Ultrasonic-crushing planetary ball mill

A planetary ball mill and ultrasonic crushing technology, which is applied in grain processing and other directions, can solve the problems that materials with high hardness cannot be crushed to the nanometer level, and achieve the effects of small energy loss, high ultrasonic frequency, and accelerated material circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the inner diameter of the ball milling tank 3 used for holding materials is 50 mm, and the outer diameter is 60 mm. The material of the ball mill is zirconia, the material of the balls is zirconia, and the average diameter of the balls is 1 mm.

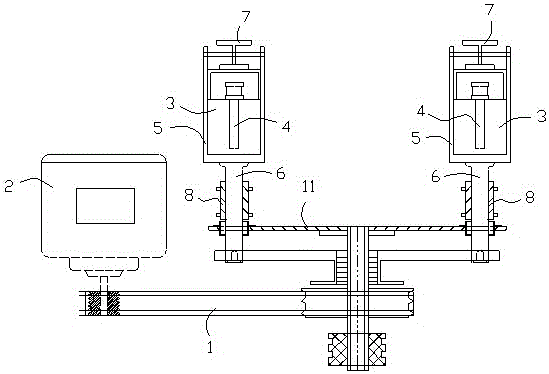

[0029] Such as figure 1 As shown, the centerline of the ultrasonic generator 4 coincides with the centerline of the ball mill jar 3, and the inclination angle is 0°. The distance between the bottom of the sonotrode and the bottom of the ball mill jar is 2mm, the length of the sonotrode into the mill jar part is 58mm, the height of the ball mill jar is 60mm, and the speed control of the ball mill is 400rpm.

[0030] The planetary gear transmission mechanism 1 is provided with 6 ball milling tanks 3, and an ultrasonic generator is placed on the upper cover of each ball milling tank, and the ultrasonic generator is connected to the upper cover of the ball milling tank by welding, and the ultrasonic generator i...

Embodiment 2

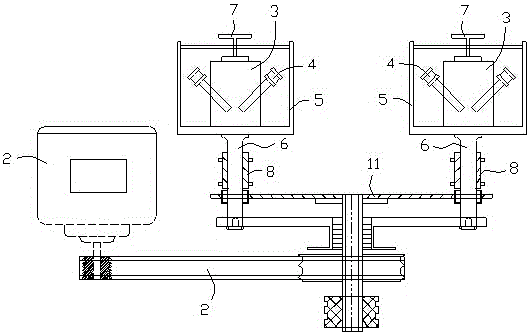

[0033] In this embodiment, the inner diameter of the ball milling tank 3 used for holding materials is 300 mm, and the outer diameter is 320 mm. The material of the ball mill is zirconia, the material of the balls is zirconia, and the average diameter of the balls is 5mm.

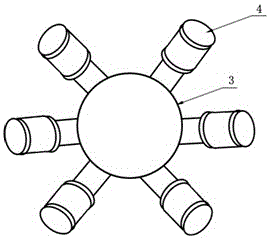

[0034] Such as figure 2 As shown, the planetary gear transmission mechanism 1 is provided with 2 ball milling tanks 3, and 6 ultrasonic generators 4 are placed on the side of each ball milling tank, and the ultrasonic generators are evenly distributed at 60°. image 3 . The inclination angle of the centerline of described sonotrode 4 and the centerline of ball mill jar 3 is 45 °, the bottom of sonotrode is 5mm from the distance of ball mill jar bottom, the ball mill jar height is 320mm, and the speed control of ball mill is 400rpm.

[0035] The ultrasonic generator 4 is connected to the side of the ball mill tank 3 by welding, and the ultrasonic generator goes deep into the fixed tank and directly contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com