Digital ink duct for a press, digital ink supply system and application method thereof

a press technology, applied in the field of digital ink supply system for press, digital ink supply system application method, can solve the problems of inability to ensure absolute accuracy and relative accuracy, difficult calculation, regulation and control of actual ink supply, and inability to accurately supply ink. , to achieve the effect of accurate supply of ink, accurate quantitative control of ink supply, and accurate calculation of theoretical ink amoun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

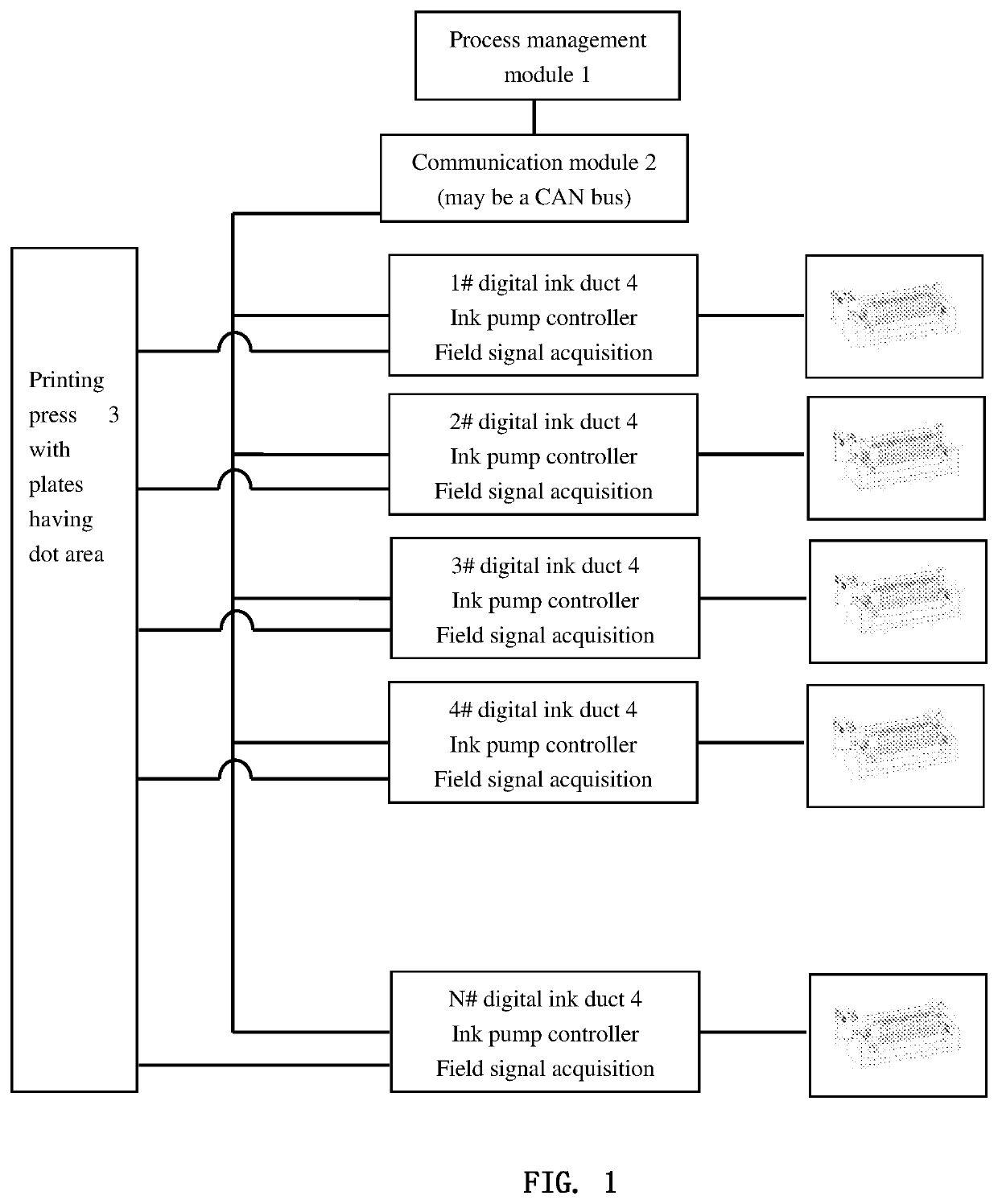

[0041]As shown in FIG. 1, the present invention comprises a process management module 1, a communication network 2 and a plurality of the digital ink ducts 4.

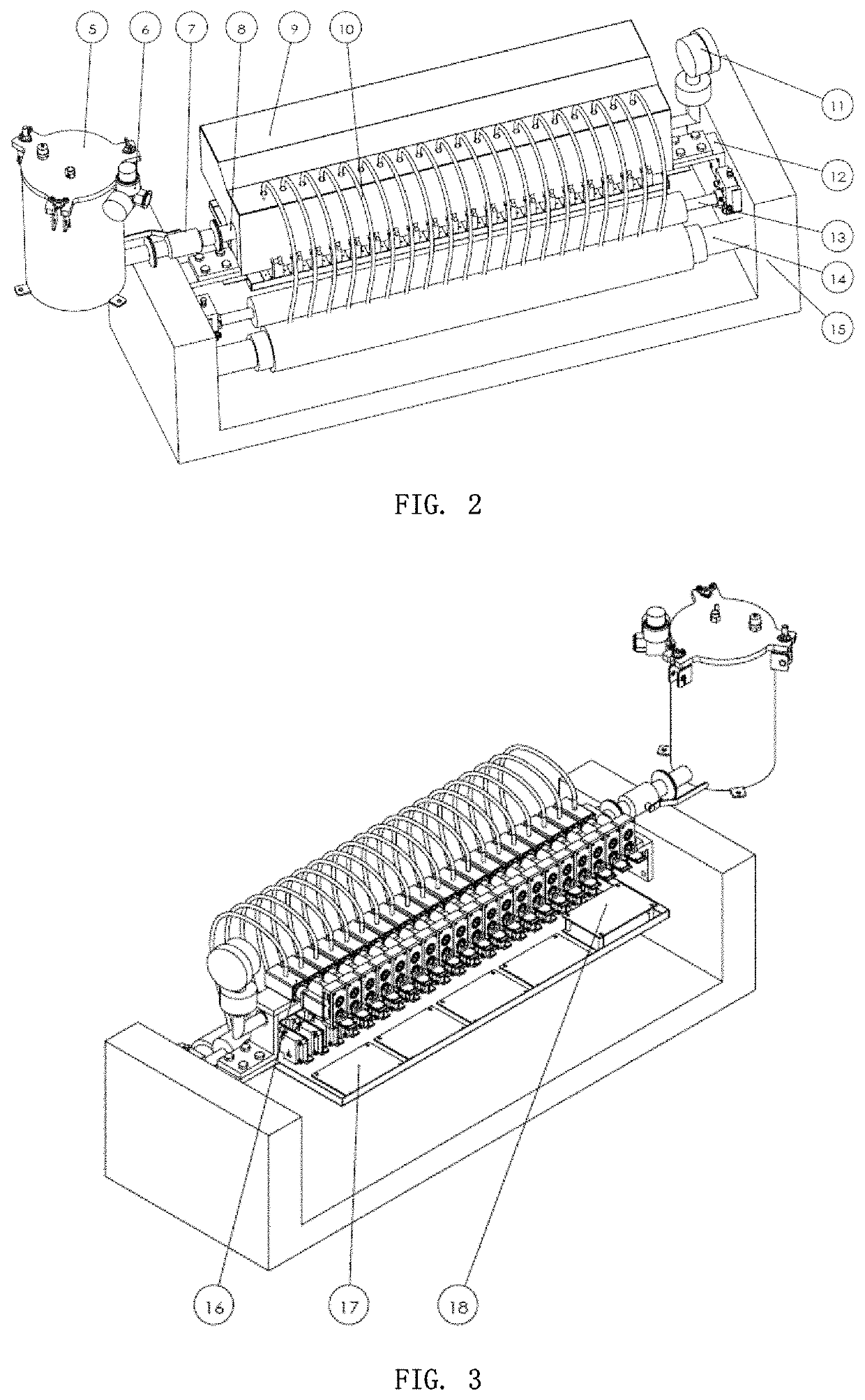

[0042]The digital ink ducts 4 are actuators, respectively installed in the single-color printing units of the press 3, and disposed between the main wall boards of the press, which means that the digital ink ducts are installed at the ink duct positions of the traditional press so as to replace the traditional ink duct device of the press.

[0043]The process management module 1 is disposed in a PC. The process management module 1 exchanges data with the digital ink duct(s) 4 and performs control through the communication network 2. The process management module 1 is capable of reading image data, calculates and obtains the ink demand of each one of the ink zones of each one of the color plates of a single printed sheet according to the image data. The process management module 1 transmits the data to each corresponding one of the...

embodiment 2

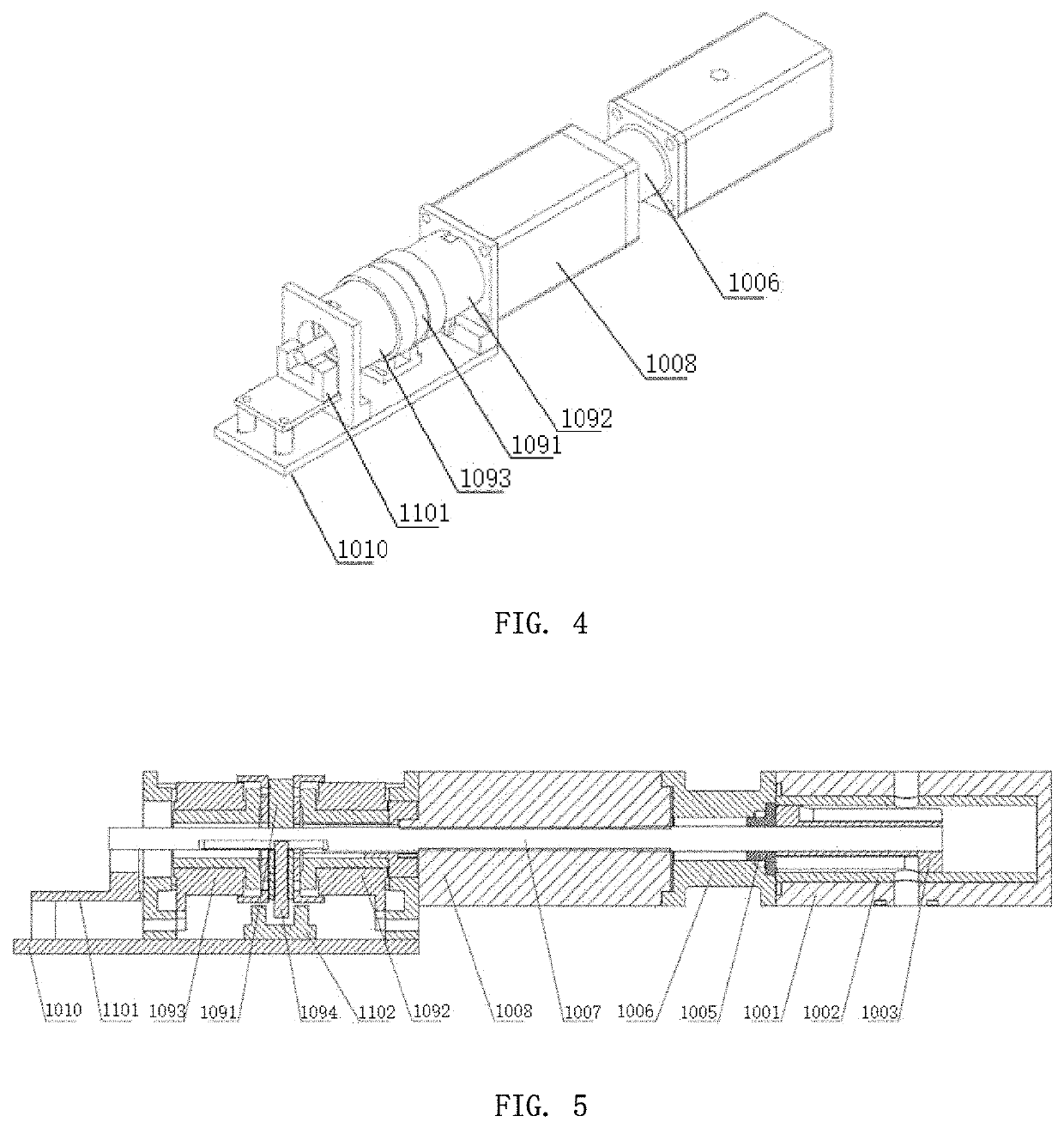

[0054]The implementation of the metering-type ink delivery device of the present invention is explained and described below by taking an injection pump mechanism as an example.

[0055]The injection pump mechanism (metering-type ink delivery device) as shown in FIGS. 4-5 is under the control of a single motor, and includes a single-pipe dual-cavity injection pump, a screw motor 1008, a clutch device, an induction device and a control device. The screw motor 1008 is respectively connected with the single-pipe dual-cavity injection pump and the clutch device on two sides through a screw 1007.

[0056]The single-pipe dual-cavity injection pump as shown in FIGS. 6-10 includes a pump shaft sleeve 1002, an injection shaft 1003, a housing 1001 and a sealing device 1006. The pump shaft sleeve 1002 is symmetrically formed with a shaft sleeve medium inlet end 1001-1 and a shaft sleeve medium outlet 1001-2 at the middle position. The outside wall of the injection shaft 1003 is formed with two long s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com