A laser sintering 3D printer

A 3D printer and laser sintering technology, applied in the field of additive manufacturing, can solve the problems of complex structure and high equipment requirements, achieve the effect of simple equipment, solve cleaning problems, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

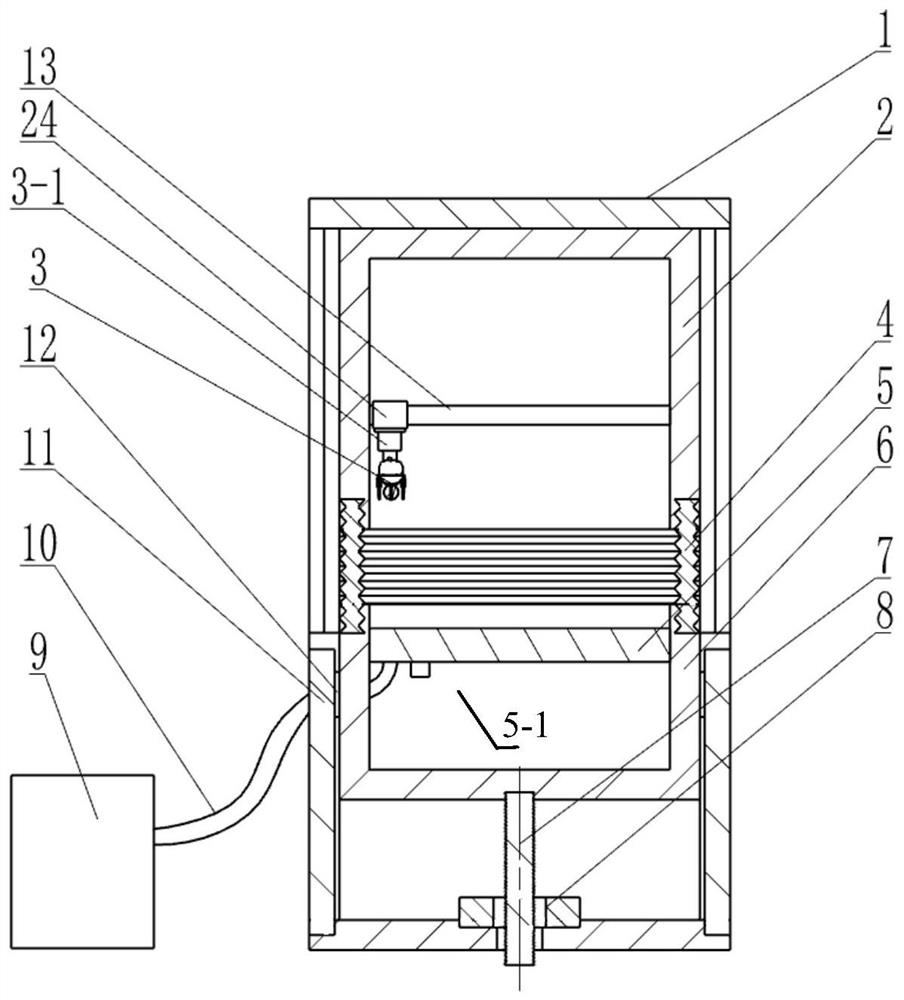

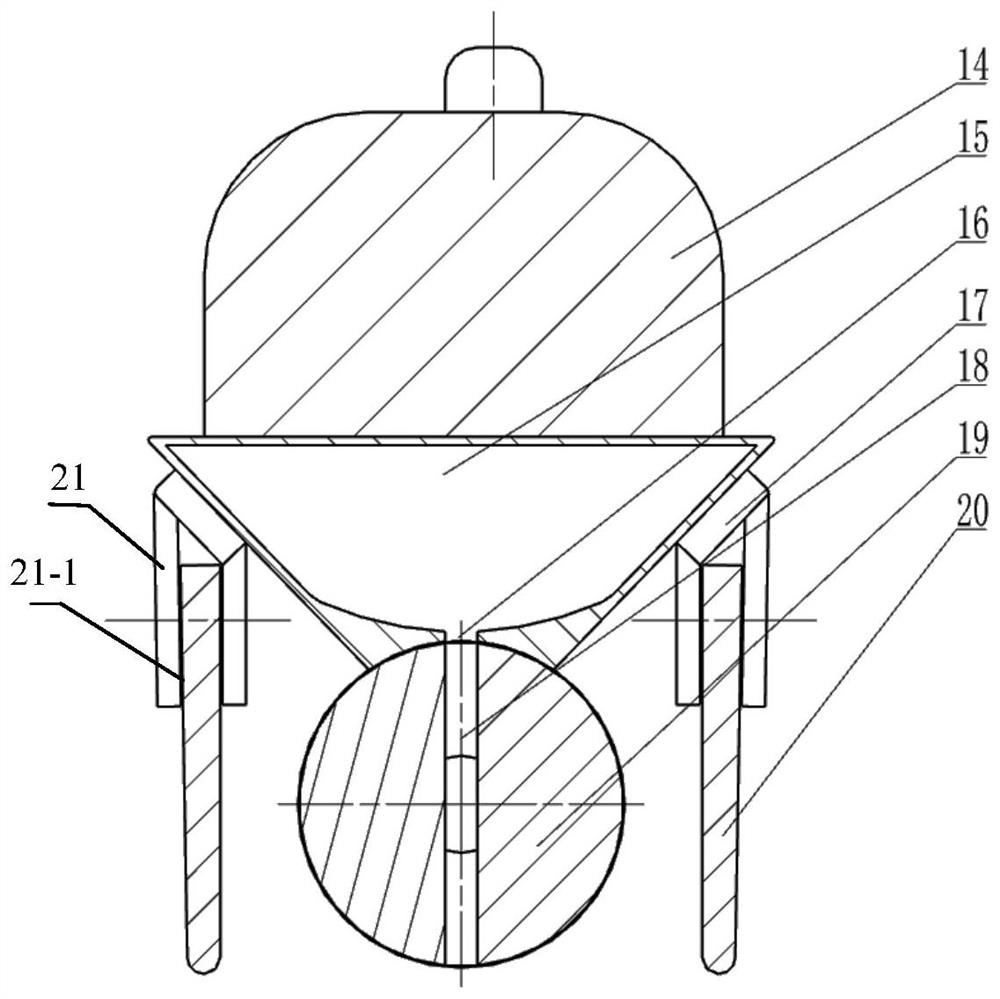

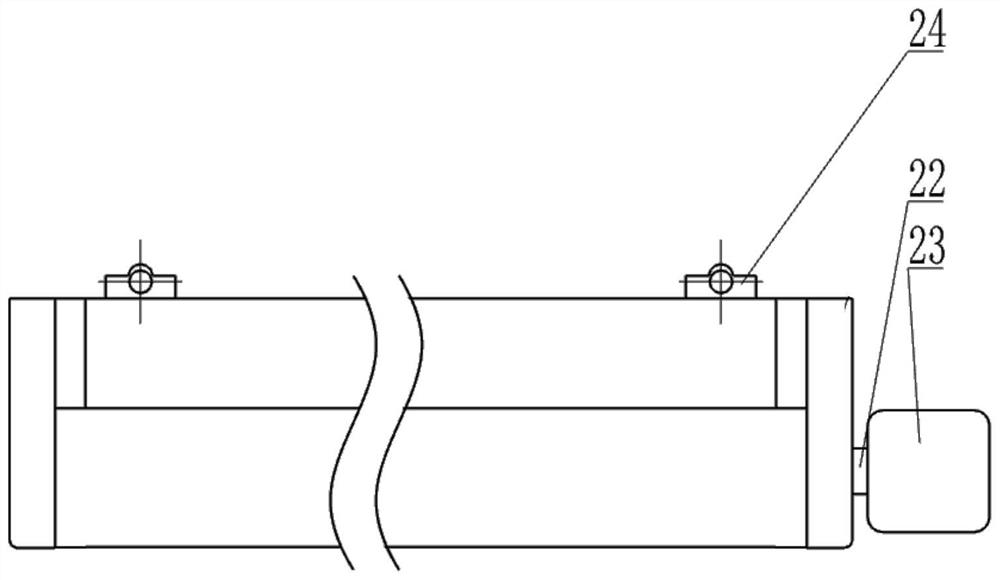

[0027] Embodiment 1: refer to Figure 1 to Figure 4

[0028] A laser sintering 3D printer includes a frame 1, a cylinder body, a workbench 5, a lead screw 7, a nut pair 8, a powder spreading device 3 and a powder collection box 9, and the cylinder body includes an upper cylinder body 2 and a lower cylinder body 6, The upper and lower cylinder bodies are connected through the telescopic structure 4; the telescopic structure together with the upper and lower cylinder bodies forms a sealed cavity. The workbench is arranged in the lower cylinder body and fixedly connected with the lower cylinder body. The screw 7 and the nut pair 8 are located at the center of the bottom end of the lower cylinder 6, which is consistent with the Z-axis direction of the cylinder; the lower cylinder 6 is equipped with a supporting cylinder and cooperates with the screw 7 and the nut pair 8 to make the lower cylinder 6 lift The stable guide rail 11 of motion. The telescopic structure 4 is a colloid...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the cross section of the telescopic structure is circular, and the rest of the structure, connection mode and working mode are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com