Vacuum auxiliary resin penetration process for composite material and mould therefor

A vacuum-assisted, resin-infiltrated technology, which is applied to the molding process of composite materials and the field of molds, can solve the problems of complex, uncontrollable, and high cost of the molding process, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

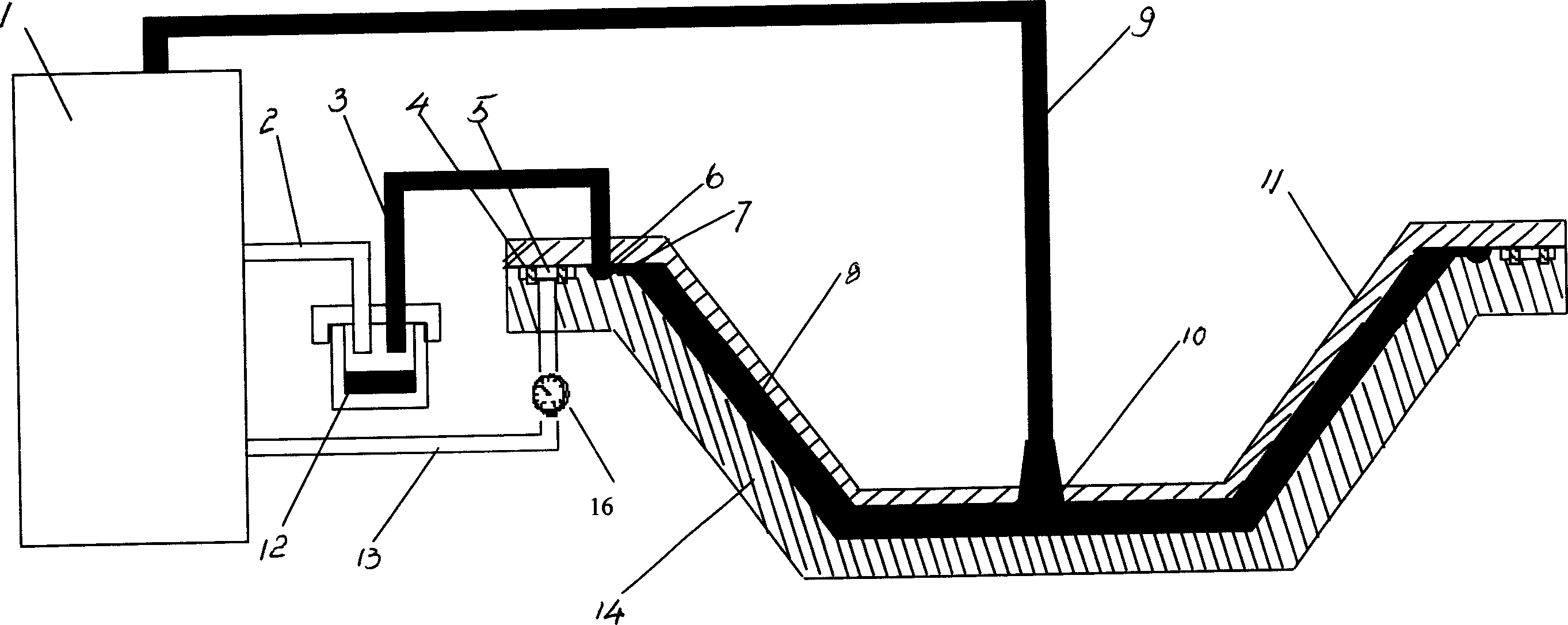

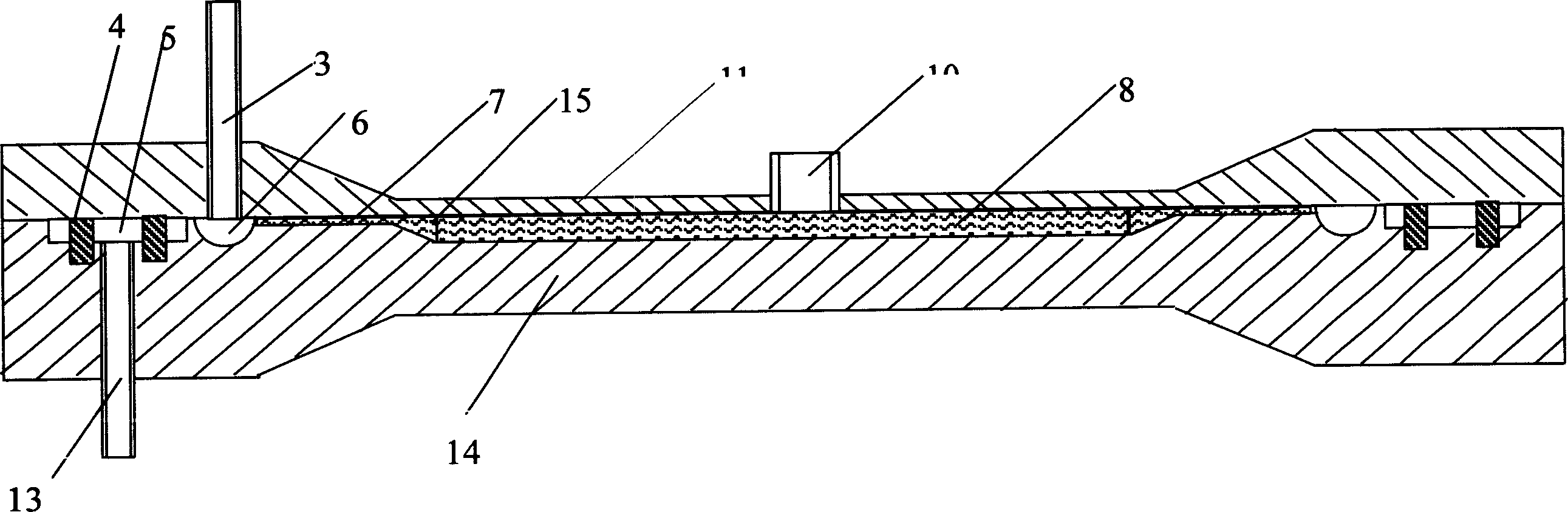

[0060] The upper mold is a glass fiber reinforced plastic soft mold, and the lower mold is a glass fiber reinforced plastic hard mold. The resin is injected through the pipeline 10, and the pipeline 3 is vacuumized. This method is suitable for products with a height less than 1.5 meters.

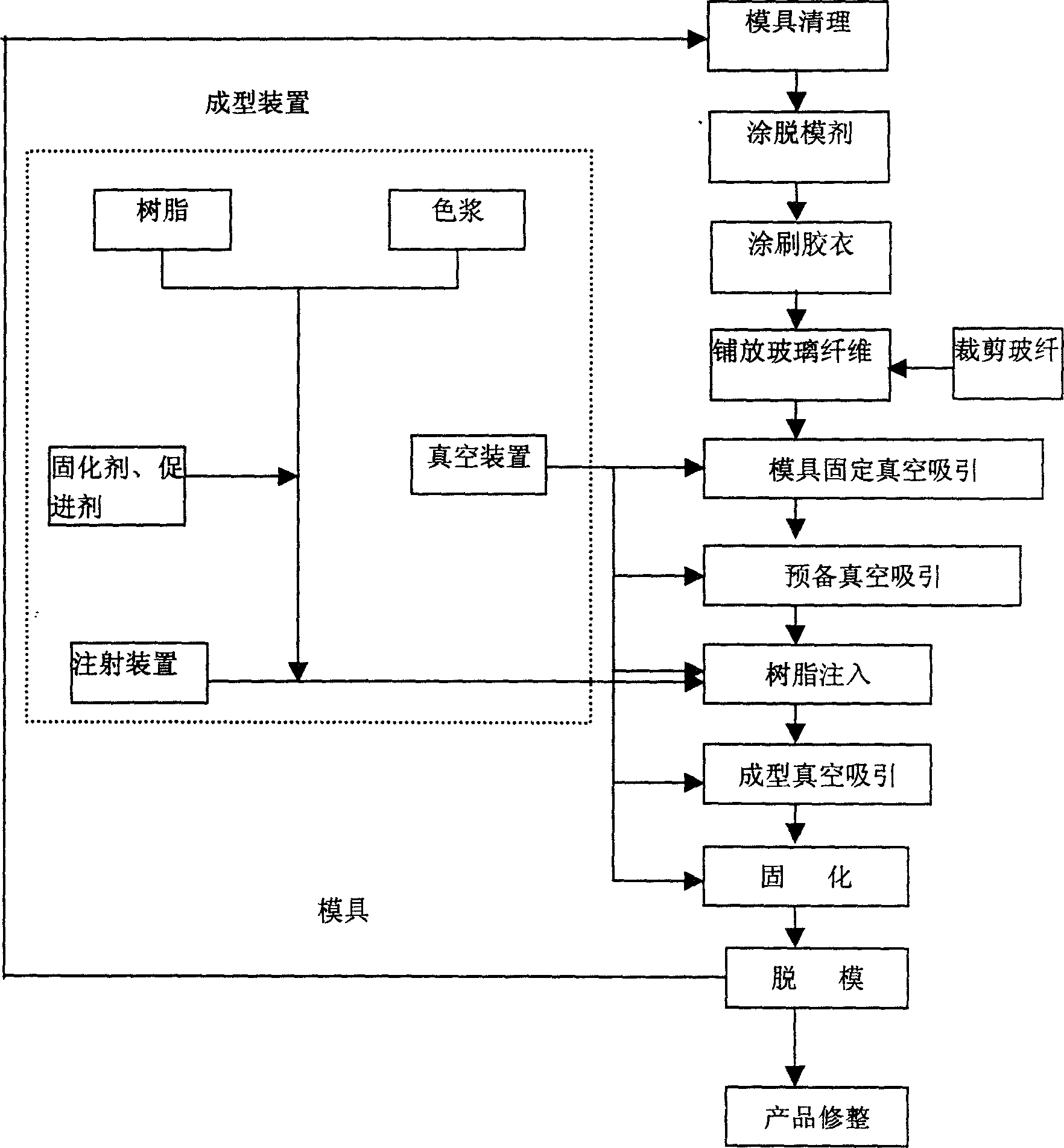

[0061] The specific process flow is: first clean the surface of the mold, apply 5-6 times of high-efficiency release agent, and the interval between each time is 15 minutes; evenly brush the gel coat on the upper and lower mold surfaces, after the gel coat is cured, according to the product Lay the glass fiber thickly, and lay the glass fiber outside the parting surface, pre-fix the edge of the mold with clamps, depressurize the mold by the RIV molding device to above -0.7MPa in the mold fixing vacuum circuit, so as to better fix the mold. Decompress the molding vacuum circuit to -0.2~-0.3MPa, compact the fibers, then release the vacuum of the molding vacuum circuit, and inject through the mol...

Embodiment 2

[0063] The upper mold is a FRP hard mold, the lower mold is a FRP soft mold, the resin is injected through the pipeline 3, and the mold cavity is evacuated through the pipeline 10. This method is suitable for products with a height of more than 1.5 meters. The specific implementation process is the same as the first embodiment.

Embodiment 3

[0065] The upper mold is made of FRP hard mold, and the lower mold is made of FRP soft mold. Inject from one side. At this time, inject evenly along the width of the mold cavity, and then suck from the other side. This method takes a long time to fill and is suitable for products that require both sides. Molding of products with light or complex shapes. The specific implementation process is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com