A kind of rapid preparation method of superhydrophobic paint surface

A super-hydrophobic and paint technology, which is applied to devices for coating liquids on surfaces, special surfaces, coatings, etc., can solve problems such as difficulties, and achieve the effects of fast preparation, simple process and large molding area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

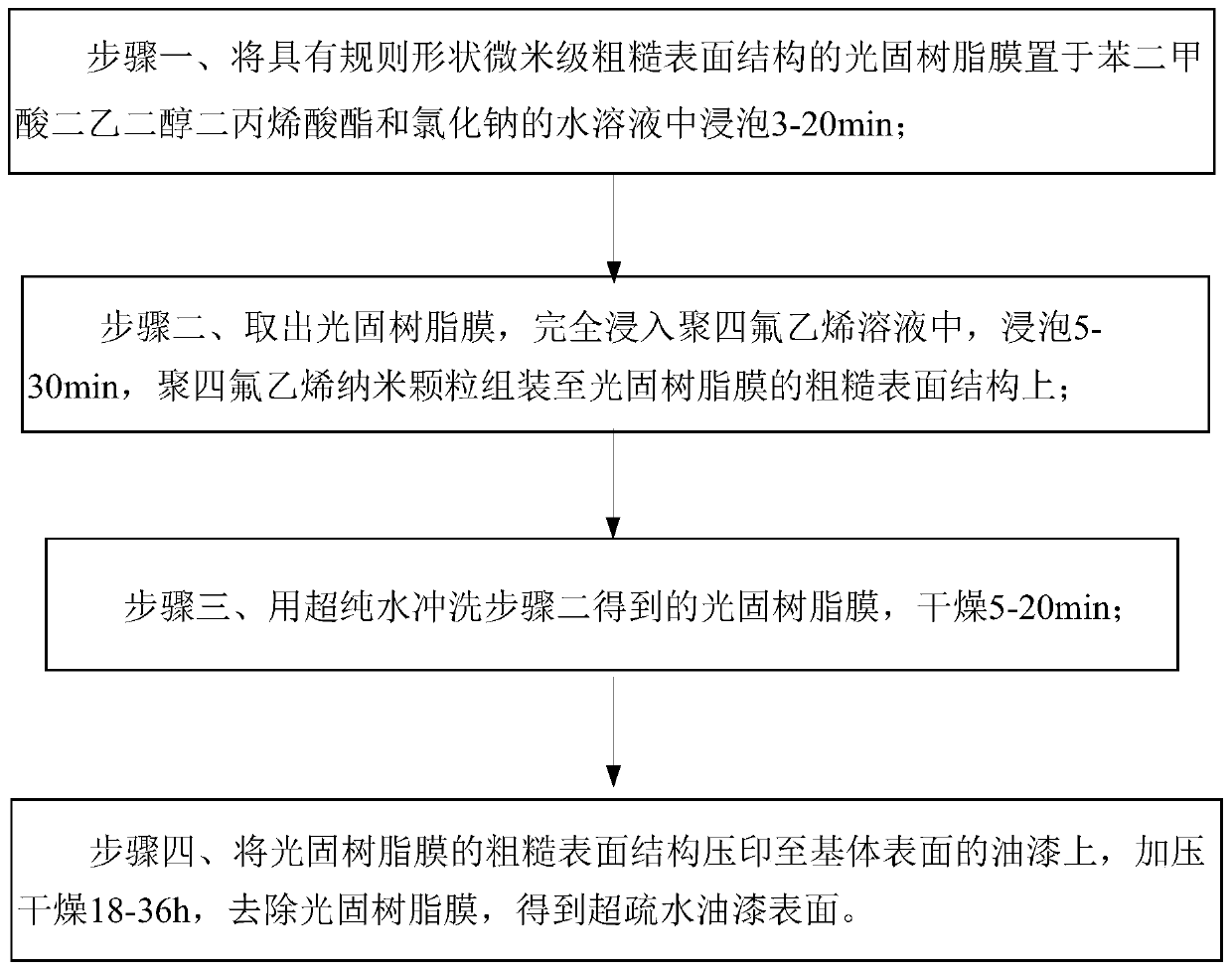

[0028] A kind of fast preparation method of superhydrophobic paint surface of the present invention, it comprises the steps:

[0029] Step 1. Place the photocurable resin film with a regular shape micron-scale rough surface structure in the aqueous solution of diethylene glycol diacrylate and sodium chloride and soak for 3-20min; adsorb on the photocurable resin film Positive charge for improved release and release properties

[0030] Step 2: Take out the photocurable resin film, completely immerse it in a polytetrafluoroethylene solution with a mass fraction of 3%-10%, soak for 5-30min, and assemble the polytetrafluoroethylene nanoparticles into the photocurable resin film rough surface structure; preferably, the mass fraction of polytetrafluoroethylene solution is 4%-8%, more preferably, the mass fraction of polytetrafluoroethylene solution is 5%-8%, for example, the polytetrafluoroethylene The mass fraction of the vinyl fluoride solution is 5%, 6%, 7% or 8%.

[0031] Step...

Embodiment 1

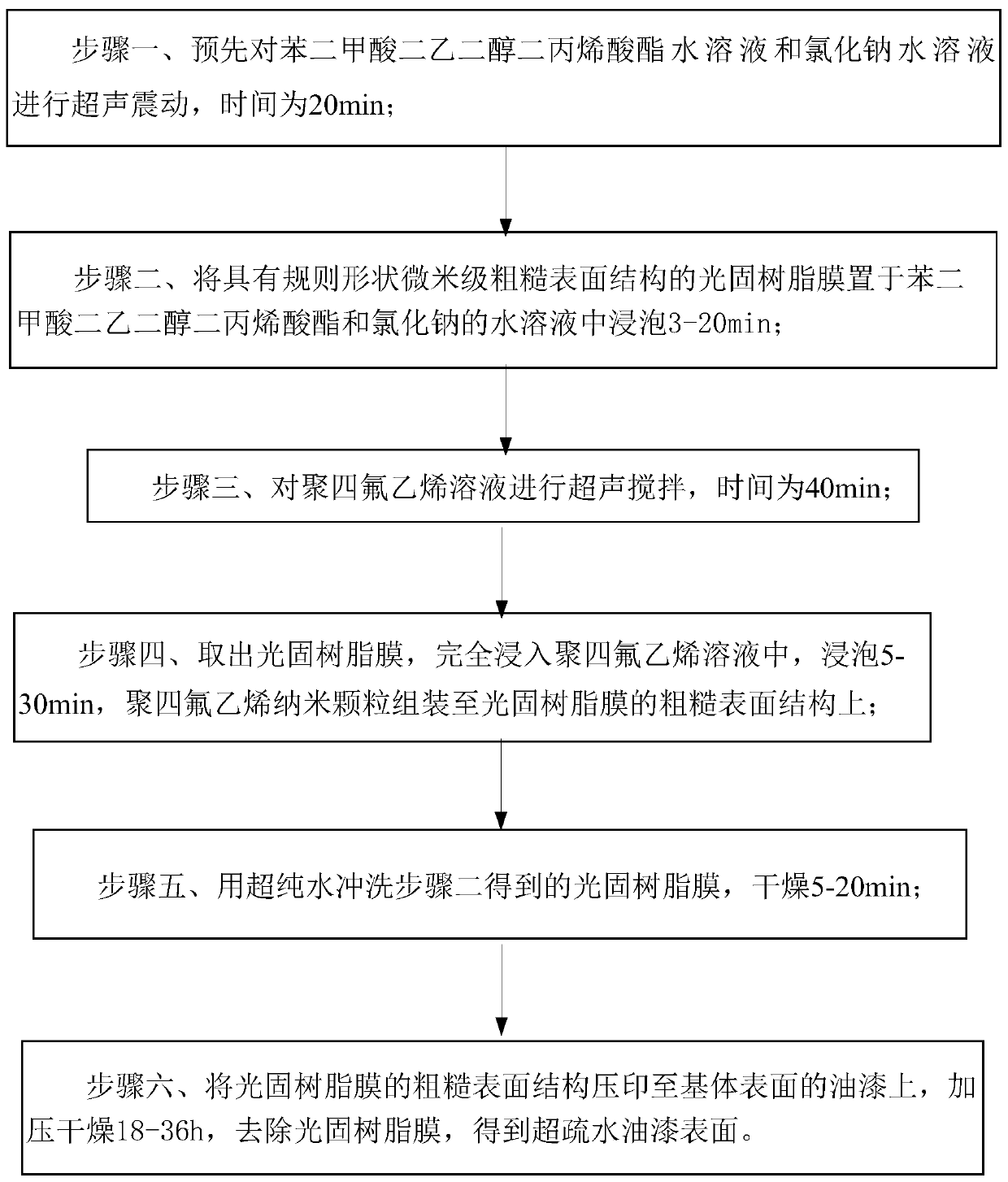

[0043] A kind of rapid preparation method of superhydrophobic paint surface, it comprises the steps:

[0044] Step 1, ultrasonically vibrate the diethylene glycol diacrylate and the sodium chloride in advance for 20 minutes;

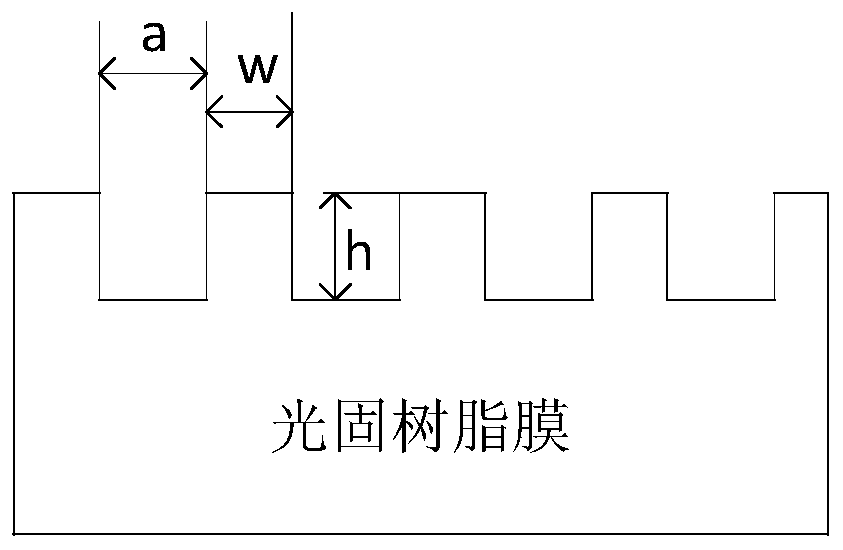

[0045] Step 2, placing the photocurable resin film with a regularly arranged pit structure in a diethylene glycol diacrylate aqueous solution with a mass fraction of 0.08% and soaking it in an aqueous sodium chloride solution with a concentration of 0.05mmol / L for 5 minutes; The square side length a of the pit structure is 12 μm, the spacing w is 11 μm, and the depth h is 9 μm;

[0046] Step 3, ultrasonically stirring the polytetrafluoroethylene solution for 40 minutes;

[0047] Step 4, taking out the photocurable resin film, completely immersing it in a polytetrafluoroethylene solution with a mass fraction of 5%, soaking for 10 minutes, and assembling the polytetrafluoroethylene nanoparticles onto the rough surface structure of the photocurable resin f...

Embodiment 2

[0051] A kind of rapid preparation method of superhydrophobic paint surface, it comprises the steps:

[0052] Step 1, ultrasonically vibrate the diethylene glycol diacrylate and the sodium chloride in advance for 20 minutes;

[0053] Step 2, placing the photocurable resin film with a regularly arranged pit structure in a diethylene glycol diacrylate aqueous solution with a mass fraction of 0.08% and soaking it in an aqueous sodium chloride solution with a concentration of 0.05mmol / L for 5 minutes; Wherein, the square side length a of the pit structure is 11 μm, the spacing w is 12 μm, and the depth h is 12 μm;

[0054] Step 3, ultrasonically stirring the polytetrafluoroethylene solution for 40 minutes;

[0055] Step 4, taking out the photocurable resin film, completely immersing it in a polytetrafluoroethylene solution with a mass fraction of 5%, soaking for 10 minutes, and assembling the polytetrafluoroethylene nanoparticles onto the rough surface structure of the photocurab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com