Rapid-plugging waterproof connecting structure

A connection structure and fast technology, applied in the direction of connection, connecting parts of devices, devices for connecting/disconnecting connecting parts, etc. problems, to achieve the effect of improving product quality, improving waterproof level, and increasing pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

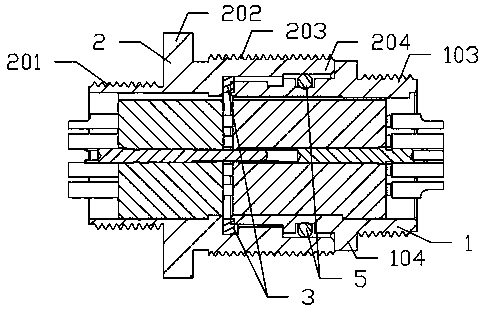

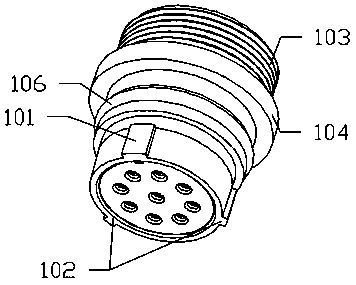

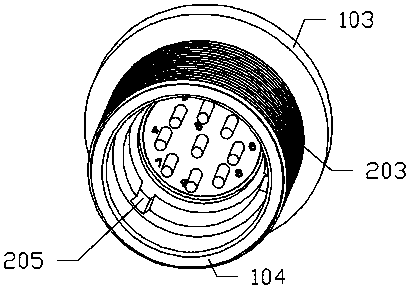

[0027] like Figure 1~3 As shown, this embodiment provides a quick-plug waterproof connection structure, including a matching plug interface 1 and a socket interface 2, and one end of the socket interface 2 is provided with a first external thread 201 for fixedly installing the Socket interface 2; the tail end of the first external thread 201 is provided with a base 202; the other end of the socket interface 2 is connected to the base 202, and the other end is a hollow inner cavity, and a second An external thread 203, a cavity wall 204 is formed between the inner cavity and the second external thread 203; a first waterproof layer is provided between the bottom surface of the inner cavity and the plug interface 1, and the first waterproof layer It is a waterproof pad 3, one end of the plug interface 1 is provided with a straight bayonet, and the plug interface is inserted into the card slot 205 in the socket interface 2 one by one along the bayonet, and the bayonet can be Div...

Embodiment 2

[0032] This embodiment is as a further improvement and supplement to embodiment 1, such as Figure 4 As shown, this embodiment is the second working form: the single socket interface 2 is fixed by the first external thread 201, a waterproof pad is laid on the bottom of the inner cavity, and the groove is sleeved The waterproof ring is inserted into the fastening nut 4 in the plug interface, and the bayonet is moved and installed to the inside of the socket interface 2 along the axis of the socket interface 2 in cooperation with the card groove. After the socket interface 2 and the plug interface are properly matched, the fastening nut 4 is screwed with the second external thread on the socket interface 2, which increases the pulling force for pulling apart the connecting structure, Moreover, the fixing method is simple in structure, avoids cumbersomeness and is not easy to plug in and out, improves the waterproof level of the connection structure, and further improves product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com