Paired-control safety socket

A technology of safety sockets and sockets, which is applied in the direction of preventing contact with live contacts, electrical components, coupling devices, etc. It can solve the problems that safety sockets cannot be realized, the cost of safety sockets is high, and the protection effect is not good, so as to prevent children from electric shock Accident, simple structure, easy to promote the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

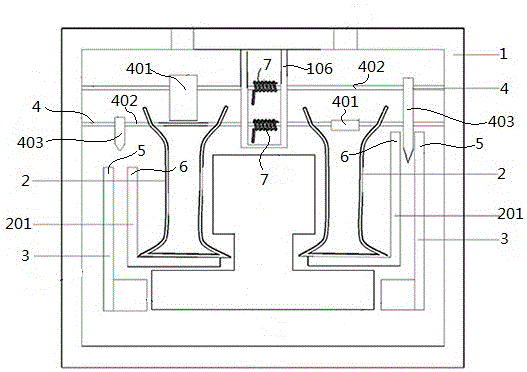

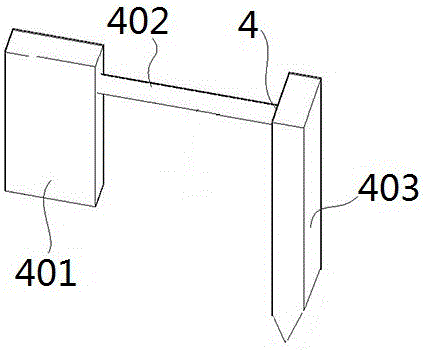

[0039] like Figure 1-2As shown, a control-type safety socket of this embodiment includes a housing (1), a socket contact piece (2) and an incoming line contact piece (3), a linkage contact device (4), a first static contact ( 5) with the second static contact (6); the linkage contact device (4) includes a power baffle (401), a linkage lever (402), a moving contact (403) and a spring (7); One end of the line contact piece (3) extends to the vicinity of the second static contact (6) to form a first static contact (5), and the other end is connected to a wire or a terminal; the second static contact (6) is a socket contact The pin structure (201) on the sheet (2); the first static contact (5) and the second static contact (6) are set at intervals relative to each other and the interval is located in the moving direction of the movable contact (403); the power The baffle plate (401), the linkage rod (402) and the movable contact (403) are fixedly insulated and connected; the pow...

Embodiment 2

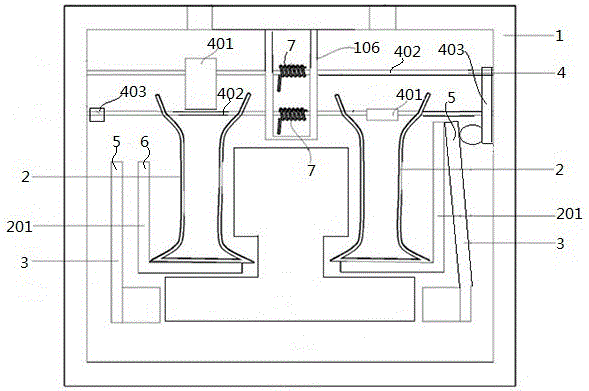

[0042] like image 3 As shown, the main structure of a control-type safety socket of this embodiment is the same as that of Embodiment 1, the difference is that the first static contact (5) and the second static contact (6) are located at the moving contact (403) Set on the same side in the direction; the moving contact (403) is located above the outer side of the first static contact (5) and the second static contact (6), and the linkage contact device (4) is triggered to rotate by inserting the plug into the socket of the shell. When the contact device (4) rotates to a certain position, it squeezes the first static contact (5) or the second static contact (6), so that the first static contact (5) and the second static contact (6) Direct contact makes electrical connection.

[0043] In order to optimize the extrusion effect, a corresponding protrusion can be provided in the extrusion direction of the end of the movable contact (403) away from the linkage rod (402).

Embodiment 3

[0045] like Figure 4 As shown, the main structure of a pair-controlled safety socket in this embodiment is the same as that in Embodiment 1, the difference is that the linkage contact device (4) is optimized to form an integrated movable contact (403) with the power baffle (401) structure, wherein the movable contact (403) is located on the back of the power baffle (401), in order to obtain better performance during use, the movable contact (403) is set as a protrusion to reduce the exertion of the linkage contact device (4). The angle of rotation required for the action; the first static contact (5) and the second static contact (6) are extended to a position where the rotation direction of the linkage contact device (4) behind the socket socket is compatible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com