Laser sintering 3D printing machine

A 3D printer and laser sintering technology, applied in the field of additive manufacturing, can solve problems such as high equipment requirements and complex structures, achieve simple equipment, solve cleaning problems, and prevent the accumulation of excess printing powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

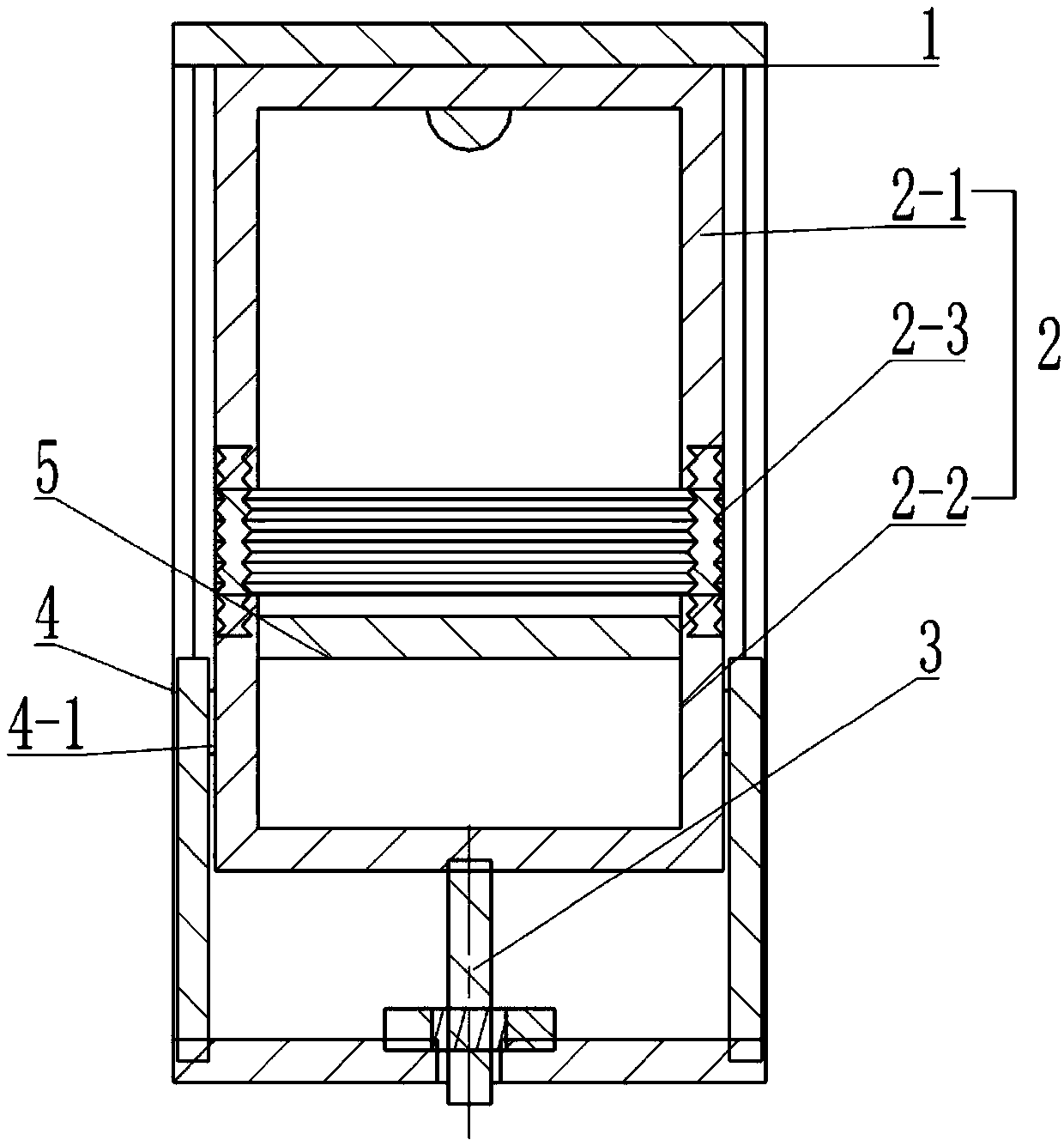

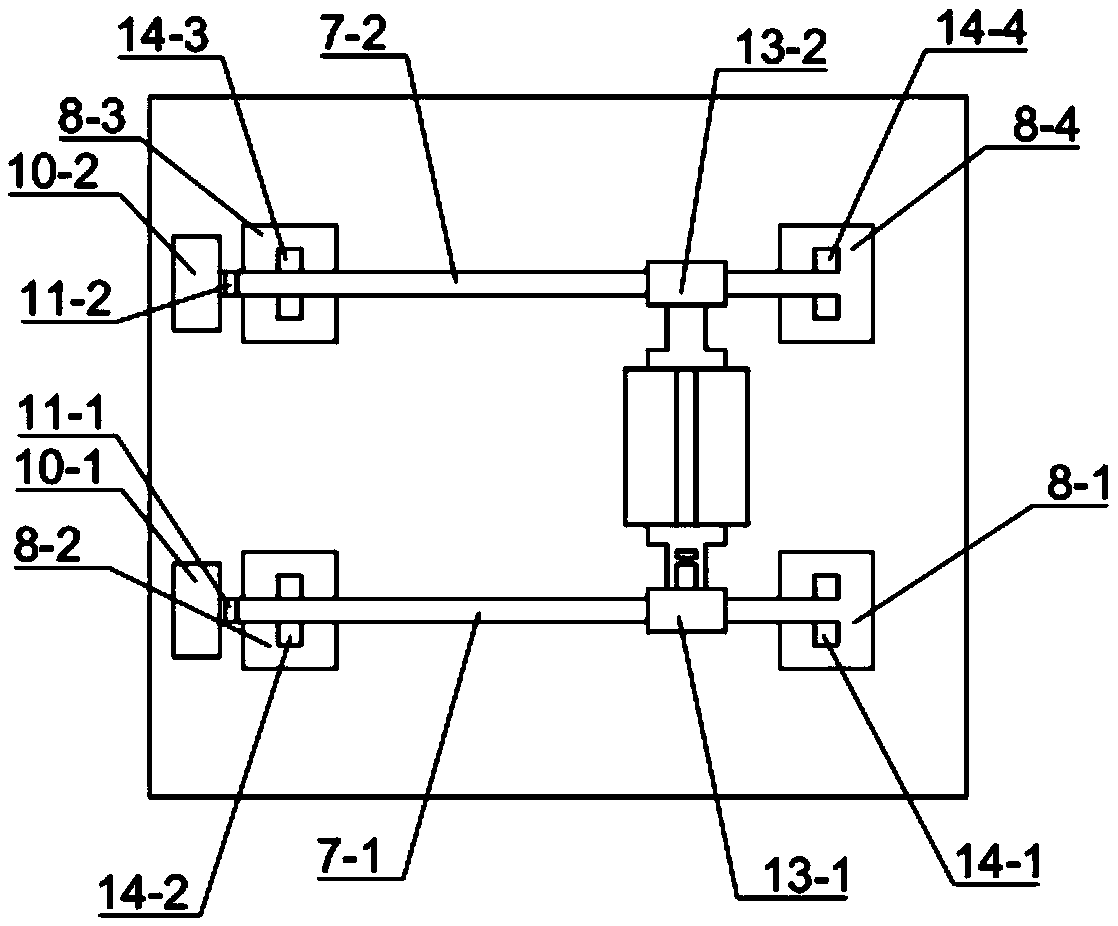

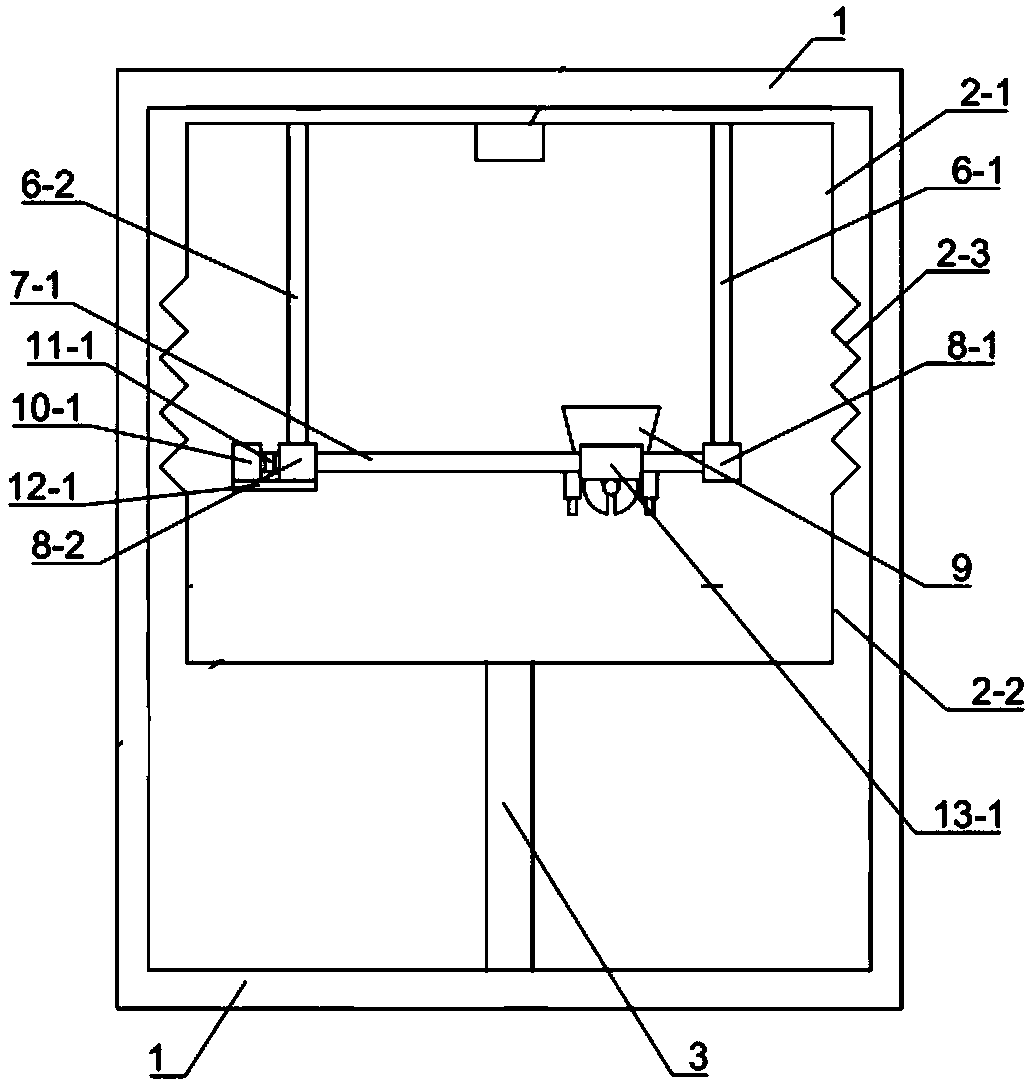

[0030] Embodiment 1: refer to Figure 1 to Figure 6

[0031] A laser sintering 3D printer, including a frame 1, a molding cylinder 2, a laser head 5 and a powder spreading device 9, the molding cylinder 2 is installed in the frame 1, and the molding cylinder 2 includes an upper cylinder body 2-1 and a lower cylinder body 2 -2. The workbench (5) is located inside the lower cylinder body (2-2), and is fixedly connected with the lower cylinder body (2-2).

[0032] The upper cylinder 2-1 is fixedly connected to the upper part of the frame 1, the lower cylinder 2-2 is movably connected to the bottom of the frame 1 through the vertical ball screw pair 3, and the lower cylinder 2-2 is connected to the vertical ball screw pair Under the drive of 3, lift motion is done in frame 1. The upper cylinder body 2-1 and the lower cylinder body 2-2 are connected through the telescopic structure 2-3, and the upper cylinder body 2-1 and the lower cylinder body 2-2 form a closed cavity through ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that a sealing gasket is installed between the arc-shaped bottom of the powder supply tank 9-1 and the powder spreading roller 9-2, and other structures, connection methods, and working methods are the same as in Embodiment 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com