Automatic dosing machine with mobile receiving function

An automatic batching and functional technology, applied in home appliances, kitchen utensils, applications, etc., can solve the problems of increased cost of material connection, complex implementation methods, and increased cost of material connection, and achieve cost saving, simple structure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail through the following embodiments. However, those skilled in the art should understand that the following embodiments do not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

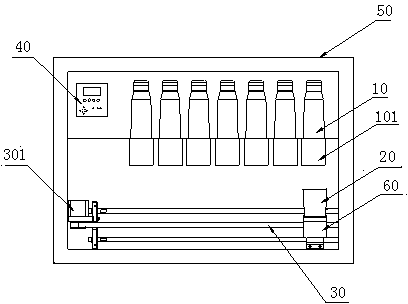

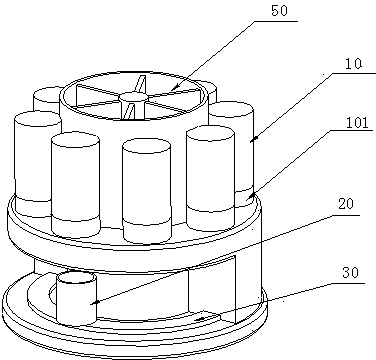

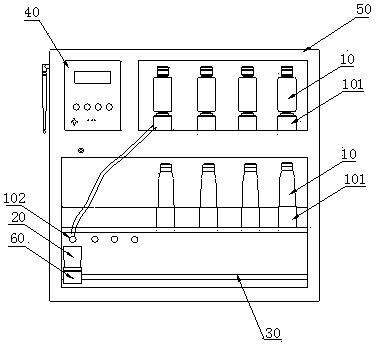

[0040] The automatic batching machine with the function of moving materials proposed by the present invention mainly includes a material storage container 10 , a material receiving container 20 , a sliding part 30 , a control part 40 and a frame 50 . Wherein, the material storage container 10 is installed on the frame 50, and its discharge port is positioned at the top of the material receiving container 20; The material receiving container 20 is arranged on the sliding part 30, and the sliding part 30 is installed on the frame 50; The material storage container 10 has a storage The material container control mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com