Method for treating nickel sulfide ore biological heap leaching solution

A nickel sulfide ore and treatment method technology, applied in the direction of process efficiency improvement, etc., can solve the problems of high recovery rate of valuable metals, difficulty in nickel/magnesium separation, small reagent consumption, etc., and achieve high recovery rate and low treatment cost The effect of low and strong economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

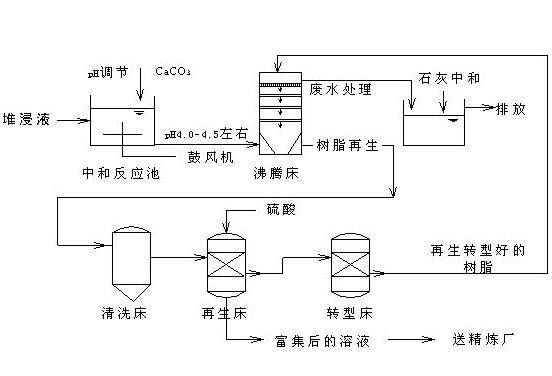

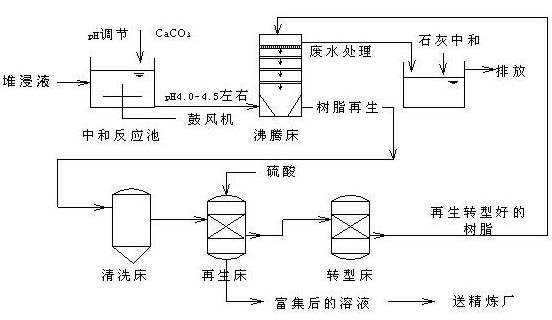

Image

Examples

Embodiment 1

[0023] (1) Slurry an appropriate amount of limestone powder (with a particle size less than 120 mesh) with water, and the ratio of liquid to solid in the slurry is 3:1.

[0024] (2) Dip the biopile leaching solution to about 1m 3 Input it into the iron removal pool, pass in an appropriate amount of air to stir, add the limestone powder slurry liquid into the reaction kettle in the iron removal pool at a certain flow rate (60-100L / h), and control the pH value of the reaction liquid in the reaction kettle to 2-4.5 And aeration oxidation time 2-6 hours, make the Fe in bioheap leaching solution under normal temperature state 2+ Oxidized to Fe 3+ , and hydrolyzed to generate Fe(OH) 3, Co-precipitate together with calcium sulfate produced in the heap leaching solution to form a thick iron slag slurry.

[0025] Table 1 The chemical composition of the supernatant after the heap leaching solution is often temperature-precipitated for iron

[0026] Element

[0027] (3) Put...

Embodiment 2

[0035] (1) First oxidize the heap leaching solution with self-cultivated bacteria for a certain period of time, and analyze Fe 3+ / Fe 2+ , and the value ratio is greater than 9 or more for later use.

[0036] (2) Dip the biopile leaching solution to about 1m 3 Input it into the iron removal pool, pass in an appropriate amount of air to stir, add the limestone powder slurry liquid into the reaction kettle in the iron removal pool at a certain flow rate (60-100L / h), control the pH value of the reaction liquid in the reaction kettle to about 4.2 and The aeration oxidation time is 2 hours, and the remaining Fe 2+ Oxidized to Fe 3+ , and hydrolyzed to generate Fe(OH) 3, Co-precipitate together with calcium sulfate produced in the heap leaching solution to form a thick iron slag slurry.

[0037] Table 3 The chemical composition of the supernatant after the heap leaching solution is often temperature-precipitated for iron

[0038] Element

pH

Ni

co

Cu

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com