Cleaning smelting technology of bastnaesite and monazite mixed rare earth ore concentrate

A technology of mixed rare earth and bastnasite, which is applied in the direction of improving process efficiency, can solve the problems such as failure to realize the recovery of valuable element phosphorus, and achieve the effects of easy extraction and separation, increased leaching rate, and efficient recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

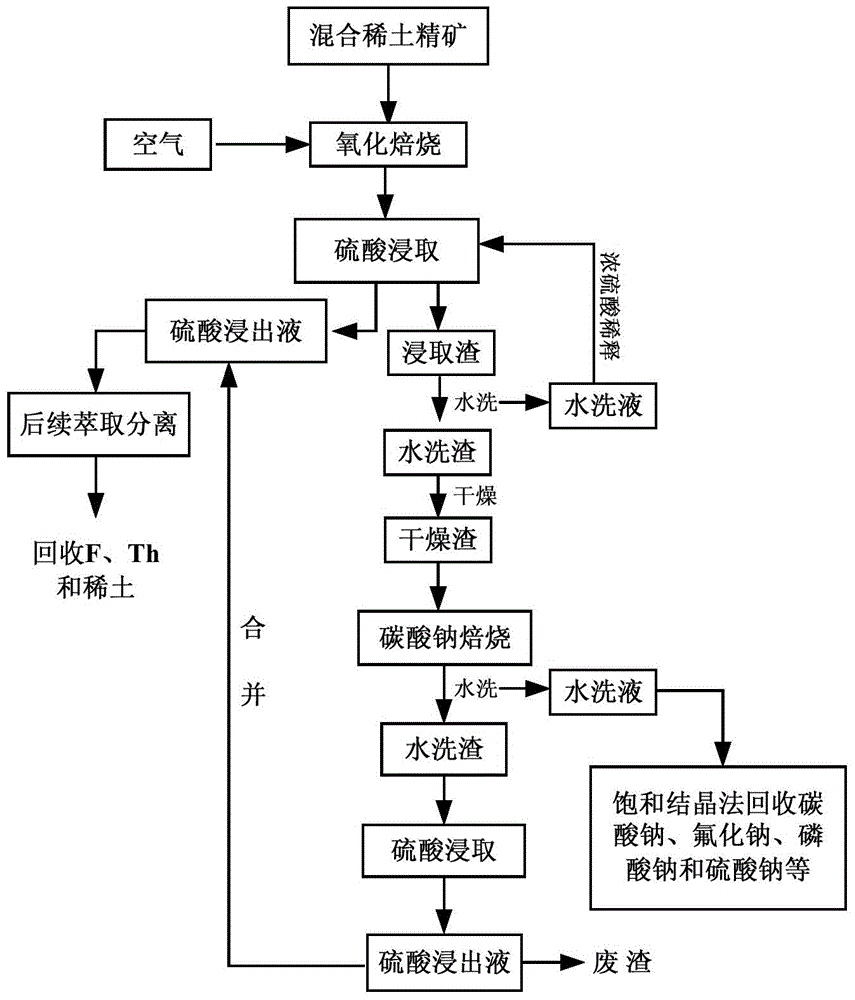

[0043] Such as image 3 Shown, a kind of clean smelting process of bastnaesite and monazite mixed rare earth concentrate, described clean smelting process comprises the following steps:

[0044] (1) The mixed rare earth concentrate of bastnaesite and monazite is oxidized and roasted in air at 700°C; the roasted product is acid-leached with sulfuric acid with a molar concentration of 1M to obtain - 、Ce 4+ 、Th 4+ and trivalent rare earth sulfuric acid leaching solution and leaching slag; the particle size of the bastnaesite and monazite mixed rare earth concentrate is 200 mesh, and its oxidized rare earth content is 50%;

[0045] (2) Wash the leaching slag in step (1) to neutrality to obtain washing slag and washing solution; the washing solution is diluted with concentrated sulfuric acid and used for the acid leaching described in step (1); after the washing slag is dried, mix with sodium carbonate According to the weight ratio of 2:1, it is calcined at 850°C to obtain a cal...

Embodiment 2

[0051] Such as image 3 Shown, a kind of clean smelting process of bastnaesite and monazite mixed rare earth concentrate, described clean smelting process comprises the following steps:

[0052] (1) The mixed rare earth concentrate of bastnaesite and monazite is oxidized and roasted in air at 600°C; the roasted product is acid-leached with sulfuric acid with a molar concentration of 3M to obtain - 、Ce 4+ 、Th 4+ and trivalent rare earth sulfuric acid leaching solution and leaching slag; the particle size of the bastnaesite and monazite mixed rare earth concentrate is 400 mesh, and its oxidized rare earth content is 60%;

[0053] (2) Wash the leaching slag in step (1) to neutrality to obtain washing slag and washing solution; the washing solution is diluted with concentrated sulfuric acid and used for the acid leaching described in step (1); after the washing slag is dried, mix with sodium carbonate According to the weight ratio of 1:2, it is calcined at 650°C to obtain a cal...

Embodiment 3

[0059] Such as image 3 Shown, a kind of clean smelting process of bastnaesite and monazite mixed rare earth concentrate, described clean smelting process comprises the following steps:

[0060] (1) The mixed rare earth concentrate of bastnaesite and monazite is oxidized and roasted in air at 500°C; the roasted product is acid-leached with sulfuric acid with a molar concentration of 2.5M to obtain - 、Ce 4+ 、Th 4+ and trivalent rare earth sulfuric acid leaching solution and leaching slag; the particle size of the bastnaesite and monazite mixed rare earth concentrate is 300 mesh, and its oxidized rare earth content is 55%;

[0061] (2) Wash the leaching slag in step (1) to neutrality to obtain washing slag and washing solution; the washing solution is diluted with concentrated sulfuric acid and used for the acid leaching described in step (1); after the washing slag is dried, mix with sodium carbonate According to the weight ratio of 1.5:1, it is calcined at 700°C to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com