Aluminum alloy and its composite material non-vacuum semi-solid state vibration-rheological connection method

A composite material and connection method technology, applied in the direction of welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of unavoidable interface reaction, difficult brazing process, over-burning and erosion of base metal, etc., to overcome adverse consequences, Ideal engineering significance and low soldering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples describe the present invention in more detail:

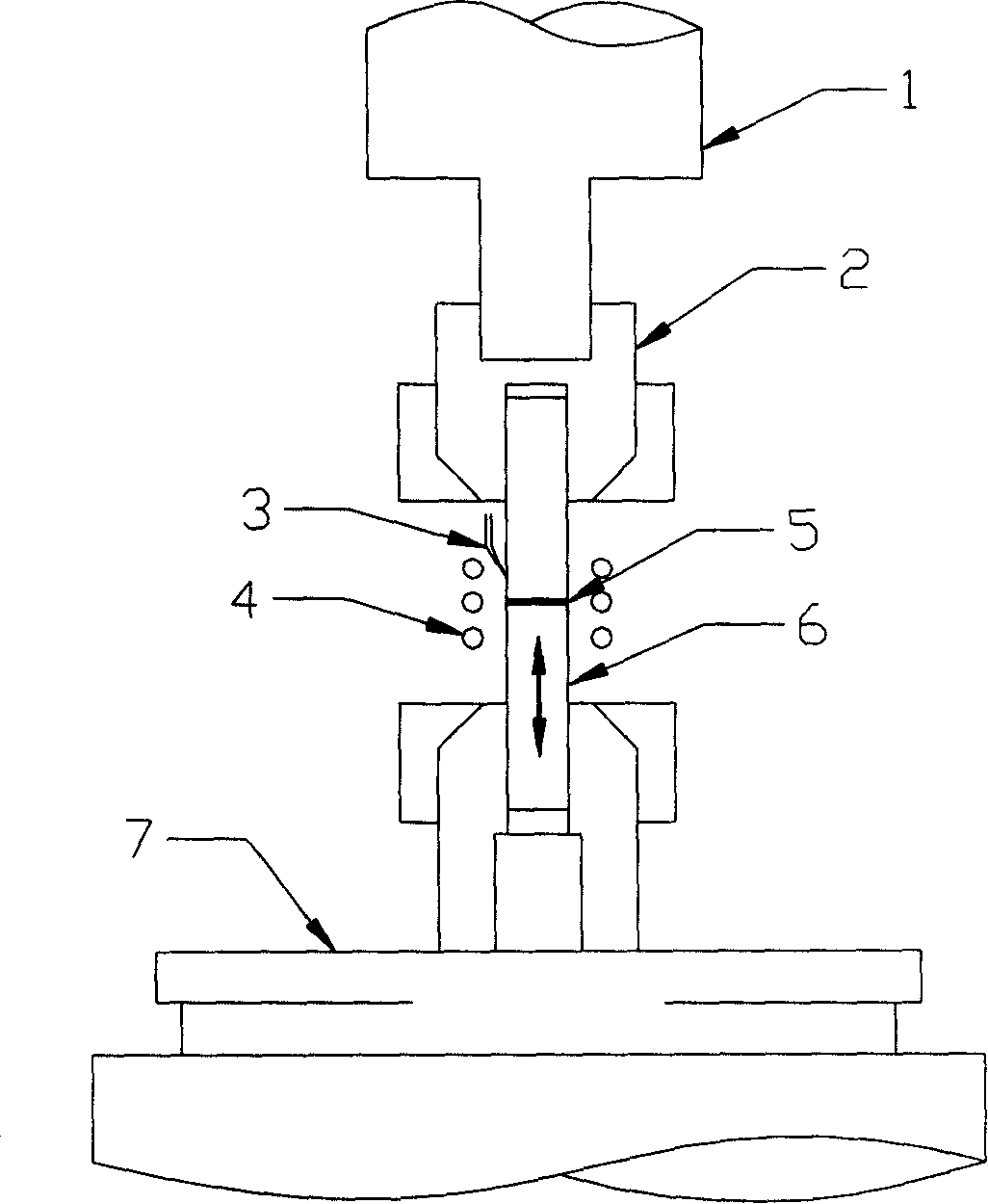

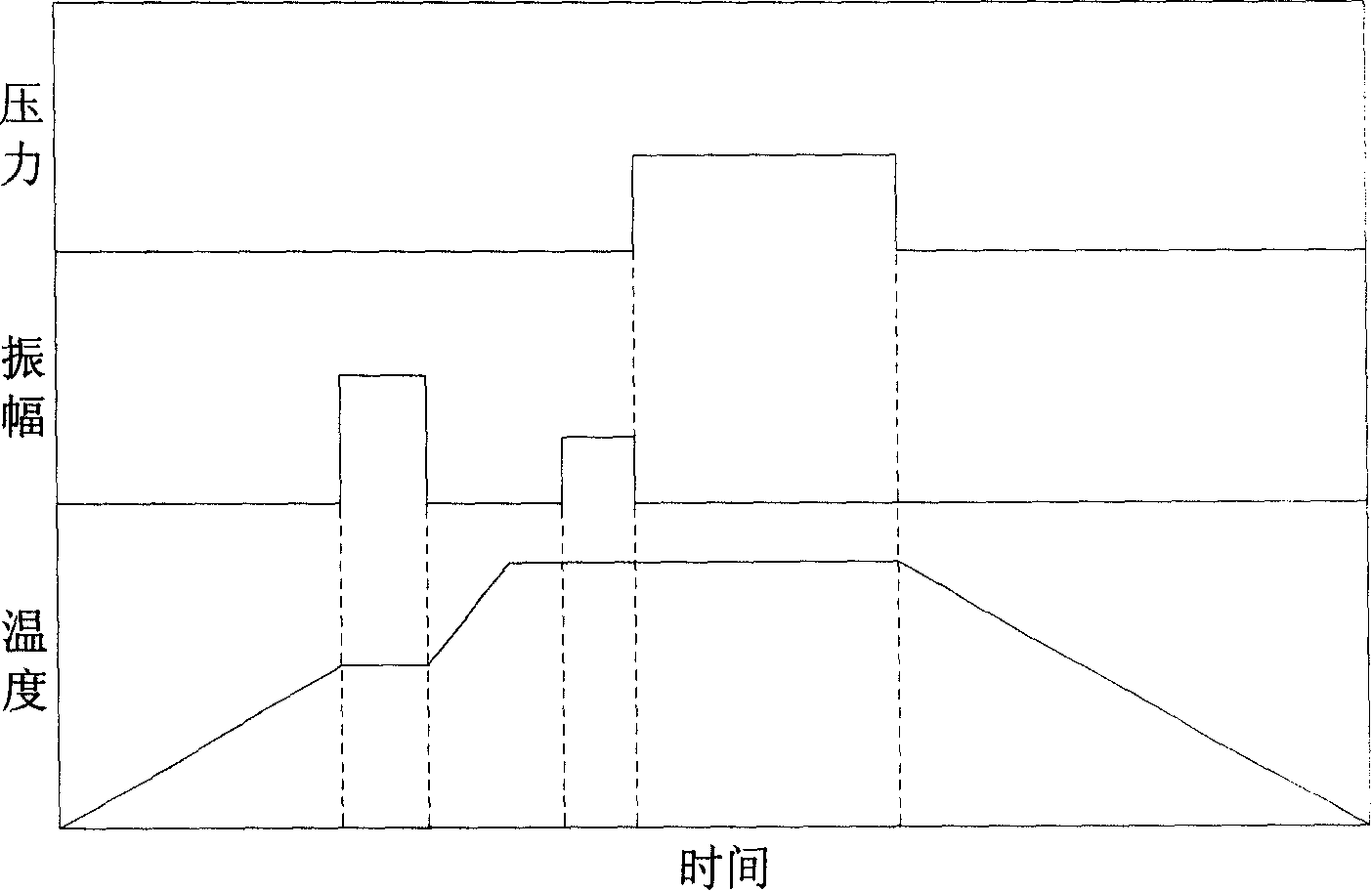

[0049] combine figure 1 1. Install the aluminum-based composite material weldment 6 on the fixture 2 and place medium-temperature solder 5 such as Zn-Al on the two surfaces to be welded. The solder can be sheet-like, foil-shaped, coated or sprayed on the surface to be welded in advance. Heating the weldment through the high-frequency induction coil 4, the heating temperature is between 380-400°C, the heating temperature is controlled by the thermal couple 3, the middle layer solder is melted by heating, the vibration device 7 is started, the amplitude is 0.1-1.5mm, during the vibration process The medium temperature is constant, and the vibration time is 10-300 seconds. After the vibration stops, the temperature rises according to a certain heating rate, and is kept at a predetermined temperature to make the brazing filler metal dissolve a certain thickness of the base metal. The holding temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com