A method and device for preparing nacl industrial salt with zero discharge of desulfurization wastewater

A desulfurization wastewater, zero-discharge technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of avoiding internal scaling, avoiding scaling, reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

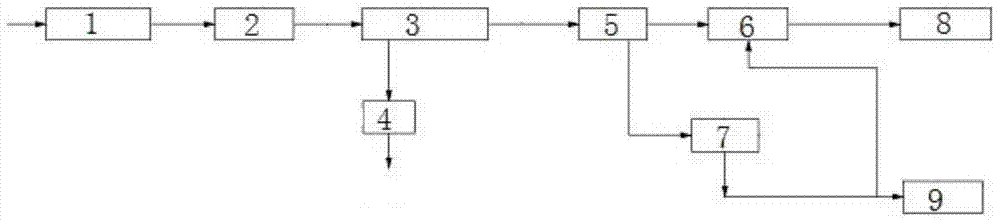

[0038] The invention provides a method for preparing NaCl industrial salt with zero discharge of desulfurization wastewater, the process flow chart of which is as follows figure 1 As shown, the specific steps are as follows:

[0039] (1) Add flocculant polyferric chloride and coagulant polyacrylamide to the desulfurization wastewater in the coagulation clarifier 1, so that the suspended solids and colloids in the desulfurization wastewater are condensed into large particles and precipitated; the desulfurization Wastewater treatment volume is 15m 3 / h, the dosage of the flocculant is 50mg / liter of desulfurization wastewater, and the dosage of the coagulant aid is 0.5mg / liter of desulfurization wastewater;

[0040] (2) Pass the waste water that step (1) removes suspended solids and colloids into the evaporator water inlet tank 2, and add antiscalant; Then it is evaporated in the evaporator 3, for the waste water in the initial stage of evaporation For detection, the wastewater...

Embodiment 2

[0045] The invention provides a method for preparing NaCl industrial salt with zero discharge of desulfurization wastewater, the specific steps are as follows:

[0046] (1) Add flocculant iron trichloride and coagulant polyacrylamide in the desulfurization wastewater in the coagulation clarifier, so that the suspended solids and colloids in the desulfurization wastewater are condensed into large particles and precipitated; the desulfurization wastewater The processing capacity is 30m 3 / h, the dosage of the flocculant is 80mg / liter of desulfurization wastewater, and the dosage of the coagulant aid is 1mg / liter of desulfurization wastewater;

[0047] (2) Evaporate the wastewater from step (1) to remove suspended solids and colloids in the evaporator, and detect the wastewater in the initial stage of evaporation, and the wastewater contains SO 4 2- and Ca 2+ The molar ratio is greater than 1, adding CaCl to the wastewater 2 crystal seeds to separate out the easily scaling su...

Embodiment 3

[0052] The invention provides a method for preparing NaCl industrial salt with zero discharge of desulfurization wastewater, the process flow is as follows figure 1 As shown, the specific steps are as follows:

[0053] (1) Add flocculant ferric chloride, coagulant polyacrylamide and appropriate amount of heavy metal removal agent sodium sulfide to the desulfurization wastewater in the coagulation clarification tank to achieve the removal of heavy metals while also suspending the desulfurization wastewater Matters and colloids condense into large particles and settle down; the treatment capacity of the desulfurization wastewater is 20m 3 / h, the dosage of the flocculant is 70mg / liter of desulfurization wastewater, and the dosage of the coagulant aid is 0.8mg / liter of desulfurization wastewater;

[0054] (2) Evaporate the wastewater from step (1) to remove suspended solids and colloids in the evaporator, and detect the wastewater in the initial stage of evaporation, and the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com