A kind of preparation method of workpiece

A technology for workpieces and conditions, applied in the field of material processing and preparation, can solve the problems of inability to obtain materials at the corners, cracks, and affecting the quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

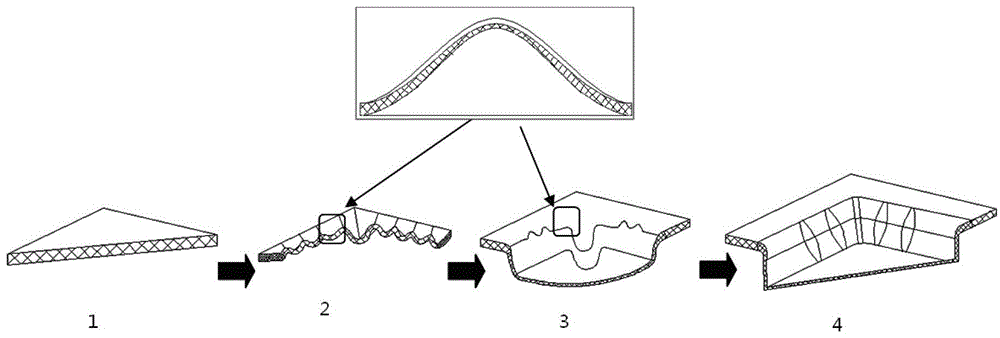

[0033] The invention provides a method for preparing a workpiece, comprising:

[0034] placing the substrate in a first mold and preforming it under a first condition to obtain a preform; the first mold includes a cavity having a first shape, and the surface of the preform matches the first shape;

[0035] placing the preform in a second mold and molding it under a second condition to obtain a workpiece; the second mold includes a cavity having a second shape, and the surface of the workpiece matches the second shape; the The first shape forms a second shape under a second condition.

[0036] The purpose of the present invention is to solve the problem in the prior art that the thickness of the deformed part is uneven or even broken due to the extreme deformation of the material under the action of pressure. The original one-step thermoforming is changed to preforming first and then forming parts.

[0037] According to the present invention, the base material for preparing t...

Embodiment 1

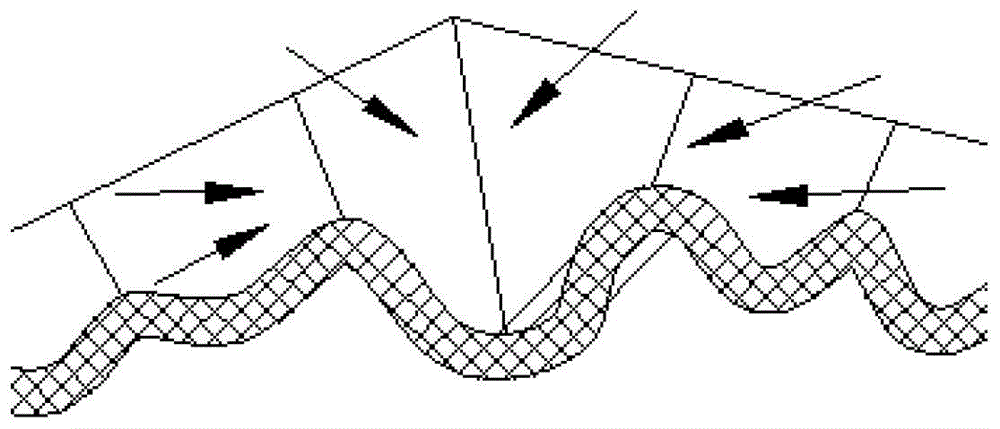

[0055] A 5083 type aluminum alloy plate with a thickness of 1.5 mm is taken, heated in a first mold, and preformed under the action of high-pressure air with a pressure of 0.5-5 MPa. The first mold includes a cavity with a wave shape. The heating temperature is 480°C. Get prefab 1.

[0056] The preform 1 is heated in the second mold and preformed under the action of high-pressure air with a pressure of 0.5-10 MPa to obtain a notebook back cover. The heating temperature in the second mold was 480° C., and the material flow rate was 0.1 mm·s.

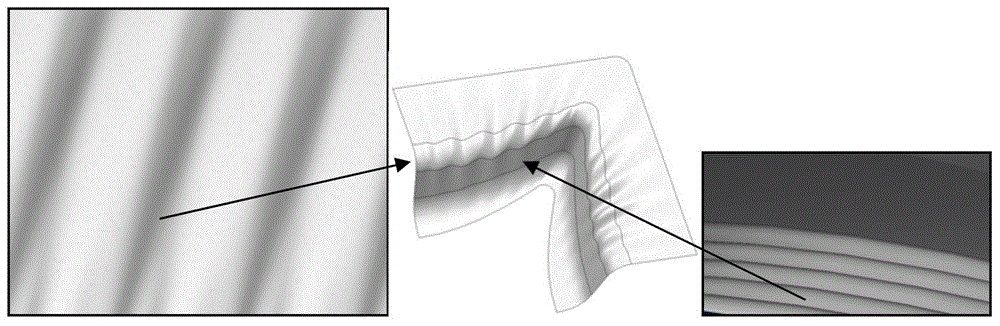

[0057] Through the local section, without this method, the thickness of the corner wall is 0.7-0.9mm. Using this method, the thickness is 9-1mm.

Embodiment 2

[0059] A 7475-type aluminum alloy plate with a thickness of 1 mm is heated in a first mold and preformed under high-pressure air with a pressure of 0.5-5 MPa. The first mold includes a wave-shaped cavity. The heating temperature is 500°C. Get prefab 2.

[0060] The preform 2 is heated in the second mold and preformed under the action of high-pressure air with a pressure of 0.5-10 MPa to obtain the back cover of the desktop monitor. The heating temperature in the second mold was 480° C., and the material flow rate was 0.1 mm·s.

[0061] Through the local section, the corners of the two methods will be cracked if this method is not used (thickness after use is 0.6-0.7mm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com