A kind of preparation method of zinc phosphomolybdate containing keggin structure

A technology of zinc phosphomolybdate and phosphomolybdic acid, applied in the direction of phosphorus oxo acid, etc., can solve the problems of no report, no keggin structure zinc phosphomolybdate compound, etc., and achieves low price, low impurity ion content, and reduced production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 0.015mol phosphomolybdic acid crystals into a beaker, add enough distilled water, stir the glass, put it in a water bath at 60°C and continue stirring until the cloudy solution turns into a yellow clear liquid; weigh 0.0221mol zinc oxide and add phosphomolybdenum In the acid solution, start the stirrer and react in a water bath at 60°C. A small amount of bubbles appear as the reaction progresses. Add the phosphomolybdic acid solution dropwise to control the pH at about 1.0, and continue to stir until the bubbles are completely released and white The powder was completely dissolved, and when the solution turned yellow-green, the solution was distilled under reduced pressure to obtain an orange-red paste, and finally dried at 80°C for 8 hours to prepare 24.76 g of orange zinc phosphomolybdate powder. 3 [PMo 12 o 40 ] 2 Calculated, the yield is 84.85%.

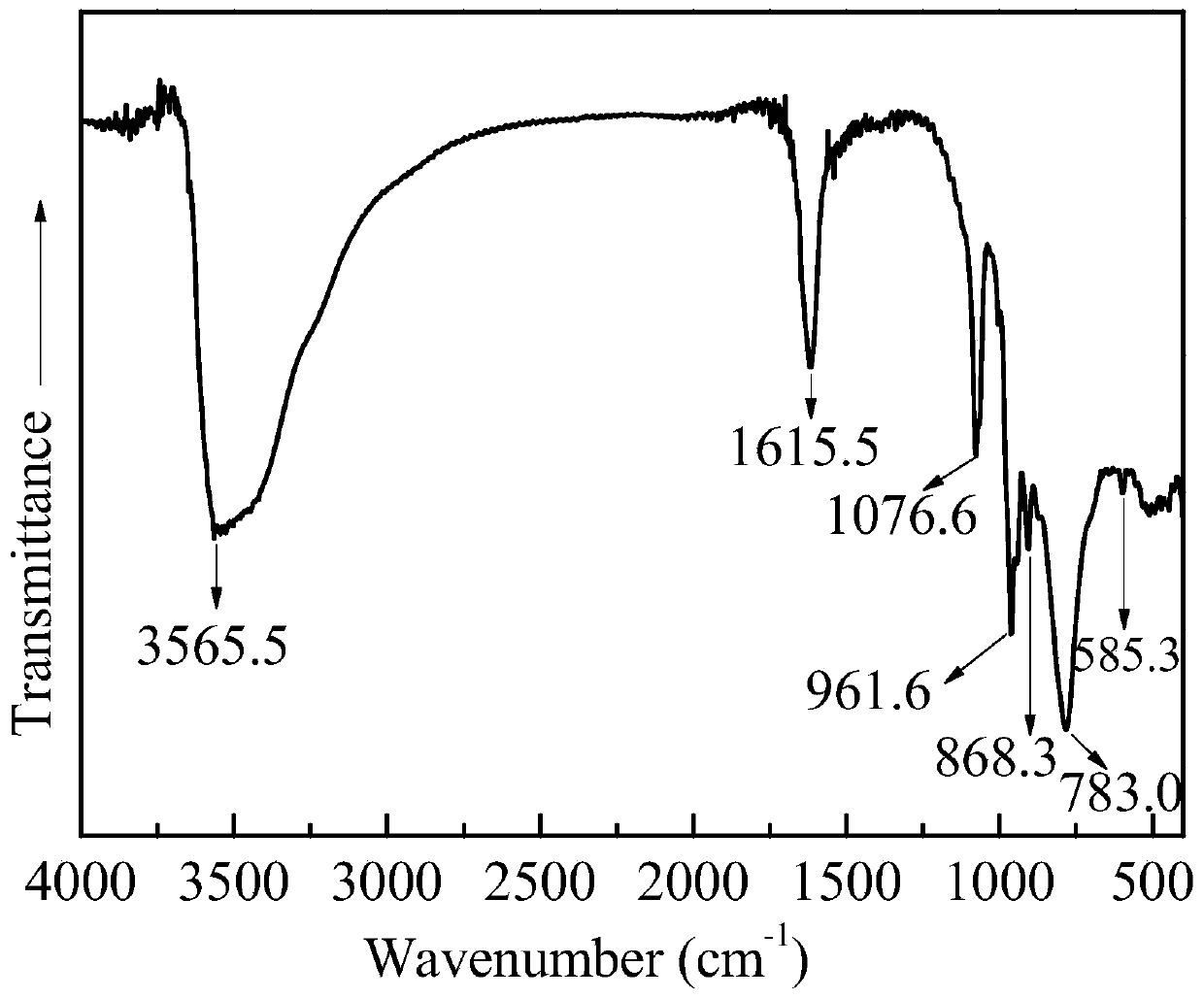

[0020] Depend on figure 1 As shown in the infrared spectrogram data, 783.0cm -1 ,868.3cm -1 ,961.6cm -1 and...

Embodiment 2

[0023] Weigh 0.0128mol phosphomolybdic acid crystals into a beaker, add enough distilled water, stir the glass, put it in a water bath at 60°C and continue stirring until the cloudy solution turns into a yellow clear liquid; weigh 0.0192mol zinc oxide and add phosphomolybdenum In the acid solution, start the stirrer and react in a water bath at 65°C. A small amount of bubbles appear as the reaction progresses. Add the phosphomolybdic acid solution dropwise to control the pH at about 2.0, and continue to stir until the bubbles are completely released and white The powder was completely dissolved, and when the solution turned yellow-green, the solution was distilled under reduced pressure to obtain an orange-red paste, and finally dried at 80°C for 8 hours to prepare 22.07 g of orange zinc phosphomolybdate powder. 3 [PMo 12 o 40 ] 2 Calculated, the yield is 88.49%.

Embodiment 3

[0025] Weigh 0.01mol phosphomolybdic acid crystals into a beaker, add enough distilled water, stir the glass, put it in a water bath at 60°C and continue stirring until the cloudy solution turns into a yellow clear liquid; weigh 0.0271mol zinc oxide and add phosphomolybdenum In the acid solution, start the stirrer and react in a water bath at 55°C. A small amount of bubbles appear as the reaction progresses. Add the phosphomolybdic acid solution dropwise to control the pH at about 3.0, and continue to stir until the bubbles are completely released and white The powder was completely dissolved, and when the solution turned yellow-green, the solution was distilled under reduced pressure to obtain an orange-red paste, and finally dried at 70°C for 10 hours to prepare 17.51 g of orange zinc phosphomolybdate powder. 3 [PMo 12 o 40 ] 2 Calculated, the yield is 85.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com