Membrane-based waste gas biological treatment method and system

A technology for biological treatment and waste gas, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of small gas-liquid mass transfer specific surface area, high investment and operation cost, easy accumulation of excessive gas, etc., and achieve efficient degradation. Microbial metabolic activity, small footprint, not easy to block the effect of gas phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

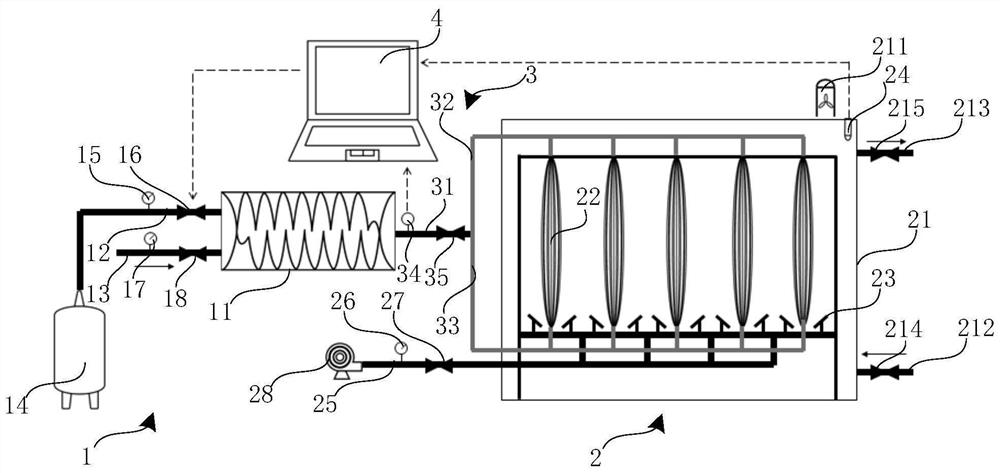

[0098] The membrane-based waste gas biological treatment system used in the embodiment is as figure 1 As shown, follow the steps below:

[0099] (1) Pass the sulfur-containing organic waste gas and oxygen into the gas mixing device and mix evenly, and the pressure of the two gases is 1psi;

[0100] (2) Adjust the concentration of sulfur-containing pollutants (mercapto) after mixing to 2.5g / m 3 , and pass it through the pipeline into the membrane module connected to it;

[0101] (3) Pump the nutrient solution and the sludge from the secondary settling tank of the sewage treatment plant with a VSS of 20g / L into the film hanging film, and run for 4 days to complete the domestication;

[0102] (4) Mix the sulfur-containing organic waste gas and oxygen evenly, the volume ratio of the sulfur-containing organic waste gas and the oxygen is 1:5, the oxygen pressure is 5psi, and the concentration of sulfur-containing pollutants (mercapto) is 0.5g / m 3 , pass into the membrane module o...

Embodiment 2

[0106] The membrane-based waste gas biological treatment system used in the embodiment is as figure 1 As shown, follow the steps below:

[0107] (1) Pass the sulfur-containing organic waste gas and oxygen into the gas mixing device and mix evenly, and the pressure of the two gases is 1psi;

[0108] (2) Adjust the concentration of sulfur-containing pollutants (mercapto) after mixing to 2.5g / m 3 , and pass it through the pipeline into the membrane module connected to it;

[0109] (3) Pump the nutrient solution and the sludge from the secondary settling tank of the sewage treatment plant with a VSS of 20g / L into the film hanging film, and run for 4 days to complete the domestication;

[0110] (4) Mix the sulfur-containing organic waste gas and oxygen evenly, the volume ratio of the sulfur-containing organic waste gas and the oxygen is 1:5, the oxygen pressure is 1psi, and the concentration of sulfur-containing pollutants (mercapto) is 0.5g / m 3 , pass into the membrane module of ...

Embodiment 3

[0114] The membrane-based waste gas biological treatment system used in the embodiment is as figure 1 As shown, follow the steps below:

[0115] (1) Pass sulfur-containing malodorous organic waste gas and oxygen into the gas mixing device and mix evenly, and the pressure of the two gases is 1psi;

[0116] (2) Adjust the concentration of sulfur-containing pollutants (mercapto) after mixing to 2.5g / m 3 , and pass it through the pipeline into the membrane module connected to it;

[0117] (3) Pump the nutrient solution and the sludge from the secondary settling tank of the sewage treatment plant with a VSS of 20g / L into the film hanging film, and run for 4 days to complete the domestication;

[0118] (4) Mix the sulfur-containing organic waste gas and oxygen evenly, the volume ratio of the sulfur-containing organic waste gas and the oxygen is 1:1, the oxygen pressure is 1psi, and the concentration of sulfur-containing pollutants (mercapto) is 5g / m 3 , pass into the membrane mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com