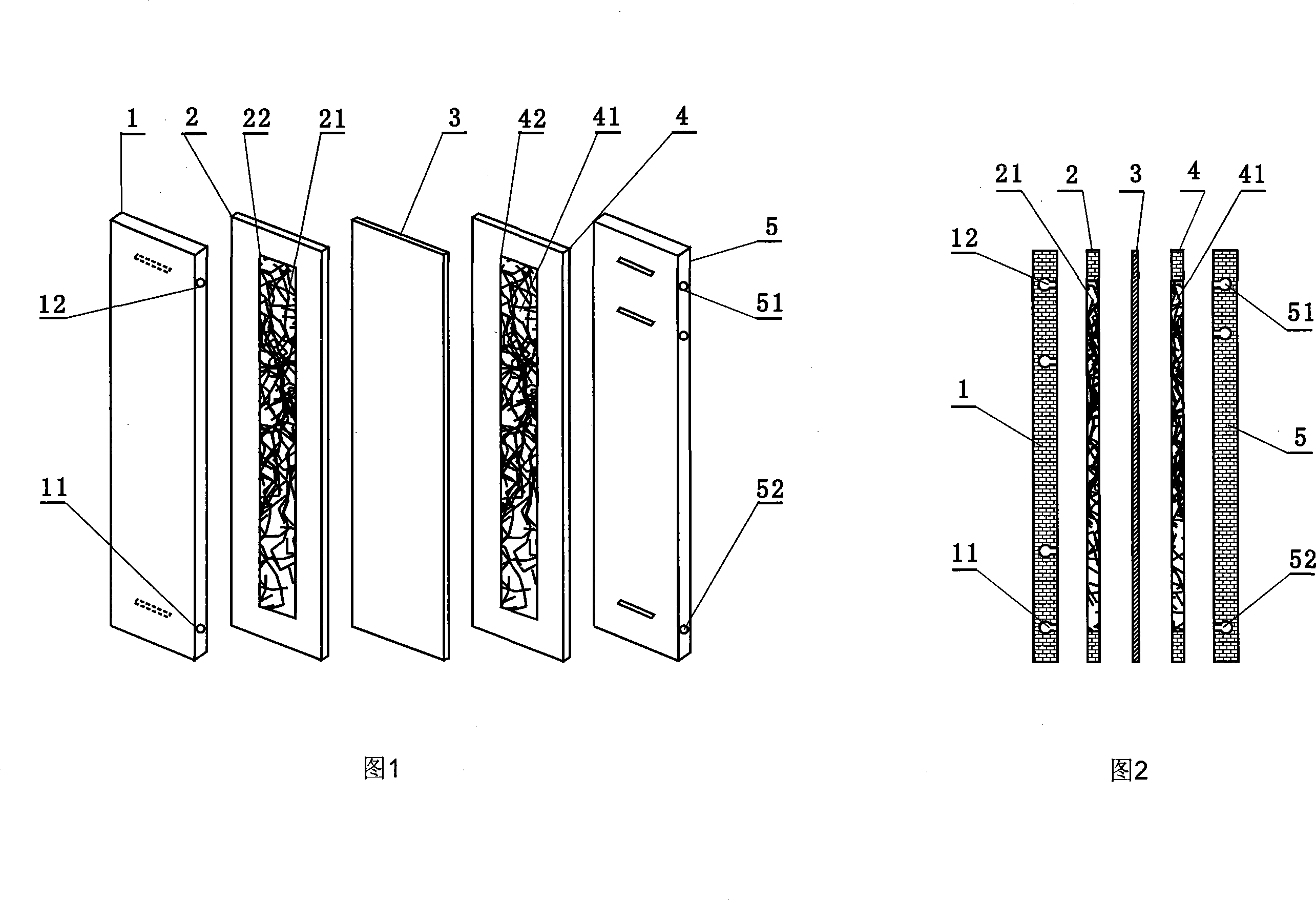

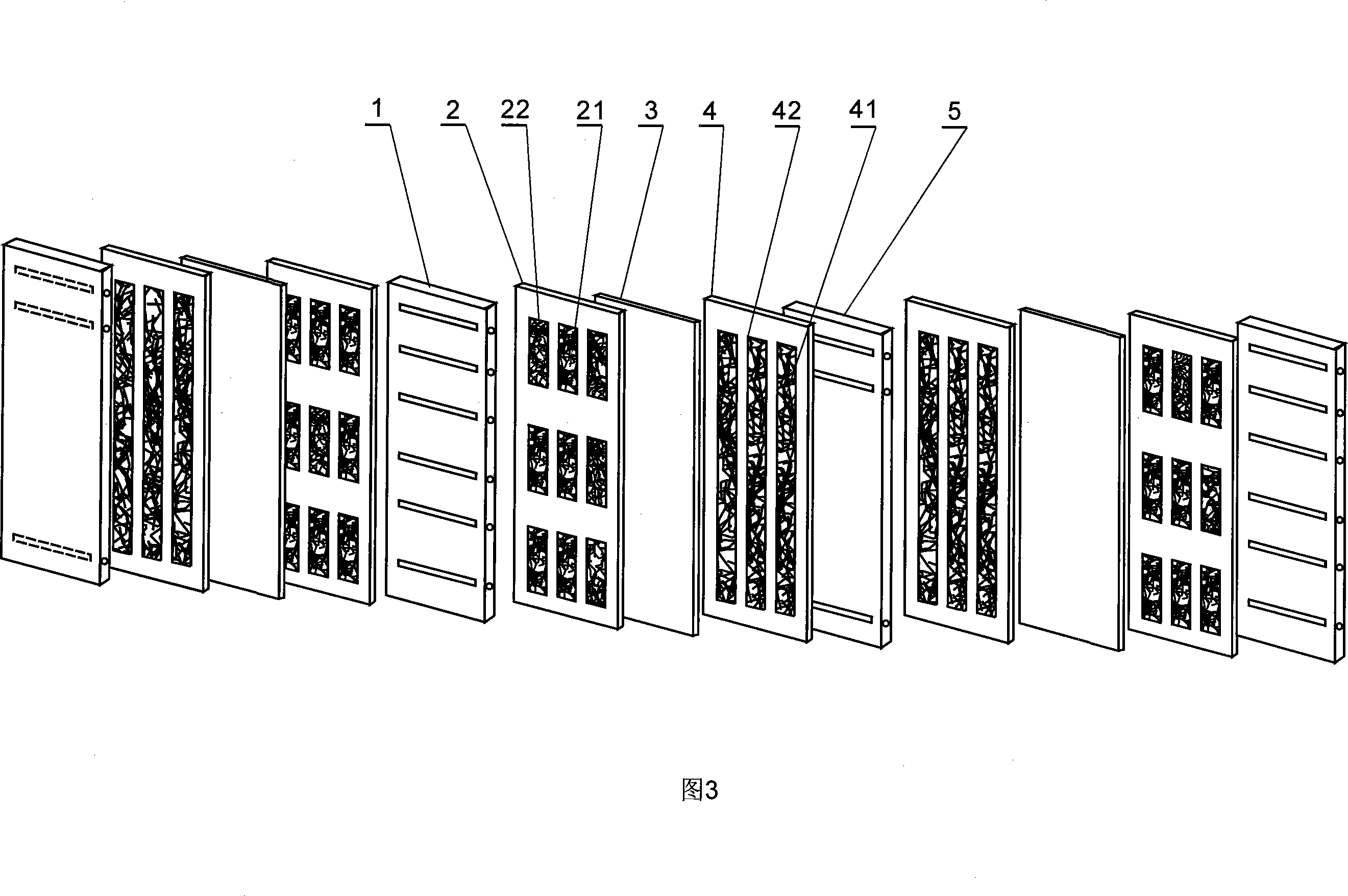

Composite heat exchange filling type micro-reactor

A micro-reactor and reactor technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the difficulty of taking heat from the reaction pipeline, increase the pressure drop in the reaction flow process, and increase the reaction temperature. It is difficult to control problems such as high reaction efficiency, large porosity, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The sintered stainless steel fiber porous composite material is cut into rectangular slices and placed in the heat exchange channel 22 and the reaction channel 42. The porosity of the bed in the channel is 97.6%; the mixed acid with a molar ratio of nitric acid and sulfuric acid of 0.48 is used at 1.60ml / min, benzene The flow rate of 0.5ml / min is pumped into the reaction channel 42; the hot water with an inlet temperature of 48.9°C is pumped into the heat exchange channel 22 at a flow rate of 42ml / min; the hot water outlet temperature is 47.3°C, the reaction product outlet temperature is 60.1°C, corresponding to benzene The conversion rate was 100%, and the nitrobenzene selectivity was 95.7%.

Embodiment 2

[0032] Repeat Example 1. The mixed acid with a molar ratio of nitric acid and sulfuric acid of 0.48 was pumped into the reaction channel 42 at a flow rate of 1.92ml / min and benzene 0.6ml / min; however, hot water with an inlet temperature of 76.6°C was pumped at a flow rate of 42ml / min Enter the heat exchange channel 22; the hot water outlet temperature is 74.2°C, the reaction product outlet temperature is 81.5°C, the corresponding benzene conversion rate is 100%, and the nitrobenzene selectivity is 95.8%.

Embodiment 3

[0034] Repeat Example 1, pump the mixed acid with a molar ratio of nitric acid and sulfuric acid of 0.48 into the reaction channel 42 at a flow rate of 2.24ml / min and benzene 0.7ml / min; but pump hot water with an inlet temperature of 85.9°C at a flow rate of 42ml / min Into the heat exchange channel 22; the hot water outlet temperature is 76.6°C, the reaction product outlet temperature is 95.7°C, the corresponding benzene conversion rate is 98.8%, and the nitrobenzene selectivity is 95.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com