Adiponitrile hydrogenation reaction system and method for treating severe clogging of reactor by the system

A hydrogenation reaction and reactor technology, which is applied to the adiponitrile hydrogenation reaction system and the field of heavy blockage of the system to deal with the reactor, and can solve the problems of return pipe blockage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

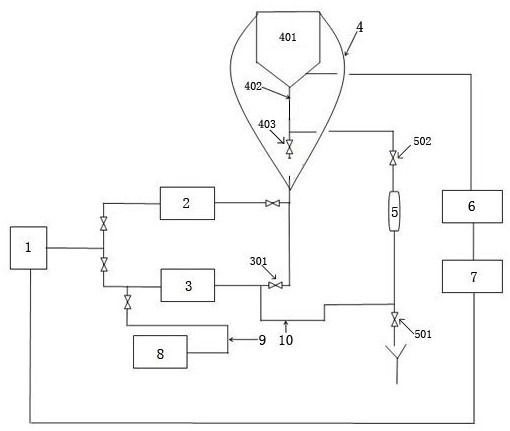

[0033] Utilize the method for adiponitrile hydrogenation reaction system to deal with severe clogging of reactor, comprising the following steps:

[0034] 1) First close the hand valve A301 and the sampling valve 501, and open the sampling root valve 502 to connect the connecting pipeline between the reactor feed pump equipment 3, the reactor sampling tank 5 and the return pipe 402;

[0035] 2) Turn on the ethanol feed pump 8 and the reactor feed pump 3, and control the reactor feed pump 3 with a load of 30% and an outlet pressure of 2.7MPa to pass ethanol as a diluent through the reactor sampling tank 5 into the return pipe 402 and the decanter 401;

[0036] 3) Open the hand valve B403, use ethanol as a diluent to wash between the return pipe 402 and the reactor 4 for 5 minutes, then close the hand valve B403, and continuously send ethanol into the return pipe 402 and decanter 401 to pass through the continuous flow The ethanol that enters builds up pressure in return pipe 4...

Embodiment 2

[0042] Utilize the method for adiponitrile hydrogenation reaction system to deal with severe clogging of reactor, comprising the following steps:

[0043] 1) First close the hand valve A301 and the sampling valve 501, and open the sampling root valve 502 to connect the connecting pipeline between the reactor feed pump equipment 3, the reactor sampling tank 5 and the return pipe 402;

[0044] 2) Turn on the ethanol feed pump 8 and the reactor feed pump 3, and control the reactor feed pump 3 with a load of 60% and an outlet pressure of 4.2MPa to pass ethanol as a diluent through the reactor sampling tank 5 into the return pipe 402 and the decanter 401;

[0045] 3) Open the hand valve B403, use ethanol as a diluent to wash between the return pipe 402 and the reactor 4 for 10 minutes, then close the hand valve B403, and continuously send ethanol into the return pipe 402 and decanter 401 to pass through the continuous flow The ethanol that enters builds up pressure in return pipe ...

Embodiment 3

[0051] Utilize the method for adiponitrile hydrogenation reaction system to deal with severe clogging of reactor, comprising the following steps:

[0052] 1) First close the hand valve A301 and the sampling valve 501, and open the sampling root valve 502 to connect the connecting pipeline between the reactor feed pump equipment 3, the reactor sampling tank 5 and the return pipe 402;

[0053] 2) Turn on the ethanol feed pump 8 and the reactor feed pump set 3, and control the reactor feed pump set 3 with a load of 45% and an outlet pressure of 3.5 MPa to pass ethanol as a diluent through the reactor sampling tank 5 into the return pipe 402 and the decanter 401;

[0054] 3) Open the hand valve B403, use ethanol as a diluent to wash between the return pipe 402 and the reactor 4 for 8 minutes, then close the hand valve B403, and continuously send ethanol into the return pipe 402 and decanter 401 to pass through the continuous flow The ethanol that enters builds up pressure in retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com