Coated positive electrode material capable of slowly releasing oxygen as well as preparation method and application of coated positive electrode material

A positive electrode material, coated technology, applied in the field of new energy, can solve the problems of battery cycle performance decline, positive plate impedance increase, etc., to achieve quantitative control, improve safety performance, and good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

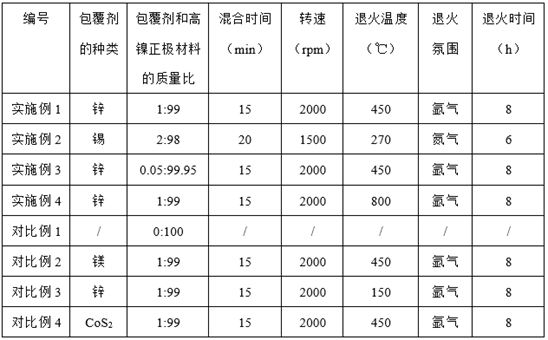

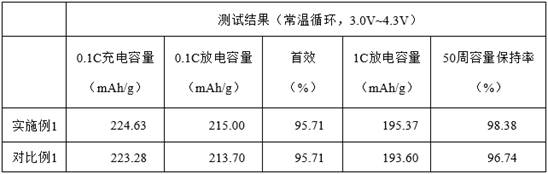

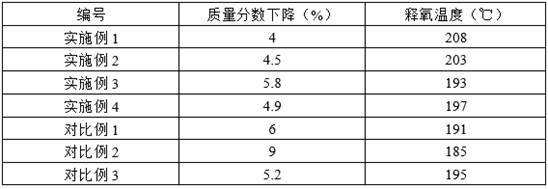

Embodiment 1

[0054] This embodiment provides a coated positive electrode material for slowing and decomposing oxygen, including a high-nickel positive electrode material and a zinc layer coated on the surface of the high-nickel positive electrode material; taking the coated positive electrode material as a whole, the mass of the zinc layer The content is 10000ppm.

[0055] This embodiment also provides a method for preparing the above-mentioned coated positive electrode material, including the following steps:

[0056] Grind and disperse coating agent zinc powder in ethanol, and vacuum dry at 80°C.

[0057] Add 1g of zinc powder and 99g of high-nickel cathode material to the mixing equipment for mixing, mixing time: 15min, rotation speed: 2000rpm. The coated material was treated at a high temperature of 450°C under an argon atmosphere for 8 hours, cooled, and the zinc powder was melted and cooled to form a continuous coating layer on the surface of the high-nickel positive electrode mater...

Embodiment 2

[0059] This embodiment provides a coated positive electrode material for slowing and decomposing oxygen, including a high-nickel positive electrode material and a tin layer coated on the surface of the high-nickel positive electrode material; taking the coated positive electrode material as a whole, the mass of the tin layer The content is 20000ppm.

[0060] This embodiment also provides a method for preparing the above-mentioned coated positive electrode material, including the following steps:

[0061] Grind and disperse the tin powder of the coating agent in ethanol, and dry it under vacuum at 80°C.

[0062] Add 2g of tin powder and 98g of high-nickel cathode material to the mixing equipment for mixing, mixing time: 20min, speed: 1500rpm. Treat the coated material at a high temperature of 270°C under a nitrogen atmosphere for 6 hours, and then cool it. After the tin powder is melted and cooled, a continuous coating layer is formed on the surface of the high-nickel positive...

Embodiment 3

[0064] This embodiment provides a coated positive electrode material for slowing and decomposing oxygen, including a high-nickel positive electrode material and a zinc layer coated on the surface of the high-nickel positive electrode material; taking the coated positive electrode material as a whole, the mass of the zinc layer The content is 500ppm.

[0065] This embodiment also provides a method for preparing the above-mentioned coated positive electrode material, including the following steps:

[0066] Grind and disperse coating agent zinc powder in ethanol, and vacuum dry at 80°C.

[0067]Add 0.05g of zinc powder and 99.95g of high-nickel cathode material to the mixing equipment for mixing, mixing time: 15min, speed: 2000rpm. The coated material was treated at a high temperature of 450°C under an argon atmosphere for 8 hours, cooled, and the zinc powder was melted and cooled to form a continuous coating layer on the surface of the high-nickel positive electrode material. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com