Carbon nanotube, device and purification method purified by gas phase damping method

A carbon nanotube and damping method technology, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, can solve the problems of high energy consumption and serious pollution, and achieve uniform particle size, high purity, and prolonged floating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

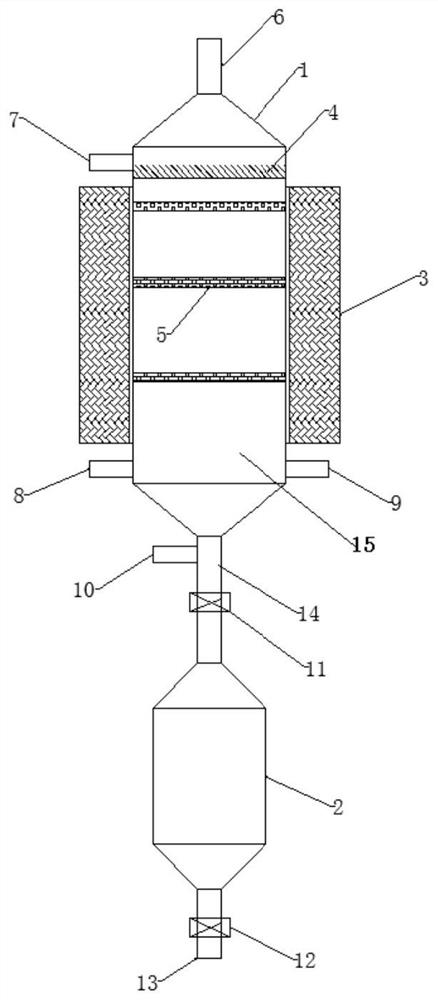

[0047] Such as figure 1 As shown, a device for purifying carbon nanotubes by a gas-phase damping method includes a purification chamber 15, a cooling chamber 2 located below the purification chamber 15 and connected thereto, and a filter 1 located above the purification chamber 15 connected thereto;

[0048] A heating furnace 3 arranged outside the purification chamber 15 for heating the purification chamber 15;

[0049] The upper side wall of the purification chamber 15 is provided with a carbon nanotube feeding port 7, the top of the filter 1 is provided with a waste gas port 6, and the bottom of the purification chamber 15 is provided with a purified gas inlet 8, a nitrogen gas inlet valve port 9 and a discharge port. Port 14, the purified gas inlet port 8 and the nitrogen gas inlet valve port 9 are symmetrically arranged on the lower side wall of the purification chamber 15;

[0050] The purification chamber 15 is sequentially provided with an ultrasonic vibrating screen ...

Embodiment 2

[0056] A device for purifying carbon nanotubes by gas-phase damping method is the same as that in Example 1.

[0057] Specifically:

[0058] With 80g nickel base catalyst (carrier is SiO 2 ) synthesized multi-walled carbon nanotubes (marked as example 2), the gas phase damping circle is set to 30 circles, after the carbon nanotube feeding port 7 is loaded into the ultrasonic vibrating screen 4, the carbon nanotube feeding port 7 is closed, and the waste gas port 6 is opened , open the nitrogen gas inlet valve port 9 to feed nitrogen gas, replace and purify the indoor air atmosphere, when the oxygen content is lower than 1%, close the exhaust gas port 6 and the nitrogen gas inlet valve port 9, and then raise the temperature to 1100°C through the heating furnace 3 , the pneumatic ultrasonic vibrating sieve 4 feeds materials to the purification chamber, the carbon nanotube feeding rate of the ultrasonic vibrating sieve is 200g / min, and the nitrogen gas inlet valve 9 is opened at...

Embodiment 3

[0061] A device for purifying carbon nanotubes by gas-phase damping method is the same as that in Example 1.

[0062] Specifically:

[0063] 12g of cobalt-based catalyst (carrier is SiO 2 ) synthesized multi-walled carbon nanotubes (marking as example 3), the gas phase damping circle is set to 22 circles, after the carbon nanotube feeding port 7 is loaded into the ultrasonic vibrating screen 4, the carbon nanotube feeding port 7 is closed, and the waste gas port 6 is opened , open the nitrogen gas inlet valve port 9 to feed nitrogen gas, replace and purify the indoor air atmosphere, when the oxygen content is lower than 1%, close the exhaust gas port 6 and the nitrogen gas inlet valve port 9, and then raise the temperature to 1100°C through the heating furnace 3 , the pneumatic ultrasonic vibrating sieve 4 is fed to the purification chamber, the carbon nanotube feeding rate of the ultrasonic vibrating sieve is 300g / min, and the nitrogen inlet valve 9 is opened at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com