Patents

Literature

30results about How to "Low content of impurity ions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing calcium gluconate from oyster shell

InactiveCN101209963ALow content of impurity ionsSolve problems such as calcium supplementationCarboxylic acid salt preparationOysterGluconic acid

The invention discloses a method for preparing calcium gluconate with an oyster shell; the oyster shell is acid split by 4mol / L of HCI solution, precipitated with 1mol / L of Na2CO3 solution, washed, purified, second calcinated and the prepared into Ca (OH) 2 emulsion with 0.7-1.5mol / L of molar concentration carries out neutrallzation reaction with 20-30 percent gluconate solution in weight percentage, thus obtaining the calcium gluconate. Calcium citrate powder prepared has over 98 percent of purity, and content of foreign ions, such as copper, lead and cadmium, etc. is low. The calcium citrate powder obtained completely meets national requirement for food, and can be further made into calcium supplement food or health products, thus providing strong material basis for solving the problem of calcium supplement.

Owner:NINGBO UNIV

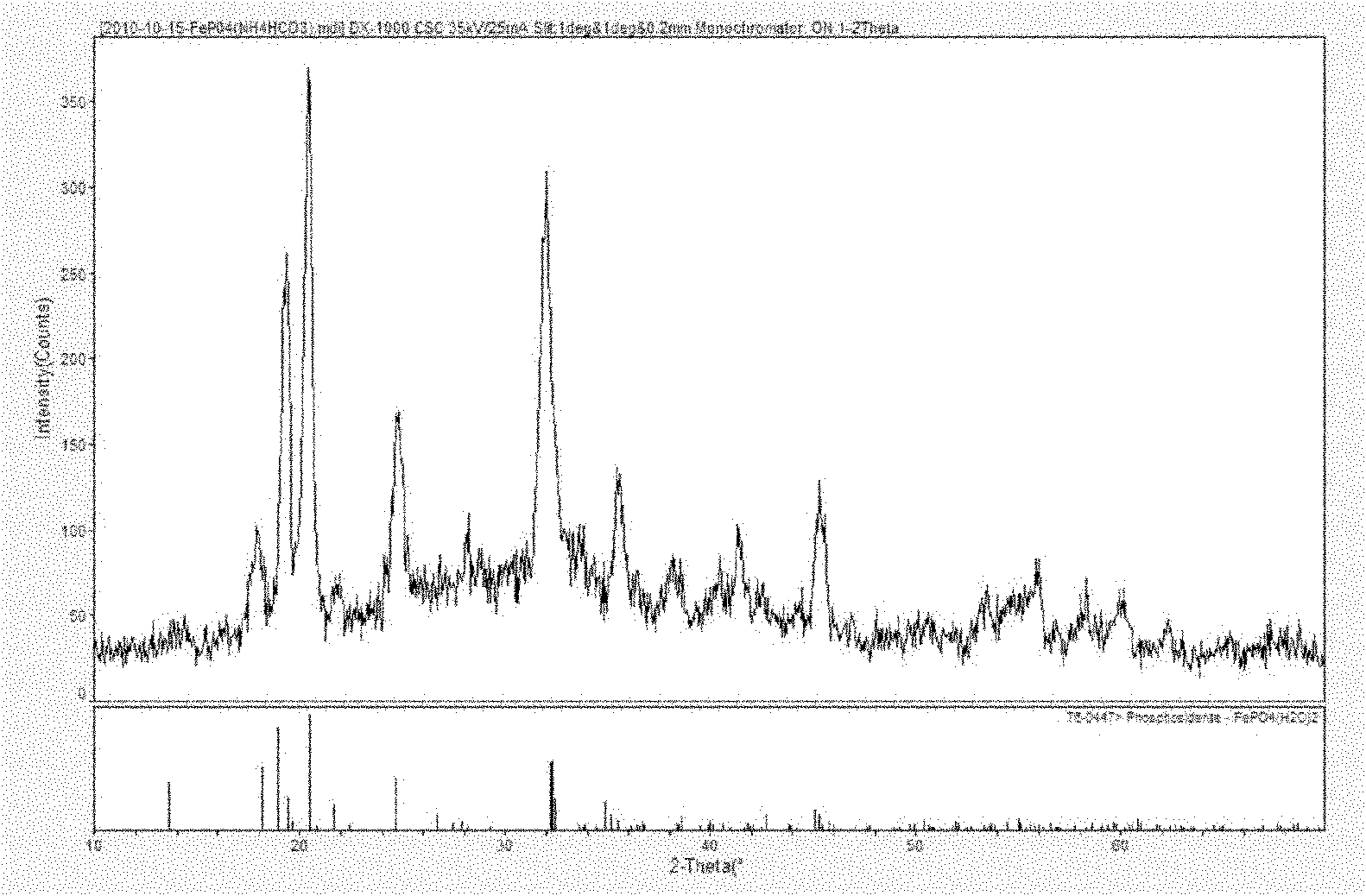

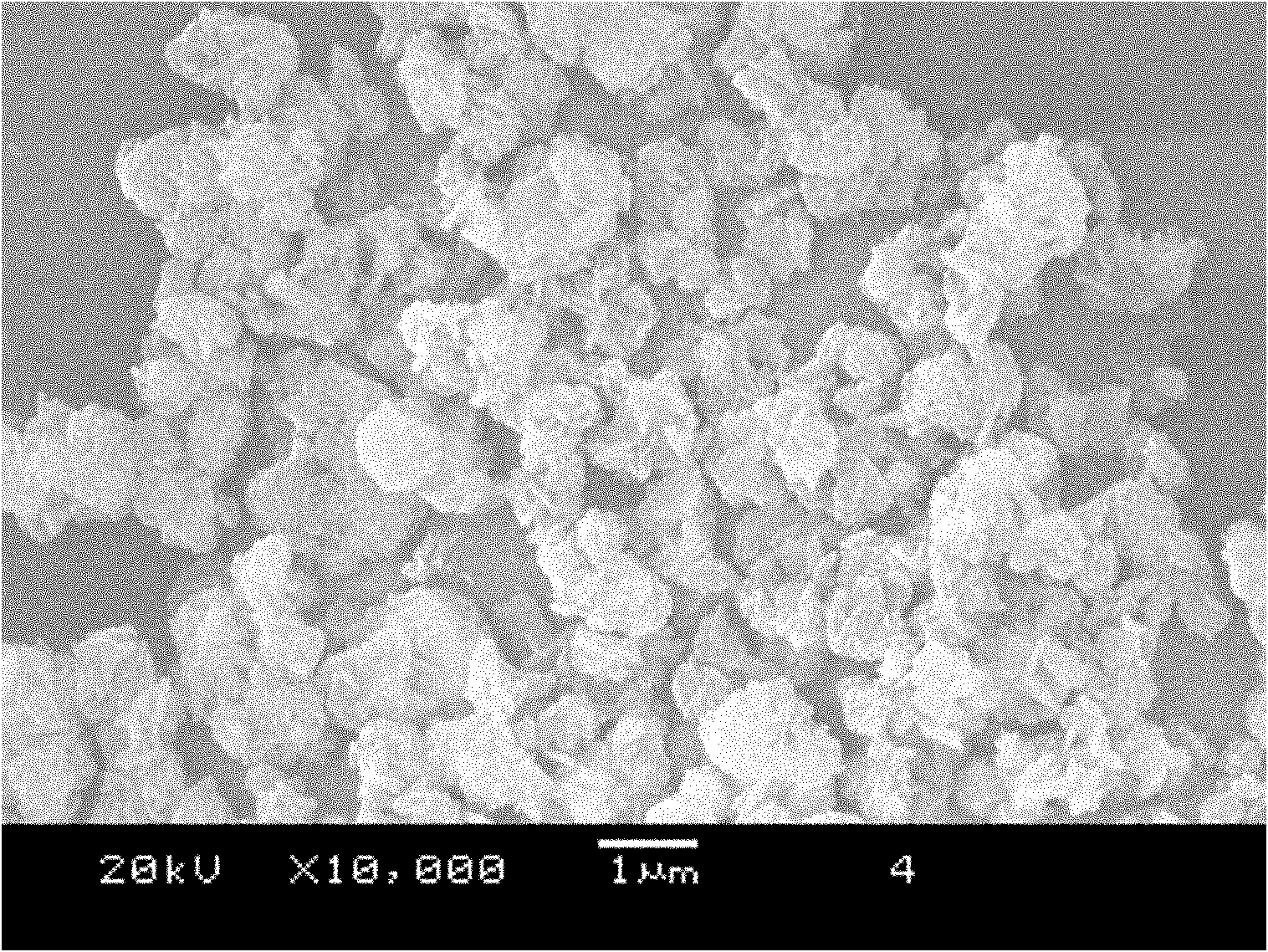

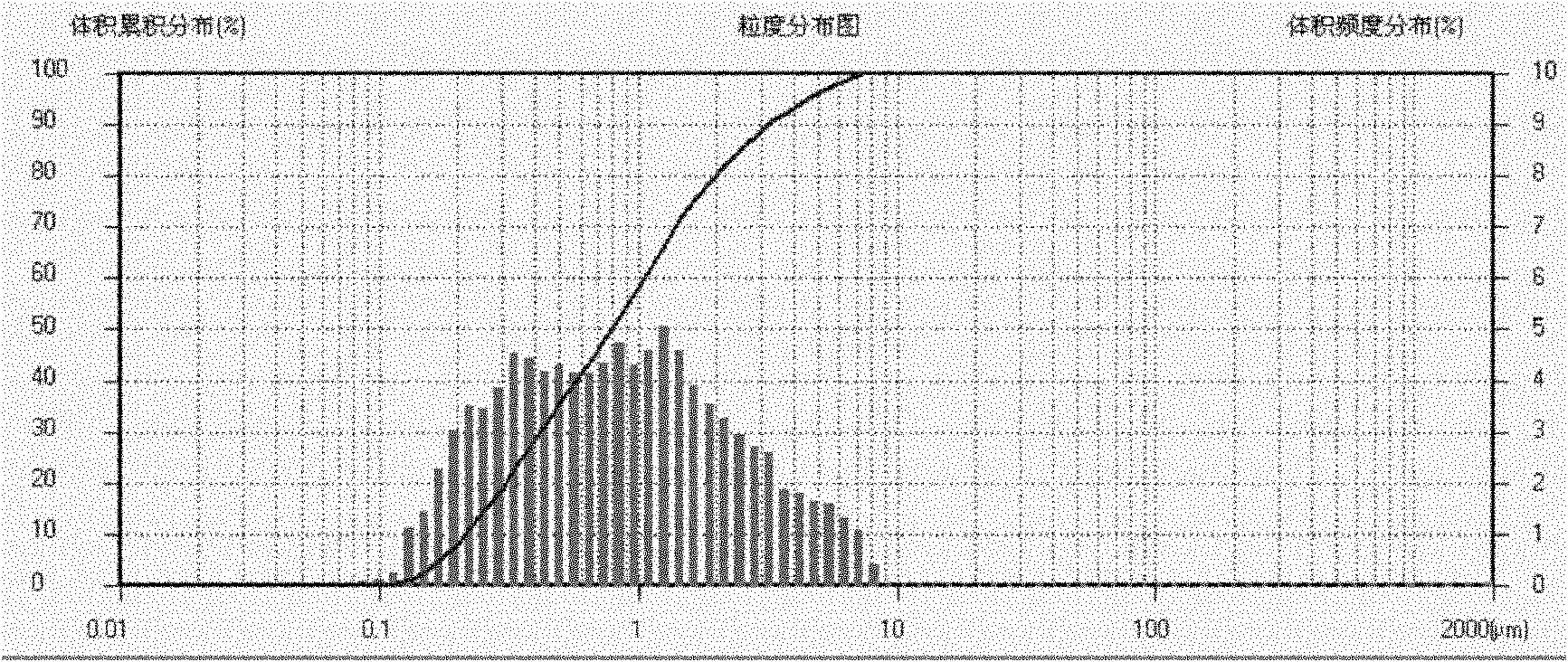

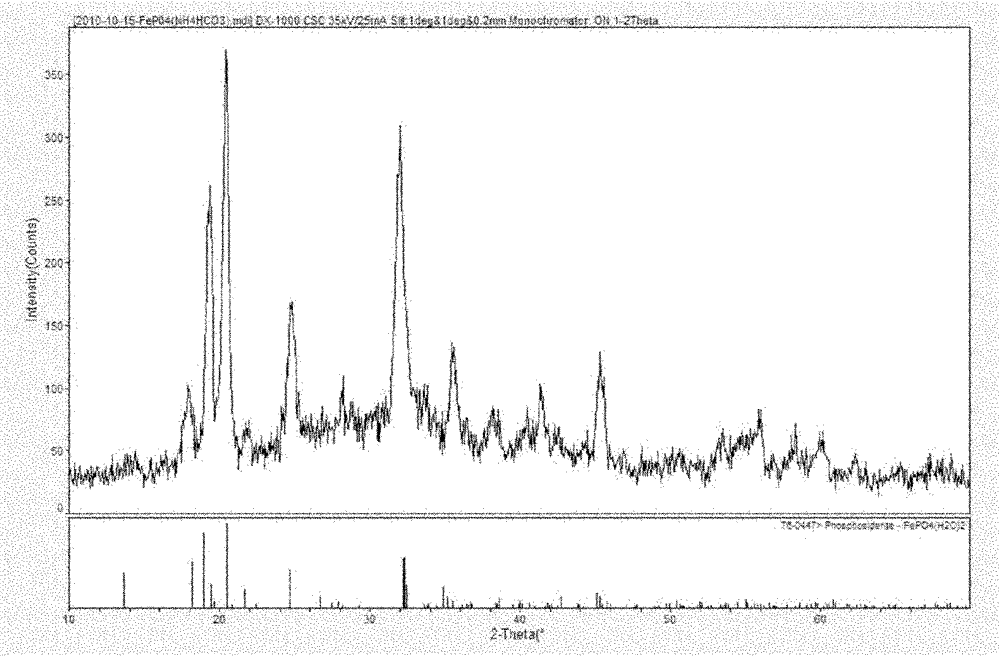

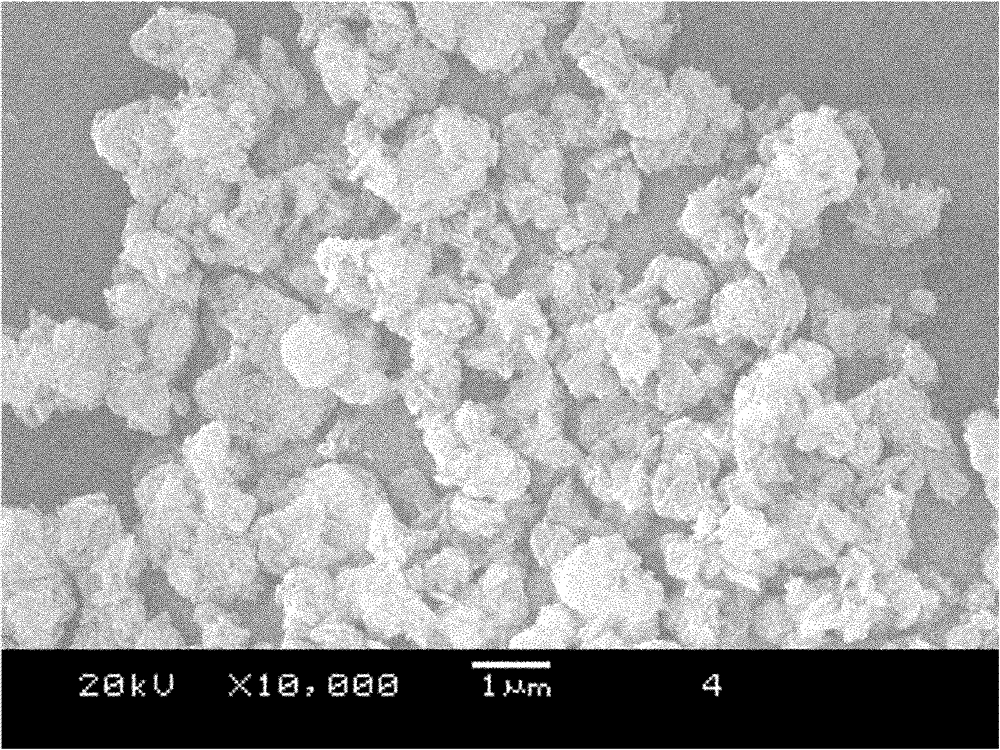

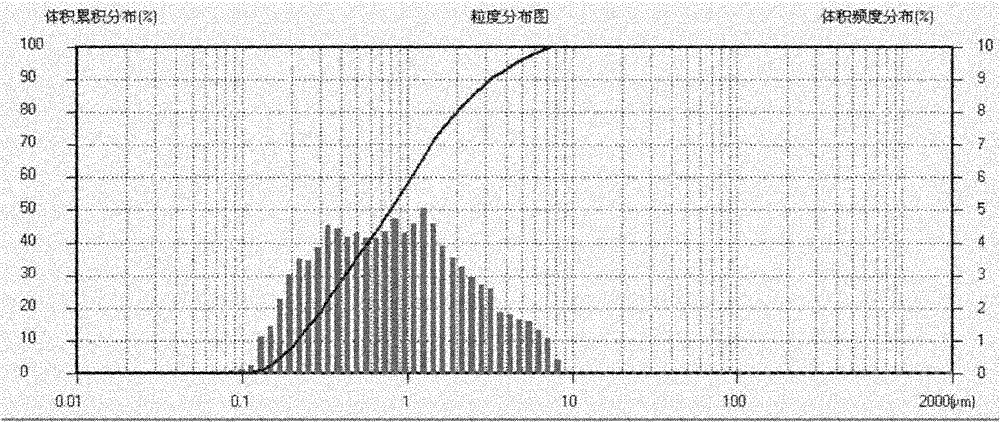

High-purity iron phosphate used for producing lithium ion battery positive-pole material and preparation method thereof

InactiveCN102126713ALow impurity contentImprove electrochemical performancePhosphorus compoundsFerrous saltsPhosphoric acid

The invention relates to high-purity iron phosphate used for producing a lithium ion battery positive-pole material and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking ferrous salt and carbonate as raw materials; reacting to generate intermediate product ferrous carbonate precipitation, wherein, the ferrous carbonate is easy to filter, and the foreign ions are easy to wash; filtering and recovering ammonium sulfate; dissolving the ferrous carbonate precipitation; adding oxidant for oxidizing; regulating the pH value of the solution; heating and preserving the temperature for a certain time to obtain the iron phosphate precipitation; filtering, drying and precipitating to obtain the high-purity iron phosphate; and mixing and calcining the high-purity iron phosphate, the lithium source and the carbon source to obtain the lithium ion battery positive-pole material with excellent electrochemistrical performance. By using the method provided by the invention, the impurity content in the iron phosphate is effectively lowered, the process time is shortened, the energy consumption is reduced, and the cost and the consumption of the raw materials are lowered; and the filter liquor is easy to recover, and the production cost is very low, thus being beneficial for large-scale production in scaled industry.

Owner:SICHUAN UNIV

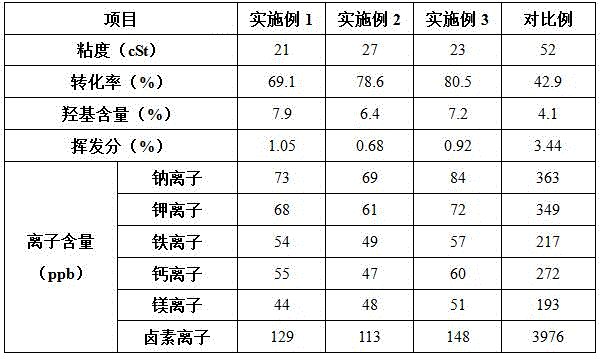

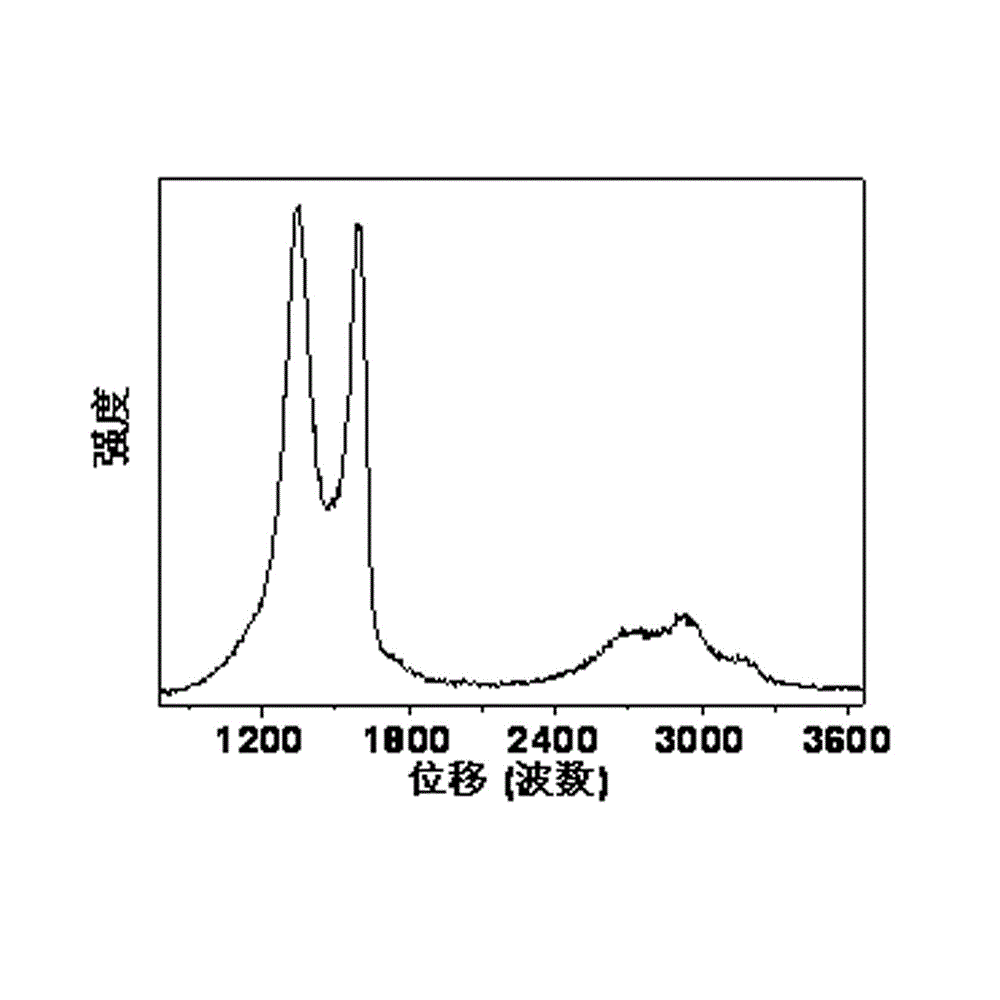

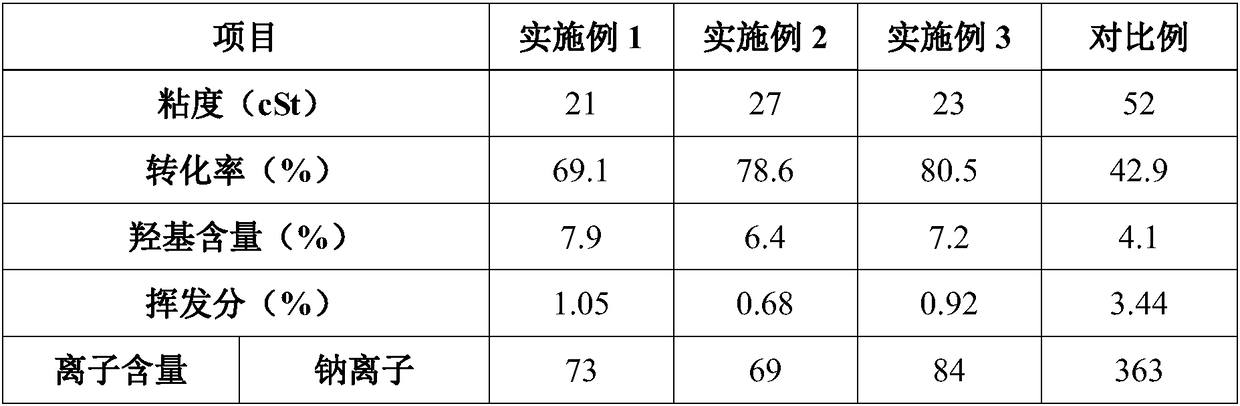

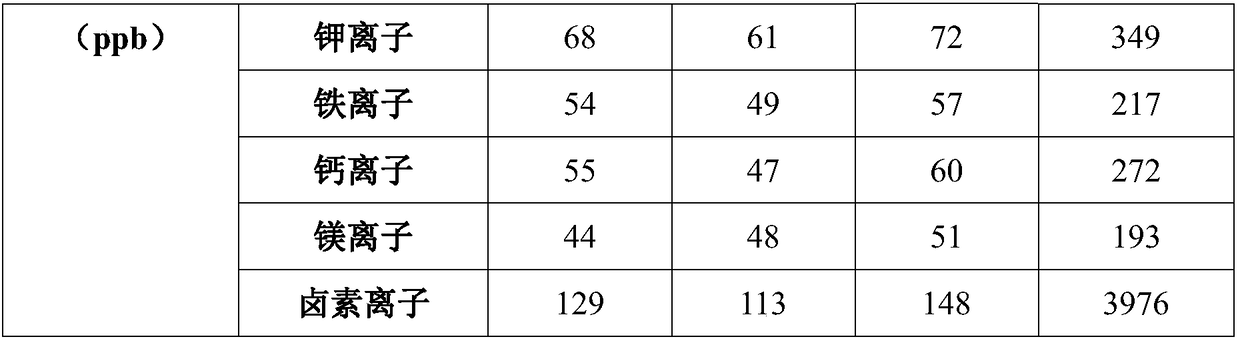

Hydroxyl silicone oil and continuous preparation method thereof

ActiveCN105754102AHigh porosityHigh catalytic efficiencyChemical industryUltrafiltrationPollutant emissions

The invention discloses hydroxyl silicone oil and a continuous preparation method thereof.The method includes the following steps of firstly, adding hexamethyl cyclotrisiloxane, solvent and water into a mixing kettle to be evenly stirred and mixed, and transferring the mixture into a sulfuration bed filled with a catalyst to sufficiently react; secondly, conducting adsorption filtering, ultrafiltration membrane filtering, normal-pressure devolatiligation and reduced-pressure devolatiligation to obtain the hydroxyl silicone oil, recovering solvent and unreacted low-molecular compounds, detecting the contents of all components and then conducting recycling.The method is high in efficiency, low in energy consumption, free of pollutant emission, clean, sanitary and low in production cost, solvent and unreacted low-molecular compounds used in reaction can enter a reaction system to be recycled after the contents of all the components are detected, and the method is free of pollutant emission, green and environmentally friendly.The hydroxyl silicone oil is low in viscosity, high in product purity, low in annulus content, low in impurity ion content and high in storage stability.

Owner:GUANGZHOU DAOLIN SYNTHETIC MATERIALS CO LTD

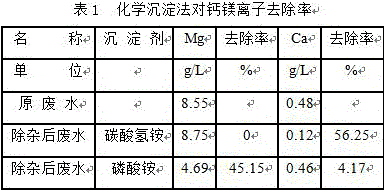

Method for removing calcium and magnesium in rare-earth industrial wastewater

InactiveCN105461002ASolve the problem of severe blockageLow content of impurity ionsWater treatment compoundsWaste water treatment from metallurgical processKeroseneEvaporation

The invention relates to a method for removing calcium and magnesium in rare-earth industrial wastewater, which is characterized by comprising the following steps: carrying out extraction under the conditions that the volume ratio of the organic phase to the liquid phase is 1-2 and the saponification degree is 45-60%, wherein ammonium sulfate wastewater generated by a rare-earth acid-process smelting technique is used as a treatment object, and 50 vol% P507+50 vol% sulfonated coal oil is used as an organic extractant; and after the extraction, standing to stratify. The treatment method is simple: after a plurality of stages of extraction tanks are connected to the wastewater outlet, wastewater at the outlet can directly enter the ammonia evaporation system; and after the extraction and standing for stratification, the removal rates of calcium and magnesium ions in ammonium ortho-sulfate wastewater can respectively reach 90% or above, thereby solving the problem of severe blockage in the ammonia evaporation system pipeline. The method can implement continuous production, and has the advantages of high treatment capacity, high reaction speed, favorable separating effect and recyclable extractant. Meanwhile, the method reduces the impurity ion content in the ammonium sulfate product, and enhances the quality of the product.

Owner:BAOTOU RES INST OF RARE EARTHS

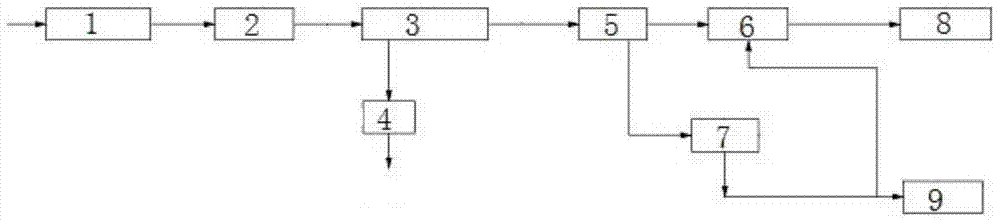

Method for preparing large-scale graphene in industrial large-scale reaction vessel

The invention relates to a method for preparing large-scale graphene in an industrial large-scale reaction vessel, wherein graphite powder is oxidized in an industrial large-scale reaction vessel to obtain graphene slurry; the graphene slurry is washed, dried, and reduced in a high-temperature sintering furnace to obtain graphene. The method for obtaining graphene has the characteristics of high output, low cost, short preparation period, high yield, low impurity ion content, and the like. In addition, waste and recovered graphite powder is used as a carbon source, which effectively improves the utilization rate of environment resources; and the method is especially suitable for industrial large-scale production, and can promote the application of graphene in fields such as energy storage devices and the like.

Owner:泰州巨纳新能源有限公司

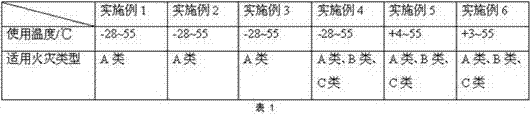

Neutral water-system fire extinguishing medium and preparation method thereof

PendingCN107213575AImprove uniformityIncrease viscosityFire extinguisherEnvironmental resistanceDistilled water

The invention relates to a neutral water-system fire extinguishing medium and a preparation method thereof. The neutral water-system fire extinguishing medium is composed of phosphorus flame retardant, nitrogenous flame retardant, gels, a surface active agent, water glass, a PH adjusting agent and the balance distilled water. The preparation method comprises the following steps of S1, material mixing; S2, adjustment of the PH value; S3, curing; and S4, manufacturing of a finished product. The neutral water-system fire extinguishing medium has the advantages of being environmentally friendly, safe, wide in use temperature range and good in flame resistance.

Owner:ANHUA FIRE NEW MATERIAL TECH (JIANGSU) CO LTD

Flame retardant rigid polyisocyanurate foam and preparation method thereof

InactiveCN108395515AEasy to prepareThe preparation method is simple, and the performance of the prepared rigid foam is simpleFoaming agentNitrogen

The invention relates to flame retardant rigid polyisocyanurate foam and a preparation method thereof. The flame retardant rigid polyisocyanurate foam is prepared from the following components in parts by weight: 150-170 parts of polyisocyanate, 5-8 parts of polyether polyol, 15-20 parts of flame retardant, 2-3 parts of catalyst, 1-2 parts of stabilizer, and 15-20 parts of foaming agent. The flameretardant is prepared by mixing a nitrogen-containing flame retardant and a phosphorus-containing flame retardant at the mass ratio of 1:1. The preparation method comprises the following steps: S1, mixing an additive; and S2, preparing rigid polyurethane foam. The flame retardant rigid polyisocyanurate foam has the advantages of being good in flame retardant effect, high in rigid foam performanceand suitable for industrial production.

Owner:江苏中昌绝热技术工程有限公司

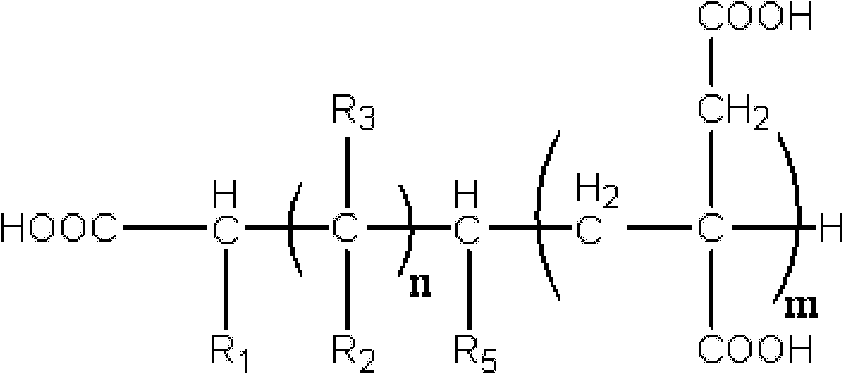

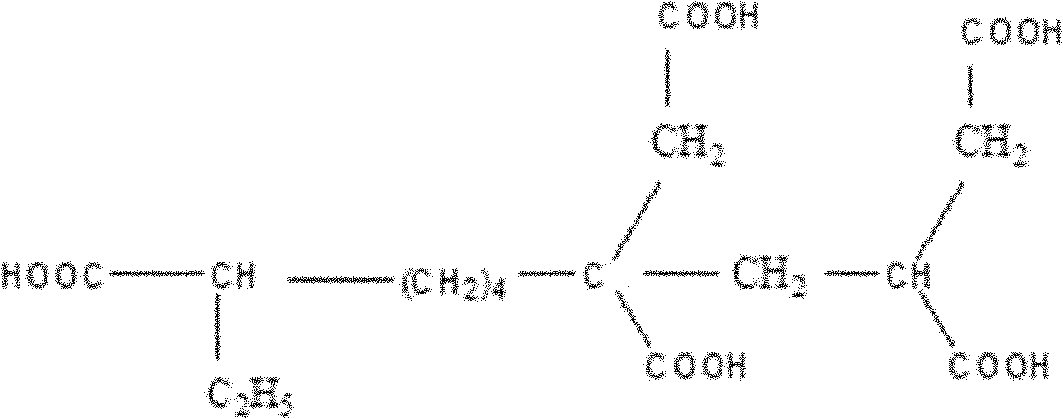

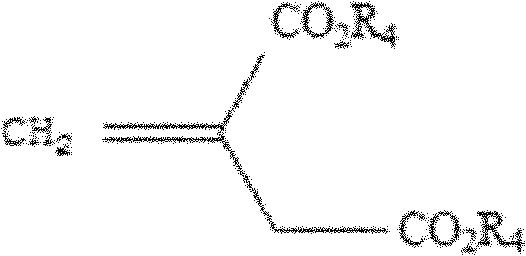

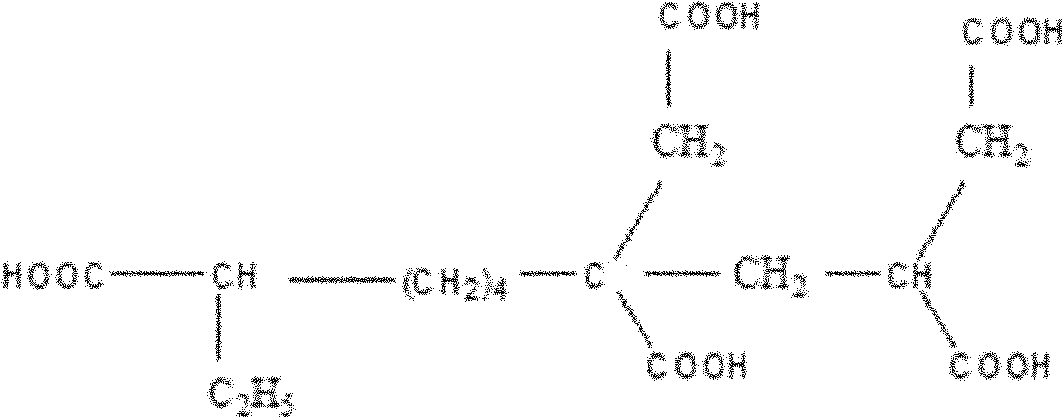

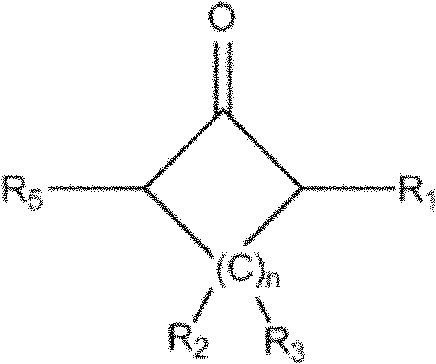

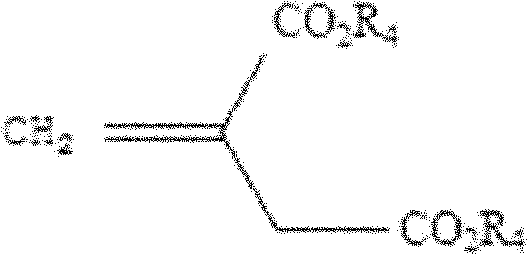

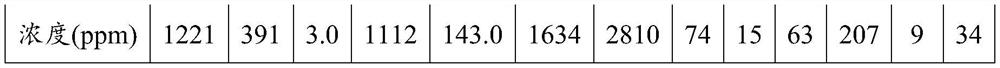

Polycarboxylic acid for electrolyte as well as preparation method and application thereof

ActiveCN102134190ALow ion contentImprove conductivityPreparation from carboxylic acid saltsElectrolytic capacitorsIonSolubility

The invention discloses a polycarboxylic acid for electrolyte as well as a preparation method and application thereof. The polycarboxylic acid for the electrolyte has a structural general formula, wherein R1, R2, R3 and R5 are hydrogen radicals and alkyl radicals; n is an integer from 2 to 12; m is an integer from 1 to 3; and R1, R2, R3 and R5 are same or different to each other. The ammonium salt of the polycarboxylic acid for the electrolyte has the advantages of high solubility in a menstruum, high conductivity, excellent high-low temperature resistance, long service life, and the like; and in addition, the invention has the advantages of simple preparation method, high yield, low foreign ion content and suitability for industrial large-scale production.

Owner:武汉海斯普林科技发展有限公司

Waste sulfuric acid recovery treatment method

PendingCN114715856AReduce processing costsImprove adsorption capacityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsAnthraquinonesPtru catalyst

The invention relates to the field of waste sulfuric acid treatment processes, in particular to a waste sulfuric acid recovery treatment method, which comprises the following steps: diluting waste sulfuric acid, adding a catalyst, carrying out ultrasonic treatment and stirring treatment for 5-20 hours under an illumination condition, filtering, adding adsorption resin into filtrate, adsorbing for 20-25 hours, filtering, and adjusting the concentration to obtain recovered sulfuric acid, by utilizing the catalytic degradation and adsorption effects of the catalyst and the resin, anthraquinone dye and other organic impurities in the waste sulfuric acid can be purified, the chromaticity is reduced, the waste sulfuric acid can be used as a crude chemical raw material after being recycled, the treatment cost of the waste sulfuric acid is reduced, and sulfuric acid resources are fully utilized.

Owner:无锡日月水处理有限公司

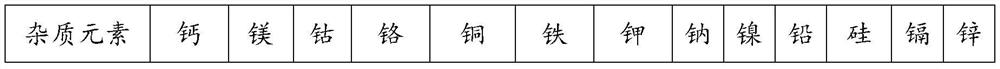

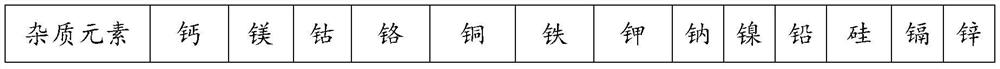

Preparation method of high-purity manganese sulfate

ActiveCN111908510ALow content of impurity ionsGood removal effectManganese sulfatesManganese sulphateManganese(II) carbonate

The invention relates to the technical field of lithium battery cathode materials, and provides a preparation method of high-purity manganese sulfate, which comprises the following steps: removing heavy metal ions in a crude manganese salt solution, and mixing the obtained liquid-phase product with bicarbonate to precipitate calcium, magnesium and manganese ions, thereby obtaining a crude manganese carbonate solid; dispersing the crude manganese carbonate solid in water, and introducing carbon dioxide into the dispersion liquid to obtain a refined manganese carbonate solid; dissolving the refined manganese carbonate solid in dilute sulfuric acid, and then concentrating and crystallizing to obtain high-purity manganese sulfate. According to the method, manganese salt is converted into manganese carbonate by controlling reaction conditions, calcium carbonate and magnesium carbonate precipitated along with manganese carbonate are converted into soluble bicarbonate by introducing carbon dioxide, then calcium and magnesium ions are removed, and high-purity manganese sulfate can be conveniently obtained through sulfuric acid redissolution and crystallization. The method provided by the invention is simple in steps and low in cost, and the content of impurity ions in the obtained high-purity manganese sulfate is extremely low.

Owner:TSINGHUA UNIV

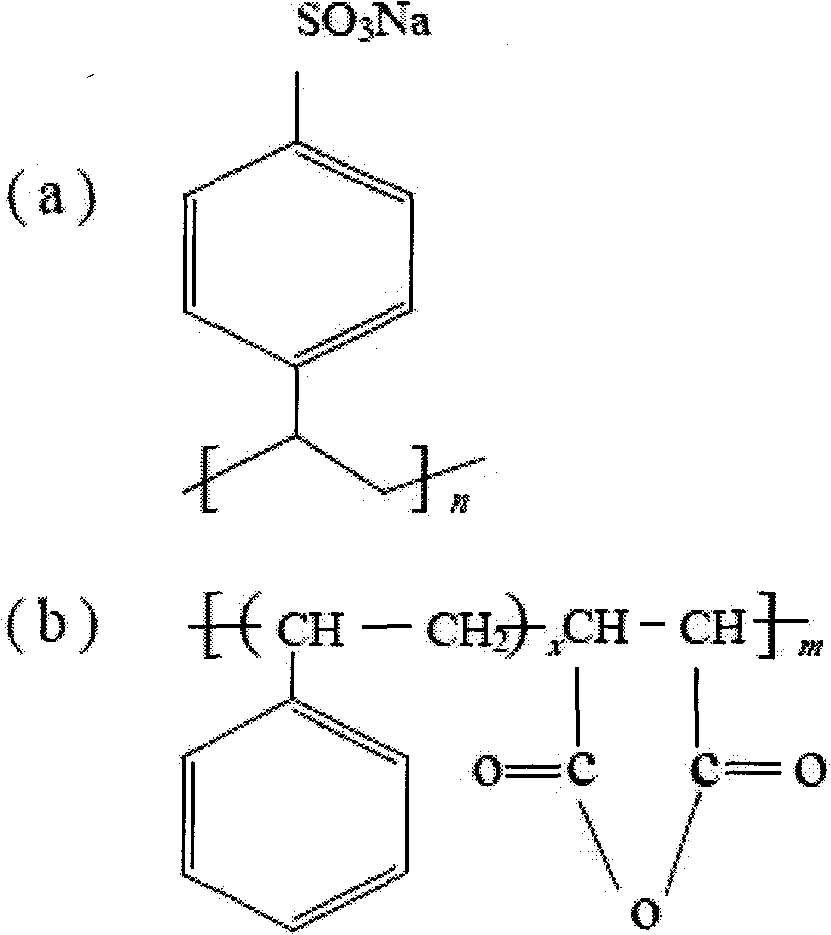

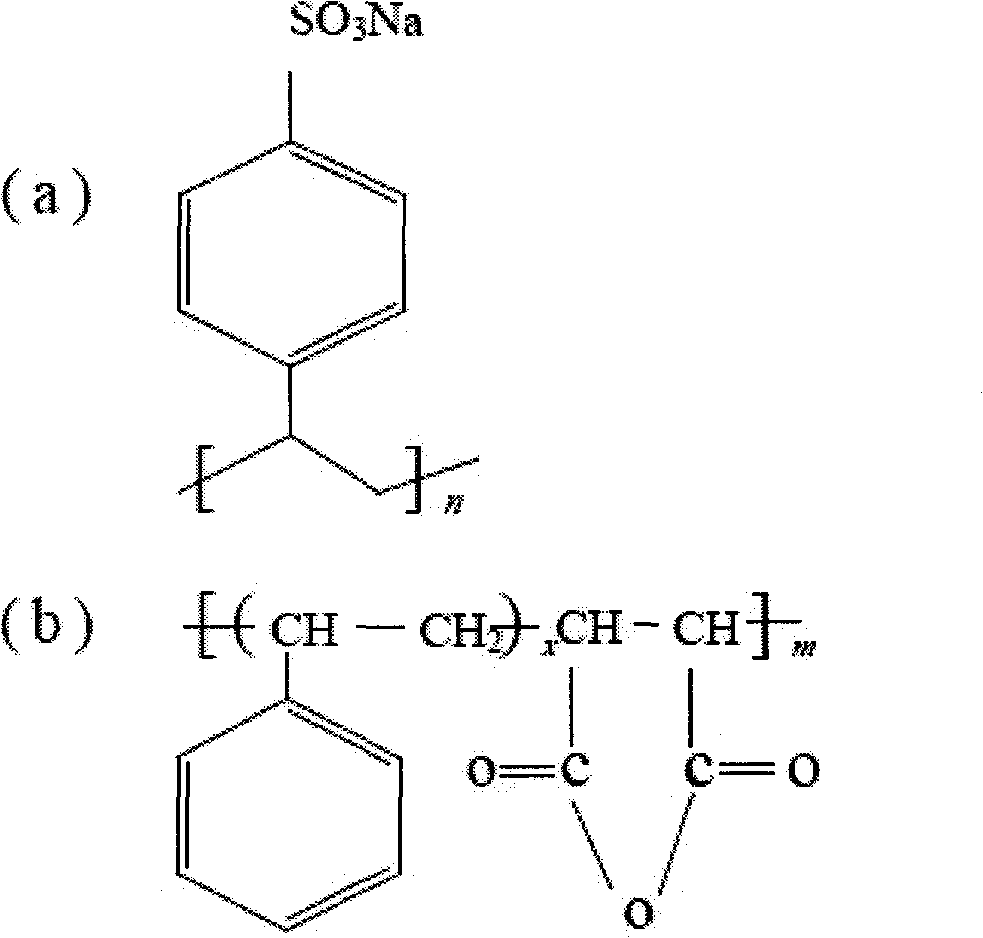

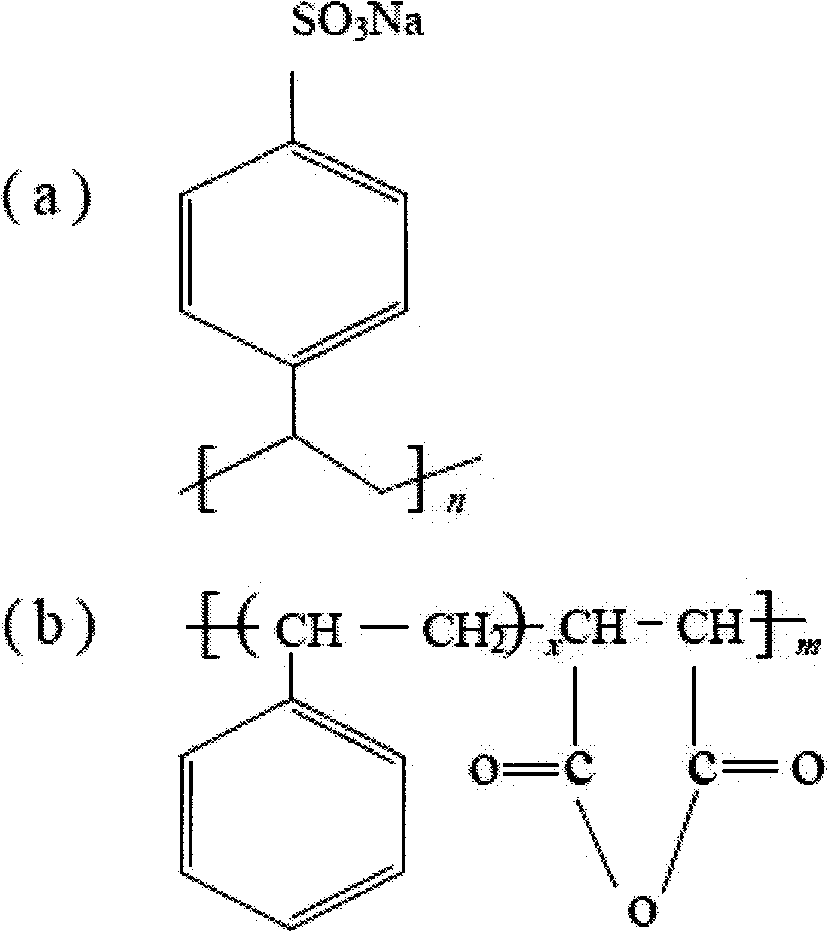

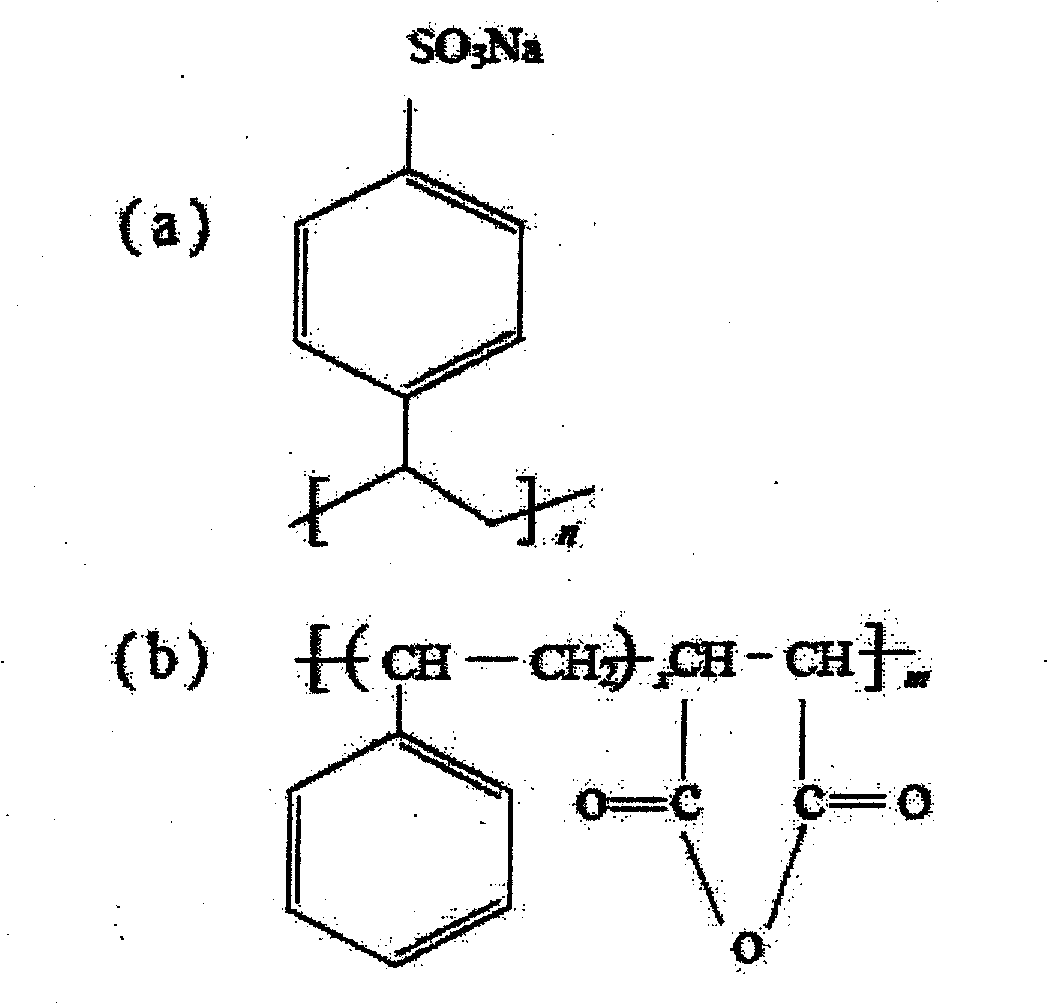

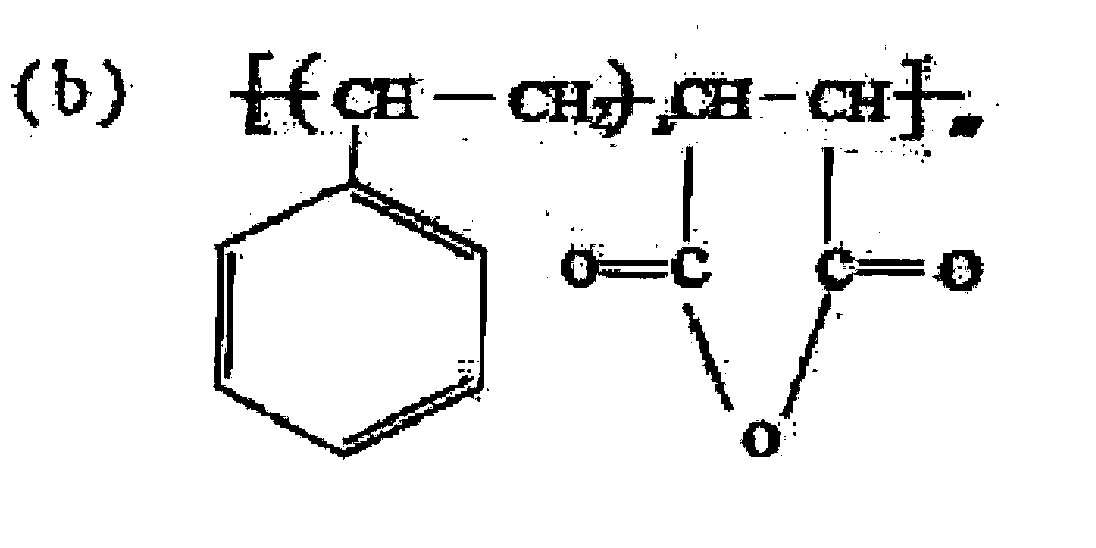

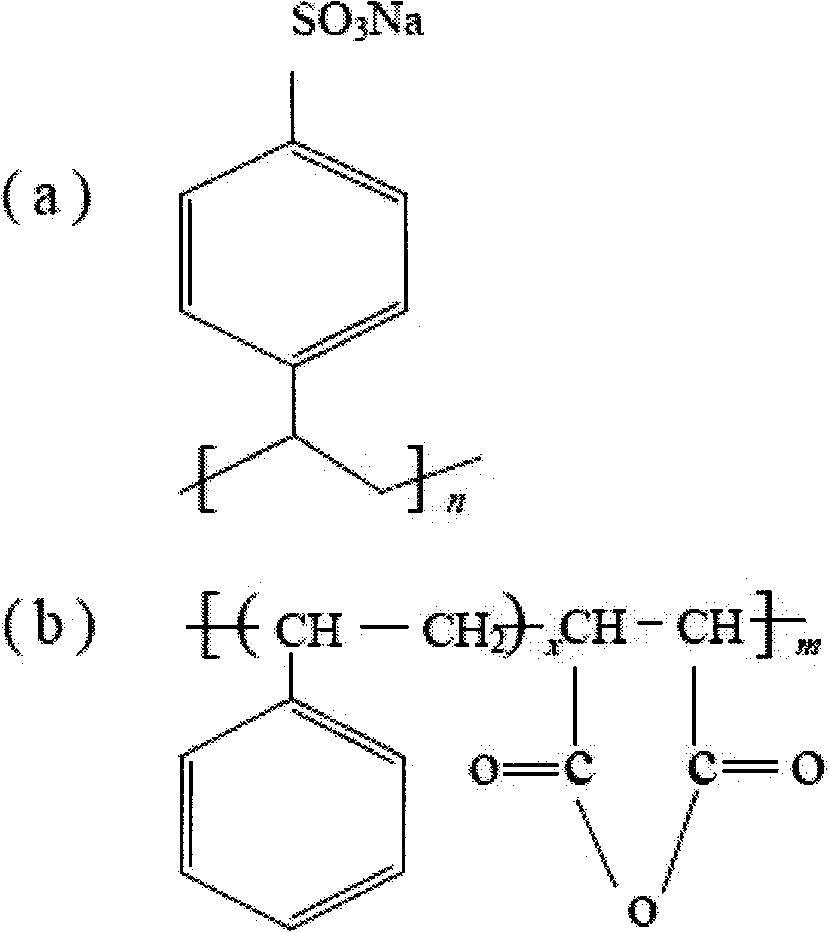

Polymer settling agent for preparation of ray emulsion, and settling desalting method

InactiveCN102109754AReduced ionized water for desalinationImprove desalination efficiencySedimentation separationSilver halide emulsionsQuaternary ammonium cationRare earth

The invention discloses a polymer settling agent for preparation of ray emulsion and a settling desalting method. The polymer settling agent for preparation of the ray emulsion at least meets one of the following two conditions that: (1) a water-soluble artificially synthesized polymer at least comprises one of -OSO3M, -SO3M and -COOM, wherein M is H, an alkali metal element, a rare earth metal element, or quaternary ammonium salt and the like; and (2) ionic monomer concentration is 65 to 85 percent, and the molecular weight range is 20,000 to 150,000. The method is implemented by the following steps of: a, desalting the emulsion at one time, namely adding the polymer settling agent in an amount which is 2 to 20 percent based on dry weight of gelatin in silver halide-gelatin ripened at one time or gelatin analogue emulsion; and b, settling the solution obtained in the step a, and separating to obtain mother liquor and a chemical cake. By a silver halide emulsion efficient desalting concentration technology, the foreign ion content in the emulsion can be effectively reduced and the whole coating and drying temperature is reduced, and the saving performance of the photography performance of a film is improved.

Owner:TIANJIN MEDIA IMAGING MATERIALS

A method and device for preparing nacl industrial salt with zero discharge of desulfurization wastewater

ActiveCN104860461BReduce hardnessHigh purityMultistage water/sewage treatmentAlkali metal chloridesEvaporationWater processing

The invention provides a method for preparing NaCl industrial salt with desulphurization waste water zero discharge. First, suspensions and colloids in desulphurization waste water are aggregated into large particles and precipitate, then the waste water without suspensions and colloids is evaporated, during the initial period of evaporation, seed crystals are added into the waste water, thus substances easy to scale are precipitated, the precipitated substances easy to scale are discharged, the residual solution system is subjected to condensation, crystallization, dehydration and drying, and NaCl industrial salt with a high purity is obtained. Through a mode of addition of seed crystals, the substances easy to scale in the waste water are precipitated with the seed crystals as crystal nucleuses firstly, then the precipitated substances easy to scale are discharged, the impurity ion content in the waste water system is lowered, the waste water hardness is lowered effectively, scaling on inner surfaces of a waste water processing device can be avoided effectively, and finally production of NaCl industrial salt products with a high purity can be achieved.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Selective leaching agent and deep separation method of complex copper-zinc mineral resources

InactiveCN112176198AIdeal separation indexIncrease ion concentrationPhotography auxillary processesProcess efficiency improvementHydrometallurgyMaterials science

The invention relates to the field of mineral processing and hydrometallurgy, and particularly relates to a selective leaching agent and a deep separation method of complex copper-zinc mineral resources. The separation method comprises the steps that copper-zinc mixed ore is subjected to crushing, screening and ore grinding, and copper-zinc ore powder with the proper particle size is obtained; zinc in the copper-zinc mixed ore is leached out of the copper-zinc ore powder in the selective leaching agent, meanwhile, copper and iron are extremely dissolved in the leaching process, and low-zinc high-grade copper concentrate and zinc-containing leachate can be obtained after solid-liquid separation; and the zinc-containing leachate is subjected to sulfide precipitation, and high-grade sphalerite can be obtained after solid-liquid separation. The deep separation method of the copper-zinc ore is low in requirement for raw ore, the ore source is wide, for example, flotation of bulk concentrate, natural copper-zinc mixed ore, copper-zinc mixed ore obtained through enrichment in other manners and the like, the requirement for the ore grade is not strict, low-grade mineral resources can be processed, and the resource utilization rate is increased.

Owner:CENT SOUTH UNIV

A kind of preparation method and application of vanadyl sulfate crystal

ActiveCN105776332BSimple processSimple equipmentFinal product manufactureRegenerative fuel cellsVanadyl sulfateEvaporation

The invention provides a preparation method of a vanadyl sulfate crystal and application of the vanadyl sulfate crystal.The method comprises the following steps that vanadium pentoxide and sulfuric acid with the concentration of 15 mol / L-20 mol / L are added into a reaction kettle and mixed to be uniform; the reaction kettle containing vanadium pentoxide and sulfuric acid with the concentration of 15 mol / L-20 mol / L is put into a sealed reactor, reduction gas is introduced into the sealed reactor, the temperature is increased, and a reduction reaction is conducted; after the reduction reaction is completed, the reaction kettle is taken out, and the vanadyl sulfate crystal is obtained.The high-purity vanadyl sulfate crystal is prepared directly through a reduction method, evaporation crystallization treatment is not needed in the whole technology process, operation is easy, the reaction condition is mild, the cost is low, and the content of foreign ions in vanadyl sulfate electrolytes prepared from the high-purity vanadyl sulfate crystal is low and lower than 10 ppm.

Owner:HEBEI IRON AND STEEL

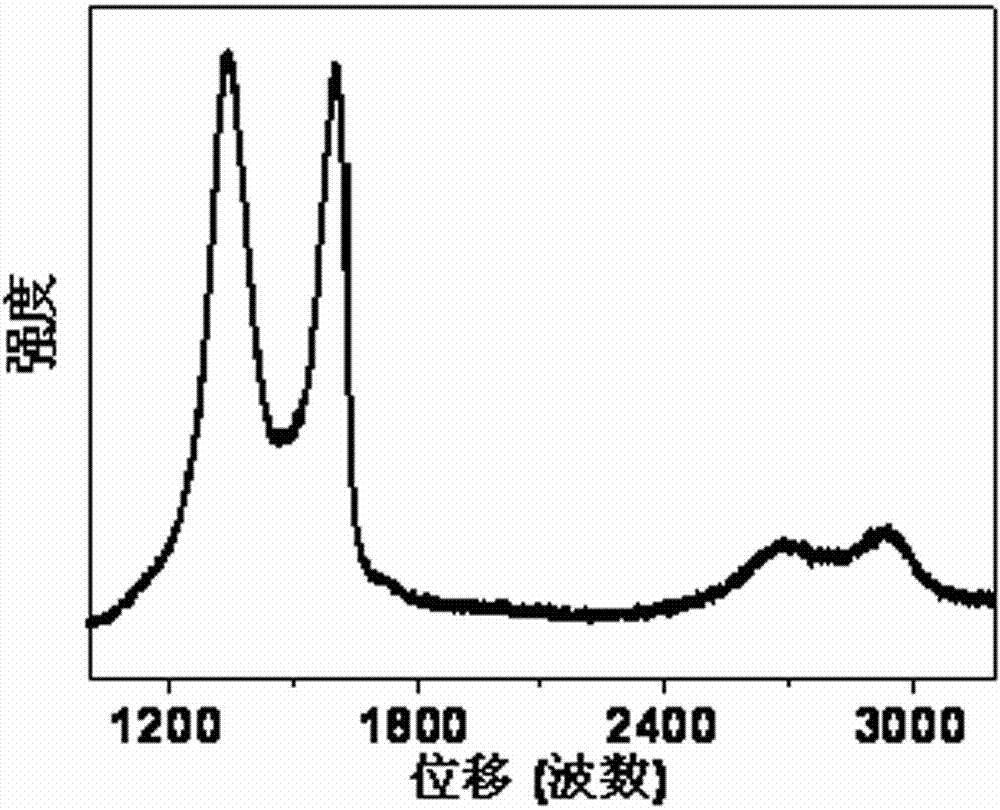

Method for preparing waste recovered graphite powder into graphene

The invention relates to a method for preparing waste recovered graphite powder into graphene. The method comprises the following steps of: mixing waste recovered graphite powder and concentrated sulfuric acid in a reaction kettle, stirring and uniformly mixing; slowly adding potassium permanganate; fully stirring and keeping a low temperature (20 DEG C); heating solution to 35+ / -5 DEG C and keeping the temperature for 30-90 minutes; slowly adding a certain amount of distilled water, heating the solution to 80-90 DEG C and keeping the temperature for 15-30 minutes; slowly adding hydrogen peroxide into the solution and slowly stirring to obtain golden yellow graphene oxide slurry; washing the slurry by using hydrochloric acid, potassium hydroxide and de-ionized water of certain concentration in sequence to remove impurity ions; and finally, holding an obtained graphene oxide sample in a high-temperature reaction furnace, and heating under an environment of argon, hydrogen or ammonia gas at 500-800 DEG C for 1-3 hours to reduce to obtain a graphene sample with thickness of 1-5 atom layers. The method has the advantages of low production cost, short period, high yield, simplicity and easiness for control of equipment and suitability for large-scale production. The waste recovered graphite powder is used as a carbon source, so that the utilization rate of an environment resource is effectively increased.

Owner:泰州巨纳新能源有限公司

A kind of preparation method of high colloidal cerium glue

ActiveCN109761259BReduce dosageImprove oxidation efficiencyCerium oxides/hydroxidesRare earth metal compounds preparation/treatmentNitrateCerous chloride

The invention belongs to the technical field of rare earth compound preparation, and particularly relates to a preparation method of cerium glue with high glue forming performance. According to the method, firstly, soluble cerium salt is prepared into a cerous nitrate or cerium chloride solution; hydrogen peroxide is used as an oxidizing agent; ammonium hydroxide is used as a precipitant; throughtransformation, cerium hydroxide precipitates are obtained; the cerium hydroxide precipitates are heated to the temperature of 85 to 100 DEG C; the state is maintained for 30 to 90 min; the materialsare washed until the electric conductivity is less than 5 ms / cm; plate frame press filtering is performed; cerium hydroxide paste is obtained; the cerium hydroxide paste and monobasic acid are pulpedinto glue; drying is performed to obtain a primary cerium glue product; the primary cerium glue product is dissolved into a solution with the cerium ion concentration being 0.2 to 0.6 mol / L through adding deionized water; then, ammonia water precipitation is performed; after the materials are washed until the electric conductivity is less than 5 ms / cm, plate frame press filtering is performed to obtain cerous hydroxide paste; monobasic acid is added for pulping to obtain glue; drying is performed to obtain a product. The dissolution degree of the prepared cerium glue product prepared by the invention can reach 350 g / L or higher (the content of rare earth oxide); the product can be applied to the production process requiring high-concentration tetravalent cerium solution.

Owner:淄博加华新材料有限公司

A method for regeneration of exhausted electrolyte of all-vanadium redox flow battery

ActiveCN111446477BReduce adverse effectsLow content of impurity ionsElectrolyte stream managementRegenerative fuel cellsElectrolytic agentElectrical battery

The invention relates to a method for regenerating the spent electrolyte of an all-vanadium redox flow battery. Its technical scheme is: according to the mass ratio of carbon material: anion exchange resin: binder: organic solvent is 1: (0.1 ~ 1): (0.05 ~ 0.5): (2 ~ 10) batching, mixing, to obtain a mixed solution Ⅰ; according to the mass ratio of carbon material: cation exchange resin: binder: organic solvent is 1: (1-5): (0.05-0.5): (2-10) ingredients, mix evenly to obtain mixed liquid II. Spray or smear the mixed solution Ⅰ and mixed solution Ⅱ on the graphite felt electrodes respectively, and then dry them, then place the dried anode composite electrode and cathode composite electrode on the corresponding positive and negative terminals of the capacitive deionization device, Under the condition of DC voltage, the exhausted electrolyte solution of the all-vanadium redox flow battery is circulated and pumped into the capacitive deionization device to obtain the electrolyte solution Ⅰ. Add a chelating agent to the electrolyte I and mix to obtain a regenerated electrolyte. The regenerated electrolyte prepared by the invention has low impurity content and good stability and electrochemical performance.

Owner:WUHAN UNIV OF SCI & TECH

Novel nano powder surface treatment method

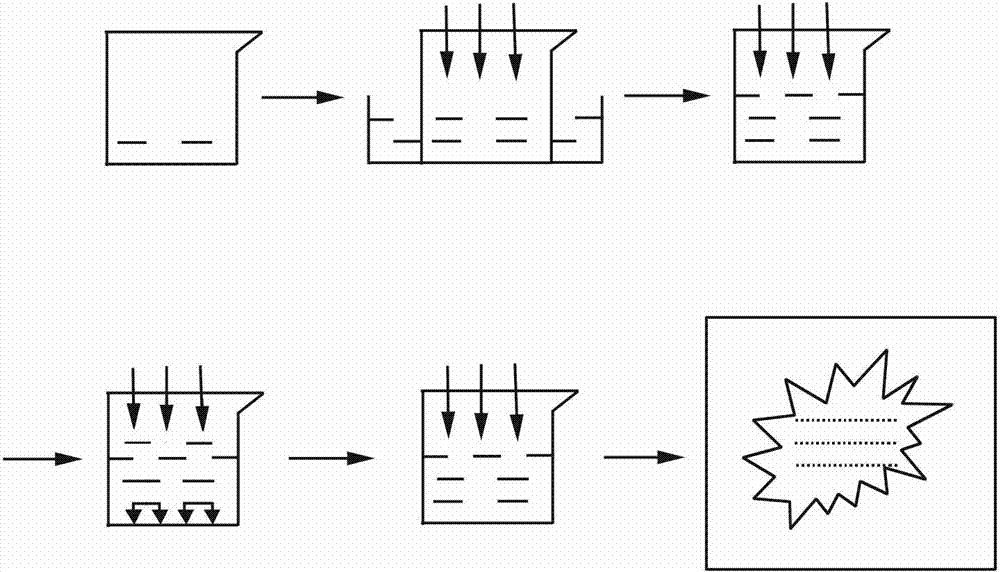

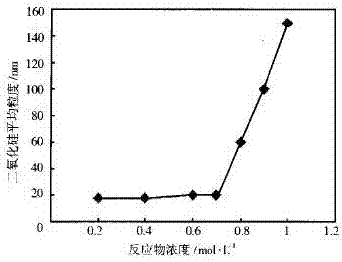

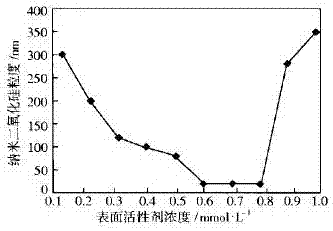

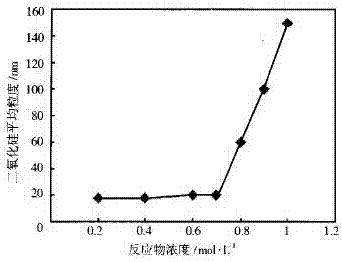

InactiveCN107304054AHigh purityLow content of impurity ionsSilicaNanotechnologySolution systemSodium silicate

The present invention relates to a new type of nano powder surface treatment method, which is characterized in that it includes using cheap technical water glass as raw material, adding different types of surfactants into the solution system by adopting micellar method to control the precipitation reaction The microenvironment makes the generated precipitation particles be back-wrapped, maintains a high degree of dispersion of the precipitation particles, prevents the aggregation and growth phenomenon between the particles, and prepares high-purity, spherical nanoparticle materials. A new nano-powder surface treatment method overcomes the hard agglomeration and uneven particle distribution that tend to occur when preparing nano-powders by traditional methods. It is an effective new method for preparing nano-powder materials with high purity, good shape and narrow particle size distribution.

Owner:JIAXING LEIZHOU COMPOSITE MATERIALS CO LTD

A kind of hydroxy silicone oil and its continuous preparation method

Owner:GUANGZHOU DAOLIN SYNTHETIC MATERIALS CO LTD

A method for improving the quality of industrial sodium hexametaphosphate

ActiveCN103407981BLow content of impurity ionsSignificant quality improvement effectPhosphorus compoundsSODIUM METAPHOSPHATEState of art

The invention discloses a method for enhancing the quality of industrial sodium hexametaphosphate. The method comprises the following steps of: dissolving the industrial sodium hexametaphosphate as a raw material into high-purity water; carrying out secondary filtration, and then keeping constant temperature through a heat exchanger; separating through a reverse osmosis device; reducing the content of impurity ions to obtain a sodium hexametaphosphate product with the quality enhanced. Compared with the prior art, the method can be used for preparing the sodium hexametaphosphate product with the quality enhanced and the total phosphate content (in terms of P2O5) more than 68.5%, and effectively reducing the content of water-insoluble substances and the foreign ions, such as Fe and F, in the sodium hexametaphosphate product which is superior to the quality standard of GB1890-2005. The method for enhancing the quality of the industrial sodium hexametaphosphate, which is disclosed by the invention, has the advantages of safety, easiness and convenience for operation, stable product quality and suitability for industrial production.

Owner:SHANGHAI WOKAI BIOTECH

High-purity iron phosphate used for producing lithium ion battery positive-pole material and preparation method thereof

InactiveCN102126713BLow impurity contentImprove electrochemical performancePhosphorus compoundsFerrous saltsPhosphoric acid

The invention relates to high-purity iron phosphate used for producing a lithium ion battery positive-pole material and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking ferrous salt and carbonate as raw materials; reacting to generate intermediate product ferrous carbonate precipitation, wherein, the ferrous carbonate is easy to filter, and the foreign ions are easy to wash; filtering and recovering ammonium sulfate; dissolving the ferrous carbonate precipitation; adding oxidant for oxidizing; regulating the pH value of the solution; heating and preserving the temperature for a certain time to obtain the iron phosphate precipitation; filtering, drying and precipitating to obtain the high-purity iron phosphate; and mixing and calcining the high-purity iron phosphate, the lithium source and the carbon source to obtain the lithium ion battery positive-pole material with excellent electrochemistrical performance. By using the method provided by the invention, the impurity content in the iron phosphate is effectively lowered, the process time is shortened, the energy consumption is reduced, and the cost and the consumption of the raw materials are lowered; and the filter liquor is easy to recover, and the production cost is very low, thus being beneficial for large-scale production in scaled industry.

Owner:SICHUAN UNIV

Method for regenerating failure electrolyte of all-vanadium redox flow battery

ActiveCN111446477AReduce adverse effectsLow content of impurity ionsElectrolyte stream managementRegenerative fuel cellsElectrolytic agentElectrical battery

The invention relates to a method for regenerating a failure electrolyte of an all-vanadium redox flow battery. The technical scheme is as follows: the preparation method comprises the steps of proportioning a carbon material, anion exchange resin, a binder and an organic solvent in a mass ratio of 1: (0.1 to 1): (0.05 to 0.5): (2 to 10), and uniformly mixing to obtain a mixed solution I; preparing a carbon material, cation exchange resin, a binder and an organic solvent according to a mass ratio of 1: (1 to 5): (0.05 to 0.5): (2 to 10), and uniformly mixing to obtain a mixed solution II; respectively spraying or smearing the mixed solution I and the mixed solution II on a graphite felt electrode and drying; placing the dried anode composite electrode and cathode composite electrode at a positive electrode end and a negative electrode end corresponding to a capacitive deionization device, and circularly pumping the failure electrolyte of the all-vanadium redox flow battery into the capacitive deionization device under the condition of direct-current voltage to obtain an electrolyte I; and adding a chelating agent into the electrolyte I, and mixing to obtain the regenerated electrolyte. The regenerated electrolyte prepared by the method is low in impurity content and good in stability and electrochemical performance.

Owner:WUHAN UNIV OF SCI & TECH

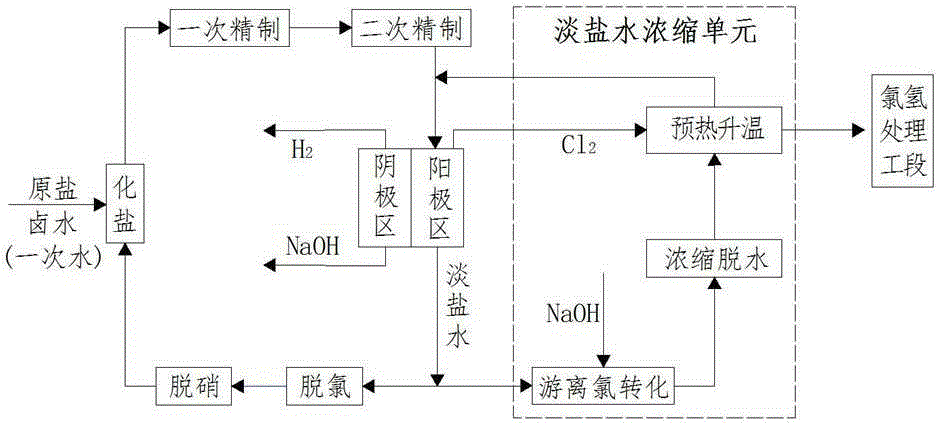

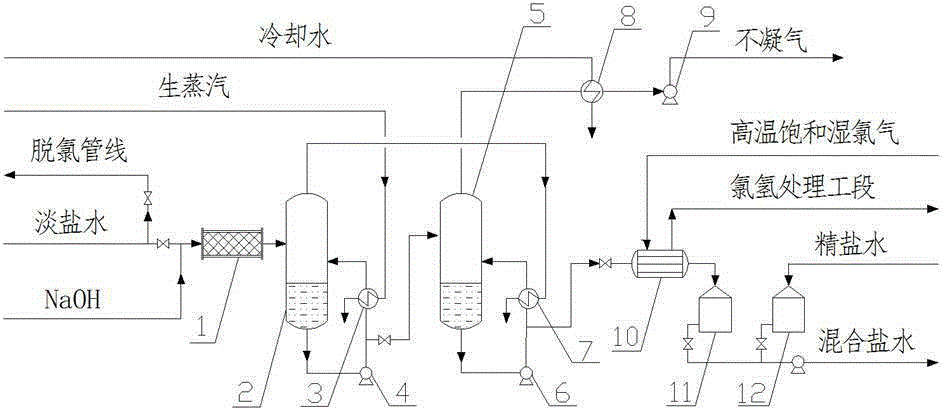

A method and device for producing caustic soda by electrolysis of light brine instead of part of refined brine

ActiveCN104532283BRaise the pHAvoid pollutionElectrolysis componentsEnergy inputSalt waterDehydration

The invention relates to a method for producing caustic soda through electrolysis by replacing part of fine brine with light salt brine, and belongs to the technical field of the production of caustic soda in an ion membrane process. The method is characterized in that outlet light salt brine is divided into two parts according to the production requirements, one part of the light salt brine enters a brine refining unit after being dechlorinated and denitrified, the other part of light salt brine enters a light salt brine recovery unit, the light salt brine recovery unit is characterized by comprising the following process steps: completely converting free chorines dissolved in the outlet light salt brine to NaClO by virtue of a free chlorine conversion subunit, concentrating and dehydrating the light salt brine with the free chlorine being removed by virtue of a concentration dehydration subunit to obtain recovered light salt brine, recovering the heat of high temperature saturated wet chlorine by virtue of a preheating subunit, directly mixing the preheated recovered light salt brine with raw material fine brine according to a given ratio to obtain a mixture, and electrolyzing the mixture in an electrolytic cell to obtain caustic soda. The invention also relates to a device for preparing the caustic soda in an electrolytic way by adopting the light salt brine to substitute the fine brine. The light salt brine refining process is simplified, the production cost is low, the electrolytic waste heat utilization rate is high, a great amount of cheap brine can be used for substituting solid salt to prepare the caustic soda, and the chlorine doping rate is more than 90 percent.

Owner:SHANDONG LUTAI HLDG GRP CO LTD

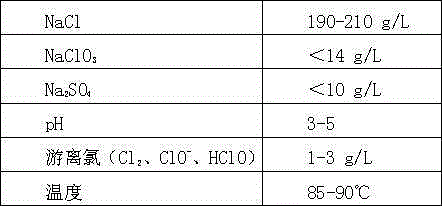

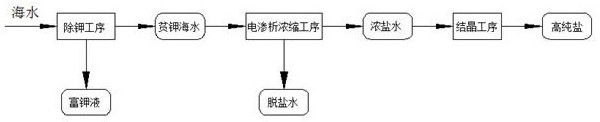

A process for producing high-purity refined salt by using selective electrodialysis to concentrate brine

ActiveCN108996521BOvercome the disadvantage of poor selectivityRaise the gradeGeneral water supply conservationDispersed particle separationSaline waterDesalination

The invention belongs to the technical field of preparing salt from seawater, and relates to a process for producing high-purity refined salt by utilizing selective electrodialysis concentration of brine. The method comprises the following steps: a potassium removal process: concretely a potassium-rich solution and potassium-poor seawater are obtained after potassium ion adsorption and elution arecarried out on seawater by using a potassium removal system, the pH value of the potassium-rich seawater is regulated, and then the potassium-rich seawater is taken as electrodialysis inflow water; an electrodialysis concentration process: concretely concentration treatment is carried out on the electrodialysis inflow water by adopting a monovalent selective ion exchange membrane, the electrodialysis water inlet water is treated by the using an electrodialysis concentration process, and then desalted seawater and concentrated brine are obtained; and a crystallization process: concretely evaporative crystallization treatment is carried out on the concentrated brine obtained in the electrodialysis concentration process, and then the high-purity refined salt is obtained. Through the adoptionof the method disclosed by the invention, a raw material for preparing potassium chloride can be obtained, and potassium ions in a raw material liquid can also be removed, so that the problem of poorselectivity of electrodialysis concentration on sodium ions and potassium ions is effectively solved, the quality of brine and refined salt is further improved, and the high-purity refined salt is obtained.

Owner:QUANZHOU NORMAL UNIV

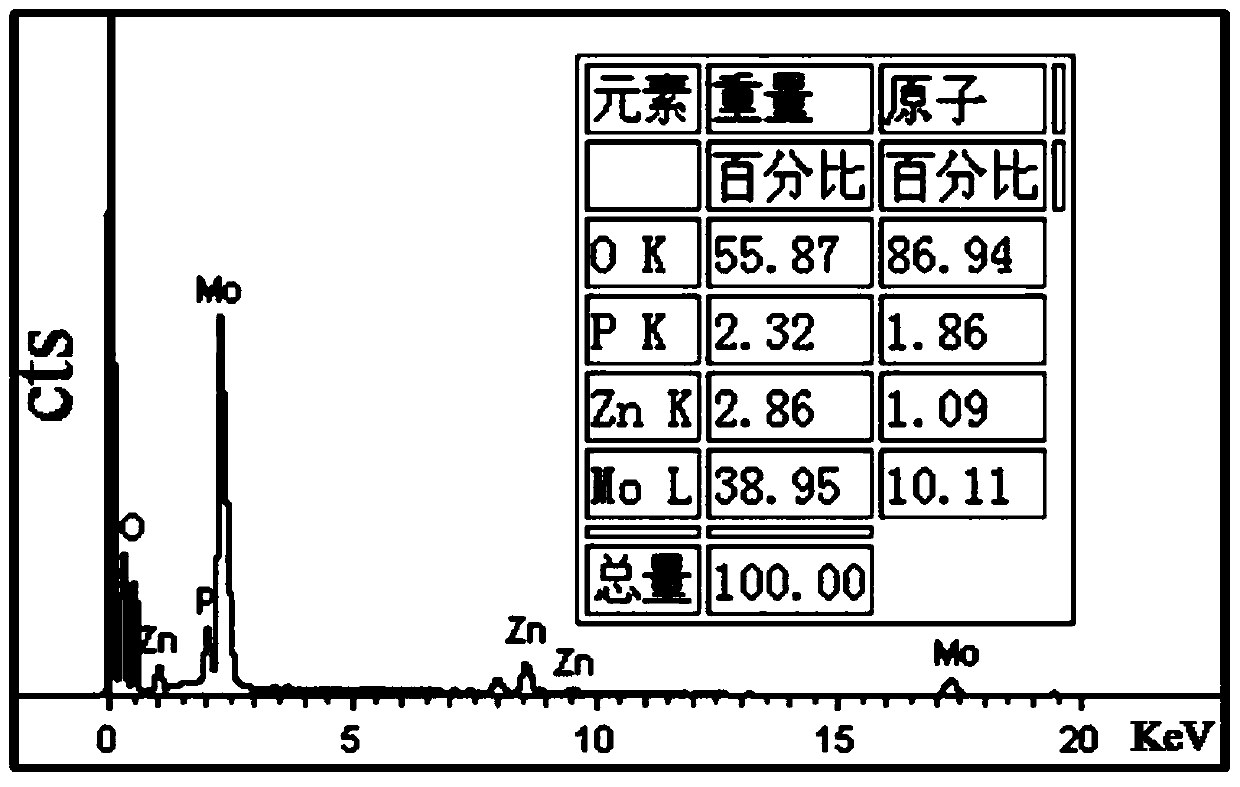

A kind of preparation method of zinc phosphomolybdate containing keggin structure

The invention belongs to the field of preparation of phosphomolybdate and relates to a preparation method of zinc phosphomolybdate containing a keggin structure. The preparation method adopts a liquid-phase method to synthesize the zinc phosphomolybdate and comprises the following steps of: adopting phosphomolybdic acid and zinc oxide as raw materials, adopting distilled water or alcohol as a solvent, controlling PH to be 1.0-3.0, and reacting under a water-bathing condition with the temperature of 55-65 DEG C; carrying out reduced-pressure distillation to obtain pasty substance, and drying for 8-10 hours at the temperature of 70-90 DEG C to obtain orange zinc phosphomolybdate. The preparation method has the beneficial effects that the process is simple, the reactant raw materials are cheap in price, the impurity-ion content is low, the yield is high and the benefit for reducing the production cost is achieved; the prepared zinc phosphomolybdate containing the keggin structure can meetthe requirements of application in the aspects of catalyst synthesis, pharmaceutical synthesis, electrochemical application and flame-retardant compounding and the like.

Owner:HUBEI UNIV OF TECH

Polycarboxylic acid for electrolyte as well as preparation method and application thereof

ActiveCN102134190BLow ion contentImprove conductivityPreparation from carboxylic acid saltsElectrolytic capacitorsSolubilityCarboxylic acid

The invention discloses a polycarboxylic acid for electrolyte as well as a preparation method and application thereof. The polycarboxylic acid for the electrolyte has a structural general formula, wherein R1, R2, R3 and R5 are hydrogen radicals and alkyl radicals; n is an integer from 2 to 12; m is an integer from 1 to 3; and R1, R2, R3 and R5 are same or different to each other. The ammonium salt of the polycarboxylic acid for the electrolyte has the advantages of high solubility in a menstruum, high conductivity, excellent high-low temperature resistance, long service life, and the like; and in addition, the invention has the advantages of simple preparation method, high yield, low foreign ion content and suitability for industrial large-scale production.

Owner:武汉海斯普林科技发展有限公司

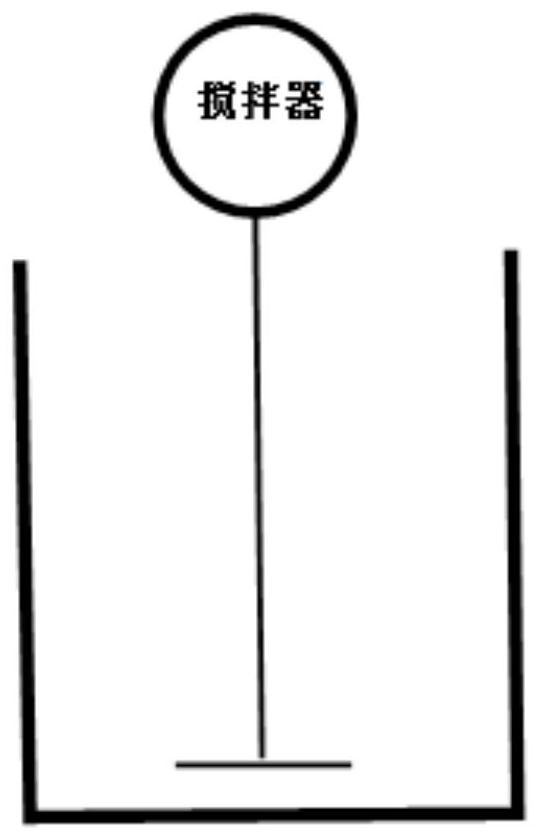

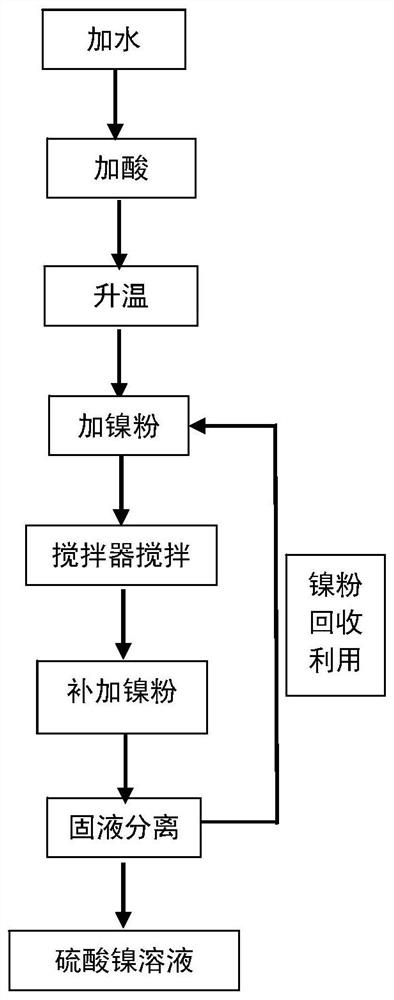

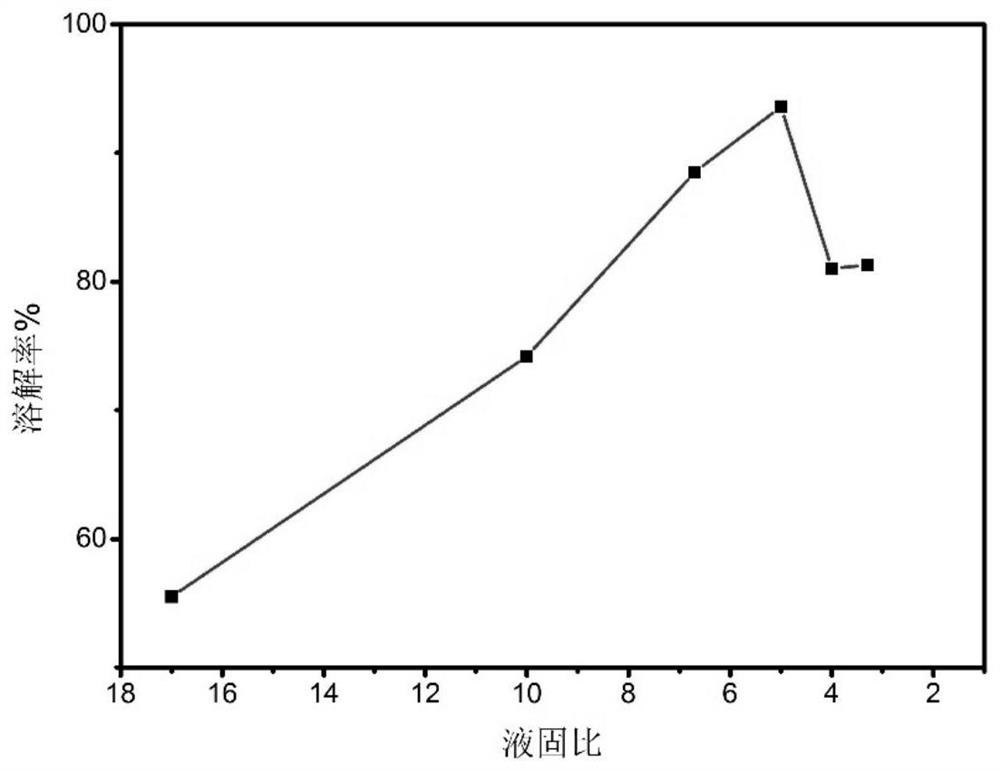

Preparation method of battery grade nickel salt

ActiveCN112429784BIncrease reaction rateIncrease responsivenessNickel sulfatesNickel saltPhysical chemistry

The invention provides a method for preparing battery-grade nickel salt, which relates to the technical field of batteries, and comprises the following steps: adding water and inorganic acid to a reaction vessel to form an acid solution; heating the acid solution to 90-110°C, and adding nickel powder Carry out the reaction, add nickel powder in the reaction process to maintain the nickel powder concentration and liquid-solid ratio of the reaction system, react for 14-20h, when the pH value of the solution is 3-5, the reaction ends, and the nickel salt solution is obtained; wherein, the acid solution The liquid-solid ratio with nickel powder is 4-6:1ml / g, and the amount of nickel powder added is 1.8-2.2 times of the theoretical consumption of nickel powder in the amount of inorganic acid; there is no baffle in the reaction vessel. The present invention optimizes the reaction conditions such as liquid-solid ratio, temperature, and nickel powder amount, and does not set baffles, so that the reaction rate is greatly increased, and the requirements can be met without adding hydrogen peroxide. The cost is low, green and safe, and the obtained nickel salt product is of high quality. , low impurity content.

Owner:江西佳纳能源科技有限公司 +2

Flocculating agent composition for preparing ray emulsion and desalination and concentration method

InactiveCN101900930AEmission reductionImprove desalination efficiencySilver halide emulsionsConcentration ratioEnrichment methods

The invention discloses a flocculating agent composition for preparing a ray emulsion and a desalination and concentration method. By widening the concentration ratio range of a primary mature emulsion, the flocculating agent composition meets the requirements of different-purpose films on the preparation of the ray emulsion. The flocculating agent composition consists of at least two polymers which accord with the requirement, or at least two polymers which are the same type according with the requirement and have different degrees of polymerization. The flocculating agent composition can perform flocculation (or precipitation) in an acid medium so as to desalt and concentrate the emulsion. Due to the silver halide emulsion high-efficiency desalination and concentration technology, the desalination and concentration method effectively reduces the content of impurity ions in the emulsion, reduces the bulk temperature for coating and drying, and improves the performance for preserving the film photographic properties.

Owner:TIANJIN MEDIA IMAGING MATERIALS

Flocculating agent composition for preparing ray emulsion and desalination and concentration method

InactiveCN101900930BLow content of impurity ionsReduce the temperatureSilver halide emulsionsFlocculationImpurity ions

The invention discloses a flocculating agent composition for preparing a ray emulsion and a desalination and concentration method. By widening the concentration ratio range of a primary mature emulsion, the flocculating agent composition meets the requirements of different-purpose films on the preparation of the ray emulsion. The flocculating agent composition consists of at least two polymers which accord with the requirement, or at least two polymers which are the same type according with the requirement and have different degrees of polymerization. The flocculating agent composition can perform flocculation (or precipitation) in an acid medium so as to desalt and concentrate the emulsion. Due to the silver halide emulsion high-efficiency desalination and concentration technology, the desalination and concentration method effectively reduces the content of impurity ions in the emulsion, reduces the bulk temperature for coating and drying, and improves the performance for preserving the film photographic properties.

Owner:TIANJIN MEDIA IMAGING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com