Membrane-based waste gas biological treatment method and system

A technology for biological treatment and waste gas, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of small gas-liquid mass transfer specific surface area, high investment and operation cost, easy accumulation of excessive gas, etc., and achieve efficient degradation. Microbial metabolic activity, small footprint, and improved gas-phase mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

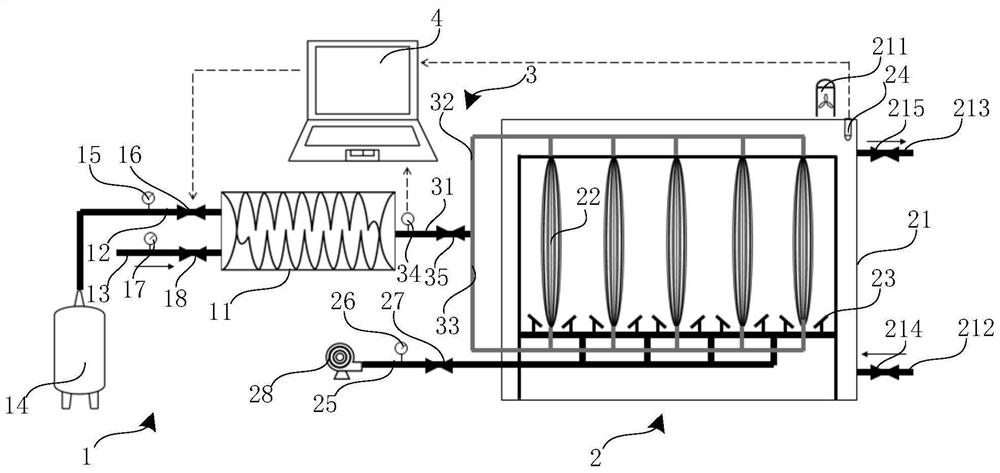

[0098] The membrane-based waste gas biological treatment system used in the examples is as follows: figure 1 shown, follow the steps below:

[0099] (1) The sulfur-containing organic waste gas and oxygen are fed into the gas mixing device to mix evenly, and the two gas pressures are both 1 psi;

[0100] (2) Adjust the concentration of sulfur-containing pollutants (mercapto group) after mixing to 2.5g / m 3 , put it into the membrane module connected to it through the pipeline;

[0101] (3) Pump the nutrient solution and the sludge from the secondary sedimentation tank of the sewage treatment plant with a VSS of 20g / L together into the hanging film, and run for 4 days to complete the domestication;

[0102] (4) Mix the sulfur-containing organic waste gas and oxygen evenly, the volume ratio of the sulfur-containing organic waste gas and the oxygen is 1:5, the oxygen pressure is 5psi, and the sulfur-containing pollutant concentration (mercapto group) is 0.5g / m 3 , pass into the ...

Embodiment 2

[0106] The membrane-based waste gas biological treatment system used in the examples is as follows: figure 1 shown, follow the steps below:

[0107] (1) The sulfur-containing organic waste gas and oxygen are fed into the gas mixing device to mix evenly, and the two gas pressures are both 1 psi;

[0108] (2) Adjust the concentration of sulfur-containing pollutants (mercapto group) after mixing to 2.5g / m 3 , put it into the membrane module connected to it through the pipeline;

[0109] (3) Pump the nutrient solution and the sludge from the secondary sedimentation tank of the sewage treatment plant with a VSS of 20g / L together into the hanging film, and run for 4 days to complete the domestication;

[0110] (4) Mix the sulfur-containing organic waste gas and oxygen evenly, the volume ratio of the sulfur-containing organic waste gas and the oxygen is 1:5, the oxygen pressure is 1 psi, and the sulfur-containing pollutant concentration (mercapto group) is 0.5 g / m 3 , pass into the ...

Embodiment 3

[0114] The membrane-based waste gas biological treatment system used in the examples is as follows: figure 1 shown, follow the steps below:

[0115] (1) The sulfur-containing malodorous organic waste gas and oxygen are fed into the gas mixing device to mix evenly, and the two gas pressures are both 1 psi;

[0116] (2) Adjust the concentration of sulfur-containing pollutants (mercapto group) after mixing to 2.5g / m 3 , put it into the membrane module connected to it through the pipeline;

[0117] (3) Pump the nutrient solution and the sludge from the secondary sedimentation tank of the sewage treatment plant with a VSS of 20g / L together into the hanging film, and run for 4 days to complete the domestication;

[0118] (4) Mix the sulfur-containing organic waste gas and oxygen evenly, the volume ratio of the sulfur-containing organic waste gas and the oxygen is 1:1, the oxygen pressure is 1psi, and the sulfur-containing pollutant concentration (mercapto group) is 5g / m 3 , pass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com