Method for removing calcium and magnesium in rare-earth industrial wastewater

A technology of industrial wastewater and rare earth, which is applied in metallurgical wastewater treatment, chemical instruments and methods, extraction water/sewage treatment, etc., can solve problems such as equipment blockage, achieve quality improvement, good separation effect, and solve serious pipe blockage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

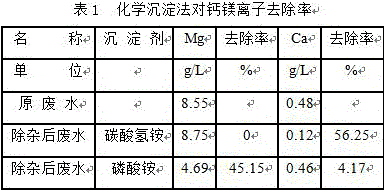

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Under the condition that the volume ratio of the organic phase to the liquid phase is 2:1, and the saponification rate is 30%, after extraction and standing for stratification, the concentration of calcium and magnesium in the raffinate is measured. The magnesium ion content in the original ammonium sulfate wastewater is 8.55g / L, the content in the raffinate is 3.49g / L, and the removal rate reaches 59.18%; the calcium ion content in the original ammonium sulfate wastewater is 0.48g / L, and the content in the raffinate 0.01g / L, the removal rate is 97.92%. As can be seen from the above examples, when the saponification rate is lower than 45%, the removal rate of magnesium ions in the original ammonium sulfate wastewater is low. The experimental results are shown in Table 2.

Embodiment 2

[0014] Example 2: Under the condition that the volume ratio of the organic phase to the liquid phase is 2:1, and the saponification rate is 45%, after the extraction is left to stand and layered, the concentration of calcium and magnesium in the raffinate is measured. The magnesium ion content in the original ammonium sulfate wastewater was 8.55g / L, and the content in the raffinate was 0.74g / L, with a removal rate of 91.35%; the calcium ion content in the original ammonium sulfate wastewater was 0.48g / L, and the content in the raffinate Less than 0.01g / L, the removal rate is greater than 97.92%. The experimental results are shown in Table 2.

Embodiment 3

[0015] Example 3: Under the condition that the volume ratio of the organic phase to the liquid phase is 2:1, and the saponification rate is 60%, after the extraction is left to stand for stratification, the concentration of calcium and magnesium in the raffinate is measured. The magnesium ion content in the original ammonium sulfate wastewater was 8.55g / L, and the content in the raffinate was 0.27g / L, with a removal rate of 96.84%; the calcium ion content in the original ammonium sulfate wastewater was 0.48g / L, and the content in the raffinate 97.92%. The experimental results are shown in Table 2.

[0016] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com