Powder quantitative supply device for selective laser melting 3D printing

A laser selective melting and 3D printing technology, applied in the field of 3D printing, can solve the problems of increased difficulty, high manufacturing requirements and cost, powder leakage, etc., and achieve the effect of improving powder utilization, simple and convenient operation, and low manufacturing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

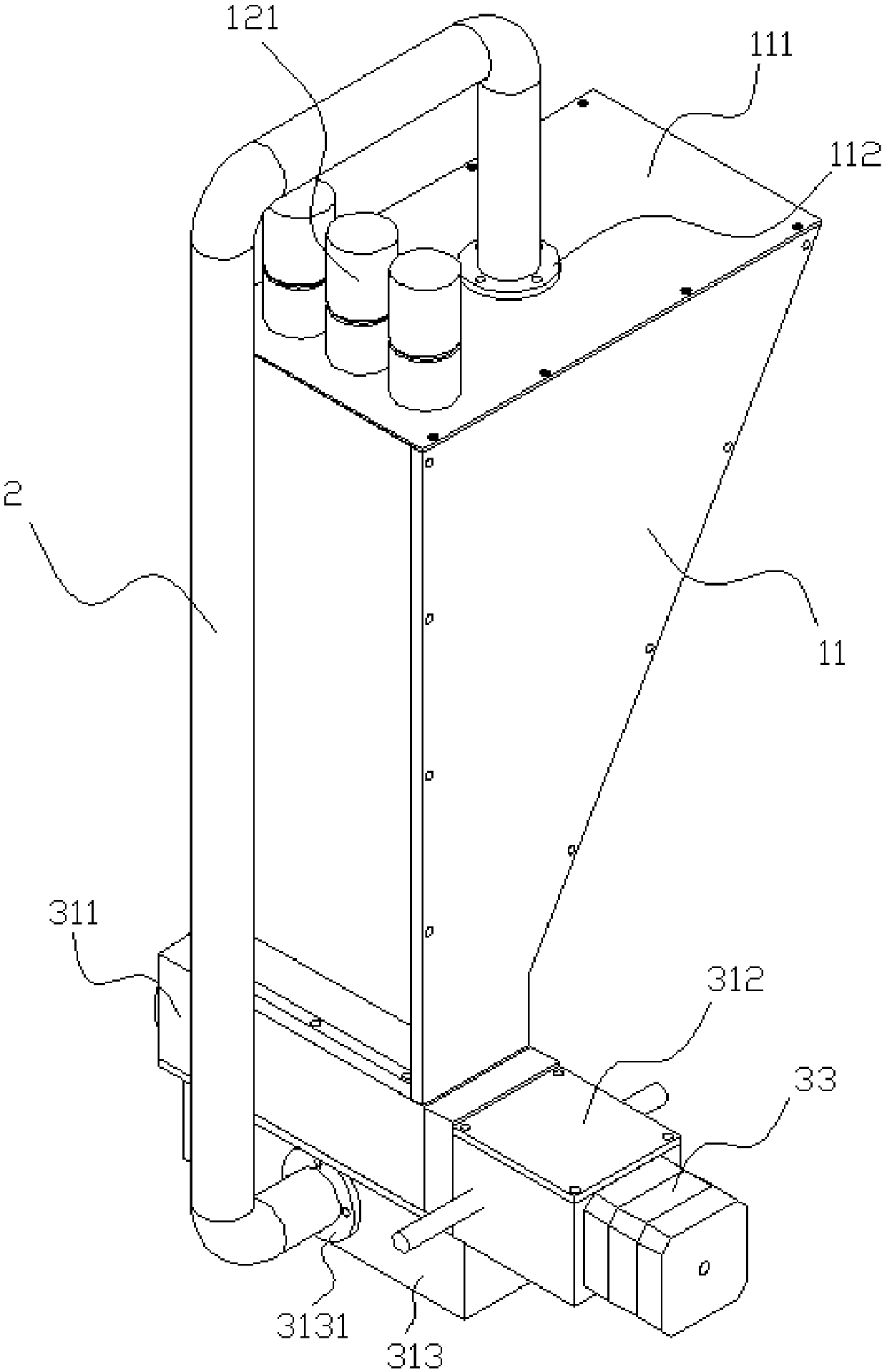

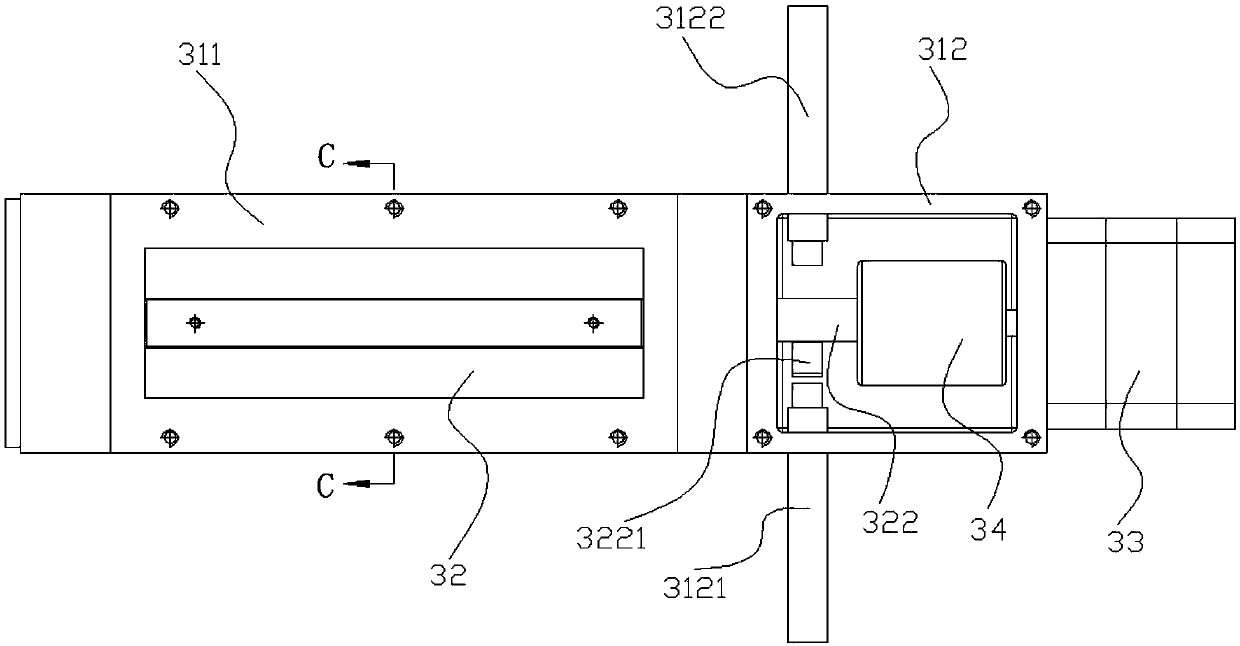

[0031] The powder quantitative supply device for laser selective melting 3D printing of the present invention includes a powder supply mechanism, an air pressure balance tube, a powder release mechanism, a forming mechanism, a powder spreading mechanism and a control system.

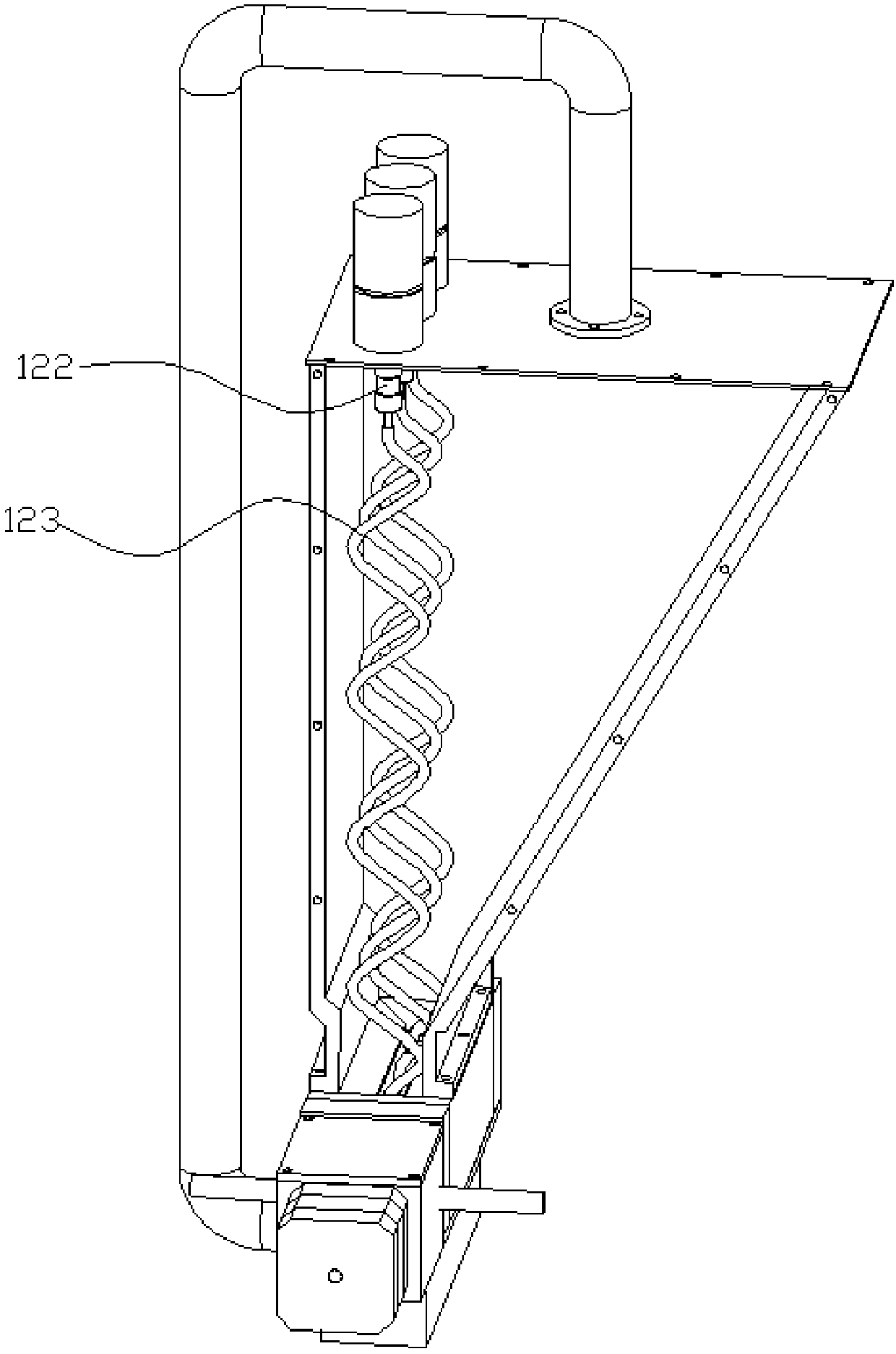

[0032] see figure 1 with 2 , the powder supply mechanism includes a powder supply box 11 and a disturbance mechanism. The powder supply box 11 is funnel-shaped, and its top is provided with an openable powder supply box cover 111, and its bottom communicates with the powder inlet 3112 on the top of the first box of the powder release mechanism. The top of the powder supply box 11 is provided with a first vent hole and a first vent flange 112 fixed thereon. The agitation mechanism includes at least one agitation motor 121 fixed on the top of the powder supply box 11, and is installed inside the powder supply box 11 and connected to the output shaft of the agitation motor 121 through a first coupling 122...

Embodiment 2

[0049] The structure of the powder quantitative supply device of the present embodiment 2 is roughly the same as that of the powder quantitative supply device of the embodiment 1, the main difference lies in the powder spreading mechanism: please refer to Figure 7 , the powder spreading mechanism includes a powder spreading box 52 and a first powder spreading scraper 53 and a second powder spreading scraper 54 respectively fixed on both sides of the powder spreading box 52; the bottom of the powder spreading box 52 is provided with a powder spreading port , the powder spreading box 52 can be controlled by the command issued by the control system, and moves from the first side of the working surface 4211 to its second side at a constant speed, and the first powder spreading scraper 53 moves synchronously to spread the powder On the effective working surface 42111, after completing the processing of one layer, the powder spreading box 52 moves at a constant speed from the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com