Sea-buckthorn fruit juice jelly and preparation method thereof

A technology for sea buckthorn juice and soft candy, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of affecting the quality of soft candy, inconvenient operation, easy to produce wood chips, etc., to improve nutritional value, convenient for workers to operate, The effect of preventing fudge from caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

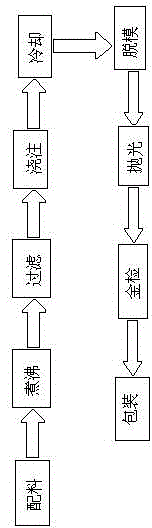

Image

Examples

Embodiment 1

[0036] The production method of described sea-buckthorn marshmallow comprises the steps:

[0037] 1) Ingredients : In the first stage, it is prepared in strict accordance with the proportion of the formula. Glucose syrup 34%, white sugar 32%, purified water 13%, seabuckthorn juice 3%, modified starch 7%, gelatin 6.9%, glucose 1.5%, sorbitol 1.2% , 0.9% citric acid, 0.12% essence, 0.05% pigment; then stir evenly;

[0038] 2) boil : Boil the prepared raw materials first, then cool the temperature to 90°C and then stir further to ensure a uniform and stable solution;

[0039] 3) Filter: Filter the solution to ensure that there are no impurities;

[0040] 4) Pouring : inject the solution into the pre-prepared mold;

[0041] 5) cooling : Send the poured grinding disc into the low-temperature 10°C molding room for low-temperature cooling and molding;

[0042] 6) Demolding : Use a mold of solid silica gel to separate the molded soft candy from the mold, and add 7% modif...

Embodiment 2

[0047] The production method of described sea-buckthorn marshmallow comprises the steps:

[0048] 1) Ingredients : The first stage, the deployment is strictly according to the formula ratio, the first stage: 34% glucose syrup, 32% white sugar, 13% purified water, 6% seabuckthorn juice, 7% modified starch, 3.9% gelatin, 1.5% glucose, sorbet Sugar alcohol 1.2%, citric acid 0.9%, essence 0.12%, pigment 0.05%; then stir evenly;

[0049] 2) boil : Boil the prepared raw materials first, then cool the temperature to 90°C and then stir further to ensure a uniform and stable solution;

[0050] 3) Filter: Filter the solution to ensure that there are no impurities;

[0051] 4) Pouring : inject the solution into the pre-prepared mold;

[0052] 5) cooling : Send the poured grinding disc into the low-temperature 10°C molding room for low-temperature cooling and molding;

[0053] 6) Demolding: Use a mold of solid silica gel to separate the molded soft candy from the mold, and a...

Embodiment 3

[0058] The production method of described sea-buckthorn marshmallow comprises the steps:

[0059] 1) Ingredients : The first stage, the deployment is strictly according to the proportion of the formula, the first stage: 34% glucose syrup, 32% white sugar, 13% purified water, 8% seabuckthorn juice, 7% modified starch, 1.9% gelatin, 1.5% glucose, sorbet Sugar alcohol 1.2%, citric acid 0.9%, essence 0.12%, pigment 0.05%; then stir evenly;

[0060] 2) boil : Boil the prepared raw materials first, then cool the temperature to 90°C and then stir further to ensure a uniform and stable solution;

[0061] 3) Filter: Filter the solution to ensure that there are no impurities;

[0062] 4) Pouring : inject the solution into the pre-prepared mold;

[0063] 5) cooling : Send the poured grinding disc into the low-temperature 10°C molding room for low-temperature cooling and molding;

[0064] 6) Demolding : Use a mold of solid silica gel to separate the molded soft candy from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com