Special heat-shrinkable tubing for aerospace and preparation method of special heat-shrinkable tubing

A heat-shrinkable sleeve, aerospace technology, applied in the field of cable materials, can solve the problems of single performance and high production cost, and achieve the effects of high mechanical strength, low dielectric loss and high transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

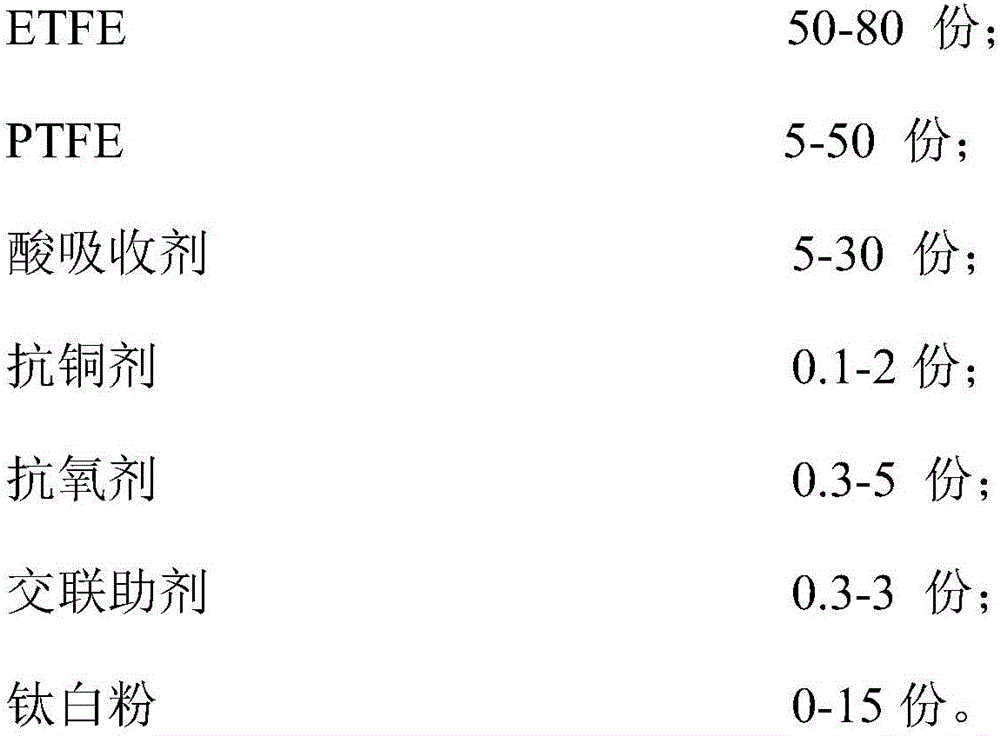

[0030] A special heat-shrinkable sleeve for aerospace, comprising the following components in parts by weight:

[0031]

[0032] The acid absorbent is magnesium oxide; the anti-copper agent is N-salicylamino-phthalimine; the antioxidant is 2,6-di-tert-butylphenol; Allyl isocyanurate.

[0033] The heat-shrinkable sleeve described in this embodiment is prepared by the following method:

[0034] 1) Take the ETFE, PTFE, acid absorbent, anti-copper agent, and antioxidant of the formula, and put them into the mixing chamber of the single-screw internal mixing granulator in sequence, and banbury evenly at 260 ° C;

[0035] 2) Then add the cross-linking aid in the formula amount to the mixing room of the single-screw banburying granulator, and banbury evenly under the condition of 260°C; obtain the mixture;-

[0036] 3) Automatically feed the mixture to the granulation part of the single-screw banburying granulator, extrude at 260-360°C, wire drawing, air cooling, and pelletizing...

Embodiment 2

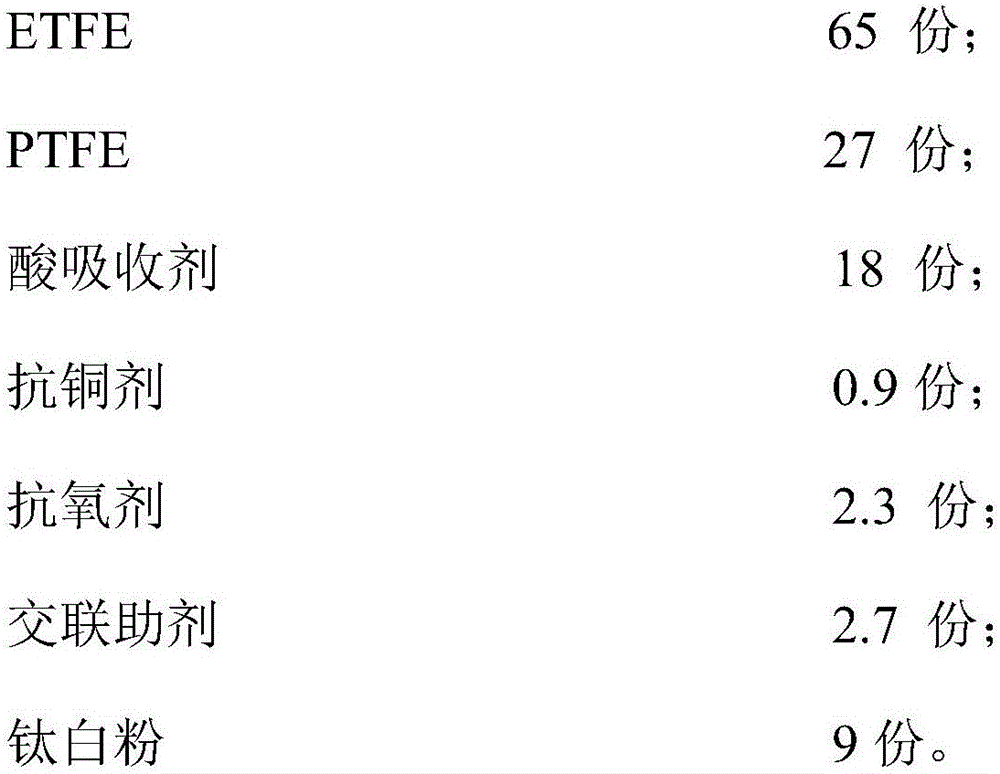

[0041] A special heat-shrinkable sleeve for aerospace, comprising the following components in parts by weight:

[0042]

[0043] The acid absorbent is magnesium hydroxide; the anti-copper agent is N, N'-bis[β(3,5-ditertiary-4-hydroxyphenyl)propionyl]hydrazine; the antioxidant Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester; the cross-linking assistant is triallyl isocyanurate.

[0044] The heat-shrinkable sleeve described in this embodiment is prepared by the following method:

[0045] 1) Take the ETFE, PTFE, acid absorbent, anti-copper agent, antioxidant, titanium dioxide in the formula quantity, put them into the mixing chamber of the single-screw internal mixing granulator in sequence, and banbury evenly at 320°C;

[0046] 2) Then add the formula amount of cross-linking aid to the mixing chamber of the single-screw banburying granulator, and banbury evenly under the condition of 320°C; obtain the mixture;-

[0047] 3) Automatically feed...

Embodiment 3

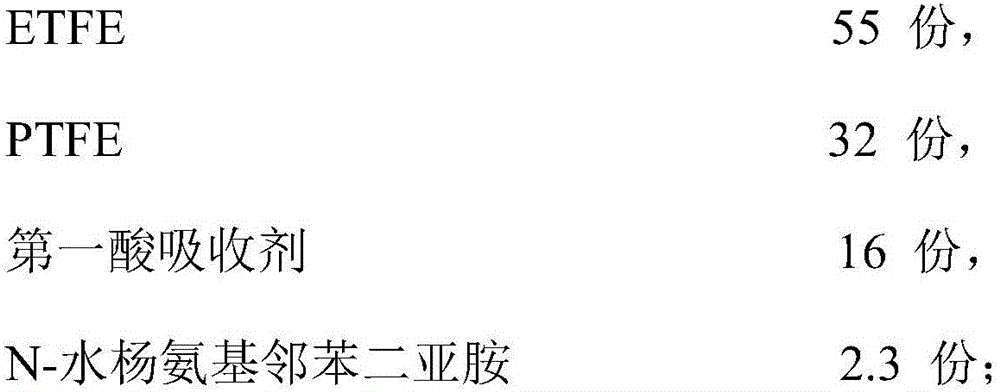

[0052] A special heat-shrinkable sleeve for aerospace, comprising the following components in parts by weight:

[0053]

[0054] The acid absorbent is magnesium hydroxide; the anti-copper agent is N, N'-bis[β(3,5-ditertiary-4-hydroxyphenyl)propionyl]hydrazine; the antioxidant Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester; the cross-linking assistant is triallyl cyanuric acid ester.

[0055] The heat-shrinkable sleeve described in this embodiment is prepared by the following method:

[0056] 1) Take the ETFE, PTFE, acid absorbent, anti-copper agent, antioxidant, titanium dioxide of the formula, put them into the mixing room of the single-screw internal mixing granulator in sequence, and banbury evenly at 300°C;-

[0057] 2) Add the formula amount of crosslinking aid to the mixing chamber of the single-screw banburying granulator, and banbury evenly under the condition of 300°C; obtain the mixture;

[0058] 3) Automatically feed the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com