System capable of stably generating dust aerosol

An aerosol and dust technology, which is applied in the field of aerosol generation, can solve the problems of unstable feeding, affecting the uniformity of aerosol, and aerosol that is difficult to disperse uniform particles, so as to achieve uniform particle dispersion, avoid clogging, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

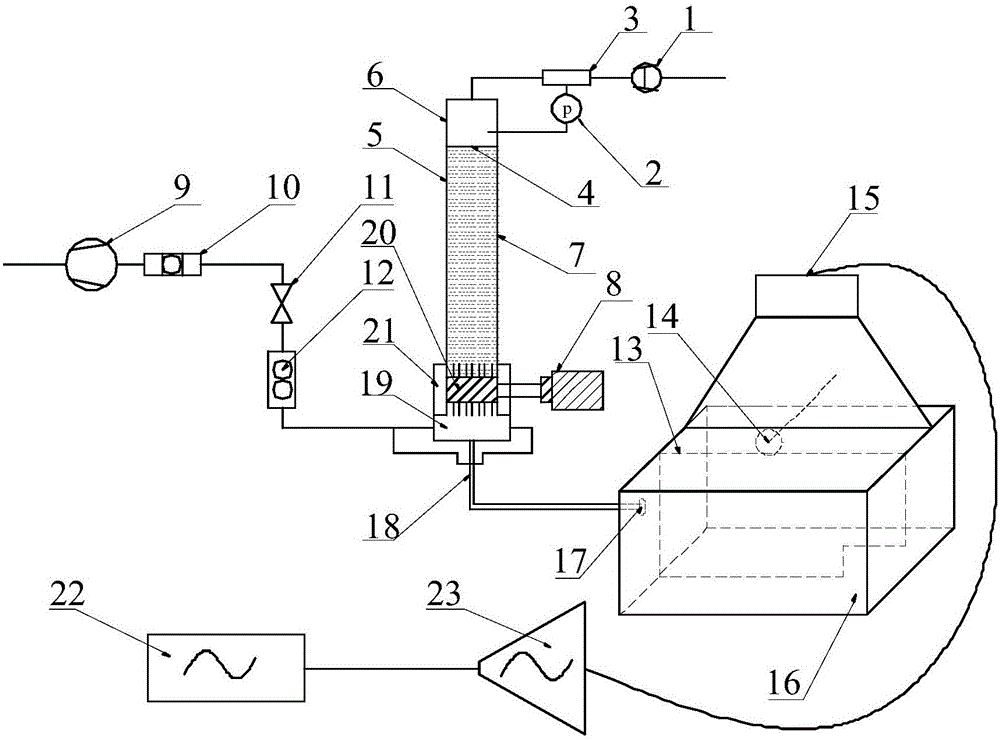

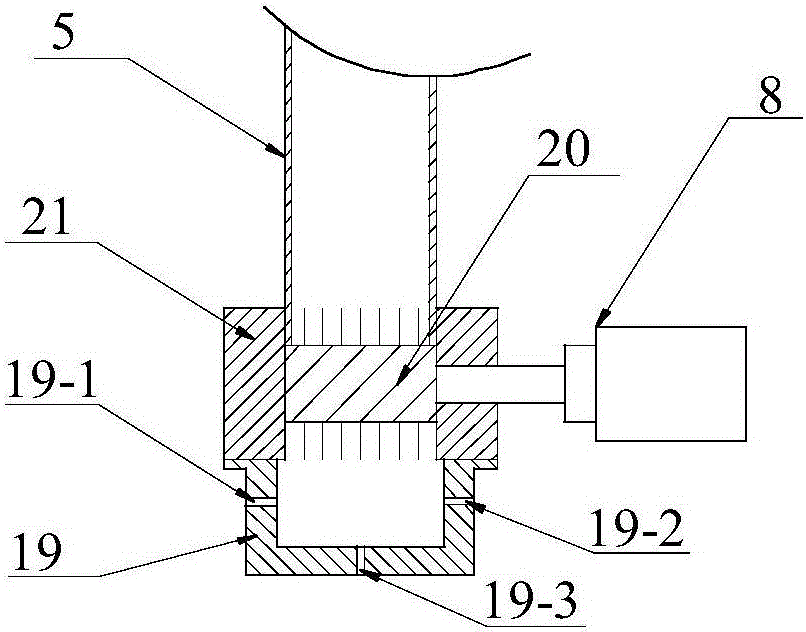

[0028] In this embodiment, the system that can stably generate dust aerosol such as figure 1As shown, it consists of a feeding device, a dust dispersing device and an acoustic aerosol stabilization device. Described feeding device comprises cylinder body 5, piston 4, pressure sensor 2, propulsion gas source 1 and pressure controller 3, and cylinder body 5 is the cylindrical body that one end is open, and one end is closed, and piston 4 is a circular frustum body, and its outer diameter It is the same as the nominal size of the inner diameter of the cylinder body and is a dynamic fit. The piston is installed in the cylinder body. A constant pressure chamber 6 is formed, and the side wall of the cylinder between the other end face of the piston and the open end of the cylinder forms a silo 7. The pressure sensor 2 is inserted into the constant pressure chamber 6 and connected with the pressure controller 3. The pressure controller 3 The air inlet is connected to the propelling ...

Embodiment 2

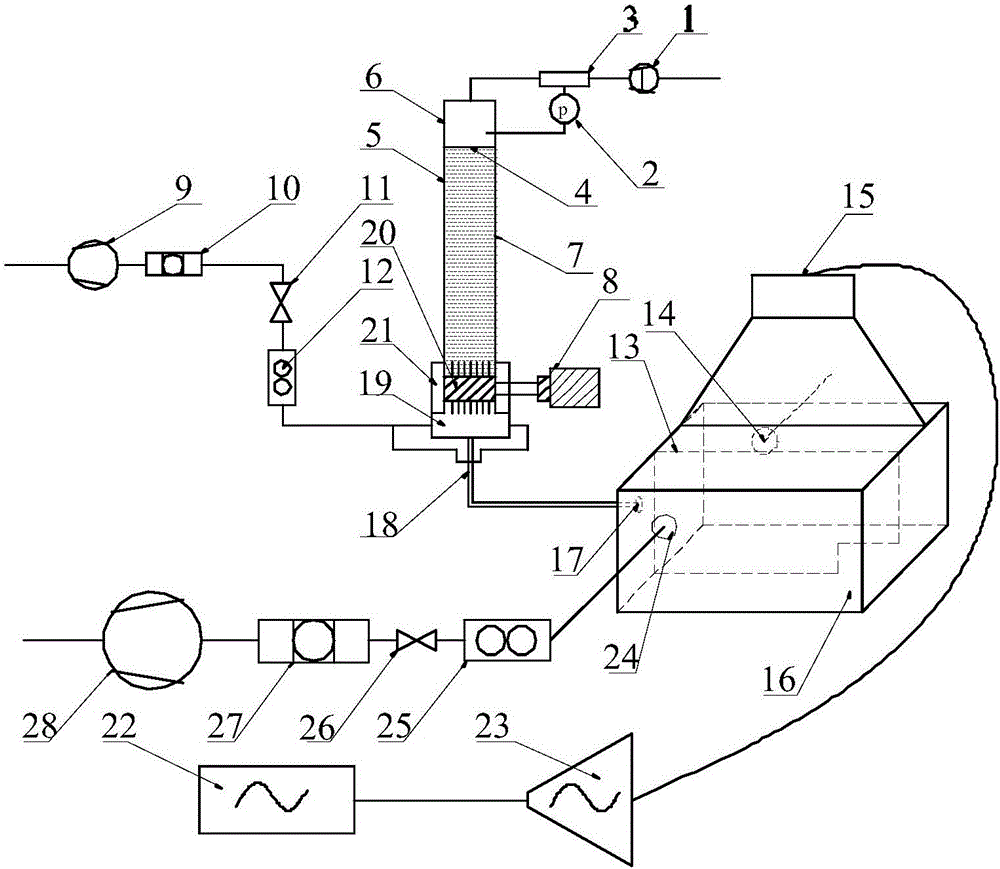

[0030] In this embodiment, the system that can stably generate dust aerosol such as figure 2 As shown, it consists of a feeding device, a dust dispersion device, an acoustic aerosol stabilization device and an aerosol dilution device. The structure of the feeding device and the dust dispersing device is the same as that of Embodiment 1. The difference between the sonic aerosol stabilization device and Embodiment 1 is that a dilution gas inlet 24 is provided on the front side wall of the first chamber 16 - 1 . The aerosol dilution device is composed of a second compressor 28, a second particulate filter 27, a second pressure reducing valve 26, and a second air flow meter 25 connected in sequence, and the second air flow meter 25 in the aerosol dilution device is connected to the The dilution gas inlet 24 provided on the front side wall of the first chamber of the aerosol stabilization chamber is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com