Decoction pot for manufacturing brown sugar

A technology for boiling pot and brown sugar, which is applied in confectionery, application, confectionery industry, etc., can solve the problems of unfavorable brown sugar production efficiency, large manpower and time consumption, and difficulty in cleaning the boiling pot, so as to reduce manpower input, The effect of shortening time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

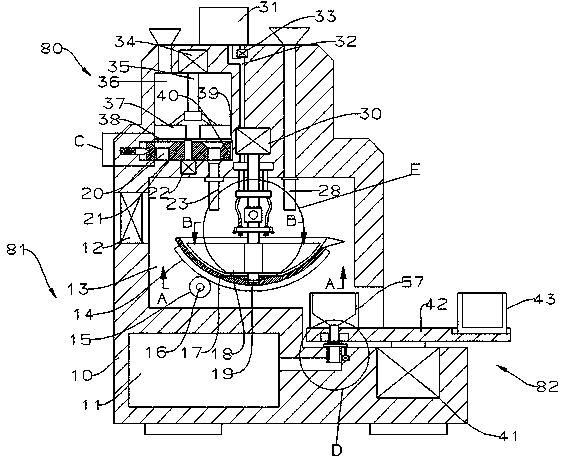

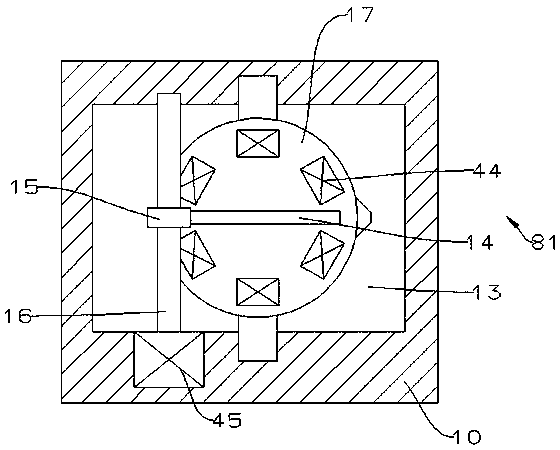

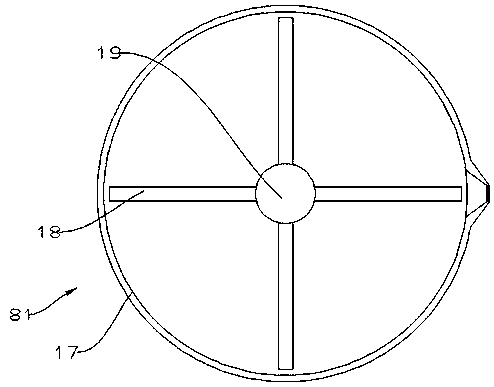

[0023] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

[0024] refer to Figure 1-6 A cooking pot for making brown sugar according to an embodiment of the present invention, comprising a casing 10, a storage cavity 36 is provided in the casing 10, and boiled solid sugar can be loaded in the storage cavity 36, The lower side of the storage chamber 36 is provided with a batching chamber 39, and a communication hole 38 is provided between the storage chamber 36 and the batching chamber 39, and the storage chamber 36 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com