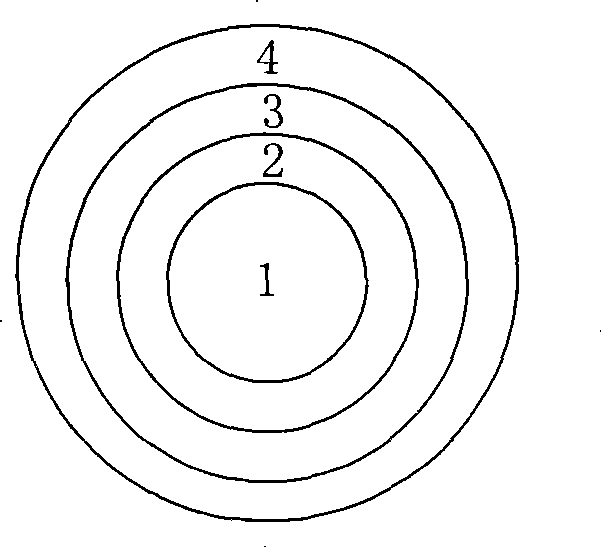

Polymer graft modification composite hollow micro-bead and preparation thereof

A technology of hollow microbeads and graft modification, which is applied in the treatment of dyed polymer organic compounds, etc., can solve the problems of improvement, decrease in yield, and increased difficulty of preparation process, so as to suppress defect structures, improve compressive strength, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

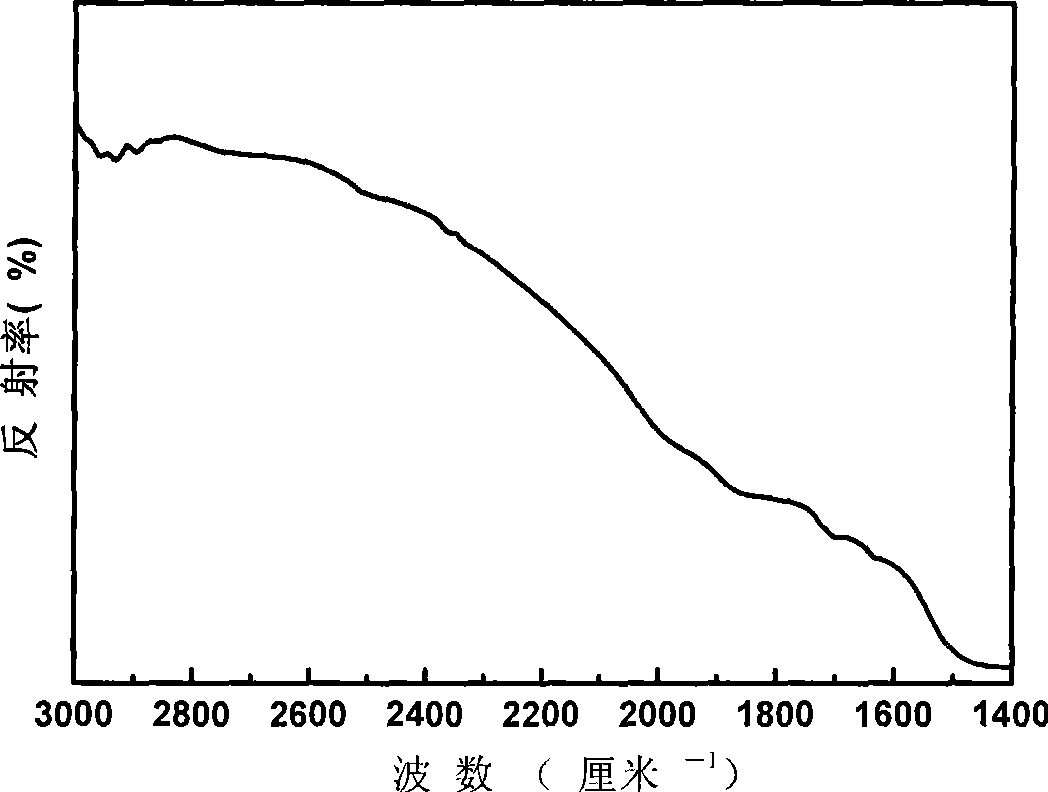

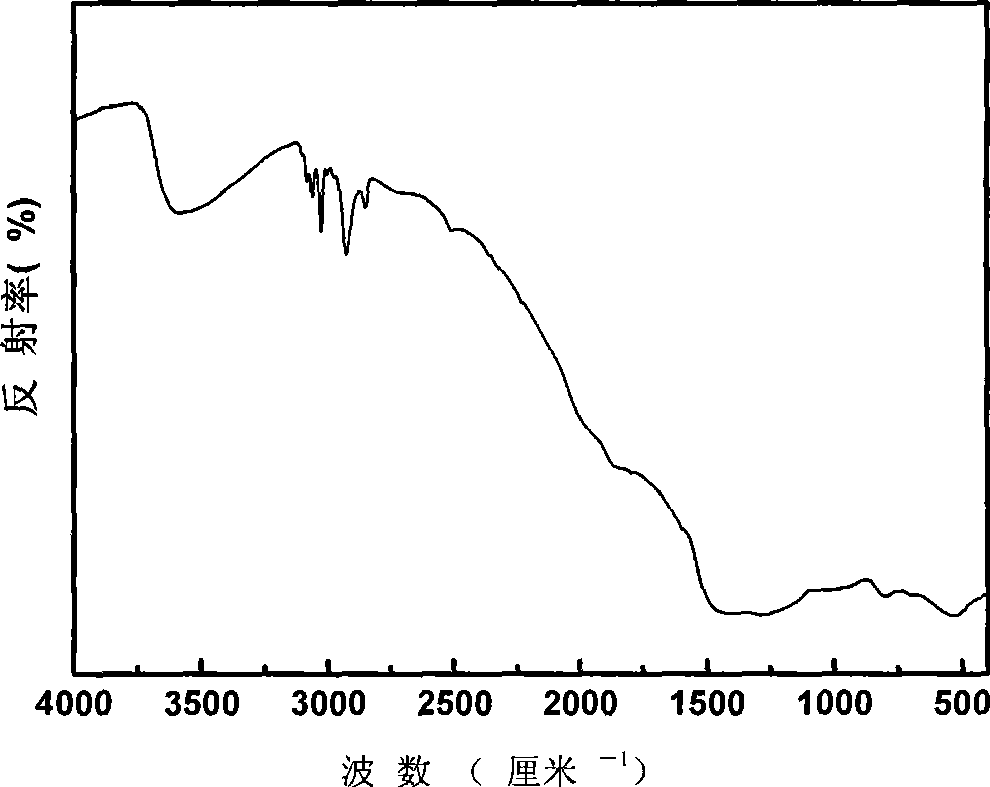

[0049] The first step of hollow microbead coupling treatment: first add the coupling agent methacryloxypropyltrimethoxysilane (KH570) into the ethanol solution. Wherein, the coupling agent content is 25%, the water content is 5%, and the ethanol content is 70%. In order to stabilize the coupling agent, the pH of the solution was adjusted to 4-5 with acetic acid in advance. 10 g of hollow glass microspheres were added into the ethanol solution under magnetic stirring, and reacted at 50° C. for 1 hour. Filter, wash with ethanol and acetone successively, and then put it into a hot air drier at 120°C for heat treatment for 2 hours, so that the coupling agent can fully react with the surface of the hollow glass microspheres, thereby introducing double bonds on the surface of the hollow microspheres to obtain Hollow glass microspheres treated with coupling agent (referred to as HGM-KH570).

[0050] The second step of graft polymerization of coupled microbeads: adding the hollow mi...

Embodiment 2

[0062] The first step of hollow microbead coupling treatment: first add vinyltrimethoxysilane coupling agent (A-171) into the ethanol solution. Wherein, the coupling agent content is 0.5%, the water content is 0.5%, and the ethanol content is 99%. In order to stabilize the coupling agent, the pH of the solution was adjusted to 3-4 with hydrochloric acid in advance. 10 g of hollow glass microspheres were added into the ethanol solution under magnetic stirring, and reacted at 80° C. for 8 hours. Filter, wash with acetone, and then put it into a rotary evaporator at 80 ° C for 5 hours of heat treatment, so that the coupling agent can fully react with the surface of the glass beads, thereby introducing double bonds on the surface of the beads to obtain the coupling agent-treated Hollow glass microspheres (referred to as HGM-A171).

[0063] The second step of coupled microbead graft polymerization: the hollow microspheres and the polymer monomer methyl methacrylate that have been...

Embodiment 3

[0073] The first step of hollow microbead coupling treatment: first add vinyltriethoxysilane coupling agent (A-151) into the ethanol solution. Wherein, the coupling agent content is 10%, the water content is 10%, and the ethanol content is 80%. In order to stabilize the coupling agent, the pH of the solution was adjusted to 5-6 with sulfuric acid in advance. 10 grams of hollow glass microspheres were added into the ethanol solution under magnetic stirring, and reacted at 25° C. for 5 hours. Filtrate, wash with ethanol, and then heat-treat it in a boiling drier at 150°C for 0.5 hours to make the coupling agent fully react with the surface of the hollow glass microspheres, thereby introducing double bonds on the surface of the hollow microspheres to obtain the coupling agent Processed hollow glass microspheres (referred to as HGM-A151).

[0074]The second step of coupling microbead graft polymerization: the hollow microspheres and the polymer monomer ethyl acrylate through cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com