Automatic device for preparing oil into fuel gas

An automatic device, oil-based technology, used in transportation and packaging, gas and gas/vapor mixing, mixers, etc., can solve the problem of inability to achieve quantitative and fixed ratio mixing of oil and air, inability to effectively prevent reduction to liquid, difficult oil. Problems such as mixing ratio with air, to achieve the effect of omitting heating device, stable pressure, and improving output and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

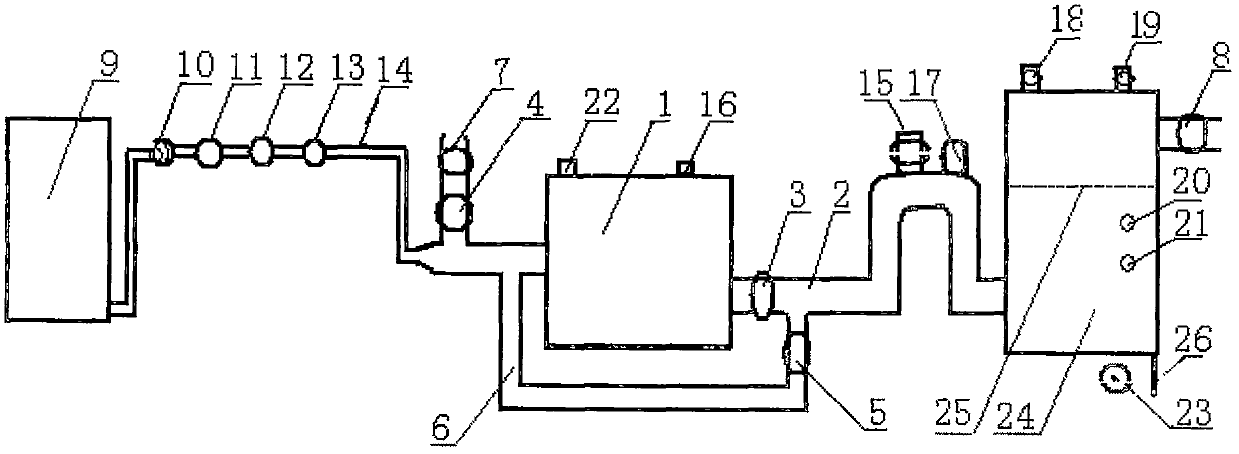

[0021] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0022]An oil-to-gas automatic device, comprising: a high-pressure blower 1, a delivery pipeline 2, a check valve 3, an air flow meter 4, a pressure relief diverter valve 5, a diverter feedback pipe 6, an air flow regulator 7, a gas switch 8, a gas storage Oil tank 9, oil valve 10, flow regulator 11, solenoid valve 12, flow meter 13, oil delivery pipe 14, automatic pressure control switch 15, automatic fan temperature control switch 16, automatic gas temperature control switch 17, safety valve 18, vent solenoid Valve 19, overpressure alarm 20, overtemperature alarm 21, fan temperature alarm switch 22, leakage alarm 23, buffer tank 24, anti-static n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com