Patents

Literature

60results about How to "Anti-acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant inorganic adhesive

InactiveCN101307212AEasy to operateSmall coefficient of thermal expansionInorganic adhesivesSoluble glassHeat resistance

The invention provides a high temeperature resistant inorganic cementing compound, relating to an inorganic cementing compound. The invention overcomes the disadvantages that the prior cementing compound has poor heat resistance and low connecting intensity of a glued joint metal material and a composite material. The high temperature resistant inorganic cementing compound consists of an inorganic solvent and a curing toughening agent which are mixed according to a mass ratio of 1 to 0.7-1.5, wherein, the inorganic solvent is a reaction solution of aluminium phosphate and cupric oxide, soluble glass or a aluminium phosphate solution; the curing toughening agent consists of 50 to 95 portions of inorganic solidified agent and 5 to 50 portions of toughening strengthening agent by weight portion. The high temperature resistant inorganic cementing compound has good heat resistance and high connecting intensity of the glued joint metal material and the composite material.

Owner:HARBIN INST OF TECH

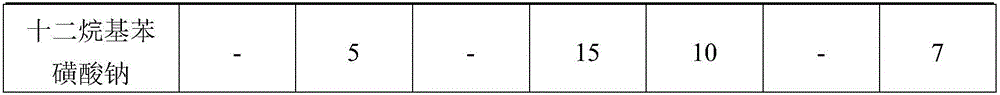

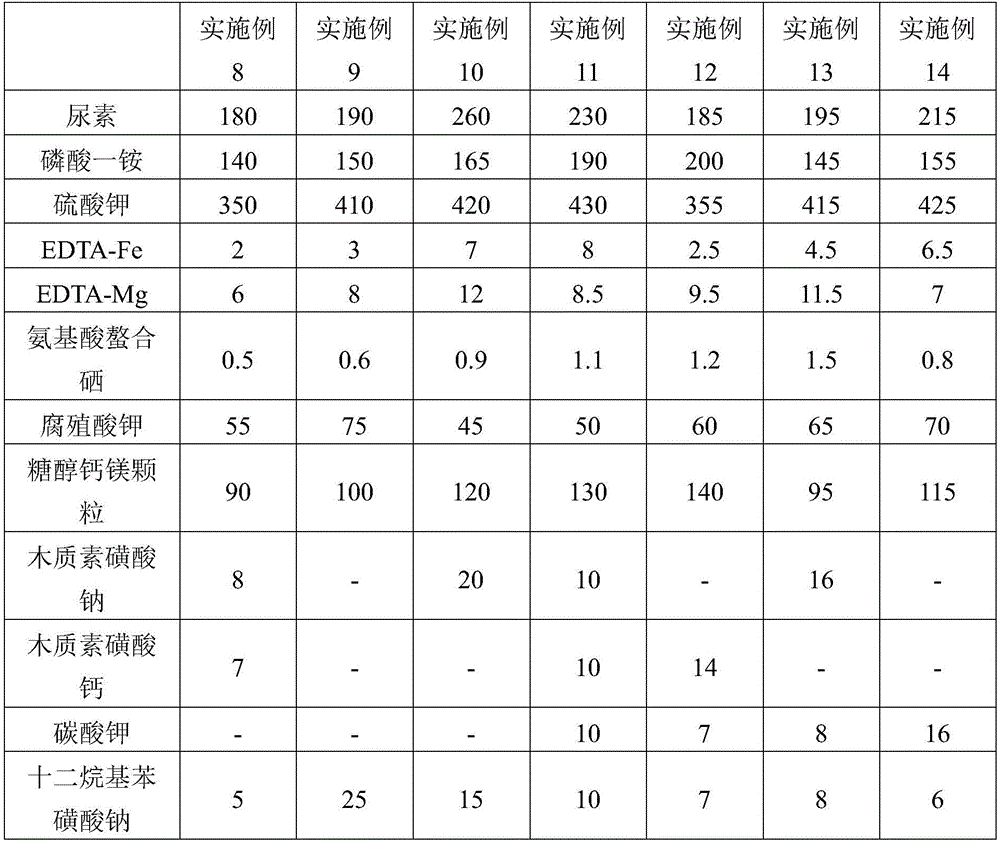

Humic-acid-containing water-soluble fertilizer capable of increasing selenium content of grapes, and preparation method and application thereof

InactiveCN106631517ANo caking phenomenonAnti-acidAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateAlcohol sugars

The invention discloses humic-acid-containing water-soluble fertilizer capable of increasing selenium content of grapes, and belongs to the technical field of fertilizer. The humic-acid-containing water-soluble fertilizer comprises, by weight, 180-260 parts of urea, 140-200 parts of monoammonium phosphate, 350-430 parts of potassium sulphate, 2-8 parts of EDTA (ethylene diamine tetraacetic acid) chelated iron, 6-12 parts of EDTA chelated magnesium, 0.5-1.5 parts of amino acid chelated selenium, 45-75 parts of potassium humate, 90-140 parts of sugar alcohol calcium magnesium particles and 20-40 parts of lignosulfonate and / or potassium carbonate and / or sodium dodecyl benzene sulfonate. The invention further provides a preparation method and application of the humic-acid-containing water-soluble fertilizer. The humic-acid-containing water-soluble fertilizer is particularly applied to selenium element absorption in growth period of the grapes, and sugar degree and yield are increased.

Owner:河北中仁化肥集团有限公司 +1

Wax emulsion and manufacture method thereof

The invention relates to wax emulsion and a manufacture method of the wax emulsion. The wax emulsion comprises the main components by weight: 22-28% of paraffin wax, 2-3% of stearic acid and 2.2-2.8% of ammonia water. The use amount of a used emulsifying agent is small and is only 1 / 2-1 / 3 of that in the prior art. The produced wax emulsion is strong in product stability, and has the advantages of acid resistance, alkali resistance, hard water resistance, strong water solubility, stable emulsion, no layering while being diluted with water in any proportion, no demulsification, no agglomeration, long storage life, high solid content and good dispersibility, so that waterproof and mechanical properties of artificial boards are improved, and the product quality of the artificial boards is improved.

Owner:广东始兴县华洲木业有限公司

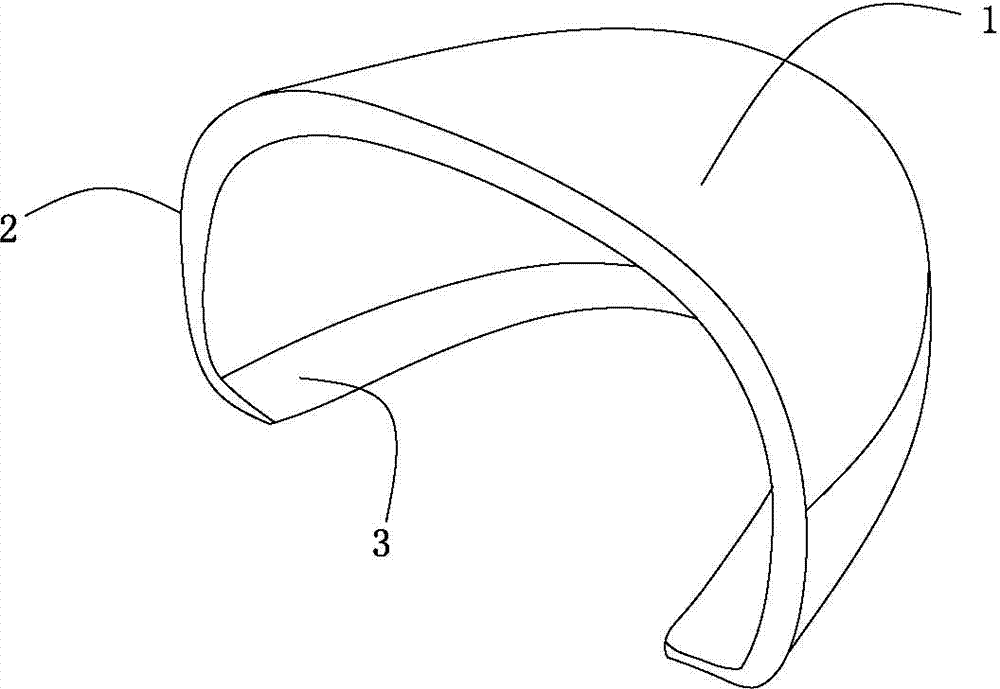

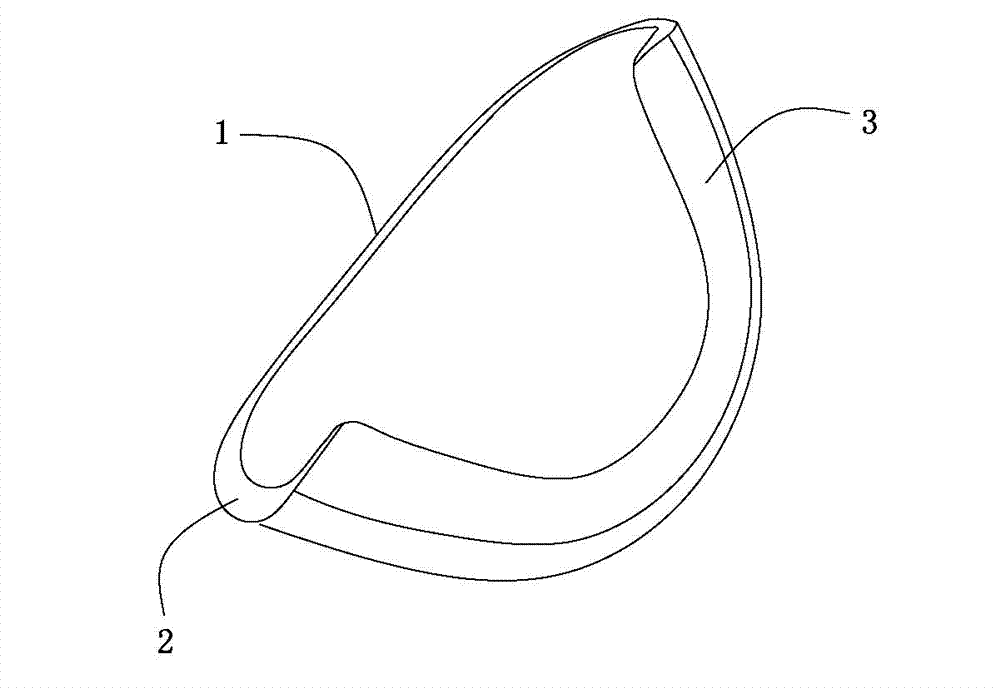

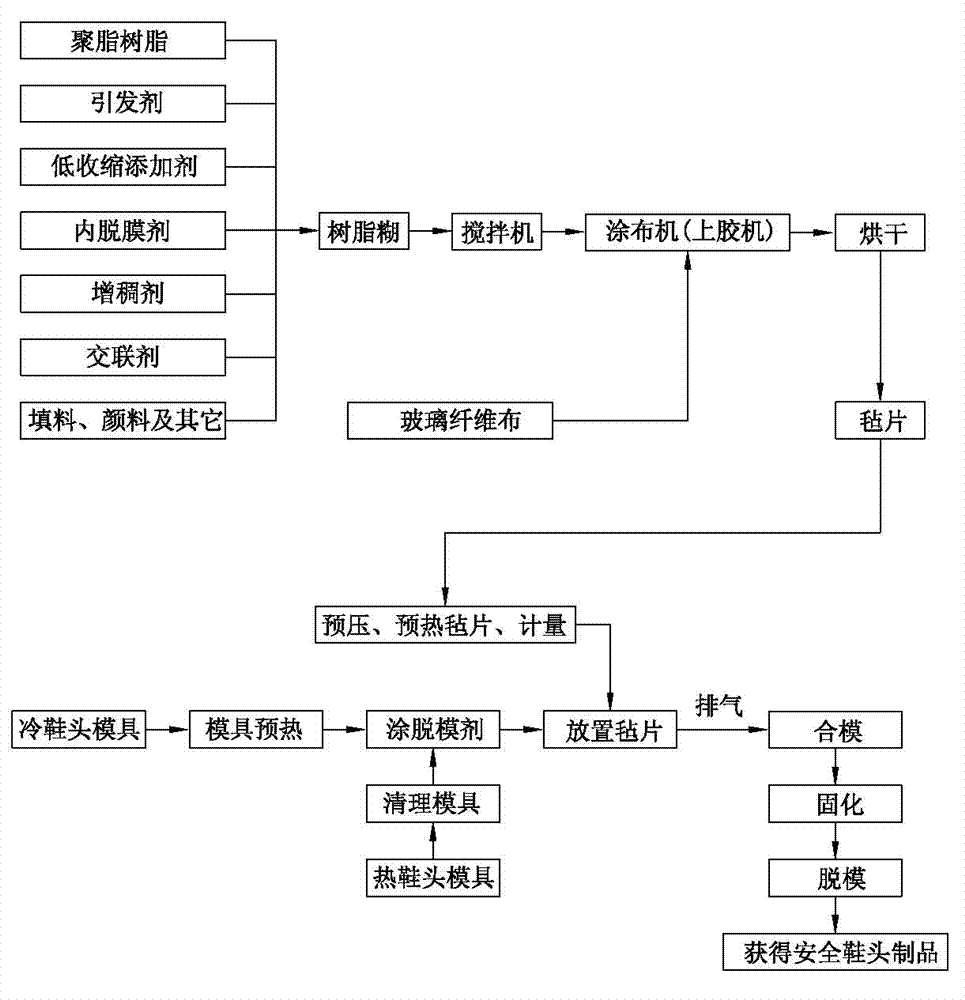

Composite material safety toe cap and manufacturing method thereof

InactiveCN103113733ADesign scienceReasonable designDomestic footwearUpperGlass fiberManufacturing technology

The invention discloses a composite material safety toe cap which is formed by bonding and pressing multiple layers of glass fiber cloth coated with resin paste, wherein the resin paste comprises polyester resin, an initiator, a low-shrink additive, an inner release agent, a thickener and a crosslinking agent; and the invention also discloses a method for manufacturing the composite material safety toe cap. The formula of the composite material safety toe cap provided by the invention is scientific and reasonable in design, has good mechanical performance and high strength, greatly enhances the impact resistance, effectively avoids the phenomena that the foot of a user kicks a foreign object or is bruised by the falling foreign object and the toes are injured, and realizes high safety; the composite material safety toe cap has the advantages of corrosion resistance, high temperature resistance, cold resistance, acid resistance and the like, and the service life is greatly prolonged; and the composite material safety toe cap can pass the International test standards such as European Union EN12568-S, Canada CSA-Z195 and the United States ASTM-F2413 and the like. The method provided by the invention has a simple manufacturing technology, is easy to realize and can quickly produce a composite material safety toe cap.

Owner:DONGGUAN HUAGU COMPOSITE MATERIAL TECH

Resin composition and production method of plastic product of resin composition

The invention relates to a resin composition and a production method of a plastic product of the resin composition. The resin composition comprises the following components by weight percent: 50-99.999% of basic resin and 0.001-50% of carbonization accelerator, wherein the basic resin is selected from one or a mixture formed by more of acrylonitrile butadiene styrene (ABS), high impact polystyrene (HIPS), polycarbonate (PC), propene polymer (PP) or poly ethylene (PE); and the carbonization accelerator is selected from one or mixture formed by more of phosphorus or a phosphorus-containing compound, bromine or a bromine-containing compound, chlorine or a chlorine-containing compound, antimony or antimony-containing compound, boron or boron-containing compound. The resin composition is suitable for laser carving to form words or patterns, and the formed words or patterns have less possibility of falling off and are environment-friendly. The preparation method has the advantages of high work efficiency and low cost.

Owner:STARLIGHT PLASTIC MATERIAL SHENZHEN

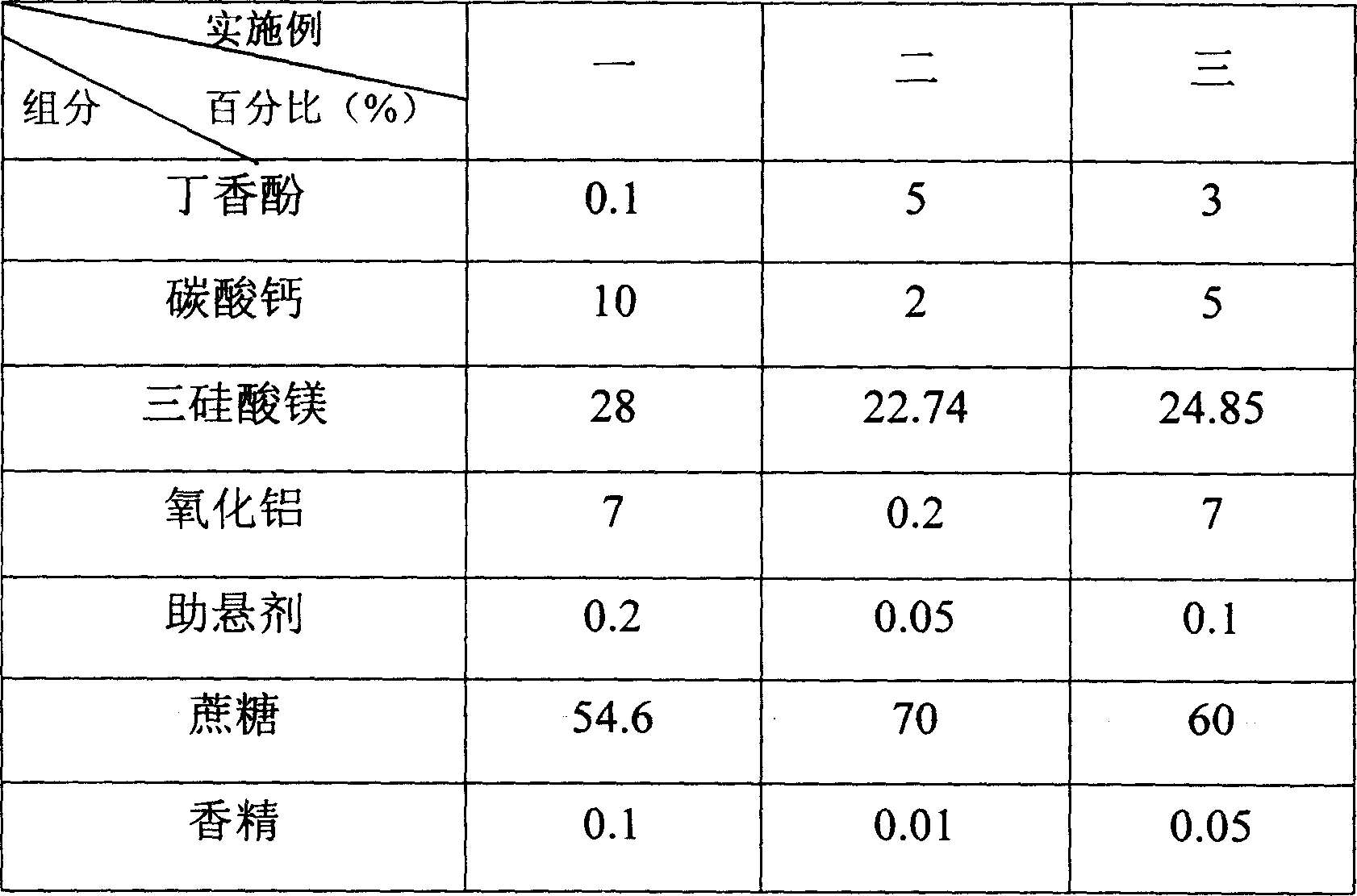

Calcium aluminium suspension

InactiveCN1517098AImprove securitySignificant antidiarrheal effectDigestive systemAluminium/calcium/magnesium active ingredientsCurative effectSugar

Owner:吴建中

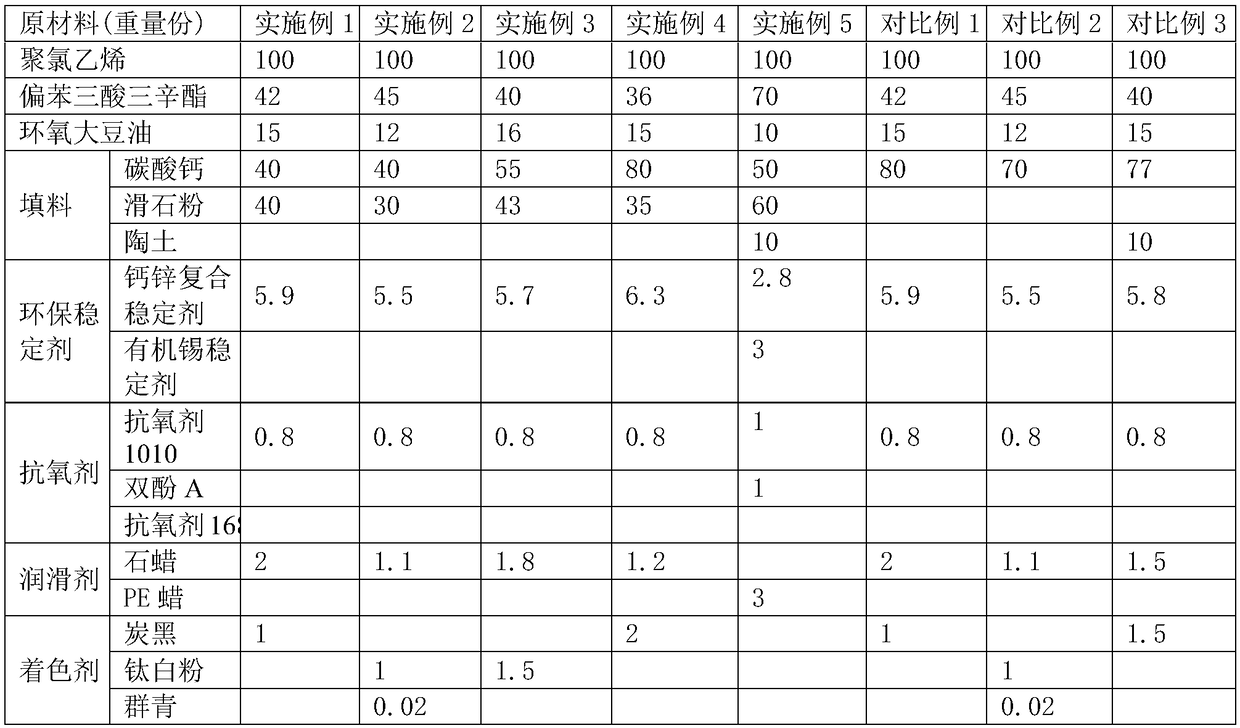

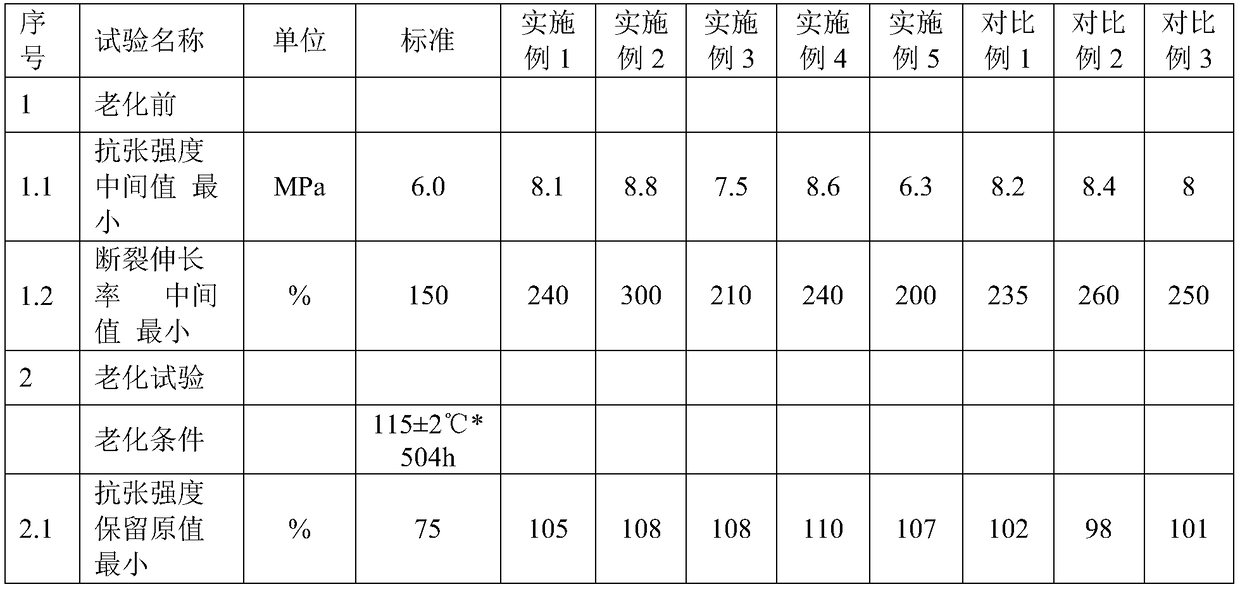

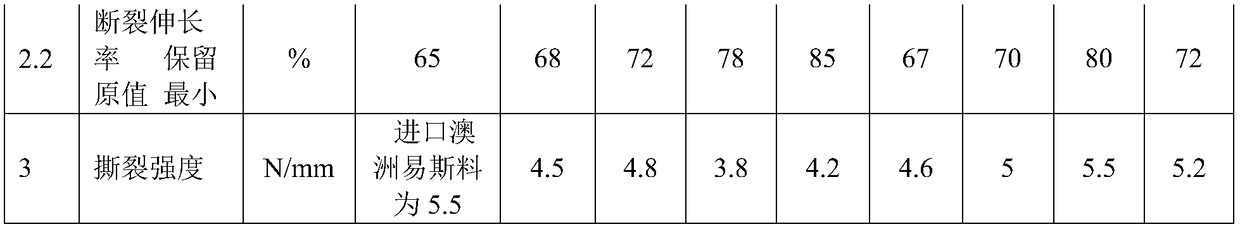

High-temperature-resistant environmentally-friendly easy-to-tear PVC protective jacket cable material and preparation method thereof

InactiveCN108727741AExcellent peelabilityAnti-adhesivePlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention discloses a high-temperature-resistant environmentally-friendly easy-to-tear PVC protective jacket cable material and a preparation method thereof. The PVC protective jacket cable material is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride resin, 30 to 70 parts of trioctyl tribenzoate, 10 to 20 parts of epoxidized soybean oil, 70 to 120 parts of filler, 3 to 8 parts of environmentally-friendly stabilizer, 0.5 to 2 parts of antioxidant, 1 to 3 parts of lubricant and 0 to 2 parts of coloring agent, wherein the filler consists of 40 to 80 parts of calcium carbonate, 30 to 60 parts of talcum powder and 0 to 25 parts of argil. The PVC protective jacket cable material meets the requirement of a table 6 in Australian AS / NZS3808:2000 standard, meets various requirements in European Unit ROHS instruction, and is low in cost and high in stripping property.

Owner:GUILIN INT ELECTRIC WIRE & CABLE GROUP

Preparation process of composite material safety toe cap

InactiveCN102717524AHigh temperature resistantCold resistantDomestic footwearCompression moldingCold resistance

The invention discloses a preparation process of a composite material safety toe cap. The preparation method comprises the following steps of: (1) preparing resin paste; (2) preparing a composite coated fabric; (3) curing the composite coated fabric; (4) cutting; (5) laminating; (6) performing compression molding; and (7) finishing burrs to obtain a composite material safety toe finished product. The preparation method has the advantages that the composite material safety toe prepared by the process has the characteristics of high temperature resistance, cold resistance, acid resistance, alkali resistance, fuel oil resistance, environmental friendliness, no need of recovery, antistatic function, antibacterial function, no toxicity and no volatile substances.

Owner:温州铭嘉新材料科技有限公司

Sea-island composite fiber mixed fabric

The invention discloses a sea-island composite fiber mixed fabric, which comprises warps and wefts. The warps are formed by blending cotton fibers and sea-island composite fibers, and the wefts consist of cotton fibers, sea-island composite fiber blended fibers and polyolefin elastic fibers by means of core spinning. All fibers in the fabric include, by weight, 50% to 70% cotton fibers, 20% to 35% sea-island composite fibers and 10% to 15% polyolefin elastic fibers. According to the above structure, the sea-island composite fiber mixed fabric has the advantages of softness, high elasticity, fine breathability and high hygroscopicity, can be used for various clothes, such as sportswear, tennis apparels, golf jackets, shirts, swimsuits, close fittings, coats and the like.

Owner:SUZHOU CHUANGYU WEAVING

Liquid water-soluble fertilizer containing humic acid and preparation method of liquid water-soluble fertilizer

InactiveCN109369276APromote growthIncrease the sugar contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersLiquid waterGlycerol

The invention discloses a liquid water-soluble fertilizer containing humic acid and a preparation method of the liquid water-soluble fertilizer. The liquid water-soluble fertilizer is prepared from the following materials in parts by weight: 8-13 parts of a urea ammonium nitrate solution, 8-14 parts of ammonium polyphosphate, 14-20 parts of potassium tripolyphosphate, 7-11 parts of mineral sourcepotassium fulvic acid, 1-3 parts of a non-ionic surfactant, 0.05-0.2 part of endophyte source extract cyclodipeptides, 0.1-0.3 part of an organic silicon defoamer, 0.2-0.6 part of IDHA iron, 0.1-0.5 part of glycerol, 0.1-0.5 part of xanthan gum and 36.9-61.45 parts of water. The preparation method comprises the following steps that the xanthan gum is added into the 6 parts of water in a reaction kettle, uniform stirring is conducted, still standing is conducted for 24 h, then the residual water, the potassium fulvic acid, the surfactant and the defoamer are added, heating is conducted to 50 DEG C, and stirring is conducted for 5 min; the urea ammonium nitrate solution, the ammonium polyphosphate, the potassium tripolyphosphate, the IDHA iron and the like are added into a solution, the cyclodipeptides and the glycerol are added after complete dissolving, heating is conducted to 50 DEG C, stirring is conducted for 5 min, cooling is conducted to the room temperature, and thus packaging can be conducted. The liquid water-soluble fertilizer is simple in process, a product meets the requirements of current drip irrigation equipment, the use effect is good, and the liquid water-soluble fertilizer can be widely popularized.

Owner:众德肥料(烟台)有限公司 +1

Paperboard waterproofing agent and preparation method thereof

InactiveCN106917323AGood waterproof effectEasy to useWater-repelling agents additionPaper/cardboardAmmonium sulfateWaterproofing

The invention discloses a paperboard waterproofing agent and a preparation method thereof and relates to the technical field of paper waterproofing. The paperboard waterproofing agent comprises a paraffin microemulsion, dimethyl silicone oil, waterborne polyurethane, acrylic acid, butyl acrylate, calcium hydroxide, oligolactic acid, chamomile, polyoxyethylene oleate, ammonium persulfate, isopropanol, ethyl acetate, xylene, ammonium hydroxide, an emulsifier, a dispersant and deionized water. In use, the paperboard waterproofing agent is diluted by water of which the use amount is 5 to 10 times that of the paperboard waterproofing agent, and a paper to be subjected to waterproof and moistureproof treatment is coated mechanically and is dried at a high temperature so that scattered water-caused destruction of box strength is reduced, the box is effectively protected and good water prevention effects are obtained. The preparation method has simple processes. The paperboard waterproofing agent prolongs a carton service life, reduces material consumption and has energy saving and environmental protection effects.

Owner:合肥天沃能源科技有限公司

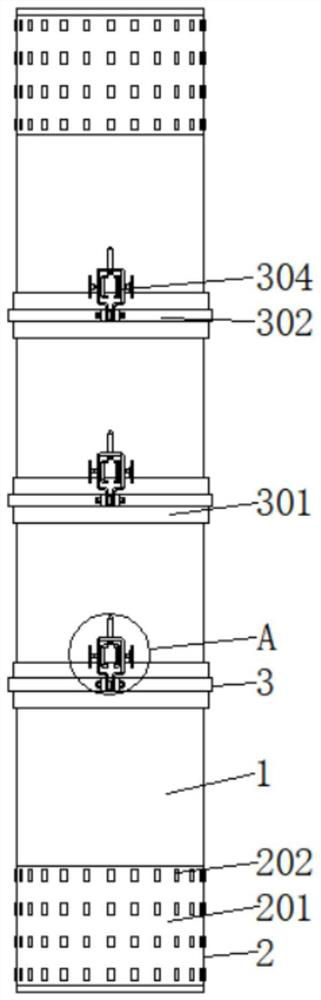

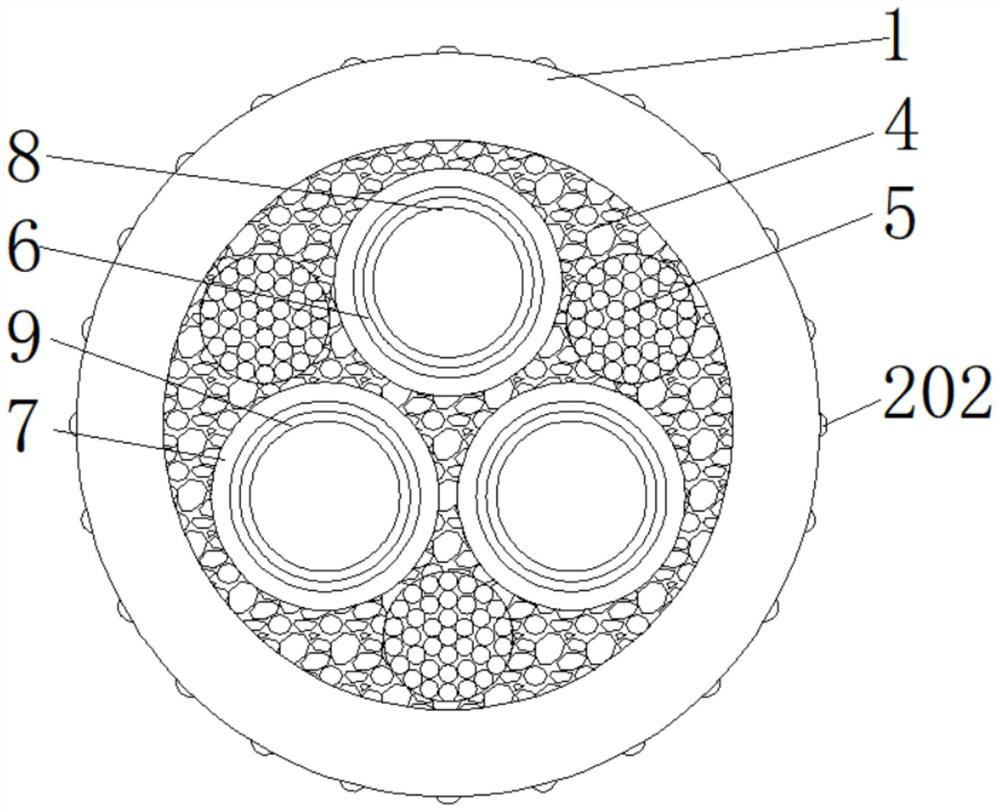

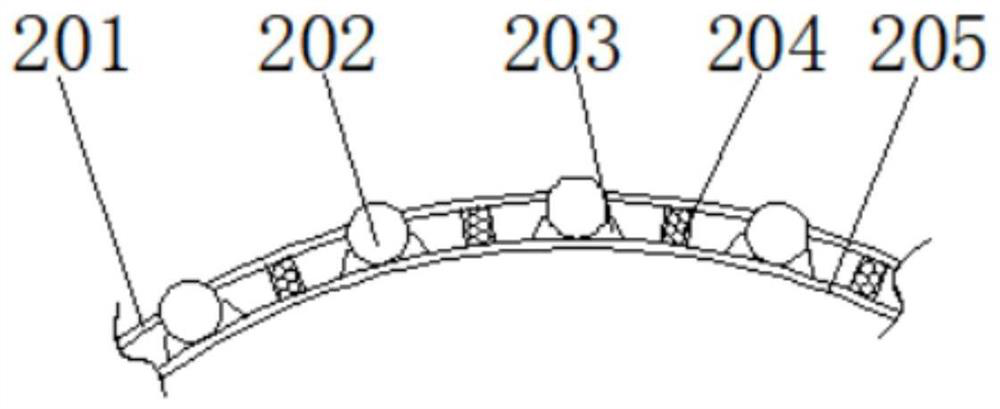

Ultrahigh-safety ceramic wire and cable design and method

ActiveCN111816358AHigh mechanical strengthHigh strengthClimate change adaptationInsulated cablesLow smoke zero halogenEngineering

The invention discloses an ultrahigh-safety ceramic wire and cable design and method. The invention relates to the technical field of ceramic electric wires and cables. A ceramic cable main body and an easy-to-disassemble installation mechanism are included, the upper and lower sides of the outer wall of the ceramic cable main body are both provided with wear-resistant protection mechanisms, and the easy-to-disassemble installation mechanism is located in the middle of the outer wall of the ceramic cable main body. According to the ultrahigh-safety ceramic wire and cable design and method, anoxygen barrier layer, a steel wire rope, a ceramic layer and an insulating layer are arranged; the overall toughness of the ceramic wire cable can be effectively enhanced through the steel wire rope;the ceramic layer can effectively guarantee the fireproof and insulating functions, the insulating layer is prepared through low-smoke halogen-free irradiation crosslinking, the insulating layer can effectively separate an external object from the copper core, an electric leakage phenomenon can be effectively avoided, and stable utilization of the ceramic wire and cable can be effectively guaranteed.

Owner:贵阳中安科技集团有限公司

Resin composition and its plastic product production method

ActiveCN1884365ANot easy to fall offAnti-acidLaser beam welding apparatusModel makingPoly(ethylmethacrylate)Thermal stability

The invention relates the resin composition and the plastic rubber product and preparing method, comprising 25%-90% base resin, 5-70% substance with butadienyl and 0.1-5% heat stability difference color. The base resin comprises polymethyl methacryate, polyethyl methacrylate, or poly-n-butyl methacrylate. The resin is used to carve word or pattern with laser ray, and the word has the advantages of environmental protection, high efficiency and low cost.

Owner:STARLIGHT PLASTIC MATERIAL SHENZHEN

Waterborne release agent and preparation method and construction method thereof

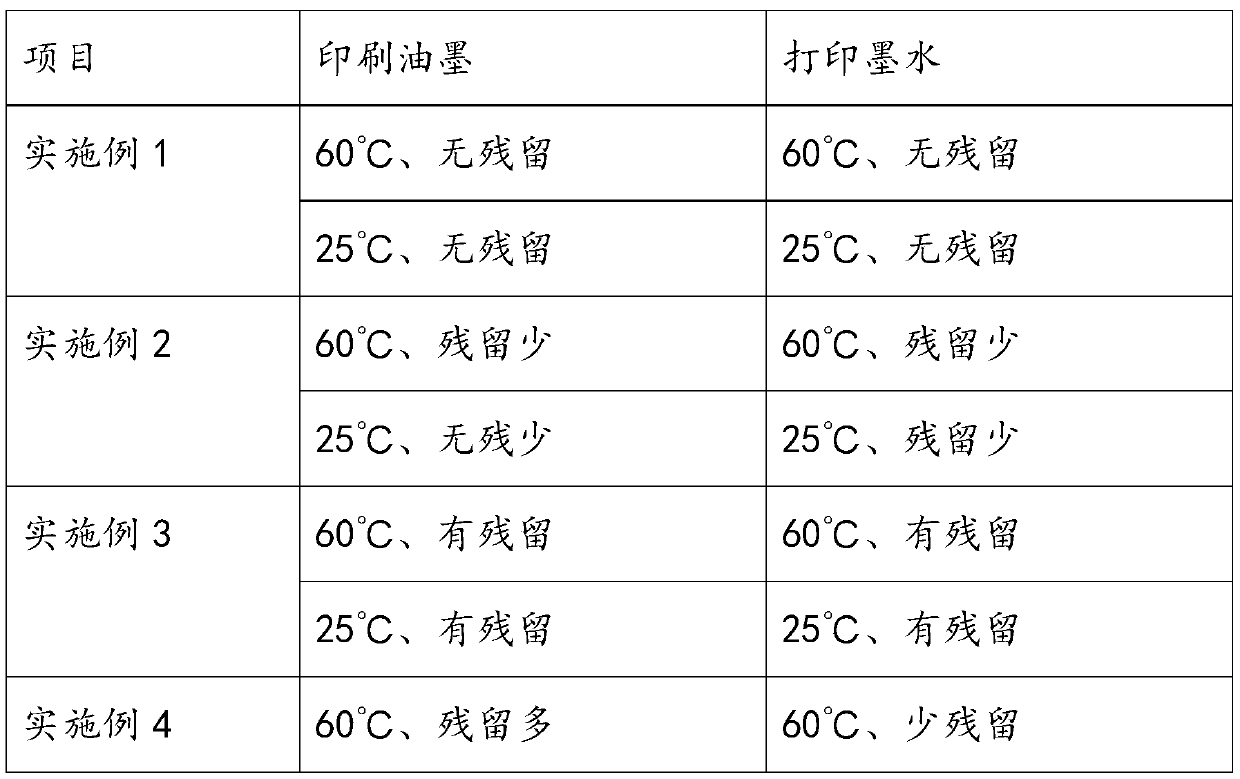

The invention discloses a waterborne release agent. The waterborne release agent is characterized by being prepared from the following components in percent by weight: 10-40% of a paraffin emulsion, 5-35% of a palm wax emulsion, 20-60% of a polytetrafluoroethylene emulsion, and 0.5-2% of an organic silicone surfactant; and the sum of the weight percentages of the above components is 100%. The invention also discloses a preparation method and a construction method of the waterborne release agent. The waterborne release agent is used for a substrate, the surface of the substrate after release does not have printing ink or ink residue, the waterborne release agent has no addition of organic solvents and no VOC emission, and is environment-friendly and low in cost, and the raw materials are human-friendly, so that the waterborne release agent can be applied to human body contactable fields.

Owner:广州山木新材料科技有限公司

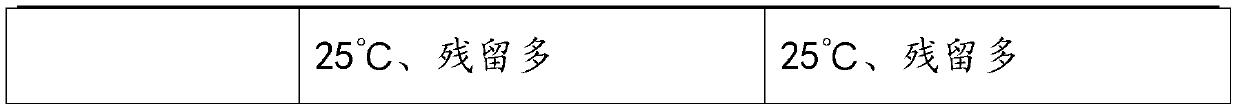

Coating process

ActiveCN102896082AEasy pretreatmentReduce energy consumptionPretreated surfacesCoatingsLacquerCircular economy

The invention discloses a coating process. The coating process comprises the following steps: pre-treating a base material; then, degreasing and / or cleaning rust, and drying; and finally, coating prime lacquer. The coating process simplifies the complex pre-treatment process, not only completely satisfies the existing economical model based on low energy consumption, low exhaustion and low pollution, but also generates the effects of circular economy and reaches the requirements for establishing a cleaning production mechanism.

Owner:长三角新能源汽车研究院有限公司 +1

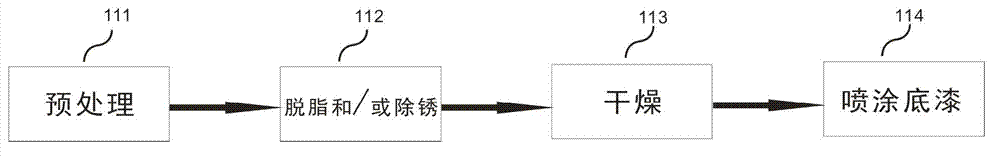

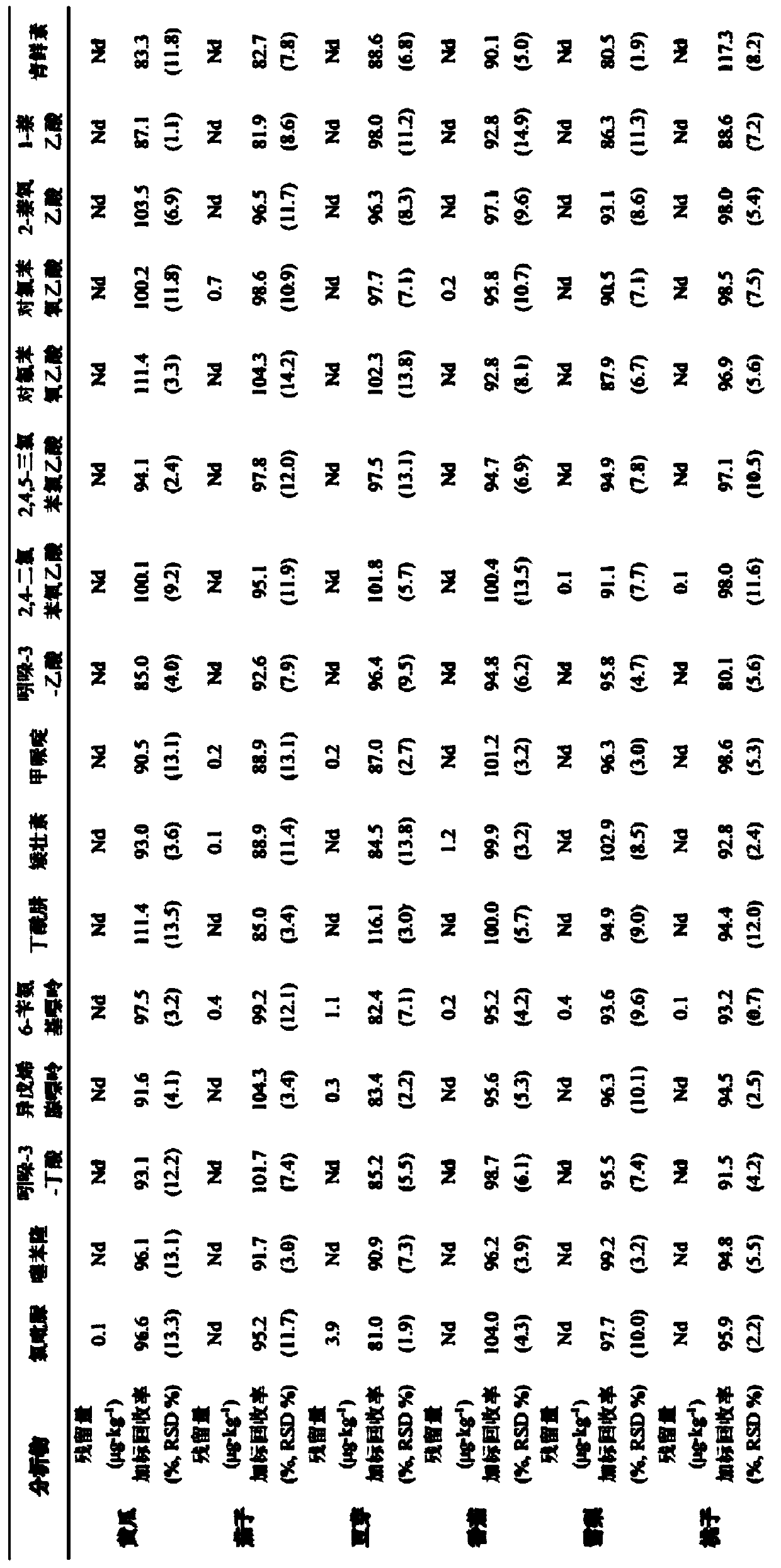

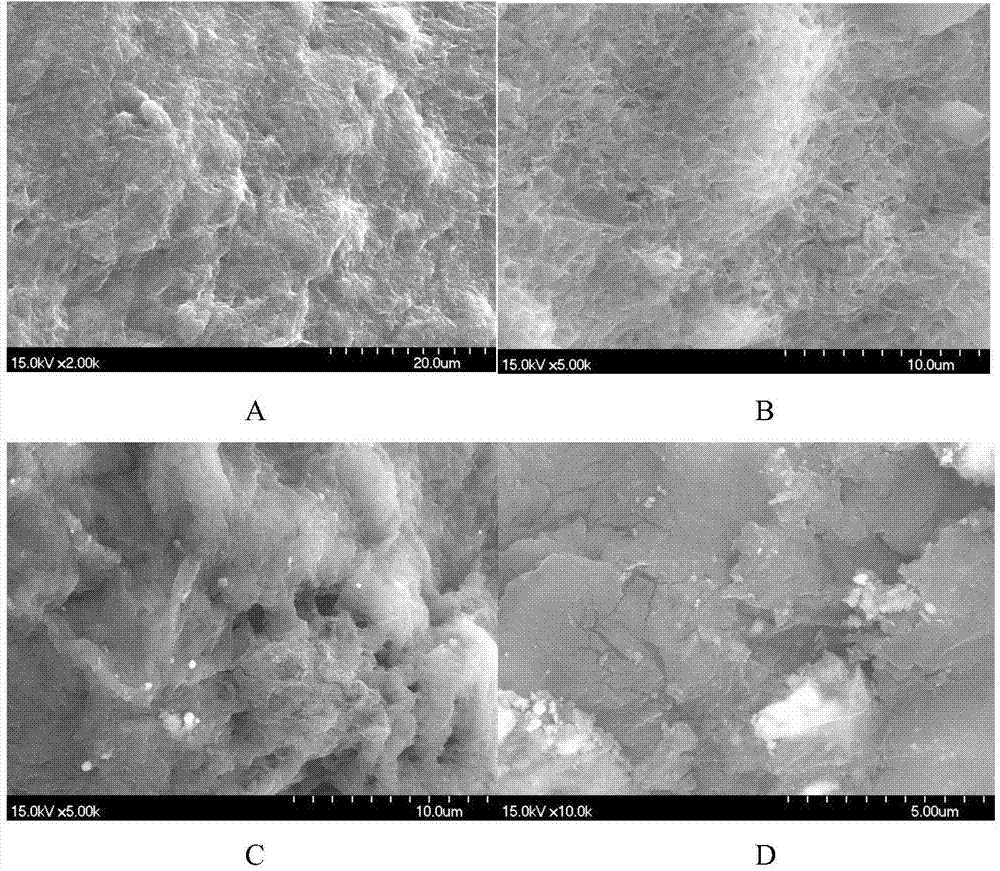

Sample preprocessing method with pollen as solid phase extractant

InactiveCN104215494AHigh temperature resistantHydrophilicComponent separationPreparing sample for investigationSorbentSolid-phase microextraction

The invention relates to a sample preprocessing method with natural pollen as solid phase extractant. The method comprises performing Soxhlet extraction and cleaning through polar solvent and then drying to obtain pollen materials. The material cleaning method is simple, safe and easy to implement, and the raw materials are cheap and easy to obtain. Materials obtained through the material cleaning method are high in reproducibility, can be taken as solid phase extracting fillings for separation and enrichment of polar compounds and Pi-electron compounds of plant, food, environmental and biological samples and have the advantages of being good in impurity removing effects, high in recovery rate, good in stability and the like.

Owner:WUHAN UNIV

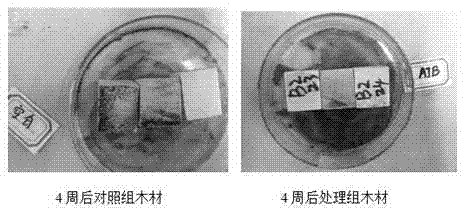

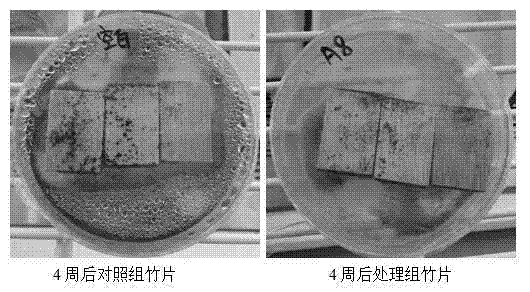

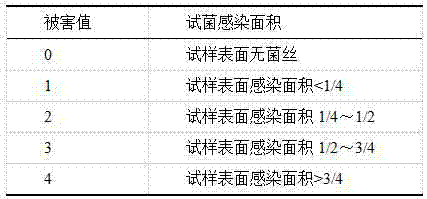

Antiseptic and mildew-proof agent for wooden and/or bamboo product and application thereof

InactiveCN104742208AExtended service lifeGrowth inhibitionWood treatment detailsWood impregnation detailsBiotechnologyEthyl hydroxybenzoate

The invention discloses an antiseptic and mildew-proof agent for a wooden and / or bamboo product and application thereof. The antiseptic and mildew-proof agent comprises the following constituents in percentage by weight: 0.15-0.25% of sodium benzoate, 0.2-0.3% of potassium sorbate, 0.02-0.05% of ethyl 4-hydroxybenzoate, and the balance of water. The antiseptic and mildew-proof agent has the advantages of being suitable for mildew-proof treatment of various wooden and bamboo products, having very good bacteria inhibiting effect and microbial growth inhibiting effect, improving the mildew-proof performance of the wooden and bamboo products, prolonging the service lives of materials, improving use value of the wooden and bamboo products and saving wood resource, and having positive significance on human healthy life. Meanwhile, the antiseptic and mildew-proof agent is simple to use, easy to operate and applicable in a wide range, further has the characteristics of being cheap, acid resistant and alkali resistant, and has good popularization and application foreground.

Owner:SOUTH CHINA AGRI UNIV

Special spraying penetrating lubricating grease for automobile parts and production process of lubricating grease

The invention provides special spraying penetrating lubricating grease for automobile parts and a production process of the lubricating grease. The special spraying penetrating lubricating grease is prepared from the following components in percentage by weight: 30%-35% of base oil (mineral oil), 0.1%-0.5% of zinc dialkyl dithiophosphate, 0.5%-1% of vulcanized grease, 3%-5% of modified calcium sulfonate, 3%-5% of polyisobutene, 3%-5% of potassium ricinoleate, 25%-30% of thickener (soap base), 5%-10% of glycol oleate and 10%-15% of LPG propellant. The special spraying penetrating lubricating grease in a liquid state is sprayed to a movable part and then penetrates into the movable part, and in dozens of seconds, the lubricating grease in a liquid state becomes a solid state and adheres to the movable part needing to be lubricated; as a result, the lubricating grease is capable of quickly penetrating into the parts and providing immediate and sufficient lasting lubrication; and the spraying penetrating lubricating grease is waterproof, alkali-resistant, acid-resistant, moisture-resistant, wear-resistant and rust-resistant, and does not run away in lubrication, and therefore, the friction parts can be lubricated effectively for a long time, noise can be eliminated and the lubricated parts can be smoothened.

Owner:DONGGUAN SEA WHALE IND INVESTMENT

High-strength packaging flame-retardant paper and a preparing method thereof

ActiveCN107700277AGood effectImprove flame retardant performanceFlexible coversWrappersFiberPolyvinyl alcohol

The invention belongs to the technical field of preparation of novel flame-retardant paper, and provides high-strength packaging flame-retardant paper and a preparing method thereof. The method includes mixing magnesium sulfate and polyvinyl alcohol fibers in water, then adding a sodium hydroxide solution into the mixture, reacting the mixture to obtain a magnesium hydroxide-polyvinyl alcohol fiber composite sol, then adding polyurethane into the composite sol to perform a grafting reaction to obtain a composite flame-retardant filler, finally mixing the composite flame-retardant filler with paper pulp, and manufacturing the high-strength packaging flame-retardant paper from the pulp mixture. Compared with traditional methods, magnesium hydroxide is adopted as the flame-retardant filler and has extremely good flame retardance, smoke suppression, acid resistance, a filling function, and other functions, the flame-retardant filler and paper fibers are fully combined, the paper has excellent toughness and mechanical properties, a whole preparing process is simple, low in energy consumption and low in equipment wear, and large-scale production can be achieved.

Owner:安徽景丰纸业有限公司

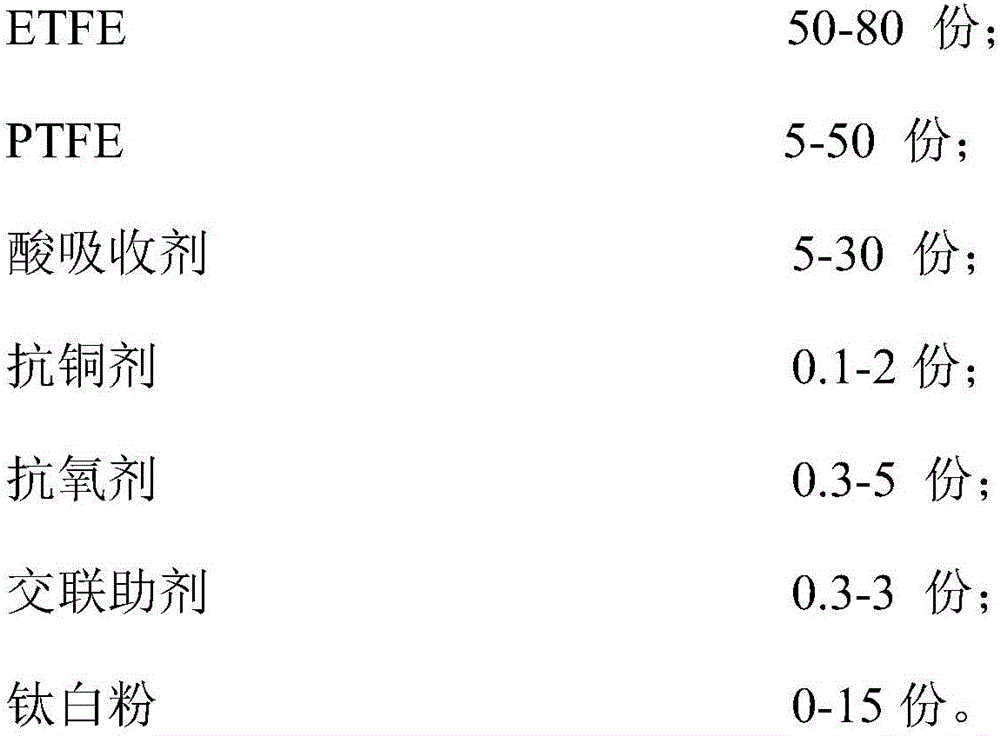

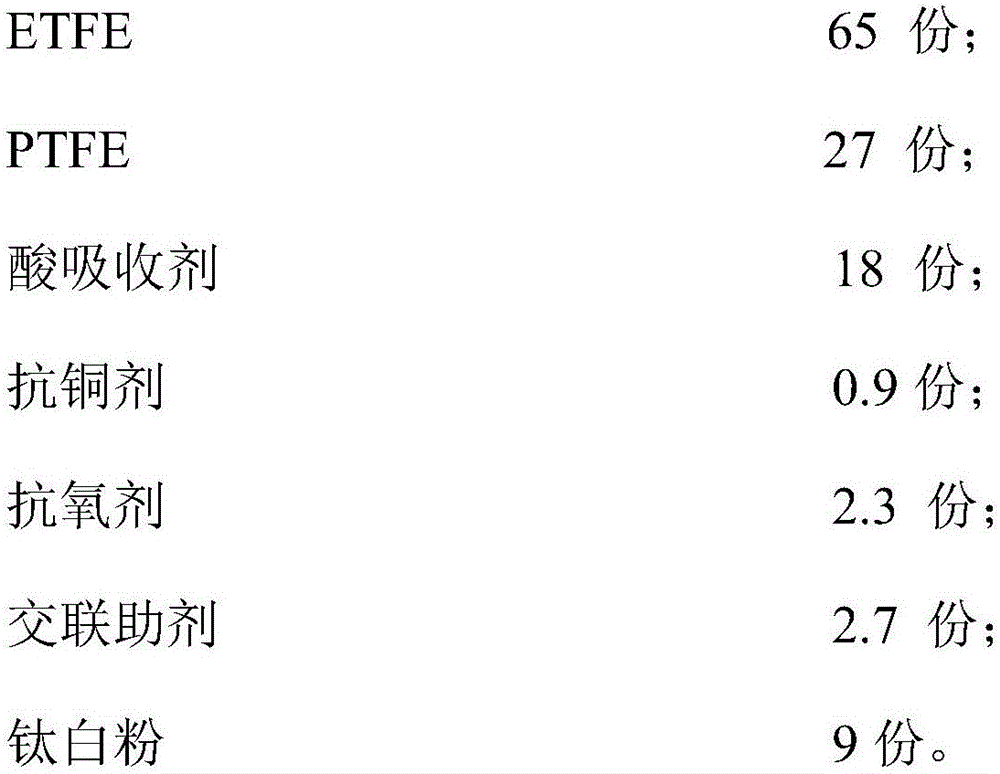

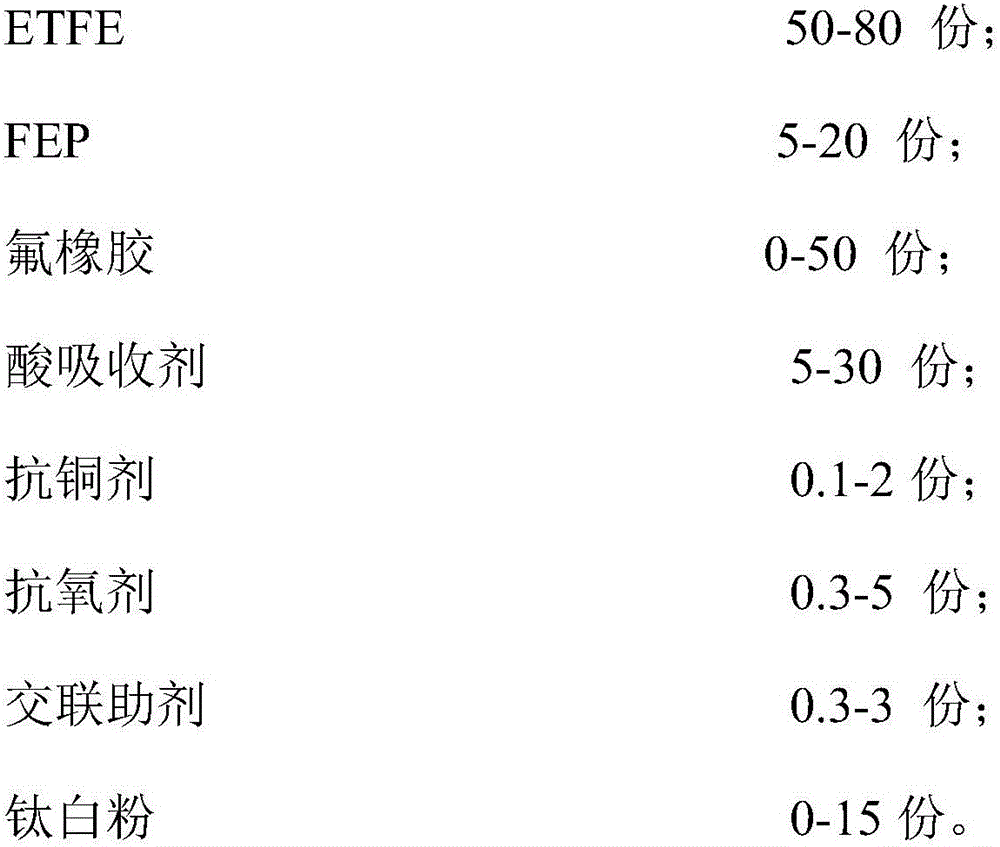

Special heat-shrinkable tubing for aerospace and preparation method of special heat-shrinkable tubing

InactiveCN106589566AHigh temperature resistantLow temperature resistanceTubular articlesDielectric lossCopper

The invention discloses special heat-shrinkable tubing for aerospace and a preparation method of the special heat-shrinkable tubing. The heat-shrinkable tubing is prepared from components in parts by weight as follows: 50-80 parts of ETFE, 5-50 parts of PTFE, 5-30 parts of an acid absorber, 0.1-2 parts of a copper ion inhibitor, 0.3-5 parts of an antioxidant, 0.3-3 parts of a crosslinking coagent and 0-15 parts of titanium dioxide. The heat-shrinkable tubing with high temperature resistance level is obtained by compounding materials such as ETFE, PTFE and the like, has the characteristics of being resistant to high temperature and low temperature and further has the advantages of little dielectric loss, high transmission performance, good oil and solvent resistance, excellent flame retardance, higher mechanical strength and the like.

Owner:广州凯恒科塑有限公司

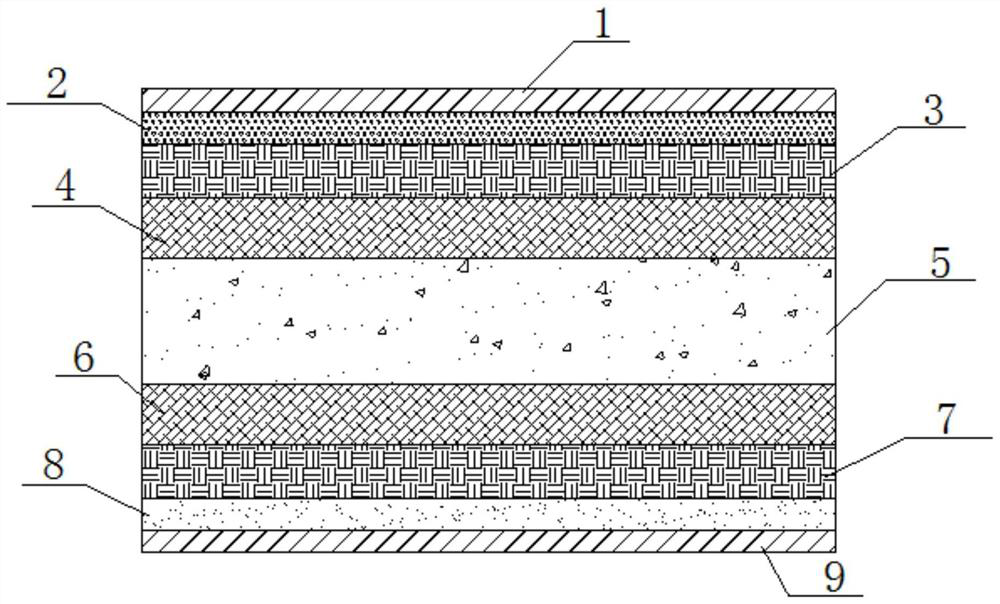

Magnesium oxide composite floor and manufacturing process thereof

InactiveCN112576003AHigh hardnessImprove fire performanceCeramic shaping apparatusFlooring insulationsGlass fiberFiber

The invention discloses a magnesium oxide composite floor and a manufacturing process thereof. The floor sequentially comprises a surface wear-resistant layer, a surface slurry layer, an upper glass fiber gridding cloth layer, an upper glass fiber short fiber felt layer, a main body material layer, a lower glass fiber short fiber felt layer, a lower glass fiber gridding cloth layer, a bottom slurry layer and a bottom wear-resistant layer from top to bottom, wherein the main body material layer contains magnesium oxide, a magnesium chloride solution, heavy calcium powder, powder and a modifier;the surface slurry layer contains magnesium oxide, a magnesium chloride solution, fossil powder, powder and a modifier; and the bottom slurry layer contains magnesium oxide, a magnesium chloride solution, fossil powder, powder and a modifier. The floor is simple in structure, the manufacturing process is simple and feasible, and the manufactured floor is good in fireproof, moisture-proof and water-resistant properties, high in strength and not easy to deform.

Owner:江苏佳运晟汇新材料有限公司

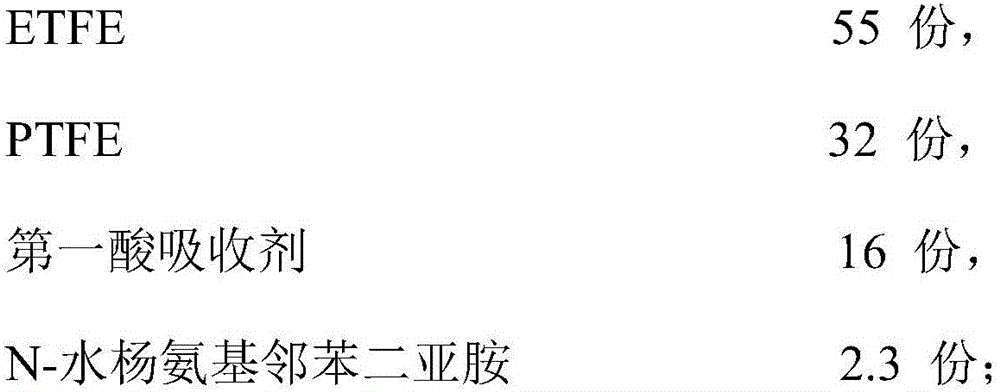

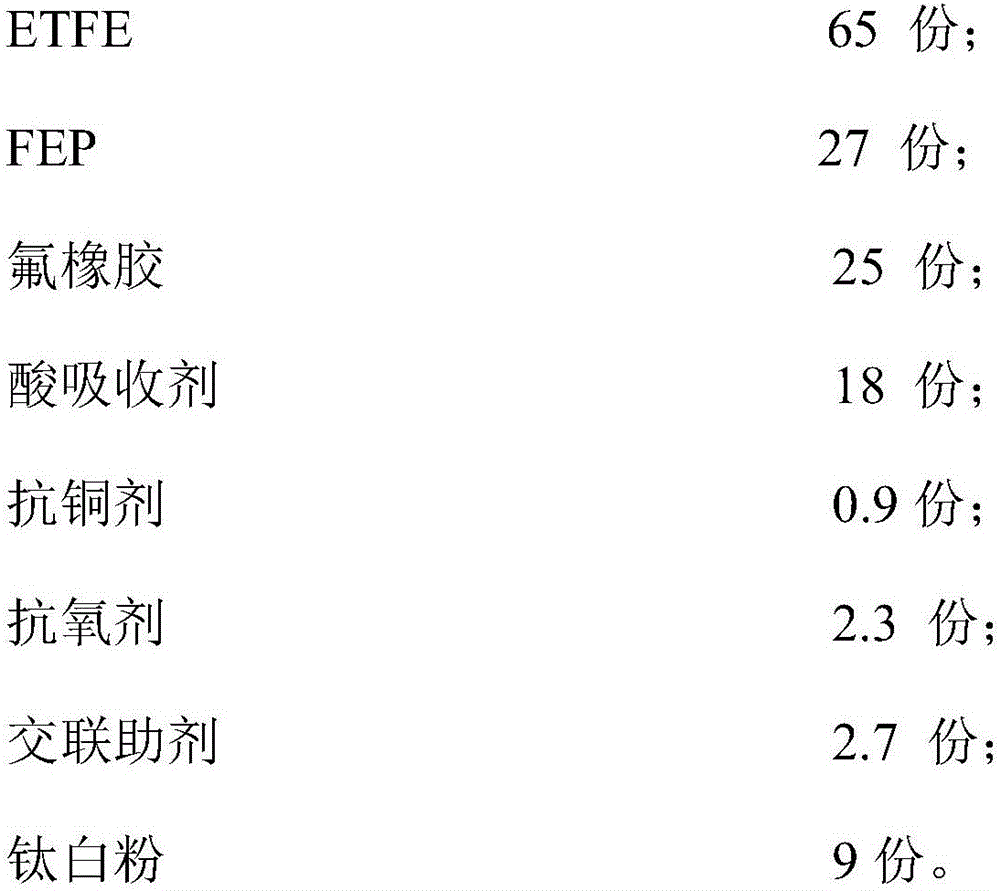

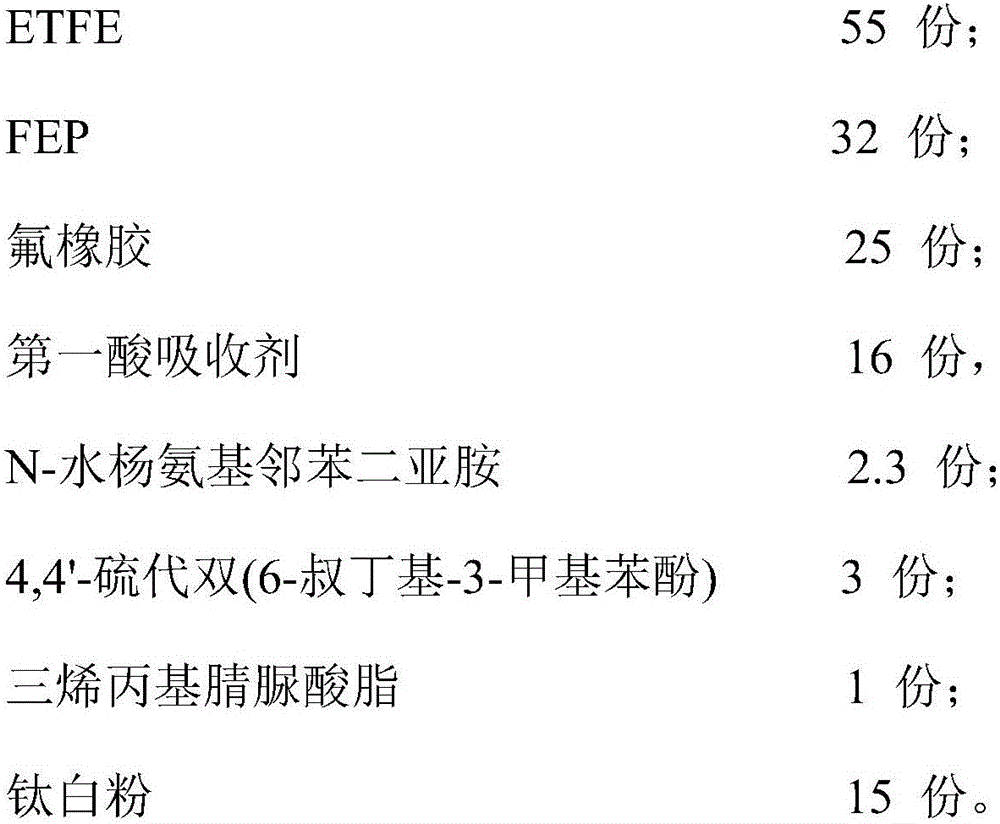

High-temperature-resistant flexible heat-shrinkable sleeve and preparation method thereof

The invention discloses a high-temperature-resistant flexible heat-shrinkable sleeve and a preparation method thereof, and the high-temperature-resistant flexible heat-shrinkable sleeve comprises the following components by weight: 50-80 parts of ETFE; 5-50 parts of FEP; 0-50 parts of fluorine rubber; 5-30 parts of an acid absorbent; 0.1-2 parts of an anti copper agent; 0.3-5 parts of an antioxidant; 0.3-3 parts of a crosslinking agent and 0-15 parts of titanium dioxide. The temperature-resistant high-grade heat-shrinkable sleeve is prepared by compounding of the ETFE, the FEP, the fluorine rubber and other materials, the high-temperature-resistant flexible heat-shrinkable sleeve has the characteristics of high temperature resistance and low temperature resistance; at the same time, the high-temperature-resistant flexible heat-shrinkable sleeve also has small dielectric loss, high transmission performance, good oil resistance, good solvent resistance, excellent flame retardancy. high mechanical strength and other advantages.

Owner:广州凯恒科塑有限公司

Production method of compound filter material

InactiveCN101954223AImprove surface smoothnessImprove wear resistanceLayered productsFiltration separationPolyesterNomex

The invention discloses a production method of a compound filter material, relating to environmental-protection treatment, in particular to the technical field of filtering. The compound filter materials is produced by laying two surface layers on both sides of an intermediate layer, acupuncturing into a felt, and then singeing, calendaring and thermally forming, wherein the intermediate layer is a nomex fiber loom fabric, and the surface layers are formed by mixing acrylic fibers, PPS fibers and polyester fibers and the lapping. The non-woven fabric produced by the invention has the advantages of high surface smoothness, can ensure that gas and solid of the filter material are completely separated, and has the advantages of high abrasive resistance, bending resistance as well as acid and basic resistant chemical property, and long service life.

Owner:JIANGSU XURI METALLURGY ENVIRONMENTAL PROTECTION EQUIP PLANT

Herbal whitening massage cream

InactiveCN106913489ANon-irritatingNo greasy feelingCosmetic preparationsToilet preparationsMicrocrystalline waxMonoglyceride

A herbal whitening massage cream is composed of the following raw materials in parts by weight: 3 parts of root of kudzu vine, 3 parts of poria cocos, 2 parts of Chinese angelica, 2 parts of licorice, 7 parts of microcrystalline wax, 2 parts of paraffin, 2 parts of beeswax, 13 parts of white oil, 7 parts of isopropyl myristate, 17 parts of squalane, 2 parts of monoglyceride stearate, 1 part of tween 601, 4 parts of 1,3-butylene glycol, a proper amount of essence, a proper amount of antiseptic, and the balance being water, wherein the total number of parts by weight is 100. Through using amount, physical properties, and chemical properties of abovementioned raw materials, a synergetic effect is generated, and the functions such as skin whitening, oxidation resistance, free radical removal, and the like, are achieved. The pH value of the massage cream is close to the pH value of human skin, and thus the massage cream is nonirritant to human skin. After use, the skin feels comfortable and soft, no oily feeling is felt, and the effects of skin cleaning, skin nourishing, skin whitening, and skin tendering are prominent.

Owner:王晓燕

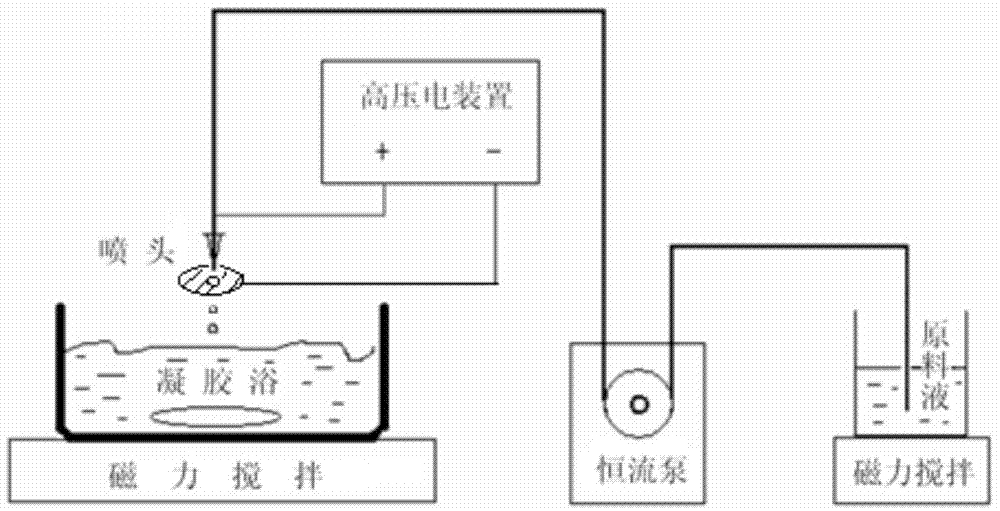

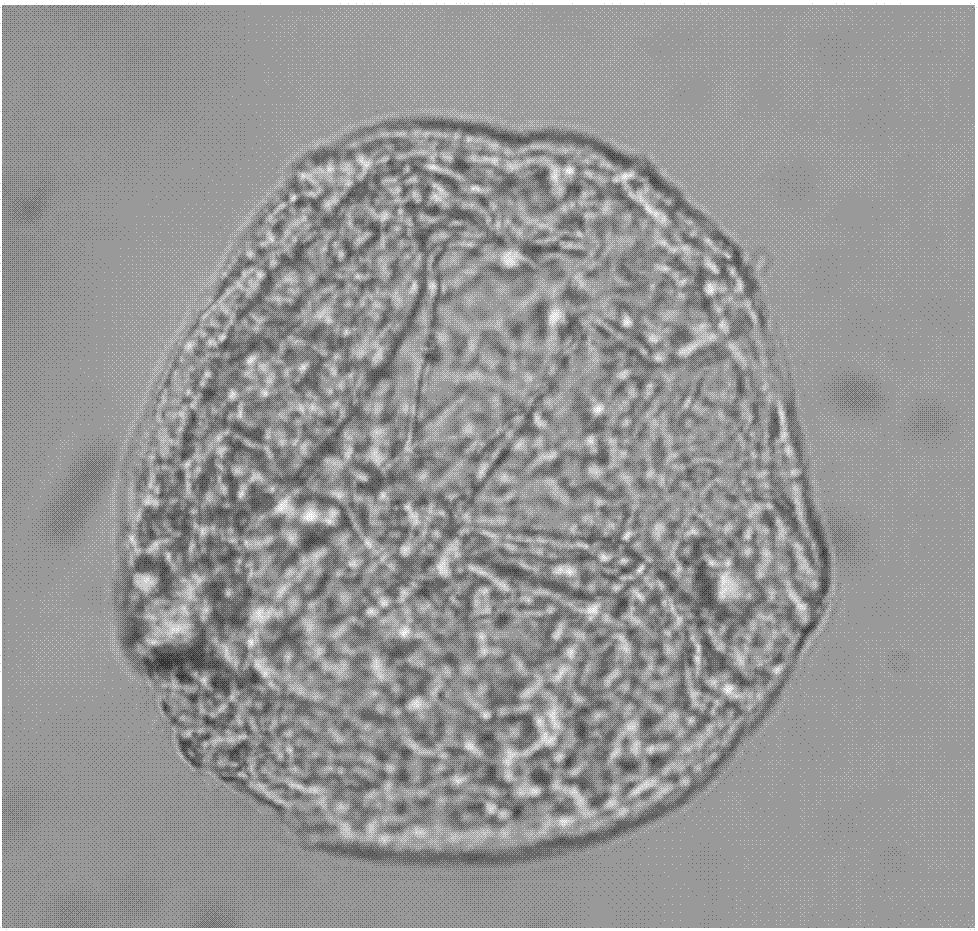

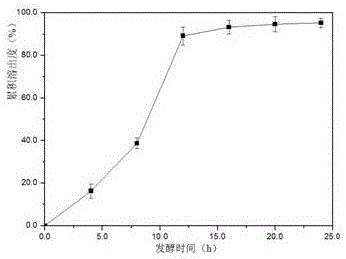

Preparation method of royal jelly microcapsule

ActiveCN103931980AReduce adverse effectsAvoid destructionFood shapingFood electrical treatmentPeristaltic pumpFreeze-drying

The invention discloses a preparation method of a royal jelly microcapsule. The method comprises the following steps: preparing a water solution of sodium alginate with a concentration of 0.015 to 0.025 g / mL and a water solution of loyal jelly with a concentration of 0.15 g / mL, taking the two water solutions as the raw material solution; preparing a mixed solution containing CaCl2 (5-15 mg / mL), chitosan (2.5-7.5 mg / mL), and royal jelly (0.15 g / mL), wherein the pH value of the mixed solution is 4.5 to 6.0, subjecting the mixed solution to a centrifugation treatment, taking the supernate as the gel bath; transporting the raw material solution to the positive pole of a nozzle through a peristaltic pump, arranging a round disc, which is made of stainless steel and is provided with a hole in the center, right under the nozzle and above the gel bath, taking the round disc as the negative pole, spraying the raw material solution into the gel bath from the nozzle to form calcium alginate micro beads in the gel bath, and then subjecting the micro beads to processes of suction filtration, water washing, and freeze-drying so as to obtain the royal jelly microcapsule. The preparation method has the advantages of low temperature and short time. The moisture absorbing property of the freeze-dried powder in the royal jelly microcapsule is reduced, the pungent smell is prominently reduced at the same time, and the microcapsule can tolerate the stomach environment and finally releases freeze-dried powder in the small intestines.

Owner:ZHEJIANG UNIV OF TECH

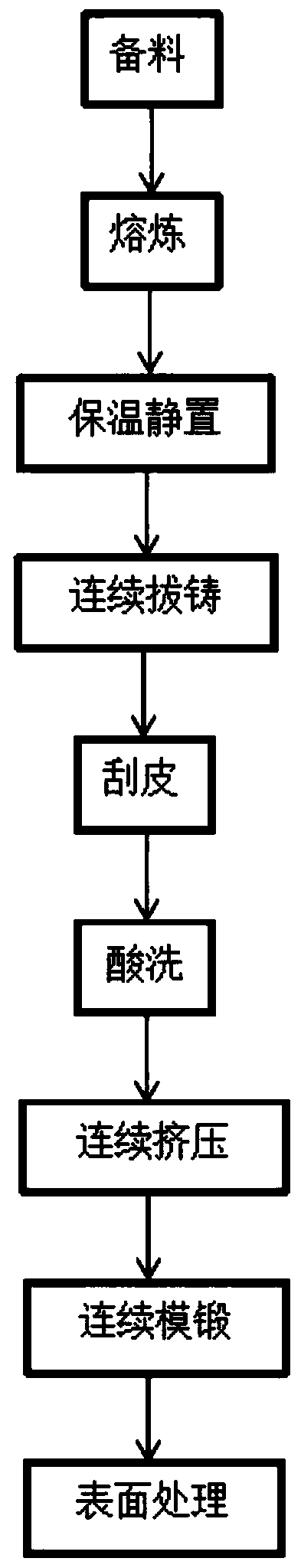

High-performance copper bus and preparation technology thereof

The invention provides a high-performance copper bus and a preparation technology thereof. The high-performance copper bus comprises the following component elements in percentage by weight: 94-99% ofcopper, 1.2-2.6% of titanium, 0.5-0.8% of silicon, 0.1-0.3% of ytterbium, 0.5-0.9% of zirconium, 0.12-0.18% of vanadium, 0.06-0.1% of niobium, 0.02-0.05% of strontium, and not greater than 0.03% of inevitable impurities. The preparation technology comprises the following steps: S1, preparing materials; S2, melting; S3, maintaining the temperature and standing; S4, continuously drawing casting; S5, rossing; S6, pickling; S7, continuously extruding; S8, continuously forging through a die; and S9, treating the surface. According to the technology, the steps of secondary annealing and secondary pickling are carried out, so that the mechanical strength of the copper bus is high; brittle failure caused by excessively high hardness performance is avoided, and the excessively soft problem causedby performance is removed.

Owner:JIANGSU HUAWEI COPPER IND

Three-high reducing health care product and method for preparing the same

InactiveCN104940461ARich in nutritional valueRich health benefitsMetabolism disorderAntinoxious agentsSexual functionDisease

The invention discloses a three-high reducing health care product and a method for preparing the same. The three-high reducing health care product comprises, by weight parts, 30-50 parts of maca, 10-30 parts of radix puerariae, 10-20 parts of saffron and 10-30 parts of glycyrrhiza uralensis. Biological health care active molecules are extracted through a modern Chinese medicine technology, and edible excipients are added to the extracted biological health care active molecules to prepare tablets, granules, hard capsules or oral liquid. The maca, the radix puerariae, the saffron and the glycyrrhiza uralensis improve the bio-utilization degree of the biological health care active molecules by means of a bionanotechnology and are prepared into a health care food for women; the three-high reducing health care product is safe to eat, effective, non-toxic and harmless. The three-high reducing health care product has collaborative effects of improving a sexual function and fertility, adjusting endocrine, reducing related diseases of osteoporosis and the like caused by ovarian function degradation and improving human immunity functions.

Owner:JIANGSU HUIBO BIOTECH

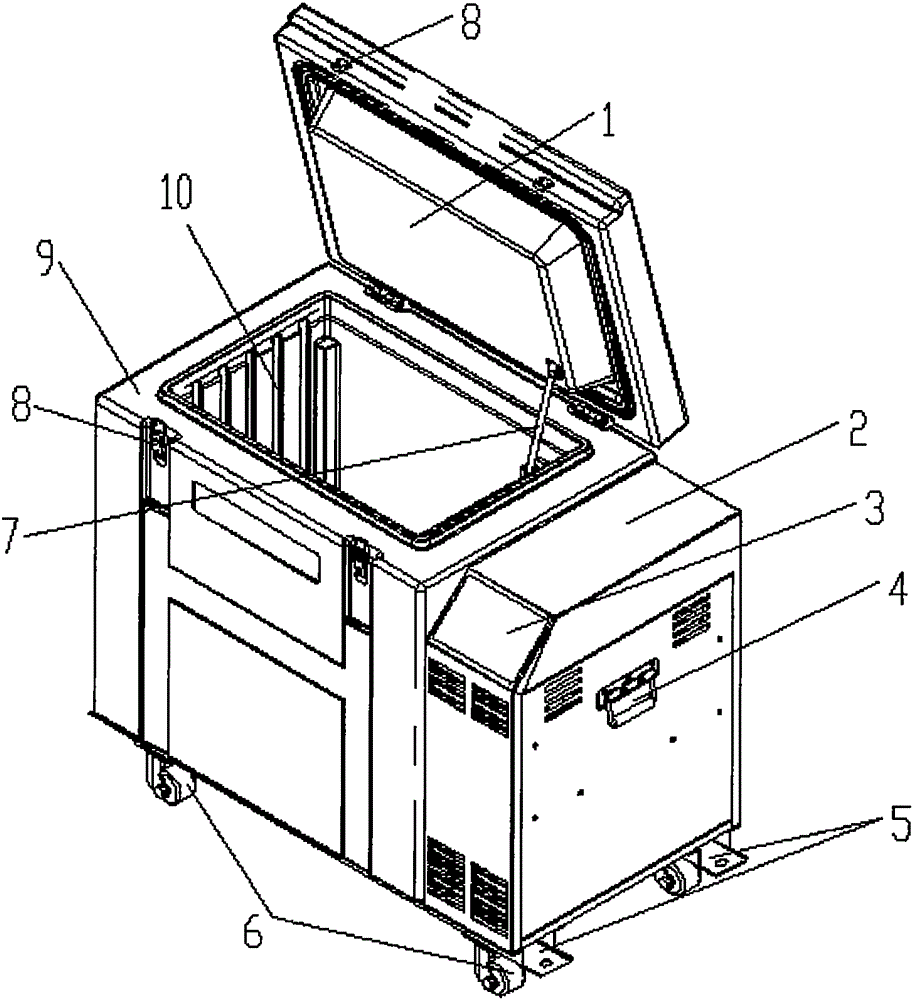

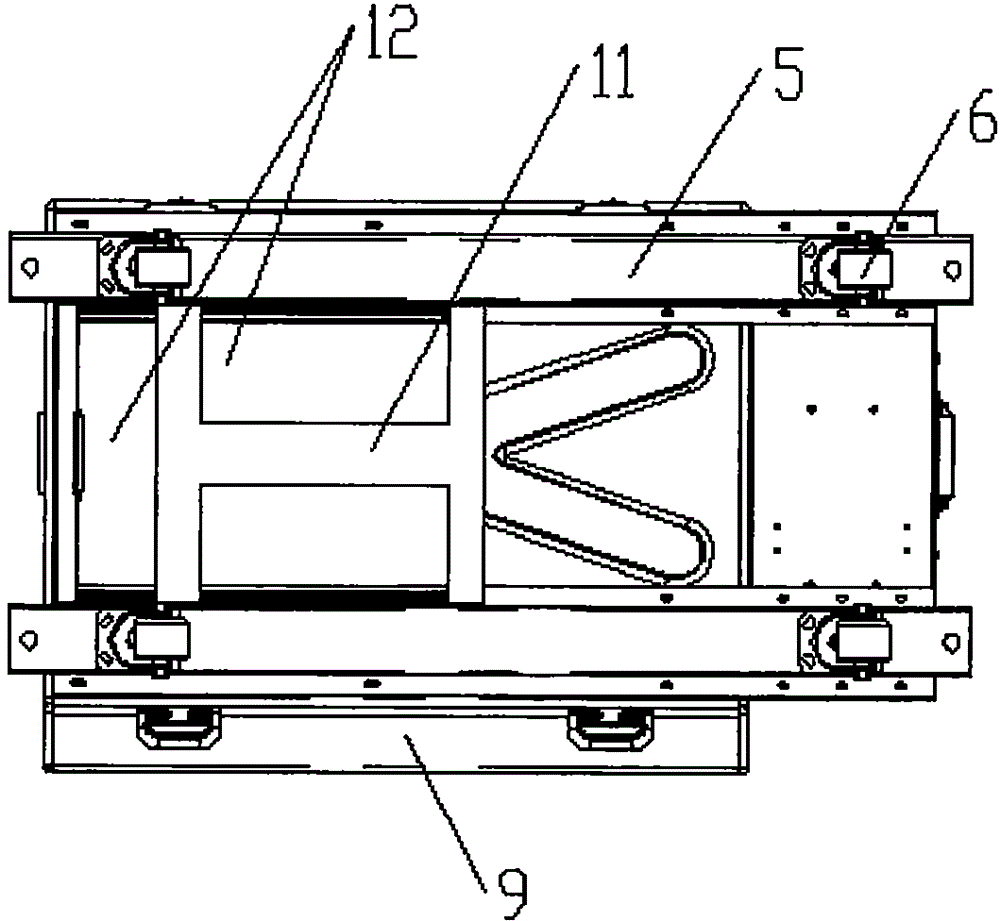

Alkali-resistant and corrosion-resistant refrigerator

InactiveCN105202848ALightweightReduce volumeLighting and heating apparatusDomestic refrigeratorsRefrigeration compressorBlow molding

The invention discloses an alkali-resistant and corrosion-resistant refrigerator. The refrigerator comprises a cold storage refrigerator body and a refrigeration case, wherein the cold storage refrigerator body is made of polyethylene plastic through one-time blow molding, a refrigerator cover made of the polyethylene plastic through one-time blow molding is arranged at the upper part of the cold storage refrigerator body, the refrigeration case is arranged on one side surface of the cold storage refrigerator body, a refrigeration system is arranged in the refrigeration case and comprises a refrigeration compressor, a condenser, a controller and an evaporator, the evaporator is arranged in the cold storage refrigerator body, and the refrigeration compressor, the condenser and the controller are arranged in the refrigeration case. According to the alkali-resistant and corrosion-resistant refrigerator, the refrigerator body is made of HDPE (high density polyethylene) through one-time blow molding by a blow molding machine, so that the refrigerator has anti-rust, alkali-resistant, acid-resistant, salt-resistant and corrosion-resistant properties, is wide in application range, and is mainly used for storing scientific research and medical articles and widely applied to storage of medicines, biological products, vaccines, genetic engineering, blood, culture bacteria and the like.

Owner:ZHONGKE MEILING CRYOGENICS CO LTD

Preparation method of storage material based on inorganic nonmetal

The invention discloses a preparation method of a storage material based on inorganic nonmetal, and specifically relates to the technical field of storage material preparation, wherein the used raw materials comprise, by weight, 50-70 parts of clay, 20-40 parts of quartz sand, 10-18 parts of silicon carbide, 8-10 parts of silicon nitride, 8-10 parts of aluminum oxide, 10-20 parts of mica, 1-5 parts of camphorwood blocks, and 2-4 parts of bamboo fibers, and the auxiliary materials comprise, by weight, 8-16 parts of bentonite, 4-8 parts of starch and 2-6 parts of a nanometer super-hydrophobic coating material. According to the invention, by adding the camphorwood blocks and the bamboo fibers, the camphorwood blocks have natural fragrance and have effects of moisture absorbing, odor eliminating and outside mosquito expelling, and the added bamboo fibers have functions of bacterial inhibiting, mite removing and deodorizing, so that the good storage environment is kept in the storage material so as to easily store articles.

Owner:韦杰

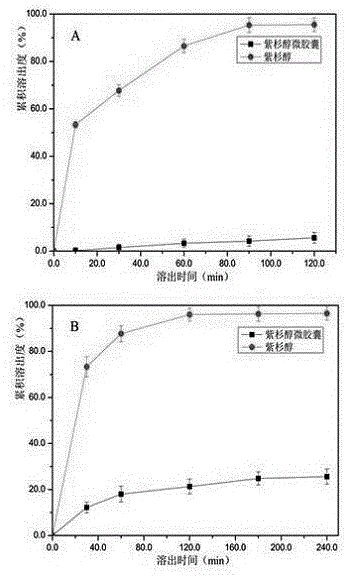

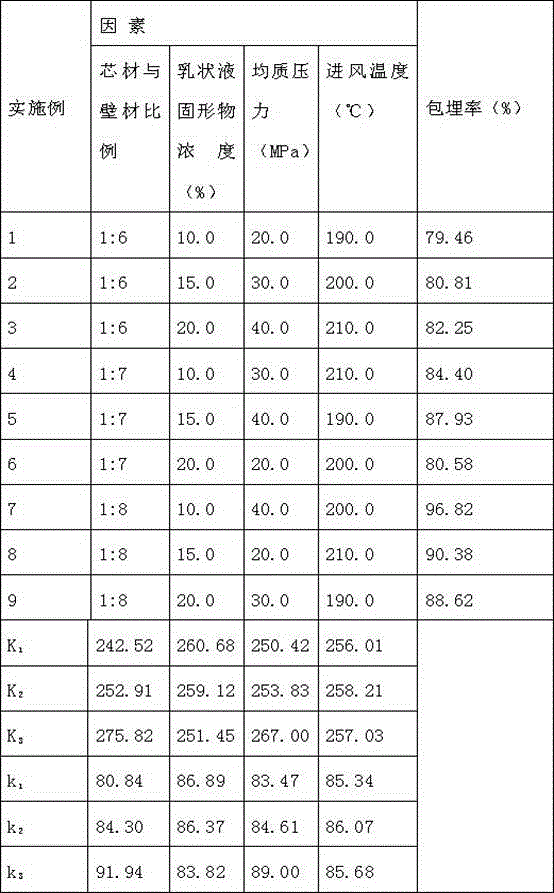

Taxol microcapsule as well as preparation method and detection analysis method thereof

ActiveCN106562938AOvercome operabilityOvercome the shortcomings of large side effectsOrganic active ingredientsSurface/boundary effectEmbedding rateCurative effect

The invention discloses a taxol microcapsule as well as a preparation method and a detection analysis method of the taxol microcapsule. According the taxol microcapsule as well as the preparation method and the detection analysis method, gingko octenyl succinic acid modified starch is taken as a wall material, taxol is taken as a core material, the taxol microcapsule is prepared by adopting the spray drying technology, the preparation method is simple, the cost is low, and the preparation method is suitable for industrial production. According to the detection a method, taxol is taken as the reference substance, by detecting the embedding rate, the in-vitro dissolution rate and the release condition, the complete and advanced production system and the detection standard which is strong in specificity and is controllable are formed, thus the effective control over the quality of the medicine is improved, and the quality and curative effects of the taxol microcapsule are guaranteed.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com