Preparation method of royal jelly microcapsule

A technology for royal jelly and microcapsules, applied in the field of food processing, can solve the problems of unspecified capsule size, destruction of active ingredients, difficulty in adding, etc., and achieve the effects of increasing the scope of use, reducing hygroscopicity and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

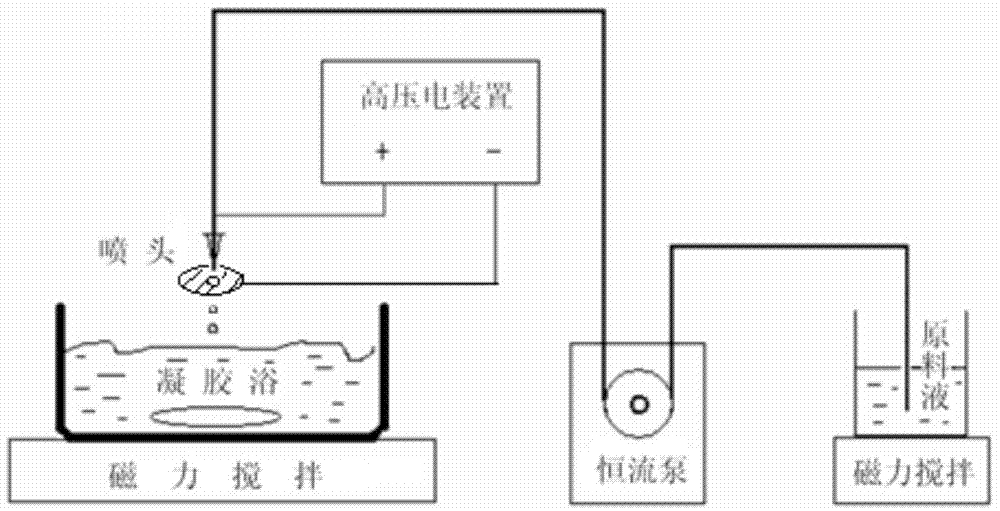

[0035] Disperse 3.84g of sodium alginate in 200mL of distilled water at 60°C to form a sodium alginate aqueous solution, cool to room temperature at 25°C, add 30.00g of royal jelly, stir well to form a raw material solution; use 1% (v / v) acetic acid to adjust 500mL containing 5.05g CaCl 2The pH of the mixed solution with 2.90g chitosan was adjusted to 4.5, and 75.00g royal jelly was added, centrifuged (1000×g, 4°C, 10min), and the supernatant was taken as a gel bath. The raw material liquid is delivered to the nozzle of the high-voltage electrostatic field (8kV) through the peristaltic pump at a speed of 1mL / min. The No. 8 needle (diameter 0.8mm) with the pointed part is used as the nozzle, and the nozzle is connected to the positive stage. Vertically below and above the gel bath, a stainless steel disc with a diameter of 1cm in the middle is set as the negative electrode, which is connected to the negative electrode of the high-voltage electrostatic field. The needle of the n...

Embodiment 2

[0043] Disperse 3.84g of sodium alginate in 200mL of distilled water at 60°C to form a sodium alginate aqueous solution, cool to room temperature at 25°C, add 30.00g of royal jelly, stir well to form a raw material solution; use 1% (v / v) acetic acid to adjust 500mL containing 5.05g CaCl 2 The pH of the mixed solution with 2.90g chitosan was adjusted to 4.5, and 75.00g royal jelly was added, centrifuged (1000×g, 4°C, 10min) to take the supernatant as a gel bath. The raw material liquid is delivered to the nozzle of the high-voltage electrostatic field (8kV) through the peristaltic pump at a speed of 1mL / min. The No. 8 needle (diameter 0.8mm) with the pointed part is used as the nozzle, and the nozzle is connected to the positive stage. Vertically below and above the gel bath, a stainless steel disc with a diameter of 1cm in the middle is set as the negative electrode, which is connected to the negative electrode of the high-voltage electrostatic field. The needle of the nozzle ...

Embodiment 3

[0045] Disperse 5.00g of sodium alginate in 200mL of distilled water at 60°C to form an aqueous solution of sodium alginate, cool to room temperature at 25°C, add 30.00g of royal jelly, and stir well to form a raw material solution; use 1% (v / v) acetic acid to adjust 500mL containing 5.00g CaCl 2 The pH of the mixed solution with 3.75g chitosan was adjusted to 5.0, and 75.00g royal jelly was added, centrifuged (1000×g, 4°C, 10min) to take the supernatant as a gel bath. The raw material liquid is delivered to the nozzle of the high-voltage electrostatic field (8kV) through the peristaltic pump at a speed of 1mL / min. The No. 8 needle (diameter 0.8mm) with the pointed part is used as the nozzle, and the nozzle is connected to the positive stage. Vertically below and above the gel bath, a stainless steel disc with a diameter of 1cm in the middle is set as the negative electrode, which is connected to the negative electrode of the high-voltage electrostatic field. The needle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com