Crushed garbage quantitative feeding device

A quantitative supply and garbage technology, which is applied in the field of crushed garbage quantitative supply devices, can solve the problems of difficult quantitative garbage collection operation, dry garbage easily blown up by wind, and troublesome operation, etc., and achieves convenient storage and quantitative supply and structure. Simple and reliable, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

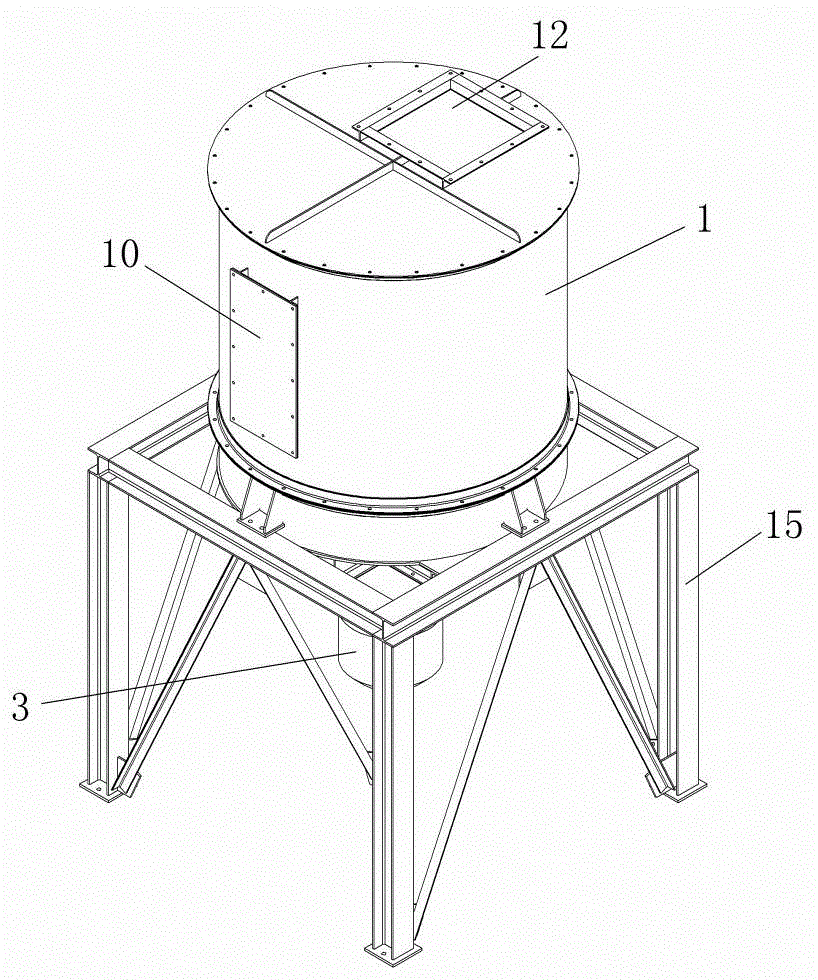

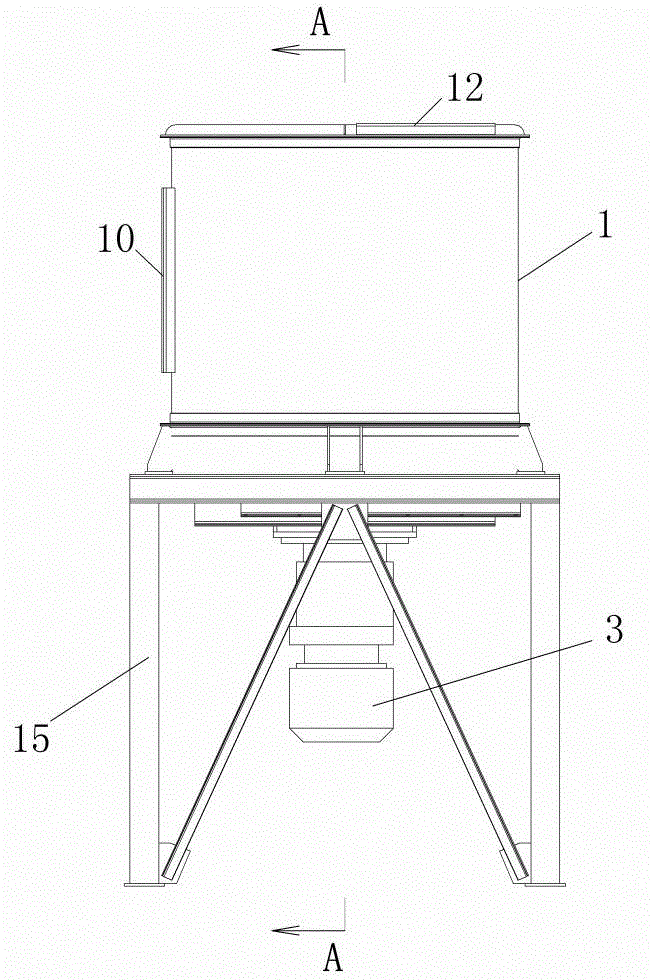

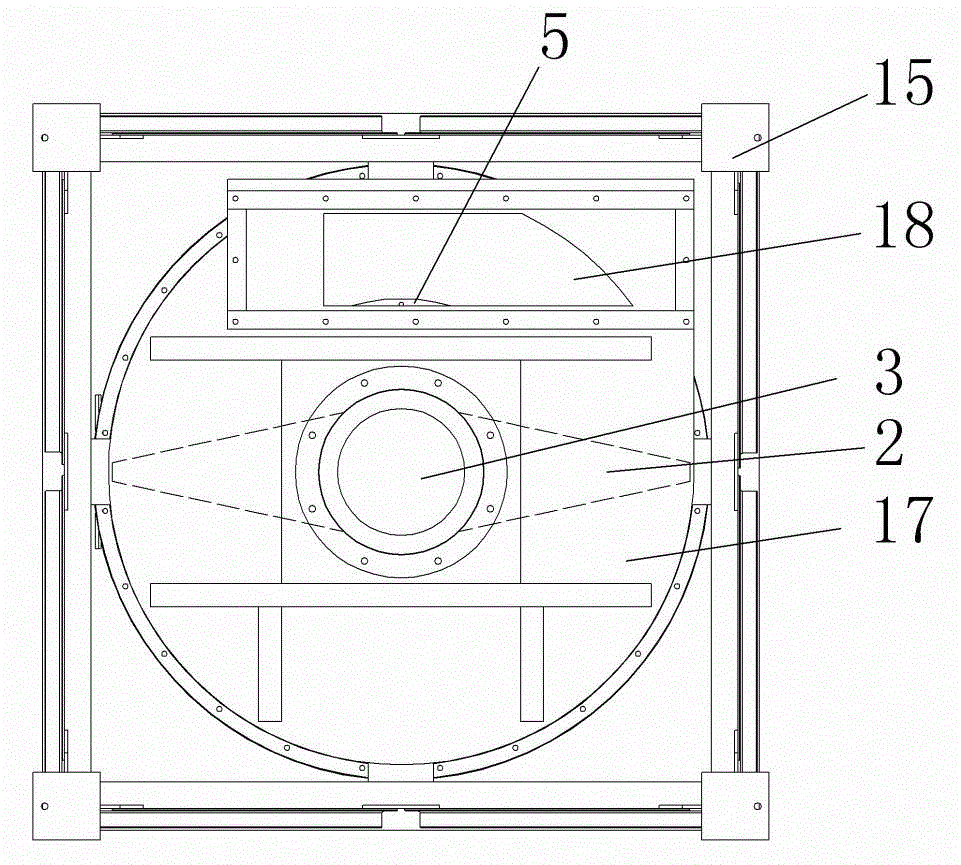

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, it is a structural schematic diagram of an embodiment of the crushed garbage quantitative supply device of the present invention, which includes a support frame 15, a storage bin 1 for storing crushed garbage arranged on the support frame, and a A discharge port 18 for quantitative discharge of garbage is provided on the horizontal bottom plate of the bin, and a toggle unit for quantitative discharge and supply is provided at the discharge port. The upper part of the storage bin is provided with a feed port 12. The toggle unit includes a plate-shaped toggle plate 2 with a fixed hole in the middle, a drive shaft 26 and a drive motor 3 that drives the drive shaft to rotate. The bottom plate 17 is provided with a rotation hole near the discharge port, so The drive shaft and the rotation hole are connected to each other in rotation, the toggle plate is fixedly connected to the drive shaft throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com