Magnesium oxide composite floor and manufacturing process thereof

A compound flooring and manufacturing process technology, which is applied in manufacturing tools, ceramic molding machines, construction, etc., can solve the problems of poor waterproof, fireproof performance, poor wear resistance and fireproof performance, short service life, etc., and achieve low cost, smooth surface, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

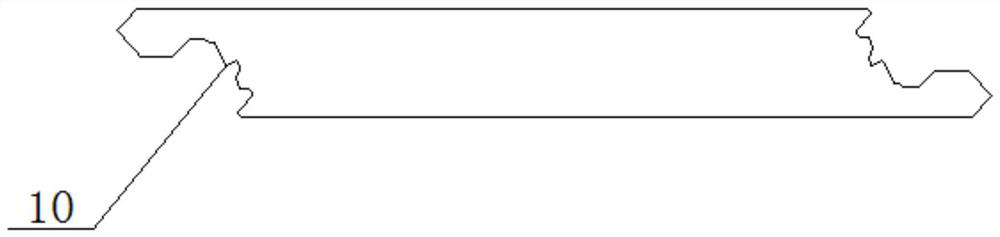

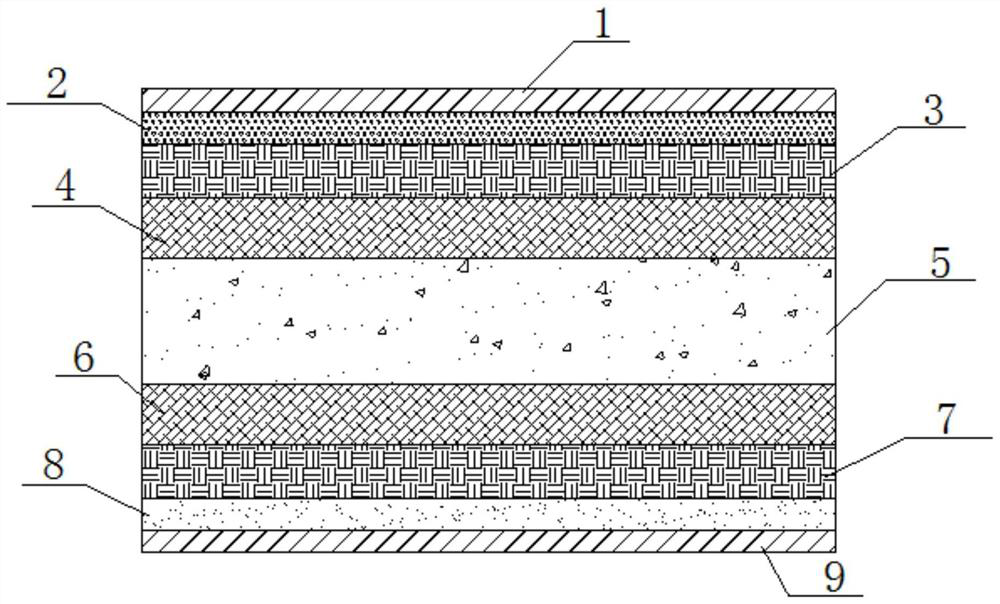

[0045] A kind of magnesia composite floor provided in this embodiment has a structure such as Figure 1-2 As shown, it includes from top to bottom: surface wear-resistant layer 1, surface paste layer 2, upper glass fiber mesh layer 3, upper glass fiber staple fiber mat layer 4, main material layer 5, lower glass fiber staple fiber mat Layer 6, lower glass fiber mesh cloth layer 7, primer layer 8, bottom wear-resistant layer 9;

[0046] The main material layer 5 contains 40% magnesium oxide, 30% magnesium chloride solution, 15% heavy calcium powder, 13% powder and 2% modifier by mass percentage;

[0047] The batter layer 2 contains 40% magnesium oxide, 30% magnesium chloride solution, 20% fossil powder, 8% powder and 2% modifier by mass percentage;

[0048] The primer layer 8 contains 40% magnesium oxide, 30% magnesium chloride solution, 25% fossil powder, 3% powder and 2% modifier by mass percentage.

[0049] In this example, the modifier is a mixture of phosphoric acid and ...

Embodiment 2

[0054] A kind of magnesia composite floor provided in this embodiment has a structure such as Figure 1-2 As shown, it includes from top to bottom: surface wear-resistant layer 1, surface paste layer 2, upper glass fiber mesh layer 3, upper glass fiber staple fiber mat layer 4, main material layer 5, lower glass fiber staple fiber mat Layer 6, lower glass fiber mesh cloth layer 7, primer layer 8, bottom wear-resistant layer 9;

[0055] The main material layer 5 contains 35% of magnesium oxide, 32% of magnesium chloride solution, 13% of heavy calcium powder, 15% of powder and 5% of modifier by mass percentage;

[0056] The batter layer 2 contains 45% magnesium oxide, 25% magnesium chloride solution, 22% fossil powder, 5% powder and 3% modifier by mass percentage;

[0057] The primer layer 8 contains 44% magnesium oxide, 25% magnesium chloride solution, 27% fossil powder, 1% powder and 3% modifier by mass percentage.

[0058] In this example, the modifier is a mixture of phosp...

Embodiment 3

[0063] A kind of magnesia composite floor provided in this embodiment has a structure such as Figure 1-2 As shown, it includes from top to bottom: surface wear-resistant layer 1, surface paste layer 2, upper glass fiber mesh layer 3, upper glass fiber staple fiber mat layer 4, main material layer 5, lower glass fiber staple fiber mat Layer 6, lower glass fiber mesh cloth layer 7, primer layer 8, bottom wear-resistant layer 9;

[0064] The main material layer 5 contains 38% magnesium oxide, 31% magnesium chloride solution, 14% heavy calcium powder, 14% powder and 3% modifier by mass percentage;

[0065] The batter layer 2 contains 42% magnesium oxide, 27% magnesium chloride solution, 21% fossil powder, 6% powder and 4% modifier by mass percentage;

[0066] The primer layer 8 contains 41% of magnesium oxide, 27% of magnesium chloride solution, 26% of fossil powder, 2% of powder and 4% of modifier in terms of mass percentage.

[0067] In this example, the modifier is a mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com