Tensioned air bag structure composite bridge

A combined bridge and cable capsule technology, which is applied in bridges, bridge construction, bridge parts, etc., can solve the problems of difficult transportation of building materials, elongated construction period, and long construction period, and achieve simple structure, shortened construction period, and materials little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

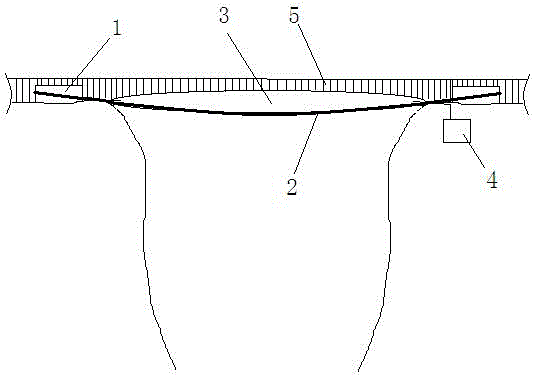

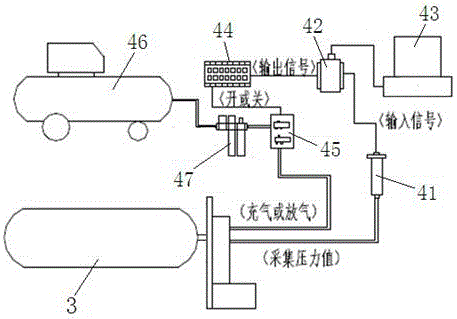

[0016] Such as figure 1 As shown, the present invention includes anchor ingot 1, steel strand cable 2, air bag 3, inflation and voltage stabilization control system 4, bridge deck pavement structure layer 5, and is used for fixing steel strand cable, air bag, bridge deck pavement A connection structure in which the structural layers are integrated. Two anchors 1 are separately installed and fixed at both ends of the bridge span. The two ends of the steel strand cables 2 are fixedly connected to the anchor spindles 1. The pavement structure layer 5 is laid on the top of the airbag 3 , and the inflation and pressure stabilization control system 4 is connected to the airbag 3 . The body of the airbag 3 includes a weather-resistant layer, a helium-resistant layer, a load-bearing layer and a heat-sealing layer from the outside to the inside. The weather-resistant layer uses a tadlar layer (or aluminized layer), the helium-resistant layer uses a Mylar layer, and the load-bearing lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com