Waterborne release agent and preparation method and construction method thereof

A water-based release and construction method technology, applied in the direction of textiles and papermaking, coatings, paper coatings, etc., can solve the problems of VOC emissions, ink or ink residue on the surface of substrates, unfriendly environment, etc., to achieve no VOC emissions, surface The effect of low tension and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of water-based release agent, comprising the following steps:

[0033] Material preparation step: Measure paraffin wax emulsion, palm wax emulsion, polytetrafluoroethylene emulsion, and silicone surfactant according to the formula ratio;

[0034] Mixing step: Put the paraffin wax emulsion, palm wax emulsion, polytetrafluoroethylene emulsion, and silicone surfactant in the mixing tank in sequence, and stir for 30 minutes at a temperature of 40°C and a rotation speed of 800r / min. Get water-based release agent.

[0035] A construction method of a water-based release agent, comprising the following steps: uniformly coating the water-based release agent on a substrate, controlling the thickness between 10-50 microns, and baking at a temperature of 80-120°C for 1- 3 minutes to complete the entire construction process.

[0036] As a preferred embodiment, the substrate is paper or thermal transfer film. Preferably, the thermal transfer film is a PET film...

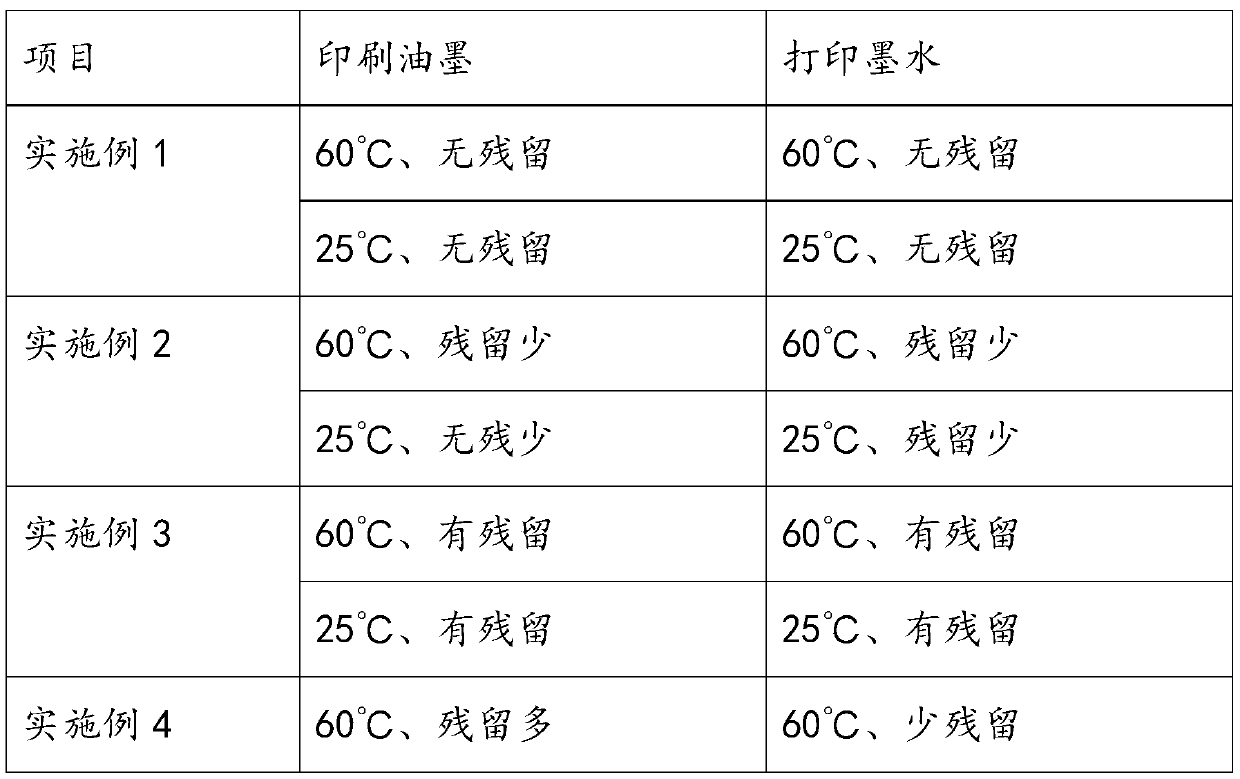

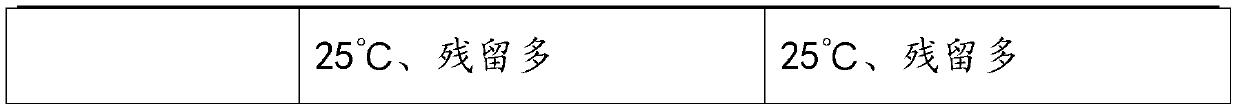

Embodiment 1

[0039] A water-based release agent is prepared from the following components by weight percentage: 25% of paraffin wax emulsion, 20% of palm wax emulsion, 54% of polytetrafluoroethylene emulsion, and 1% of organic silicon surfactant.

[0040] A preparation method of water-based release agent, comprising the following steps:

[0041] Material preparation step: Measure paraffin wax emulsion, palm wax emulsion, polytetrafluoroethylene emulsion, and silicone surfactant according to the formula ratio;

[0042] Mixing step: Put the paraffin wax emulsion, palm wax emulsion, polytetrafluoroethylene emulsion, and silicone surfactant in the mixing tank in sequence, and stir for 30 minutes at a temperature of 40°C and a rotation speed of 800r / min. Get water-based release agent.

[0043] A construction method of a water-based release agent, comprising the following steps: uniformly coating the water-based release agent on a substrate, controlling the thickness between 10-50 microns, and ...

Embodiment 2

[0045] A water-based release agent is prepared from the following components by weight percentage: 20% of paraffin wax emulsion, 30% of palm wax emulsion, 49.5% of polytetrafluoroethylene emulsion, and 0.5% of organic silicon surfactant.

[0046] The preparation method of described water-based release agent, the construction method of water-based release agent are all identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com