Miniaturized brown beverage production process

A production process and browning technology, applied in dairy products, applications, milk preparations and other directions, can solve the problems of increasing browning variable, unsatisfactory browning effect, aseptic tank caking, etc., to improve quality and stability, The effect of reducing the burden of cleaning equipment and reducing product impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

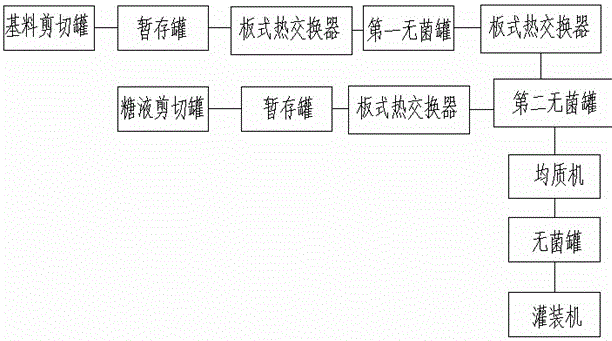

Image

Examples

Embodiment 1

[0029] Production Process:

[0030] Step ①, heat up 1000kg of demineralized water in the shearing tank to 50°C, add 133kg of skim milk powder and 33kg of edible glucose into the shearing tank and stir for 10 minutes until uniform, turn off the stirring, and stand at 50°C for 30 minutes to obtain Liquid;

[0031] Step ②, raise the temperature of the feed liquid in the shearing tank to 90°C, stir and keep it warm for 3 hours, and promote the Maillard reaction between the milk protein in the skim milk powder and the edible glucose at high temperature to produce brown, and brown to brown material liquid;

[0032] Step 3: Sterilize the browning feed liquid after step 2 through a plate heat exchanger at 118°C for 15s, control the discharge temperature at 37°C, and enter the first aseptic tank after filtration to obtain aseptic feed liquid ;

[0033] Step 4: Add 150 DCU / t of Lactobacillus paracasei strains activated by aseptic milk or sterile water at 35°C to the aseptic feed liqu...

Embodiment 2

[0039] Production Process:

[0040] Step ①, heat up the demineralized water in the shearing tank to 55°C, add skim milk powder and edible glucose into the shearing tank and stir for 15 minutes until uniform, turn off the stirring, and stand at 55°C for 30 minutes to obtain the feed liquid;

[0041] Step ②, raise the temperature of the feed liquid in the shearing tank to 95°C, stir and keep it warm for 4 hours, and promote the Maillard reaction between the milk protein in the skim milk powder and the edible glucose at high temperature to produce brown, and brown to browning material liquid;

[0042] Step ③, the browning feed liquid after step ② is sterilized at 116°C for 15s through a plate heat exchanger, and the discharge temperature is controlled at 35°C. After filtering, it enters the first aseptic tank to obtain aseptic feed liquid ;

[0043] Step 4: Add Lactobacillus paracasei strains activated by aseptic milk or sterile water at 33°C to the aseptic feed liquid in the f...

Embodiment 3

[0053] Production Process:

[0054] Step ①, warm up the demineralized water in the shearing tank to 52°C, add skim milk powder and edible glucose into the shearing tank and stir for 12 minutes until uniform, turn off the stirring, and stand at 52°C for 30 minutes to obtain the feed liquid;

[0055] Step ②, raise the temperature of the feed liquid in the shearing tank to 92°C, stir and keep it warm for 3 hours, and promote the Maillard reaction between the milk protein in the skim milk powder and the edible glucose at high temperature to produce brown, and brown to browning material liquid;

[0056] Step 3: Sterilize the browning feed liquid after step 2 through a plate heat exchanger at 118°C for 15s, control the discharge temperature at 37°C, and enter the first aseptic tank after filtration to obtain aseptic feed liquid ;

[0057] Step ④: Add Lactobacillus paracasei strains activated by aseptic milk or sterile water at 35°C to the aseptic feed liquid in the first aseptic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com