Ceramic coating with high hardness in hot environment

A ceramic coating, high hardness technology, applied in the direction of coating, to achieve the effect of reducing cost, reasonable proportion and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

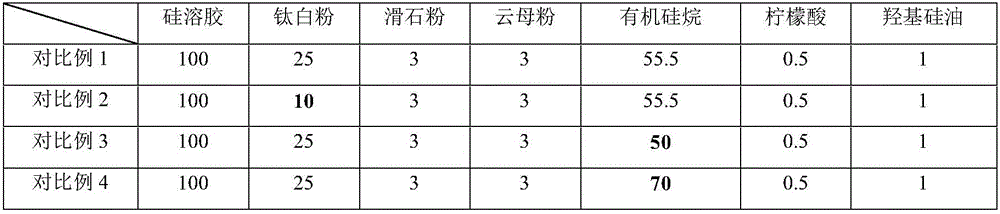

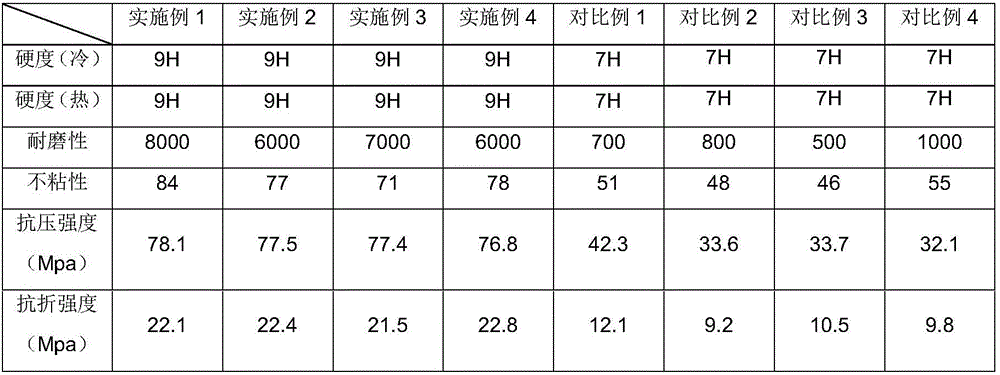

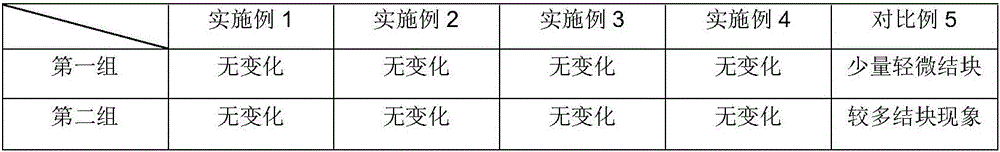

Examples

Embodiment 1

[0034] 100g of silica sol, 25g of titanium dioxide, 3g of talc and 3g of mica powder are fully dispersed until the precipitate disappears completely as a color slurry; 55.5g of organosilane, 0.5g of citric acid and 1g of hydroxyl silicone oil are mixed uniformly as a resin slurry, and then the resin slurry is mixed with The color paste is fully mixed evenly, and finally filtered through a 100-150 mesh filter to prepare a ceramic coating with high hardness in a hot environment.

Embodiment 2

[0036] 100g of silica sol, 24g of titanium dioxide, 20g of boron nitride, 5g of kaolin and 5g of titanium dioxide are fully dispersed until the precipitate disappears completely as a color slurry; 57g of organosilane, 0.7g of citric acid and 2g of hydroxy silicone oil are mixed uniformly as a resin slurry, and then The resin paste and the color paste are fully mixed evenly, and finally filtered through a 100-150 mesh filter screen to prepare a ceramic coating with high hardness in a hot environment.

Embodiment 3

[0038] 100g of silica sol, 22g of titanium dioxide, 10g of boron nitride, 5g of kaolin and 5g of titanium dioxide are fully dispersed until the precipitation completely disappears as a color slurry; 59g of organosilane, 0.9g of citric acid and 4g of hydroxy silicone oil are mixed uniformly as a resin slurry, and then The resin paste and the color paste are fully mixed evenly, and finally filtered through a 100-150 mesh filter screen to prepare a ceramic coating with high hardness in a hot environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com