Lift, in particular traction sheave lift

A technology for pulling pulleys and elevators, which is applied in the field of elevators and can solve problems such as increasing the height of shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

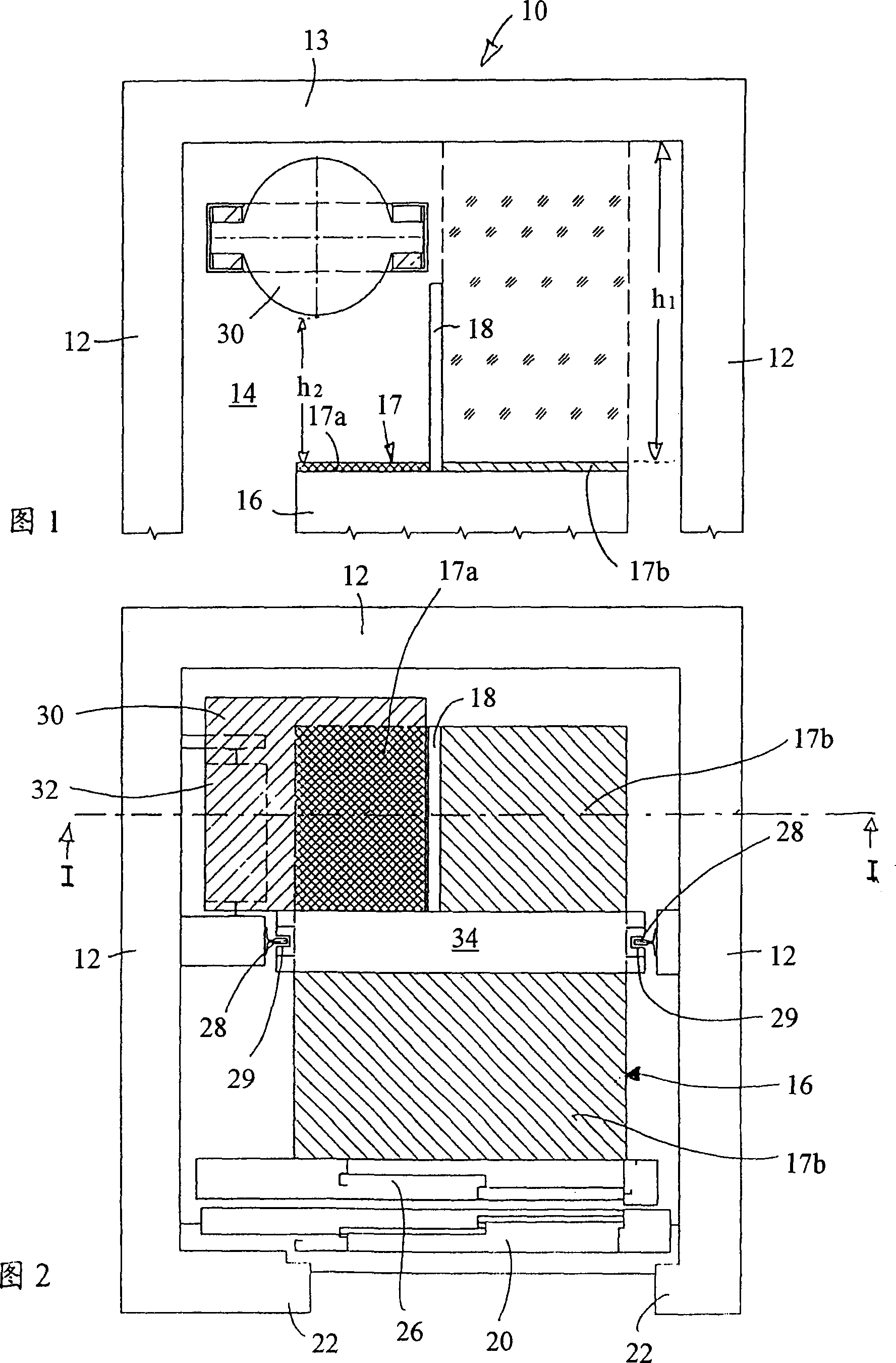

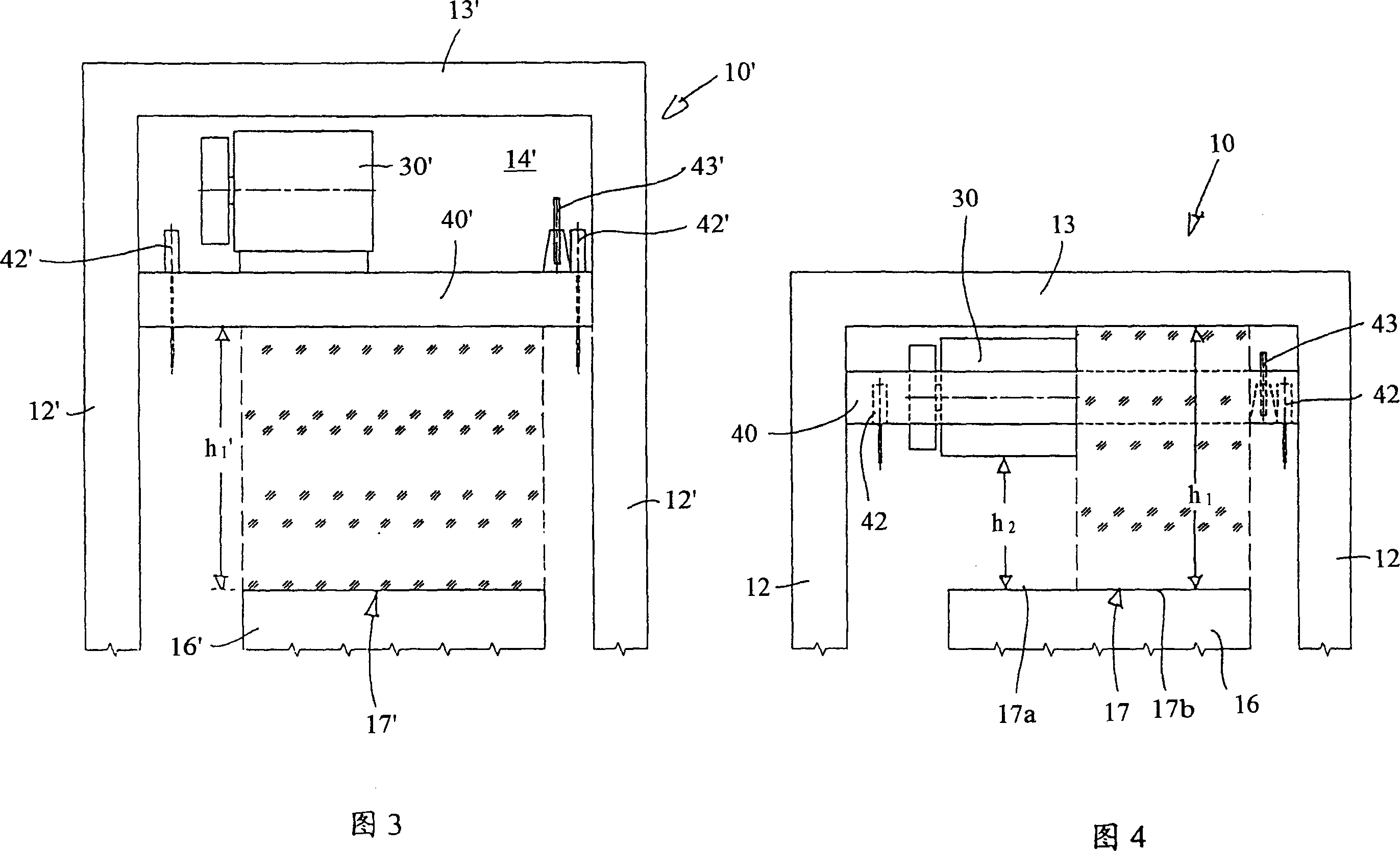

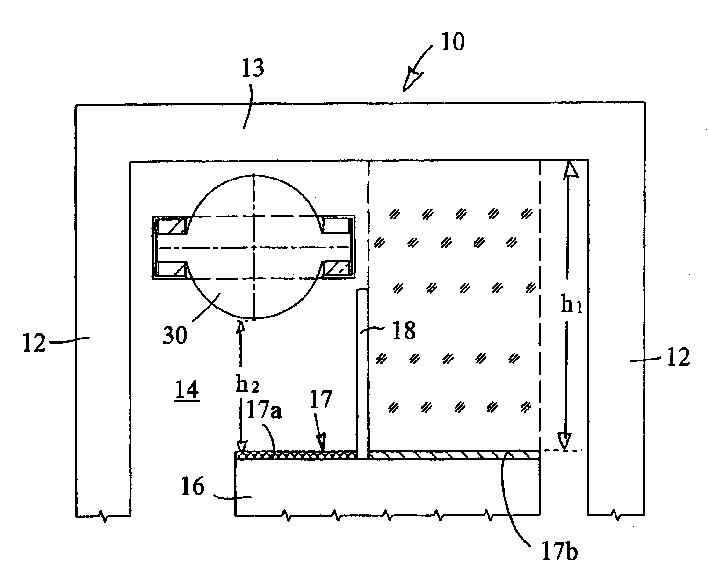

[0032] Figure 1 shows a schematic cross-sectional view of the top of an elevator 10 of the present invention. The elevator 10 comprises an elevator car 16 which is located in an elevator shaft 14 and has an elevator car roof 17 . In Figure 1, the elevator car 16 is in its upper rest position, only the top of which is shown.

[0033] The elevator shaft 14 of the elevator 10 is delimited by a shaft wall 12 and a shaft roof 13 . On the elevator platform on the shaft wall 12 there is provided a door opening defined by a door side 22 which is closed by a shaft door 20 (see FIG. 2 ). The elevator car is provided with an elevator car door 26 which is used to open the passage between the elevator car and the elevator platform and which can be opened together with the shaft door 20 .

[0034] In the elevator shaft 14 the elevator car 16 is equipped with a drive so that the elevator car is moved vertically in the elevator shaft 14 . The drive device comprises a drive machine 30 which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com