Soldering tin propelling and sucking multi-purpose device based on single chip microcomputer

A technology of a propulsion device and a single-chip microcomputer, which is applied in the field of solder suction device and solder propulsion, can solve the problems of increasing the overall weight of the cylinder, short circuits, time-consuming and labor-intensive, etc., and achieve the effects of improving welding efficiency, reducing virtual welding and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

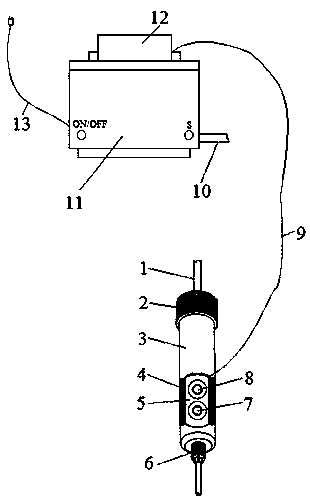

[0015] Such as figure 1 As shown, the multipurpose device of the present invention includes a cylinder body 3, a needle (6), an air pump 11 and a single-chip control unit 12. One end of the cylinder body 3 is provided with an air inlet, and the air inlet is connected to the air pump 11 through the gas hose 1. The gas port 10 of the air pump is connected, the other end of the cylinder 3 is equipped with a needle 6, the cylinder 3 is covered with a control mechanism 4, the control mechanism 4 is connected with the single-chip microcomputer control unit 12 through the communication wire 9, and the driver 22 on the air pump 11 is controlled by the single-chip microcomputer. Unit 12 is connected.

[0016] Driver 22 employs a portable vacuum pump.

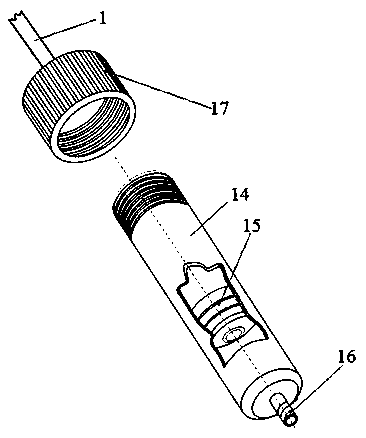

[0017] Such as figure 2 As shown, the cylindrical body 3 in the multipurpose device of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com