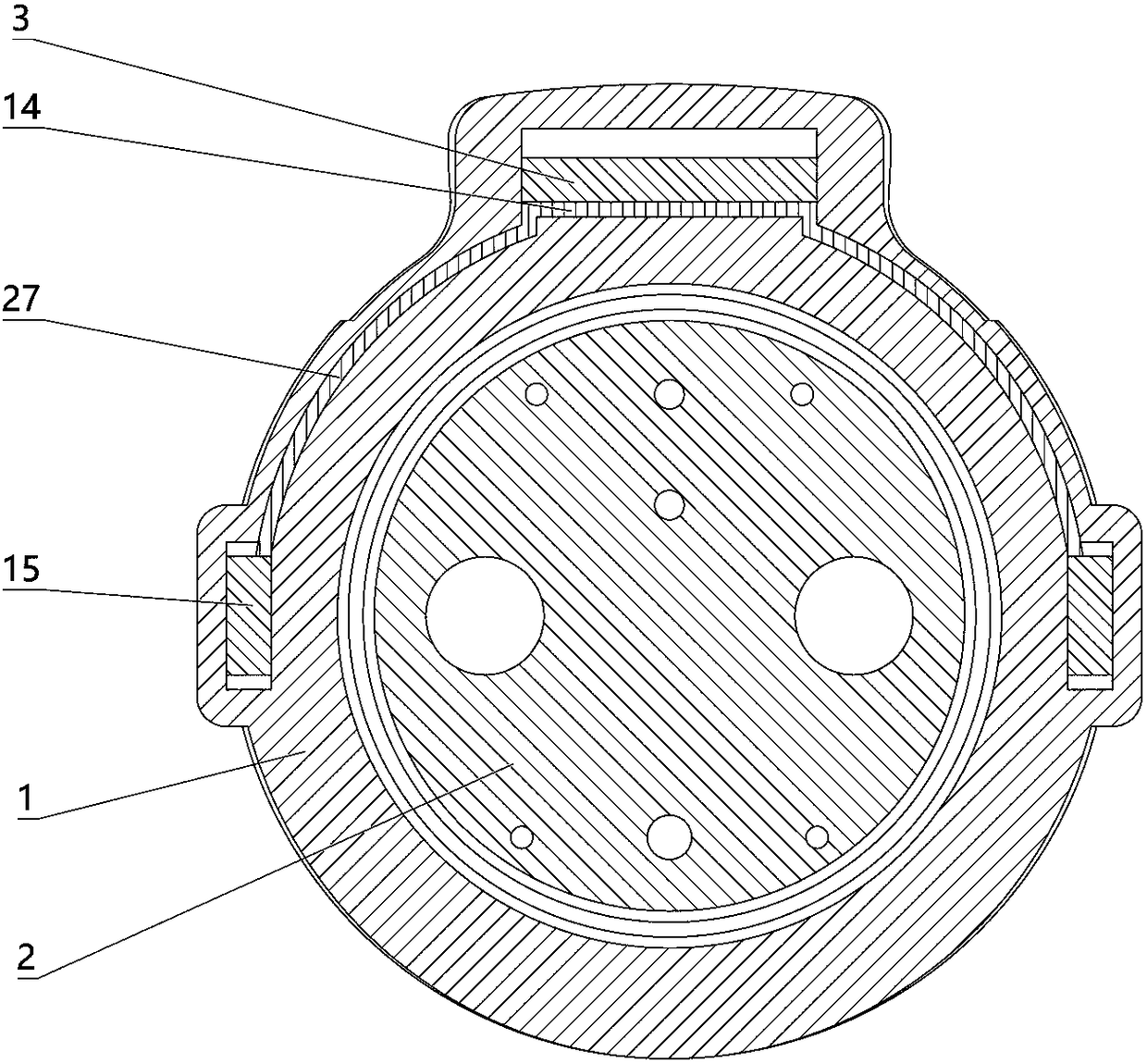

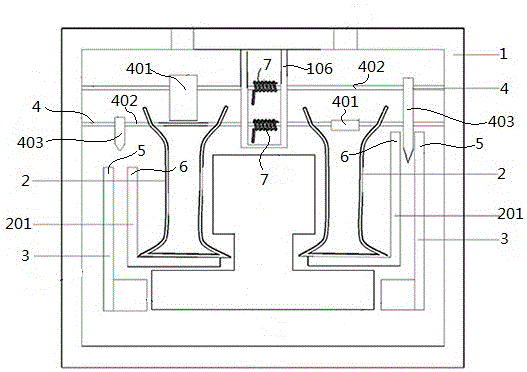

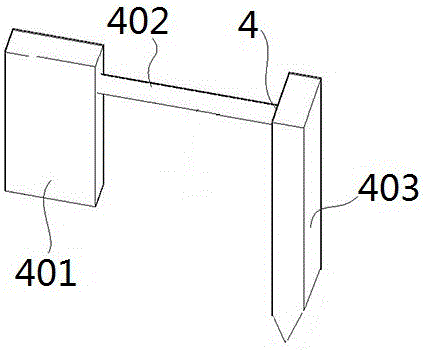

Paired-control safety socket

PendingCN107437685APrevent Children from Electric Shock AccidentsSatisfy normal useLive contact access preventionEngineeringElectrical conductor

The invention provides a paired-control safety socket. The paired-control safety socket comprises a casing, a linkage contact device, a socket contact plate and a wire incoming contact plate, wherein the linkage contact device comprises a power baffle board, a linkage rod and a moving contact which are fixedly connected, a pin is arranged on the socket contact plate, the socket contact plate is arranged to be in an opening state with a circuit, the power baffle board is mounted at the corresponding position of jacks, the moving contact is driven through the linkage rod, through the moving contact, the wire incoming contact plate and the socket contact plate, position optimization is carried out, when the present side jack is inserted with an object, the moving contact is driven by the power baffle board to act to make the other jack access to the circuit, and the present side jack is in a non-live-line state, through quantity and structural optimization of the linkage contact device, the socket can operate normally when a plug is inserted. The control safety socket is advantaged in that children safety accident events related to sockets mostly occur when the children insert conductors into single jacks, the paired-control scheme is proposed, circuit connection in the jacks can be effectively controlled, and a problem of hidden safety trouble generated because of error insertion into the jacks carried out by the children can be avoided.

Owner:马鞍山虹迈专业化设计有限公司

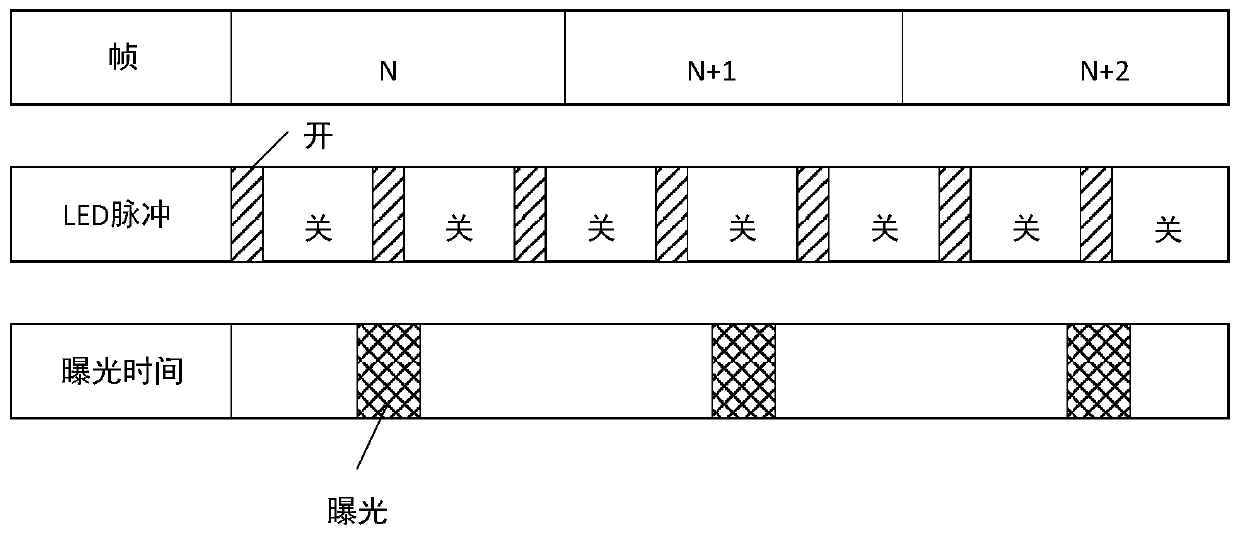

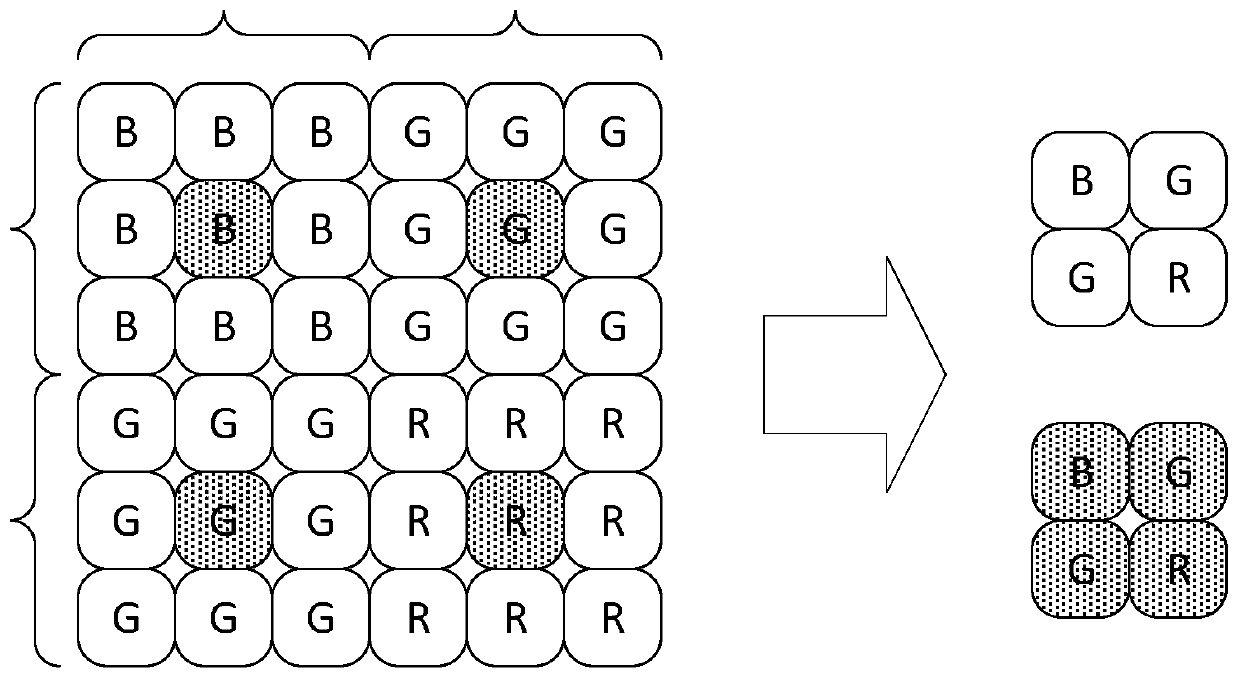

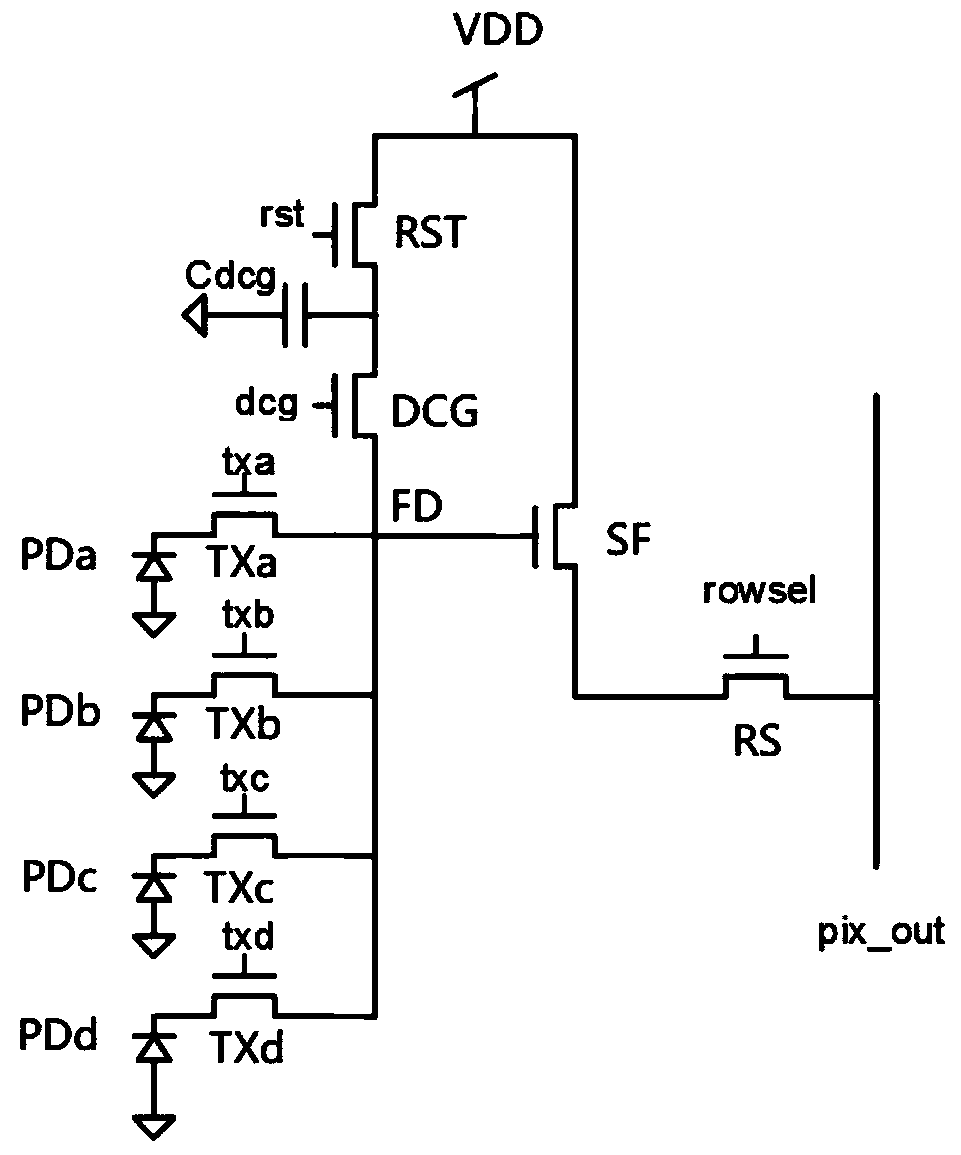

LED stroboscopic suppression method in image sensor imaging

ActiveCN110661982ASatisfy normal useSuppress flickerTelevision system detailsColor television detailsRadiologySignal light

The invention provides an LED stroboscopic suppression method in image sensor imaging, and the method comprises the steps: setting pixels in an image sensor pixel array as a pixel unit in a 3 * 3 structure, setting a central pixel of each pixel unit as a first group of pixels, and setting eight pixels at the periphery as a second group of pixels; wherein the first group of pixels and the second group of pixels are respectively provided with different exposure time and conversion gain, the first group of pixels is provided with longer exposure time, and the second group of pixels is provided with higher conversion gain; and the first group of pixels and the second group of pixels are exposed in one frame and are alternately output as two frames of image data line by line. The back-end processing synthesizes the two frames of images into one frame of image with a high dynamic range and outputs the image. According to the scheme provided by the invention, the flickering problem generatedby an LED signal light source when the image sensor outputs the image can be effectively inhibited, and meanwhile, the dynamic range of the image output by the image sensor can be effectively improved.

Owner:思特威(上海)电子科技股份有限公司

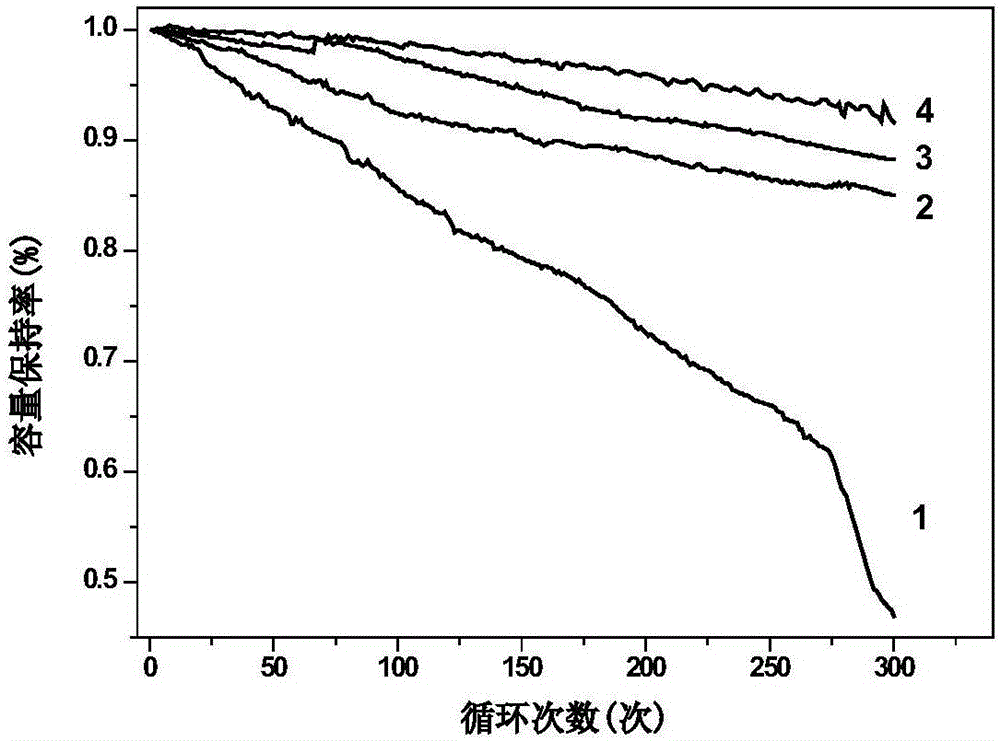

Recycling method of power lithium-ion batteries

InactiveCN106450543ASatisfy normal useEasy to useWaste accumulators reclaimingBattery recyclingEngineeringElectric vehicle

The invention relates to a recycling method of power lithium-ion batteries. The method comprises the following steps of (S1) firstly discharging the recycled power lithium-ion batteries to corresponding minimum standard voltage according to the batteries of different material systems; (S2) opening battery injection openings and injecting a lithium hexafluorophosphate electrolyte; (S3) after the electrolyte completely infiltrates, carrying out charging formation by using predetermined current; and (S4) finally sealing the openings and dividing the capacity. According to the manufactured lithium-ion batteries, through a test at a room temperature of 25 DEG C, the initial capacity is improved by over 10% in comparison with the capacity of each battery before being recycled; the capacity retention ratio after 300 IC current charge and discharge cycles is greater than 85% of the initial capacity; normal use in the industries, with low power performance requirements, of an energy storage power supply, daily digital and household appliances, lamps and the like can be met; and stepwise reuse of the lithium-ion batteries eliminated from the power industries of electric vehicles, electric bicycles, model airplanes, electric tools and the like is achieved.

Owner:MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

Preparation method of resin for casting

ActiveCN103554832AImprove toughnessImprove moisture resistanceFoundry mouldsFoundry coresFuranDistillation

The invention relates to a preparation method of resin and in particular relates to a preparation method of resin for casting. The preparation method of the resin for casting is characterized by comprising the following steps: adding furfuraldehyde, cardanol, urea and an alkali catalyst into a reactor, preserving heat, carrying out a reaction, and then cooling to room temperature, thus obtaining resin; adding the resin, furfuraldehyde and an acid catalyst into the reactor, controlling the reaction temperature at 70-100 DEG C, preserving heat and carrying out a reaction for 1-3 hours, transferring reaction products into a reduced pressure distillation kettle, carrying out reduced pressure distillation and dehydration for 1-2 hours under the conditions that the temperature is 50-80 DEG C and the vacuum degree ranges from minus 0.05MPa to minus 0.08MPa, cooling to room temperature, regulating pH value to be 7.0-7.5, then adding 6-10 parts by weight of silicon compound and 15-20 parts of dibasic ester, and uniformly stirring, thus obtaining the resin for casting. The preparation method of the resin for casting is unique and environment-friendly, and the moisture resistance is better than that of the traditional furan resin.

Owner:共享新材料(山东)有限公司

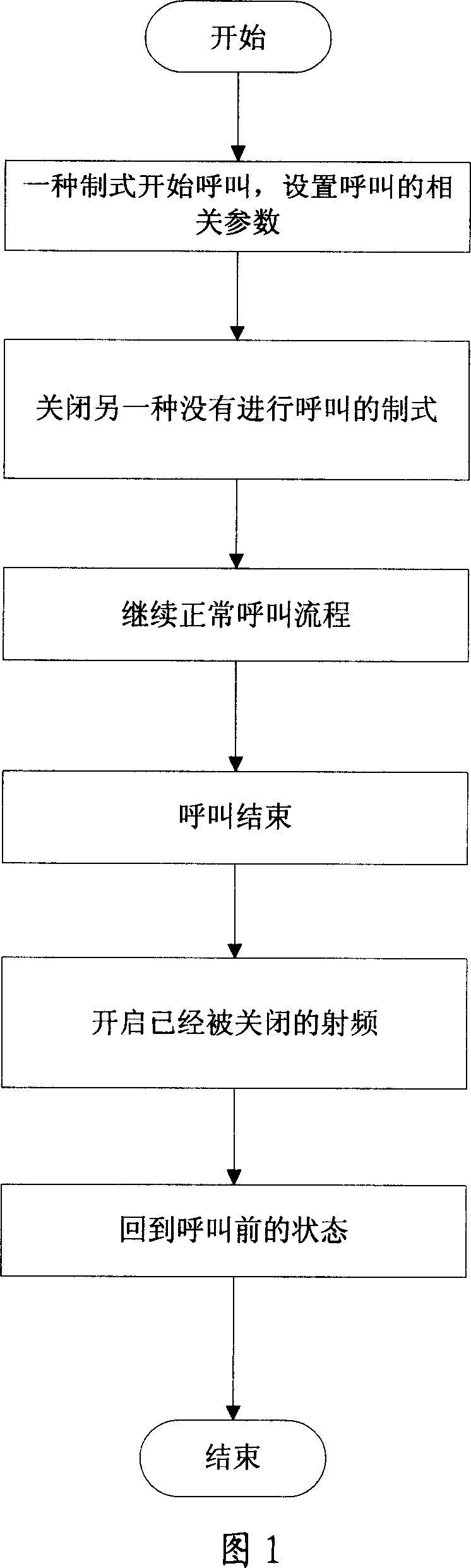

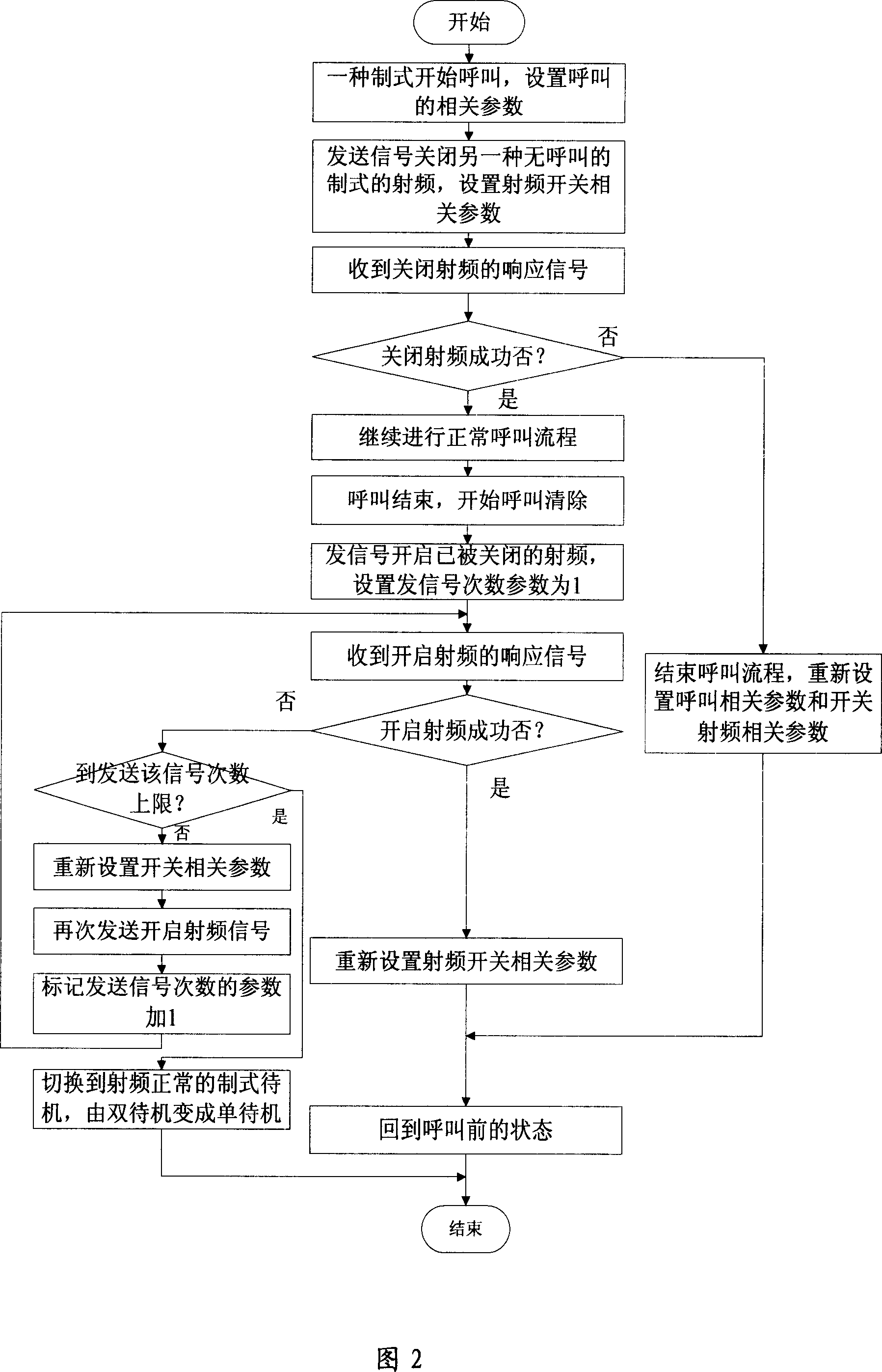

TD-SCDMA and GSM dual-mode mobile terminal calling method

PendingCN101072427ASatisfy normal useSatisfies the requirement of normal use of TD-SCDMA to make callsRadio/inductive link selection arrangementsWireless communicationTD-SCDMADual mode

Under condition of dual stand by in TD-SCDMA and GSM two systems, when calling event occurs at module in one system, first, mobile terminal closes down radio frequency of module in the system, where no calling occurs; then, carries out normal call flow. When the call is eliminated, the method turns on the closed radio frequency of the module in the system so as to get back to stand by state. In calling time, the invention only runs one system, thus, signal interference will not occur so as to guarantee quality of call.

Owner:ZTE CORP

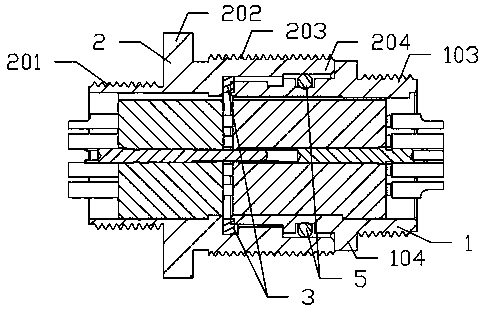

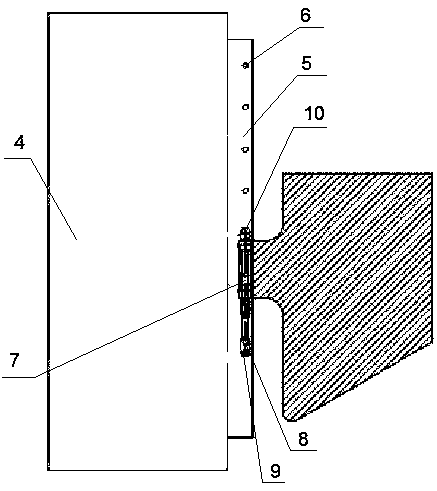

Rapid-plugging waterproof connecting structure

InactiveCN107611687AImprove waterproof levelImprove pullout forceEngagement/disengagement of coupling partsCouplings bases/casesEngineeringCavity wall

The invention discloses a rapid-plugging waterproof connecting structure, and the structure comprises a plug interface and a socket interface, which cooperate with each other. The outer ring of one end of the socket interface is provided with a first external thread, and the tail end of the first external thread is provided with a pedestal. The diameter of the pedestal is greater than the nominaldiameter of the first external thread. The pedestal enables two ends of the socket interface to be connected. The other end of the socket interface is a hollow inner cavity, and the exterior is provided with a second external thread, wherein the inner cavity and the second external thread form a cavity wall. A first waterproof layer is disposed between the bottom surface of the inner cavity and the plug interface. One end of the plug interface is provided with straight bayonets which are corresponding to the card slots in the socket interface in a one-to-one manner. The other end of the socketinterface is provided with a third external thread. The tail ends of the third external thread is provided with a shaft shoulder. A second waterproof layer is disposed between the bayonets and the shaft shoulder, and is located at a groove of the plug interface. The structure is simple, and is good in waterproof function. The structure can be independently used or combined with other structures provided by the invention, and the assembly efficiency of a connecting device is improved.

Owner:湖北云万光电子科技有限公司

Heavy plastering gypsum and preparation method thereof

The invention discloses heavy plastering gypsum. The heavy plastering gypsum comprises the following raw materials by weight: 480 to 520 kg of phosphogypsum, 80 to 120 kg of triple superphosphate powder, 380 to 450 kg of mechanical sand, 0.2 to 0.4 kg of a PE gypsum retarder, 1 to 3 kg of cellulose H620, 0.2 to 0.4 kg of starch ether and 3 to 5 kg black iron. The heavy plastering gypsum has the advantages of firm bonding with a base layer, no hollowing, no falling, no dusting, hydration micro-expansion, no cracking, convenient construction, early strength, rapid hardening, environmental protection, etc., is ensured in service life, satisfies the requirements of normal use of the construction industry and has high promotion and application value.

Owner:贵州砂浆博士科技有限公司

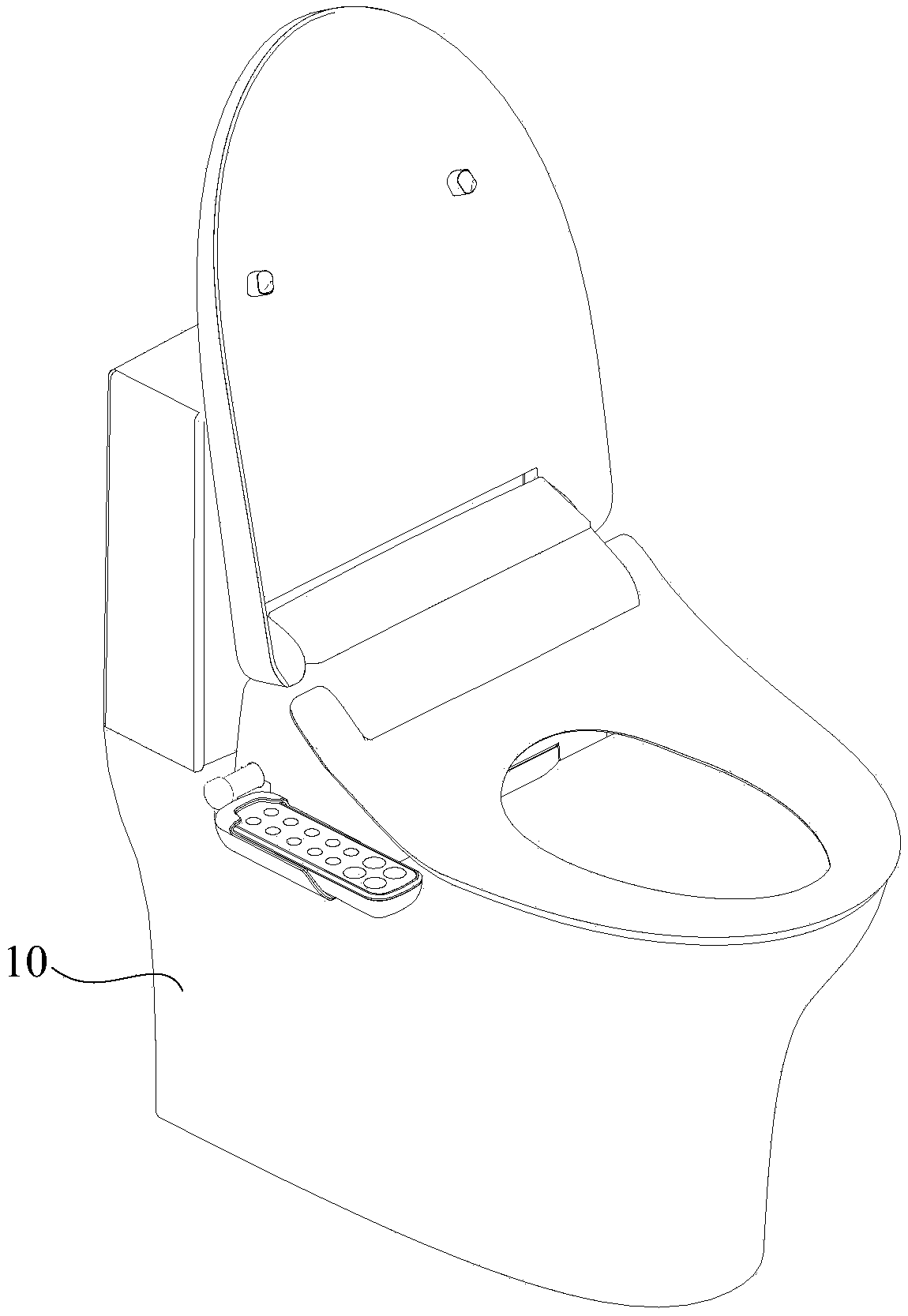

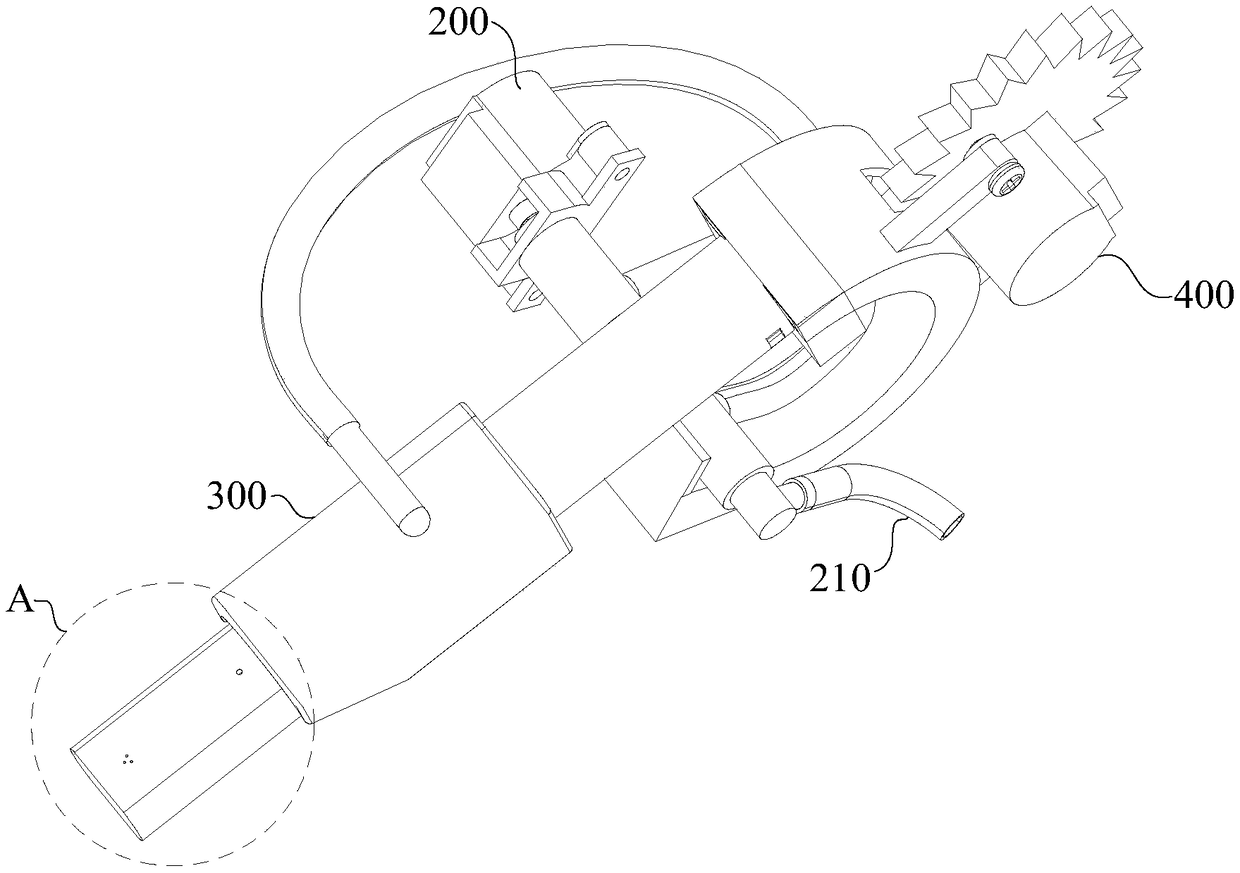

Flushing device and intelligent toilet

InactiveCN108824587AEasy to useImprove flushing efficiencyLavatory sanitoryControl valvesDouche device

The invention discloses a flushing device and an intelligent toilet. The flushing device comprises a spraying pipe and a control valve, the spraying pipe is provided with hip cleaning holes and bidetcleaning holes, and the hip cleaning holes and the bidet cleaning holes are sequentially formed in the direction which is close to the rear end of the spraying pipe at intervals; the control valve isprovided with a first water outlet passage which is communicated with the spraying pipe, the first water outlet passage comprises a first secondary passage and a second secondary passage which are independent, and the first secondary passage is communicated with the hip washing holes; the second secondary passage is communicated with the bidet cleaning holes; the control valve is used for controlling the switching on and off of the first and second secondary passages. According to the flushing device, the hip cleaning holes and the bidet cleaning holes are formed in the spraying pipe of the flushing device, water spraying can be conducted by the bidet cleaning holes and the hip cleaning holes simultaneously, bidet cleaning and hip cleaning can be conducted simultaneously, the use of a useris convenient, and the flushing efficiency when the device is used by the user is improved.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

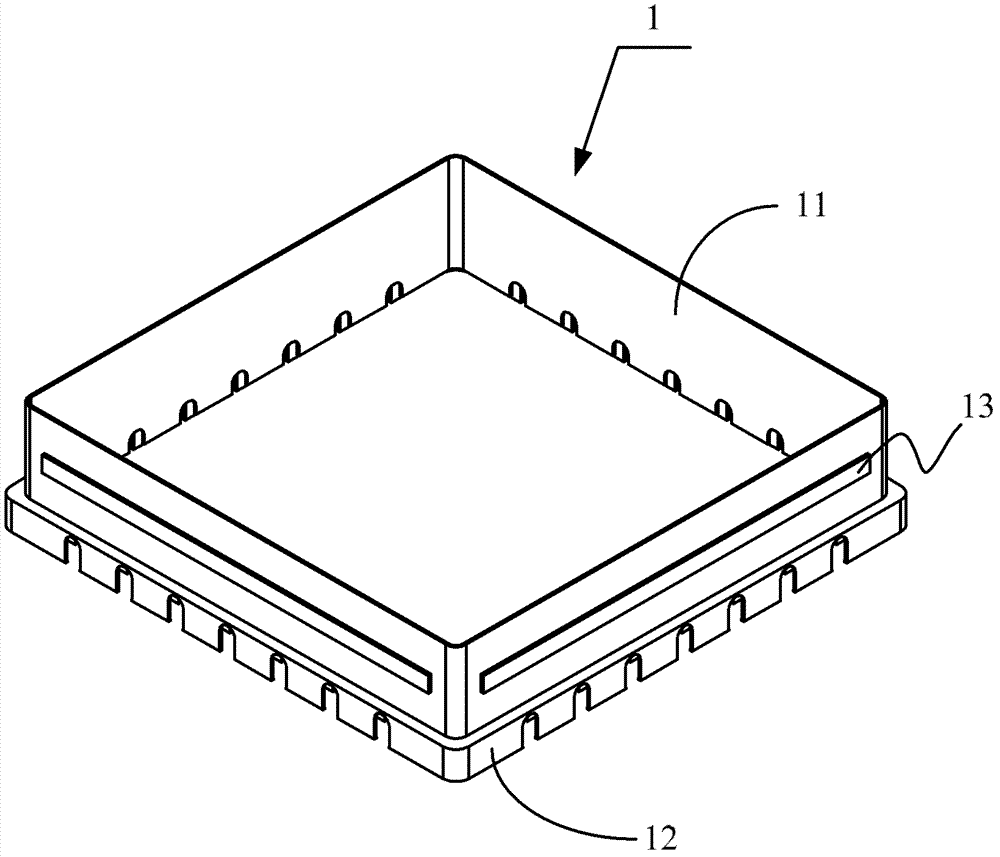

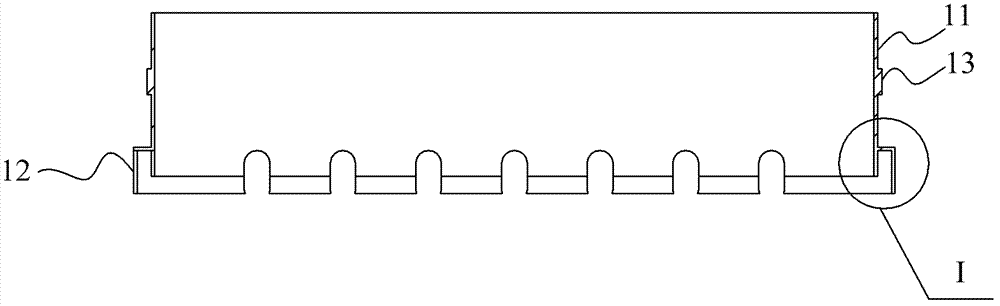

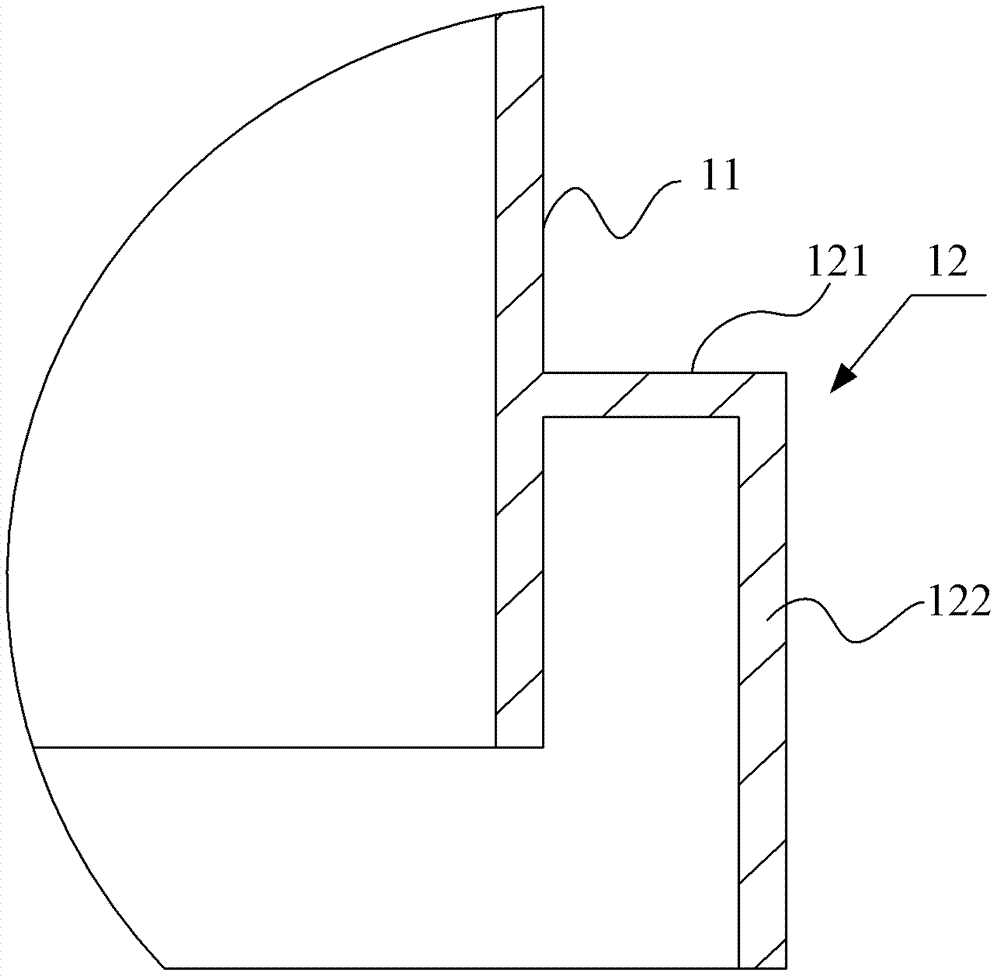

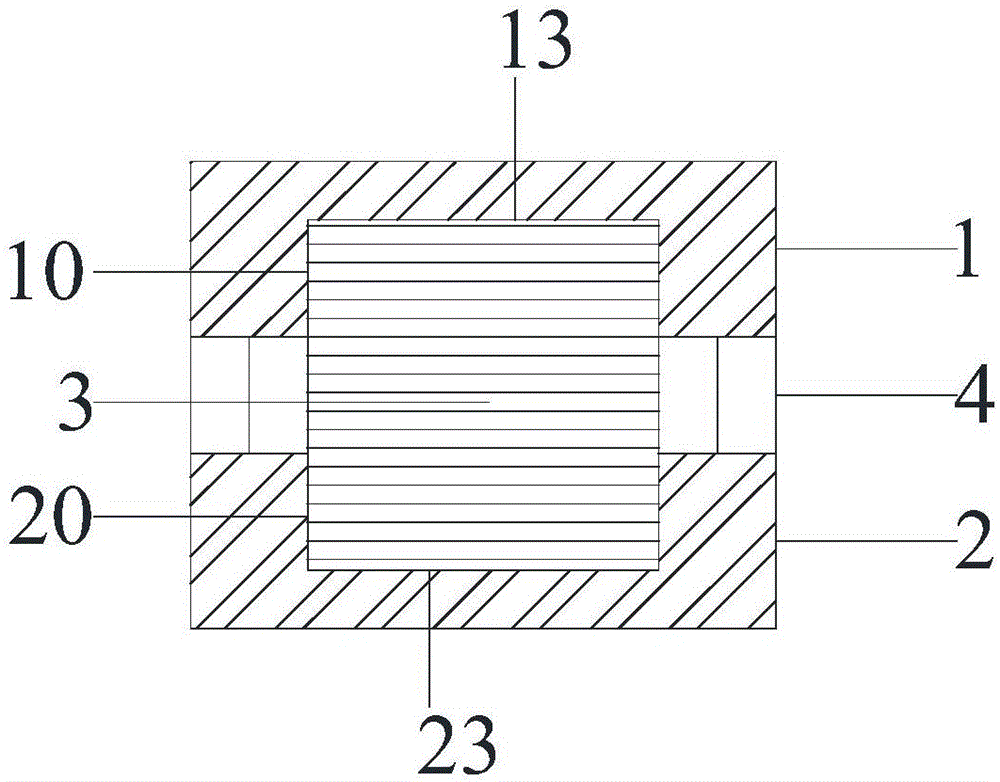

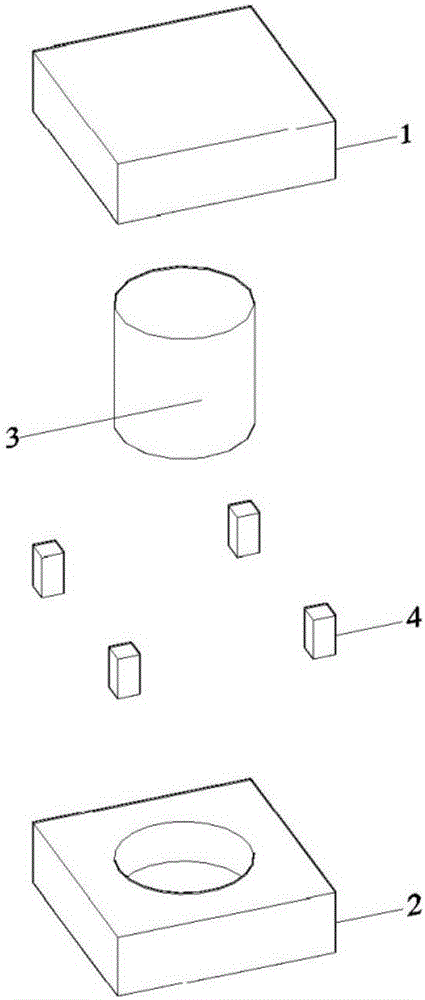

Ceramic crucible assembly and connection plate device thereof

InactiveCN102787362ALower the altitudeReduce the overall heightAfter-treatment apparatusCrucibleIngot

The invention discloses a connection plate device which is connected at a top opening end of a ceramic crucible; the connection plate device comprises a substrate frame (11); the substrate frame (11) comprises a plurality of side plates; a through hole is enclosed by the side plates and is communicated with the opening end of the ceramic crucible; the connection plate device also comprises a connection part (12); the connection part (12) is disposed at the bottom of the substrate frame (11), and is connected with the top opening of the ceramic crucible. The connection plate device provided by the invention can be used repeatedly, and thus about 1 / 3 of the ceramic crucible cost can be saved after casting of a furnace of ingots is completed; with the cost saved by paint, about 1700 yuan can be saved in total. With the guarantee that the height of the ceramic crucible itself is reduced, the invention can enable the continued normal application of the ceramic crucible. The invention also discloses a ceramic crucible assembly with the connection plate device.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

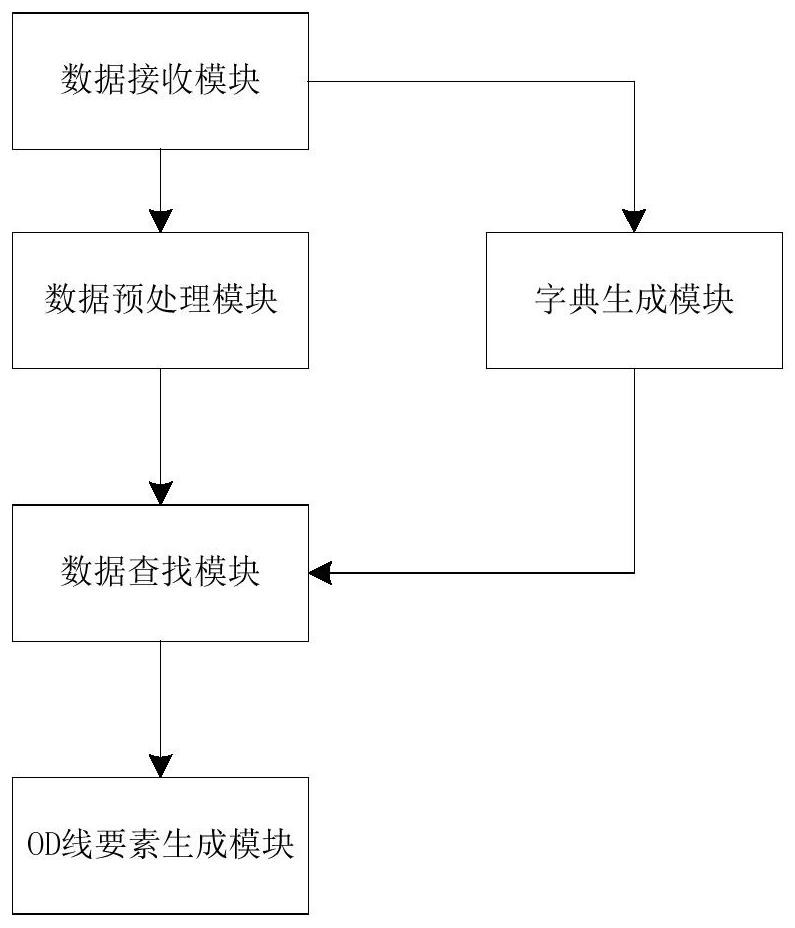

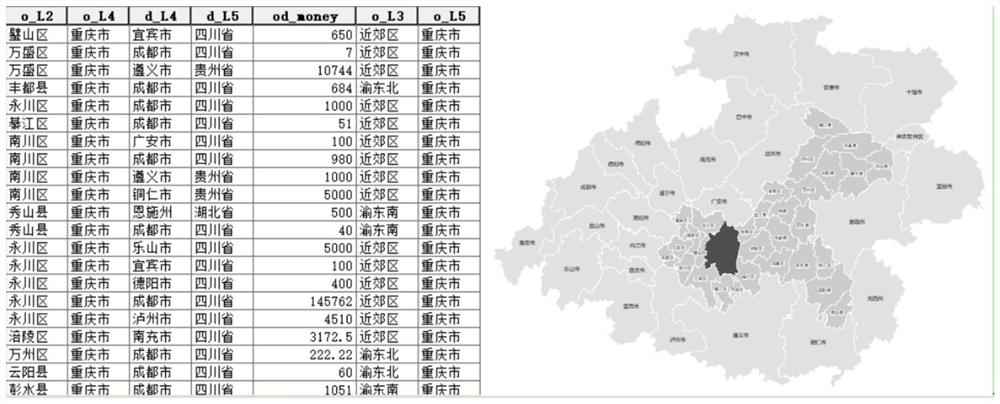

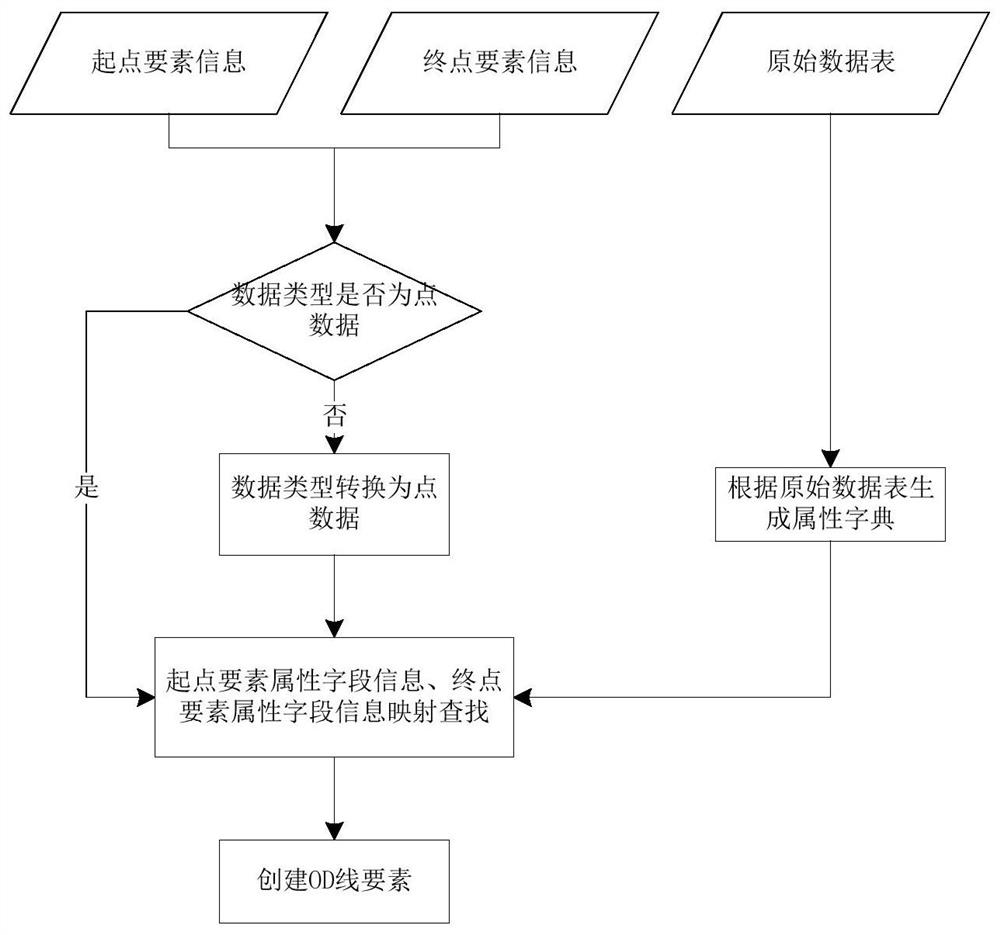

Efficient OD data visualization method and system

ActiveCN112948651ASatisfy normal useIncrease draw rateOther databases queryingOther databases browsing/visualisationDatasheetType conversion

The invention relates to the technical field of urban planning, and particularly discloses an efficient OD data visualization method and system, and the method comprises the steps: a dictionary generation module carries out the correlation searching of the OD terminal point information of a corresponding terminal point column or the OD starting point information of a starting point column according to the same OD starting point information in a starting point column of an original data table or the same OD terminal point information in a terminal point column, copying, extracting, permutation and combination are carried out to obtain sub-data tables, and an attribute dictionary is generated according to all the obtained sub-data tables; the data preprocessing module is used for performing data type analysis on the starting point element information and the end point element information respectively, and performing data type conversion on the starting point element information and the end point element information of which the data type is surface data to obtain the starting point element information and the end point element information of which the data type is point data; and the data searching module is used for searching corresponding OD line starting point information and OD line terminal point information from the attribute dictionary. By adopting the technical scheme of the invention, the OD line drawing efficiency can be improved.

Owner:重庆市规划设计研究院

Courtyard lighting equipment and control system

ActiveCN107270174AReduce complexitySuitable for different occasionsLighting support devicesElectric circuit arrangementsLight equipmentControl system

The invention discloses courtyard lighting equipment and a control system. The courtyard lighting equipment comprises a plastic shell, a light emitting assembly, a driving assembly and a control assembly, and the top of the plastic shell is open. The light emitting assembly is installed in the plastic shell. The light emitting pointing angle can be adjusted. An LED light bar fixed to an aluminum base plate is arranged in the light emitting assembly. A light guide column used for gathering light rays to the center, and two reflectors with adjustable angles are fixed to the light bar. The opening angles of the reflectors are adjusted by magnets attracting the reflectors. The whole light emitting assembly is a full-sealed waterproof structure. The control assembly controls the light emitting assembly to turn on or turn off light through an infrared signal. According to the courtyard lighting equipment and the control system, the structure is simple, installation is convenient, the light emitting angles of the light can be adjusted, wiring cost is low, waterproof and heat dissipation properties are both good, the courtyard lighting equipment and the control system are suitable for being used for courtyard lighting, and performance is stable and reliable.

Owner:广东煜航照明科技有限公司

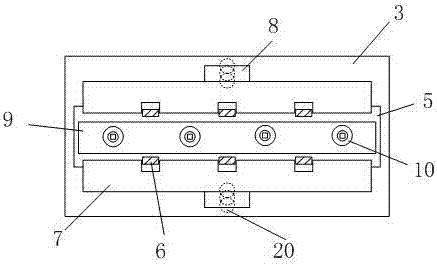

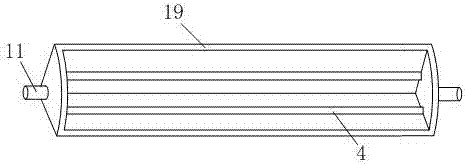

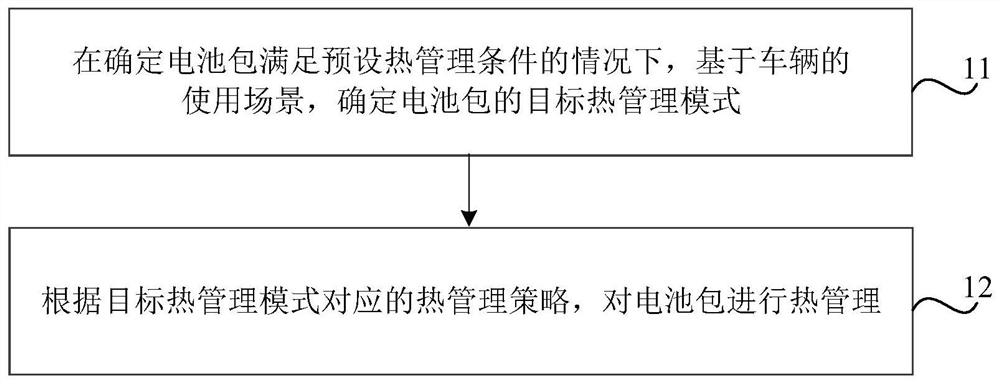

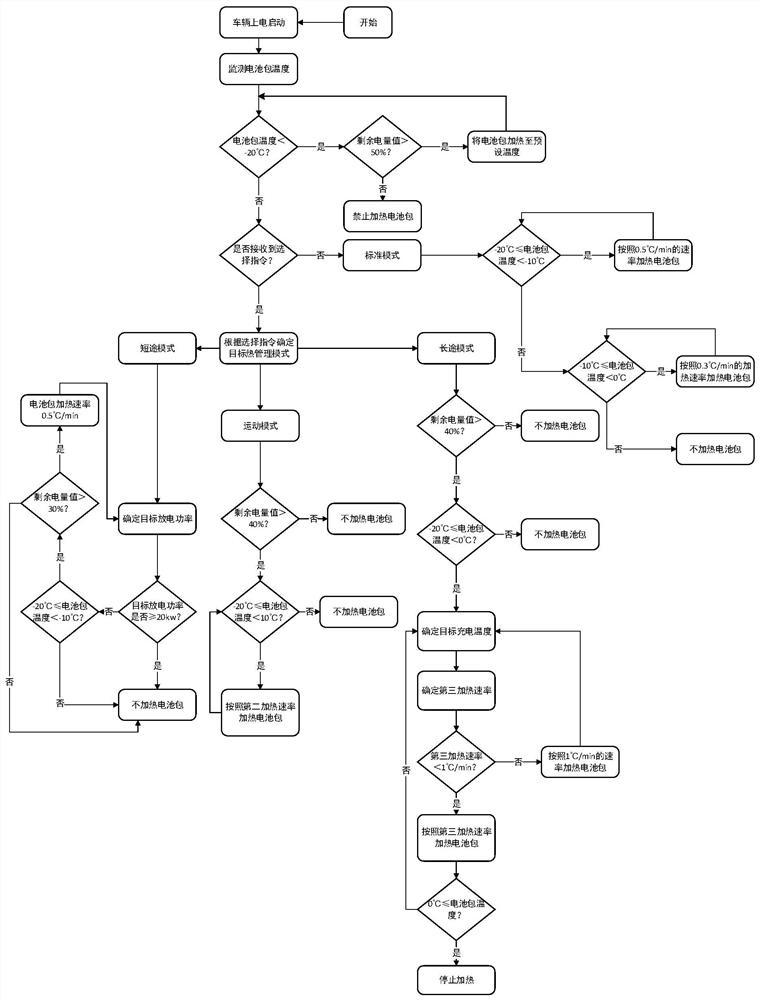

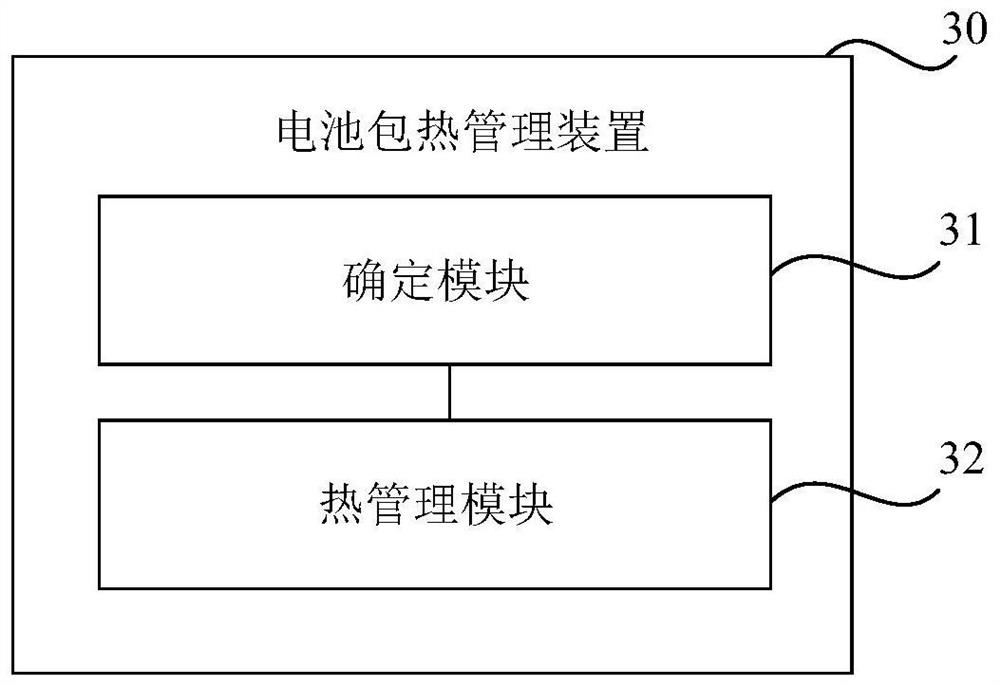

Battery pack thermal management method and device and vehicle

PendingCN114572060ASatisfy normal useReduce energy consumptionVehicular energy storageBattery/fuel cell control arrangementThermodynamicsHeat management

The invention relates to a battery pack heat management method and device and a vehicle. The method comprises the steps that under the condition that it is determined that the battery pack meets preset thermal management conditions, a target thermal management mode of the battery pack is determined based on a use scene of a vehicle, and the target thermal management mode is one of multiple preset thermal management modes; and performing thermal management on the battery pack according to a thermal management strategy corresponding to the target thermal management mode. Therefore, proper thermal management modes and thermal management strategies are set for different vehicle use scenes, so that the optimal thermal management strategy can be adopted to heat the battery pack in the different vehicle use scenes, normal use of the vehicle can be met, energy consumption for heating the battery can be saved, and energy waste is avoided.

Owner:GREAT WALL MOTOR CO LTD

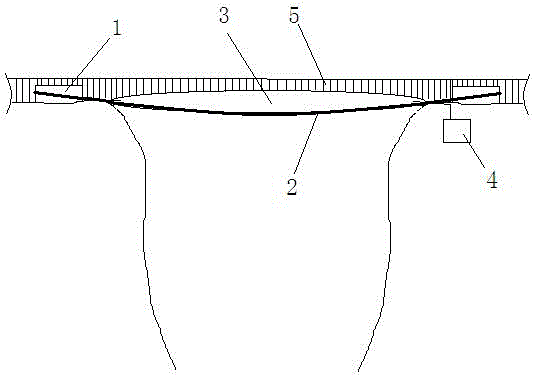

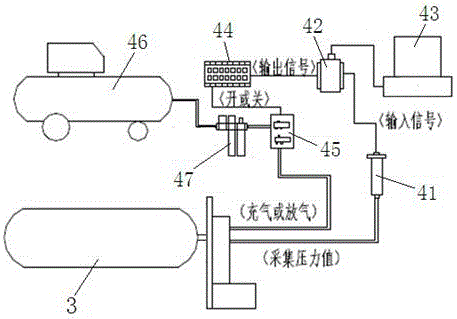

Tensioned air bag structure composite bridge

The invention discloses a tensioned air bag structure composite bridge comprising anchors, a steel strand pull string, an air bag, an air inflation pressure-stabilizing control system, a bridge surface paving structural layer and a connecting structure. The connecting structure is used for fixing the steel strand pull string, the air bag and the bridge surface paving structural layer into a whole. The two anchors are stably fixed on the two ends of a bridge span correspondingly, the anchors are fixedly connected with the two ends of the steel strand pull string, and the air bag is arranged above the steel strand pull string. The bridge surface paving structural layer is paved on the air bag, and the air inflation pressure-stabilizing control system is connected with the air bag. According to the tensioned air bag structure composite bridge, the good tensile performance achieved by combining the air bag manufactured from high performance fabric composite materials with the steel strand pull string is adequately used, so that the load requirement of crowds and vehicles on small and medium bridges is met, and less pressure surge in the air bag is guaranteed by the air inflation pressure-stabilizing control system, so that continuous tensile stress is provided. The tensioned air bag structure composite bridge is simple in structure and portable to transport, overall material using is less, the construction period is greatly shortened, and overall cost is remarkably reduced.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

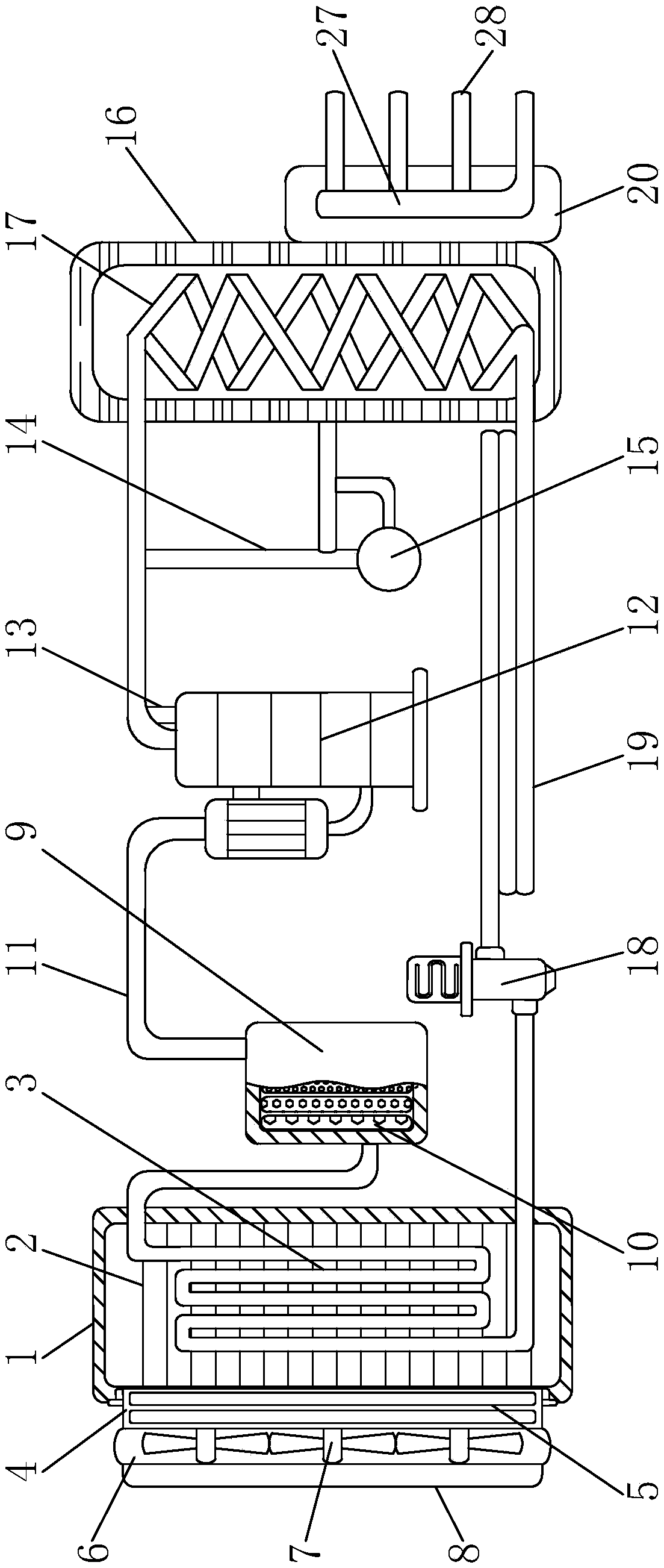

Air-energy water heater

ActiveCN108518862AAffect normal workImprove product performanceFluid heatersPump componentsEvaporationEngineering

The invention discloses an air-energy water heater. The air-energy water heater comprises an evaporator, a drying tank, a heat exchange water tank and a transition water tank, wherein an isolation sealing plate is installed on the inner wall of the evaporator, and the evaporator is connected with the isolation sealing plate in a welding manner; an evaporation contact pipe is arranged at the middleof the evaporator, and a first filter plate is installed at the left side of the evaporator; the first filter plate is installed at the left side of the evaporator in an embedding manner; a filter screen is arranged in the first filter plate, and the first filter plate is fixedly connected with the filter screen; water absorption sponge is arranged in the drying tank, and the drying tank is located at the right side of the evaporator; a heat exchange pipe is installed in the heat exchange water tank, and the heat exchange water tank is located at the right side of a condensation water collection ball; and cutting plates are fixed to the upper side and the lower side of the back surface of the transition water tank, and the transition water tank is located below the right side of the heatexchange water tank. The air-energy water heater can be used in a cold environment, and is rapid in heating and stable in running.

Owner:日照新睿招商发展有限公司

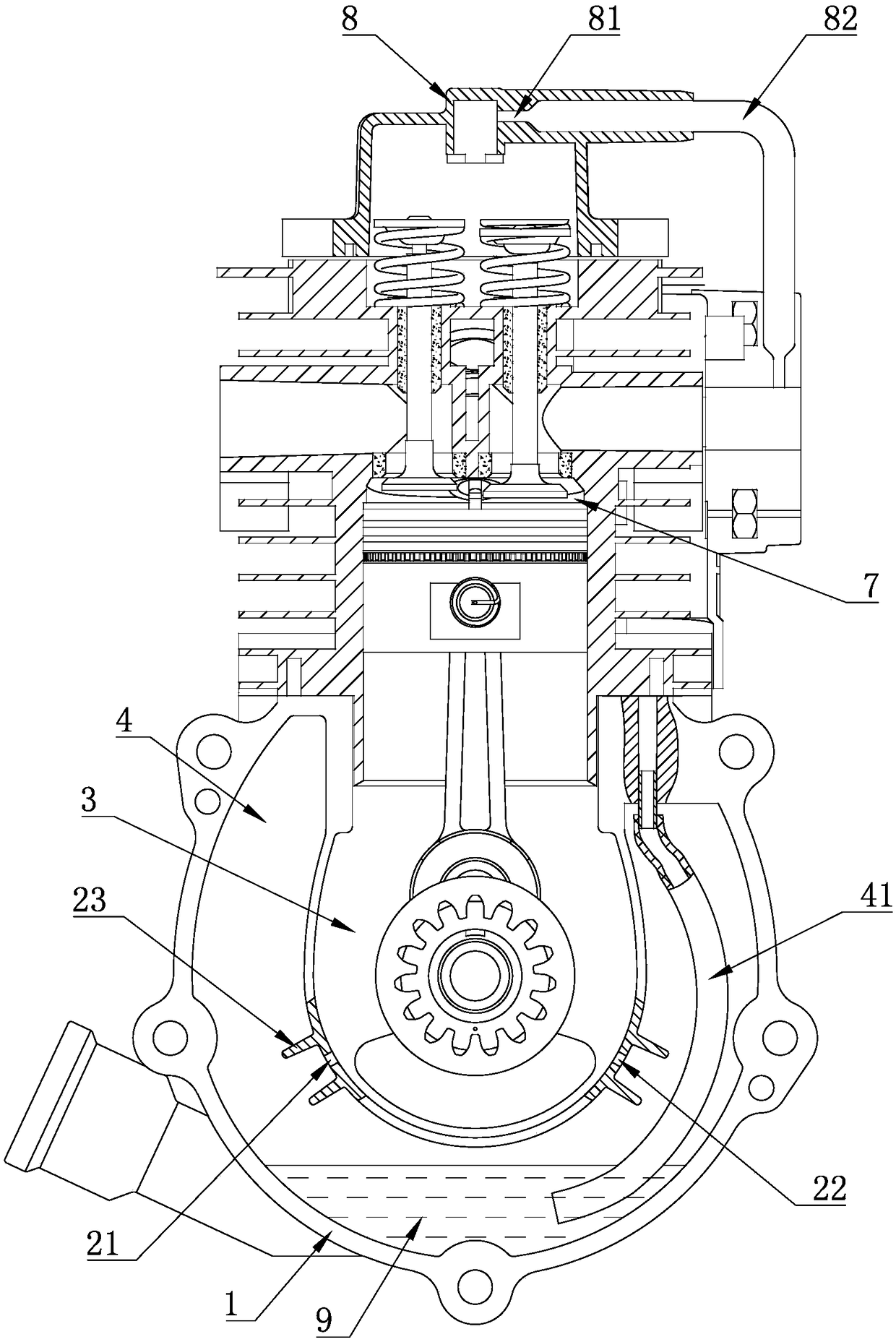

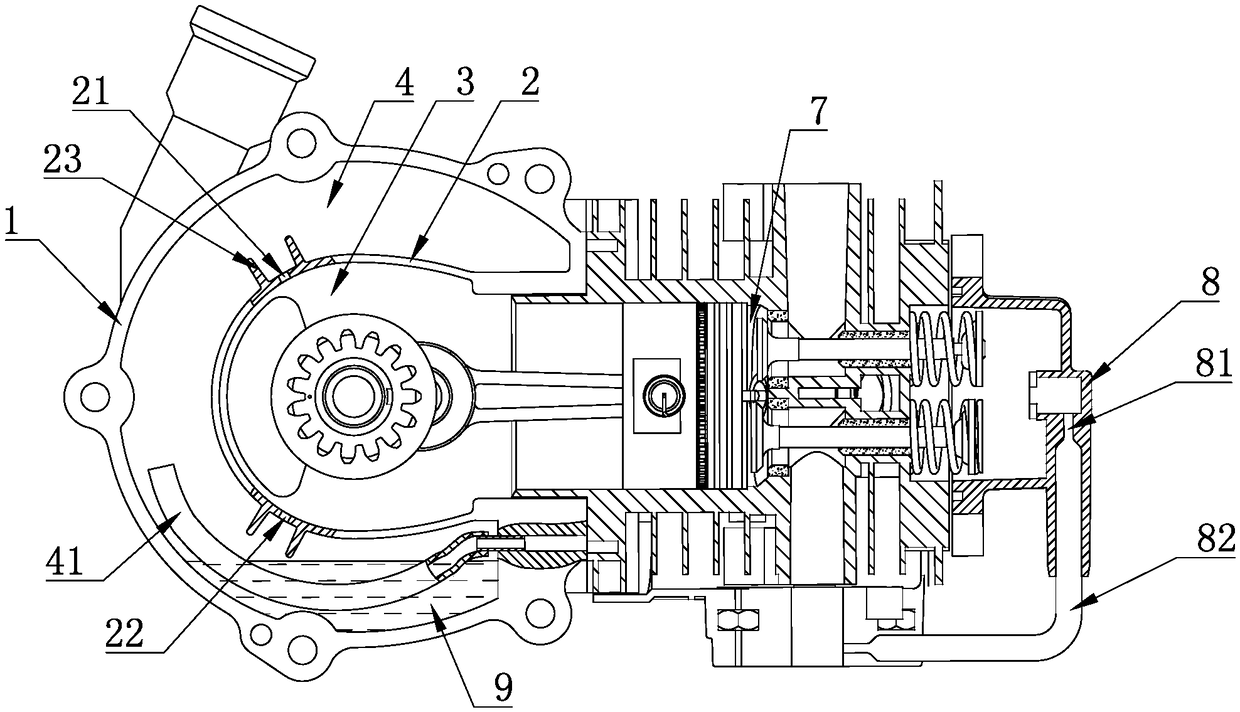

Lubricating system of four-stroke engine and tool equipment with four-stroke engine

PendingCN109268101AStable pressureTimely lubricationLubrication of auxillariesMachines/enginesFour-stroke engineCrankcase

The invention discloses a lubricating system of a four-stroke engine. The lubricating system comprises a crankcase, a lubricating oil tank and a cam chamber, the crankcase is provided with a crank chamber, the lubricating oil tank is positioned outside the crankcase, and the cam chamber is used for storage of a cam. A lubricating oil chamber for storage of lubricating oil is formed between the lubricating oil tank and the crankcase. The crankcase is provided with front oil taking holes in communication with the crank chamber and the lubricating oil chamber, and an oil pipe is connected betweenthe cam chamber and the lubricating oil chamber. By communication between the cam chamber and the lubricating oil chamber through the oil pipe, in operation of the four-stroke engine, vertical movement of a cylinder piston enables lubricating oil to enter the cam chamber through the oil pipe without passing through the crank chamber, and sufficient lubricating oil can enter the cam chamber to timely lubricate structures of the cam and the like to prevent abrasion. The invention further provides tool equipment with the four-stroke engine. The tool equipment comprises the four-stroke engine which adopts the lubricating system.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

Self-reset vacillation percussion energy-dissipation seismic isolation device

ActiveCN106437259AMinimize or even avoid damageAvoid damageProtective buildings/sheltersShock proofingStructural deformationEngineering

The invention discloses a self-reset vacillation percussion energy-dissipation seismic isolation device comprising an upper support seat and a lower support seat which are oppositely arranged; the opposite surfaces of the upper support seat and the lower support seat are provided with grooves; a vacillation percussion energy-dissipation block is installed between the grooves; a group of two-stage tensioned spacing assistant device is installed between the upper support seat and the lower support seat; the vacillation percussion energy-dissipation block is unbonded with the upper support seat and the lower support seat. According to the device of the invention, seismic isolation is achieved through lifting and dropping percussion of the vacillation percussion energy-dissipation block, structural deformation is concentrated in the seismic isolation system so as to reduce or even avoid damage on a main structure. Vacillation will not occur under effect of wind load or small seisms, which satisfies normal usage of buildings. Under strong earthquakes, seismic energy can be dissipated by the vacillation and percussion of the vacillation percussion energy-dissipation block; the vacillation and percussion stop when the external effect stops and self reset is achieved under the effect of gravity. After strong earthquakes, only a group of two-stage tensioned spacing assistant device is needed to replace, which is convenient for quick restoration after the earthquakes.

Owner:SOUTHEAST UNIV

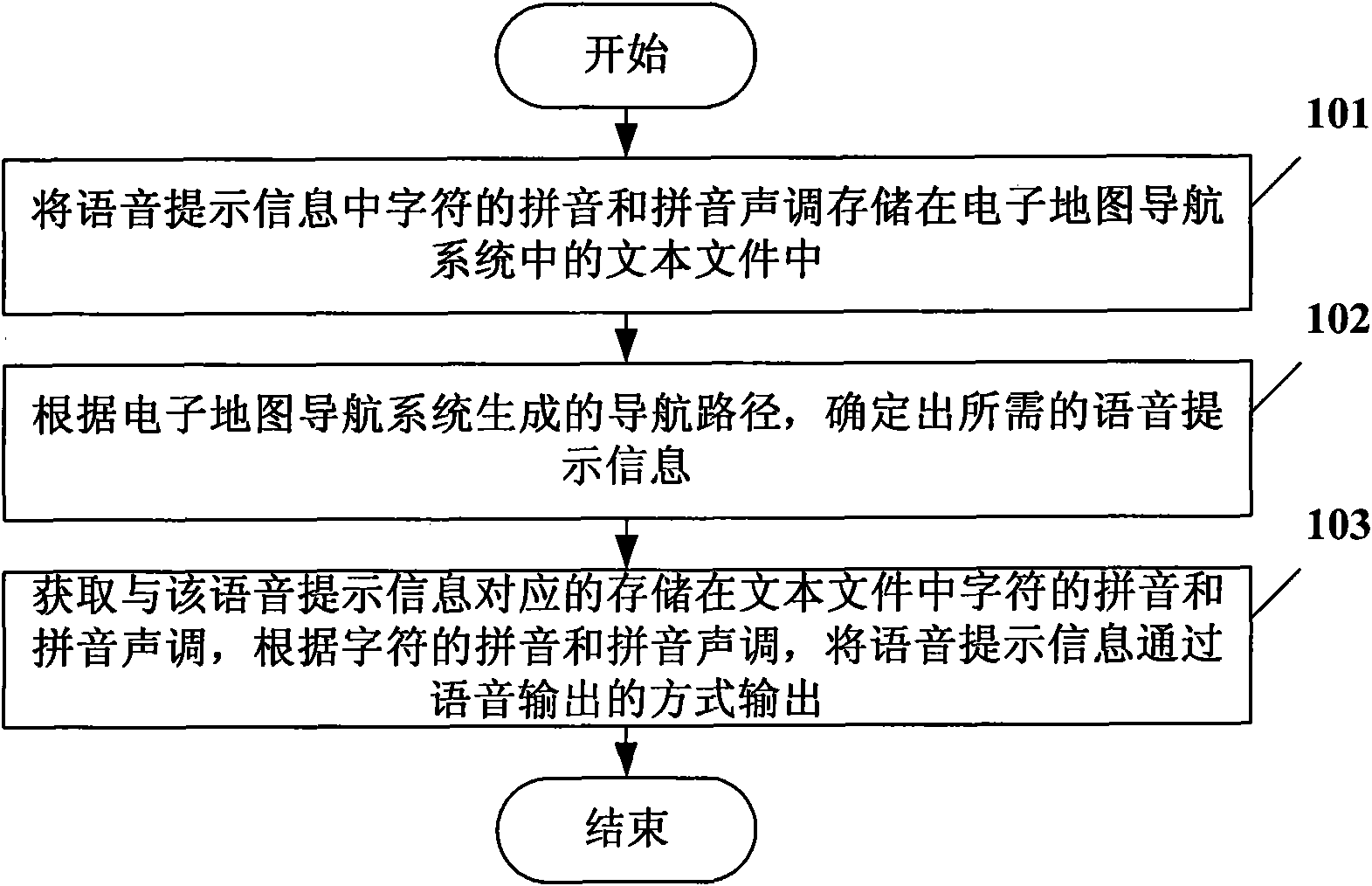

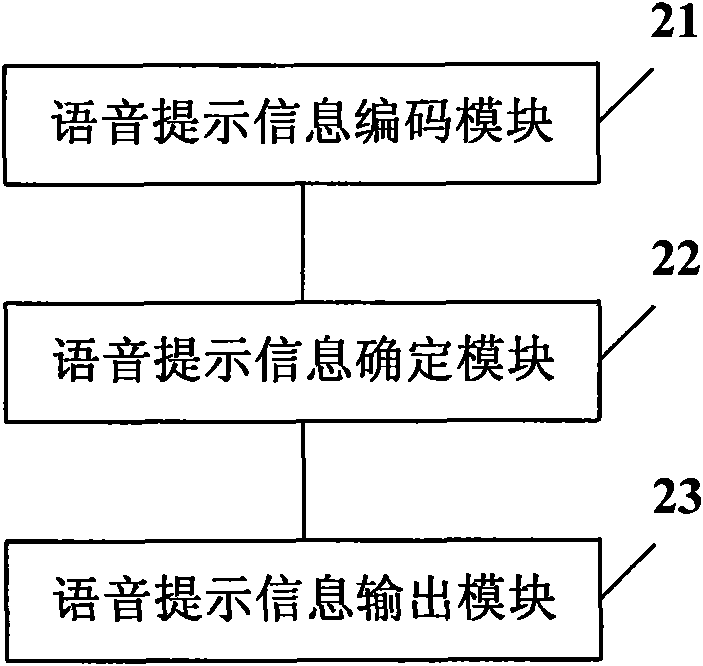

Method of voice navigation in electronic map navigation system and device thereof

InactiveCN101639362ASave storage spaceGuaranteed accuracyInstruments for road network navigationNavigation systemSpeech sound

The invention provides a method of voice navigation in an electronic map navigation system and a device thereof, belonging to the technical field of navigation. The method comprises the following steps of: memorizing the Pinyin and the Pinyin tone of the character in voice prompt information into a text file in the electronic map navigation system; according to a navigation route generated by theelectronic map navigation system, ensuring the required voice prompt information; and obtaining the Pinyin and the Pinyin tone of the character, which are memorized in the text file and are corresponding to the voice prompt information, and according to the Pinyin and the Pinyin tone of the character, outputting the voice prompt information by means of voice output. By memorizing the Pinyin and the Pinyin tone of the voice prompt information in the electronic map navigation system into the text file, the invention reduces the memory space of the voice prompt information, and leads the electronic map navigation system to be capable of voice indicating and guiding millions of interesting points.

Owner:NAVINFO

Putty powder for building and manufacturing process thereof

InactiveCN108373642ASatisfy normal useSimple manufacturing processFilling pastesMethyl celluloseNano zinc oxide

The invention discloses putty powder for a building. The putty powder is prepared from the following raw materials in parts by weight: 60-65 parts of ground calcium carbonate, 10-12 parts of talc powder, 6-8 parts of glue powder, 4-6 parts of redispersible latex powder, 2-4 parts of nano zinc oxide, 2-4 parts of lignocellulose, 1-3 parts of hydroxypropyl methyl cellulose, 1-3 parts of sodium hexametaphosphate, 1-3 parts of polyurethane resin and the balance water. The putty powder for the building is scientific in raw material formula, and enhances the adhesive force of a putty powder wallspace better, the putty powder is firmly adhered, block separating and falling problems are avoided, and the building quality is ensured. Problems of upheavals due to moisture return and coarse wallspacecan be also solved better, so that the wallspace attraction is ensured, and the building quality is also improved. The manufacturing process of the putty for the building is reasonable and simple, thelabor cost is saved better, the manufacturing efficiency is improved, the quality of the putty powder for the building is ensured, and the normal use for the building is met.

Owner:陈模永

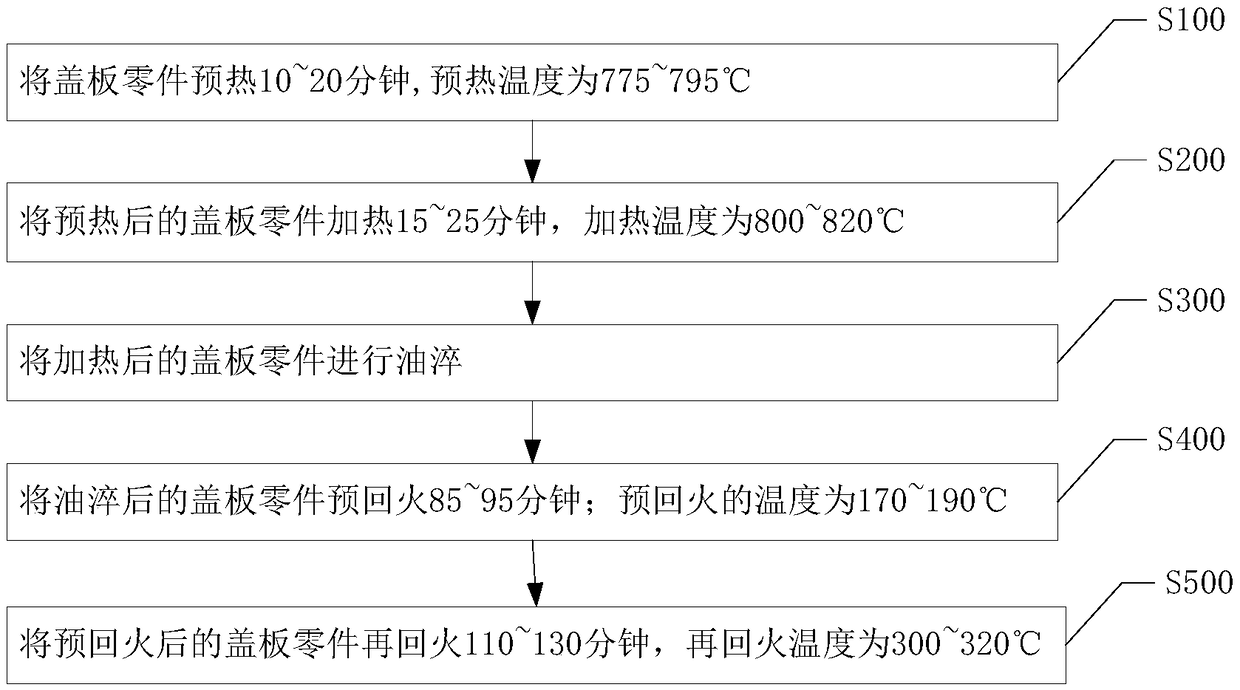

Method for preventing cracking of cover plate part

ActiveCN109182665AAvoid stress concentrationHigh hardnessFurnace typesHeat treatment furnacesQuenchingMechanical property

The invention discloses a method for preventing cracking of a cover plate part. The method comprises the following steps that S100, the cover plate part is preheated for 10-20 minutes, and the preheating temperature is 775-795 DEG C; S200, the preheated cover plate part is heated for 15-25 minutes, and the heating temperature is 800-820 DEG C; S300, oil quenching is carried out on the heated coverplate part; S400, pre-tempering is performed on the oil-quenched cover plate part for 85-95 minutes, and the temperature of the pre-tempering is 170-190 DEG C; and S500, the pre-tempered cover platepart is re-tempered for 110-130 minutes, and the re-tempering temperature is 300-320 DEG C. According to the method, imported steel is replaced with domestic manufacturing 65 Mn steel to prepare the cover plate part, so that the part not only has good mechanical properties, but also can be prevented from generating cracks, and then the manufacturing cost of the cover plate part is reduced.

Owner:RAINBOW METAL TECH

Charging type voice-control electromagnetic lock

InactiveCN105569453AObvious human characteristicsRealize automatic switch lockNon-mechanical controlsPasswordElectromagnetic lock

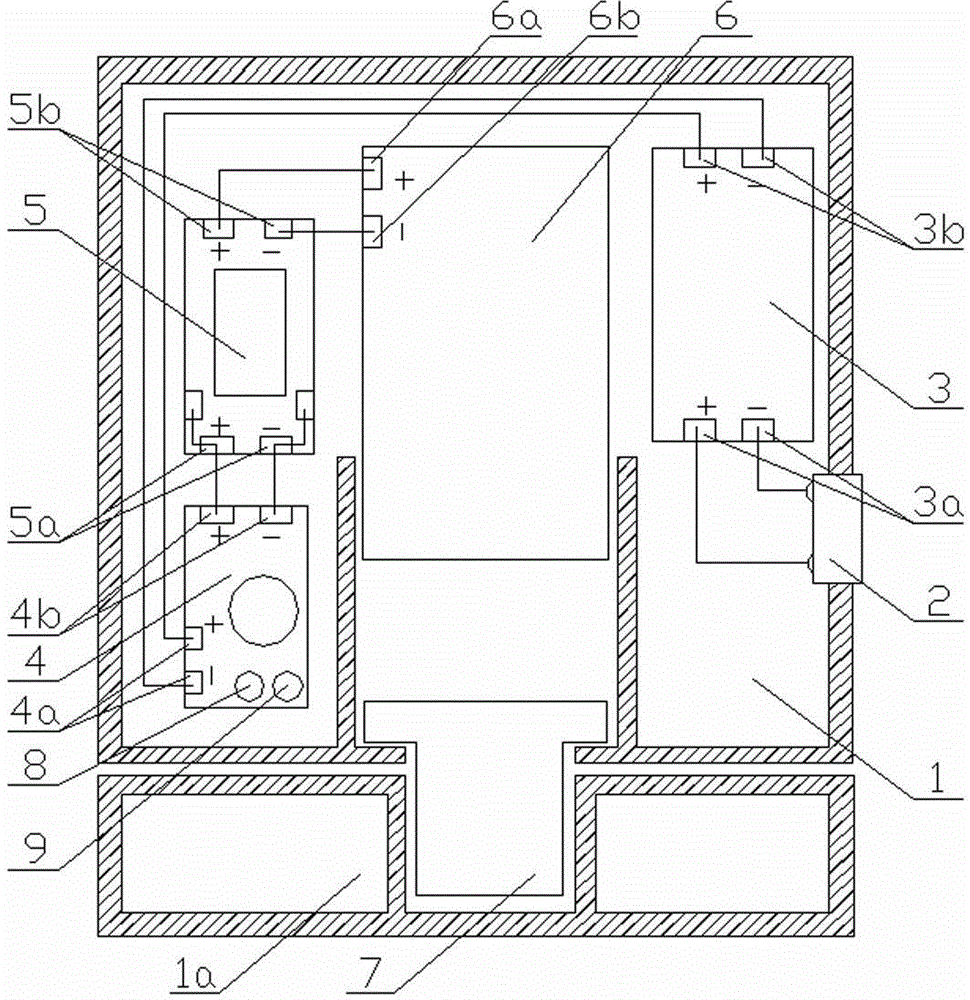

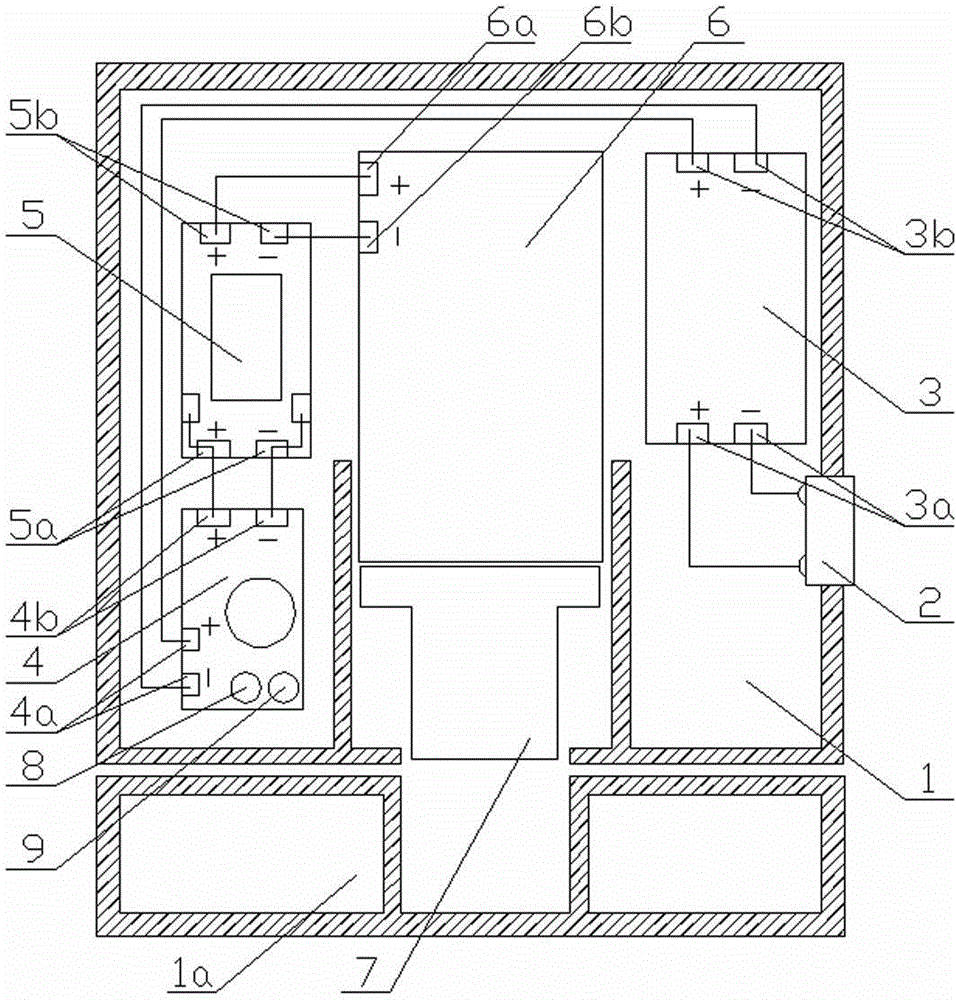

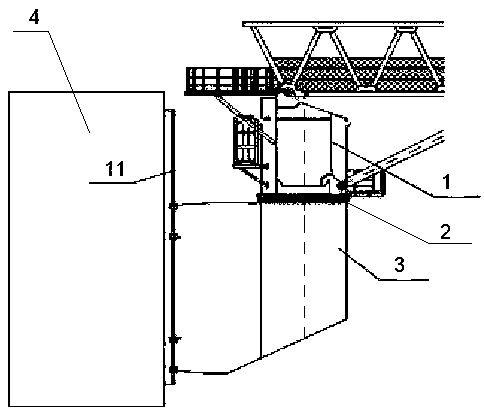

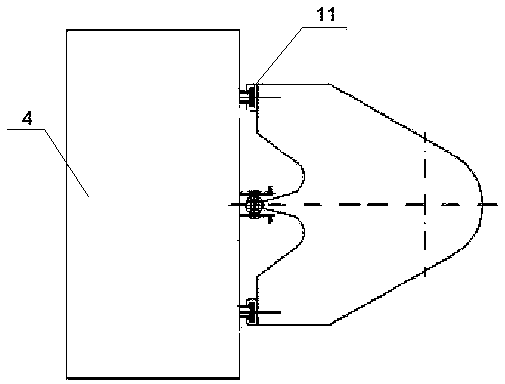

The invention discloses a charging type voice-control electromagnetic lock. The electromagnetic lock is characterized in that the lower portion of a shell (1) is provided with an opening, and a rechargeable battery (3) is installed in the shell (1); the output end (3b) of the rechargeable battery (3) is connected with the input end (4a) of a voice control module; the output end (4b) of the voice control module is connected with the input end (5a) of a relay module (5); the output end (5b) of the relay module (5) is connected with the input end (6a) of an electromagnet (6); an iron block (7) is installed below the electromagnet (6) and in the opening in the lower portion of the shell (1). According to the electromagnetic lock, unlocking and locking can be achieved only by saying passwords; especially, great convenience is achieved when the lock is used by people holding things with hands or by special populations; in addition, the storage battery is additionally arranged in the lock so that the lock can be used by people normally during power failure; meanwhile, the lock is simple in structure, low in cost and suitable for wide popularization.

Owner:CHONGQING JINGDI TECH

Gangway ladder base with lifting function

InactiveCN110775203ASatisfy normal useEasy to useCargo handling apparatusPassenger handling apparatusHull structureGangway

The invention discloses a gangway ladder base with a lifting function. The gangway ladder base comprises a gangway ladder, wherein a base at the bottom of the gangway ladder is driven by a gangway ladder supporting structure; the gangway ladder supporting structure comprises a supporting plate fixed at the bottom of the base; the supporting plate is connected with a lifting device of a ship body structure; the lifting device comprises a fixed plate connected with the ship body structure; the supporting plate is driven by a lifting oil cylinder on the fixed plate; lug plates at the two ends ofthe lifting oil cylinder are connected with pin holes in the edge of the fixed plate through low-position bolts and high-position bolts; and the supporting plate slides on the ship body structure through tracks on the two sides of the fixed plate. According to the gangway ladder base, the gangway ladder can be lifted to different heights, so that the gangway ladder can be normally used when an ocean platform and the outside have different heights.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com