Processing method of lightweight xpe automobile air conditioning air duct

An automotive air-conditioning and lightweight technology, which is applied to tubular objects, other household appliances, and other household appliances. It can solve the problems of poor surface quality, uneven product wall thickness, and poor sound and heat insulation effects of the blister process, and reduce the wall. Uneven thickness, good heat insulation effect, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

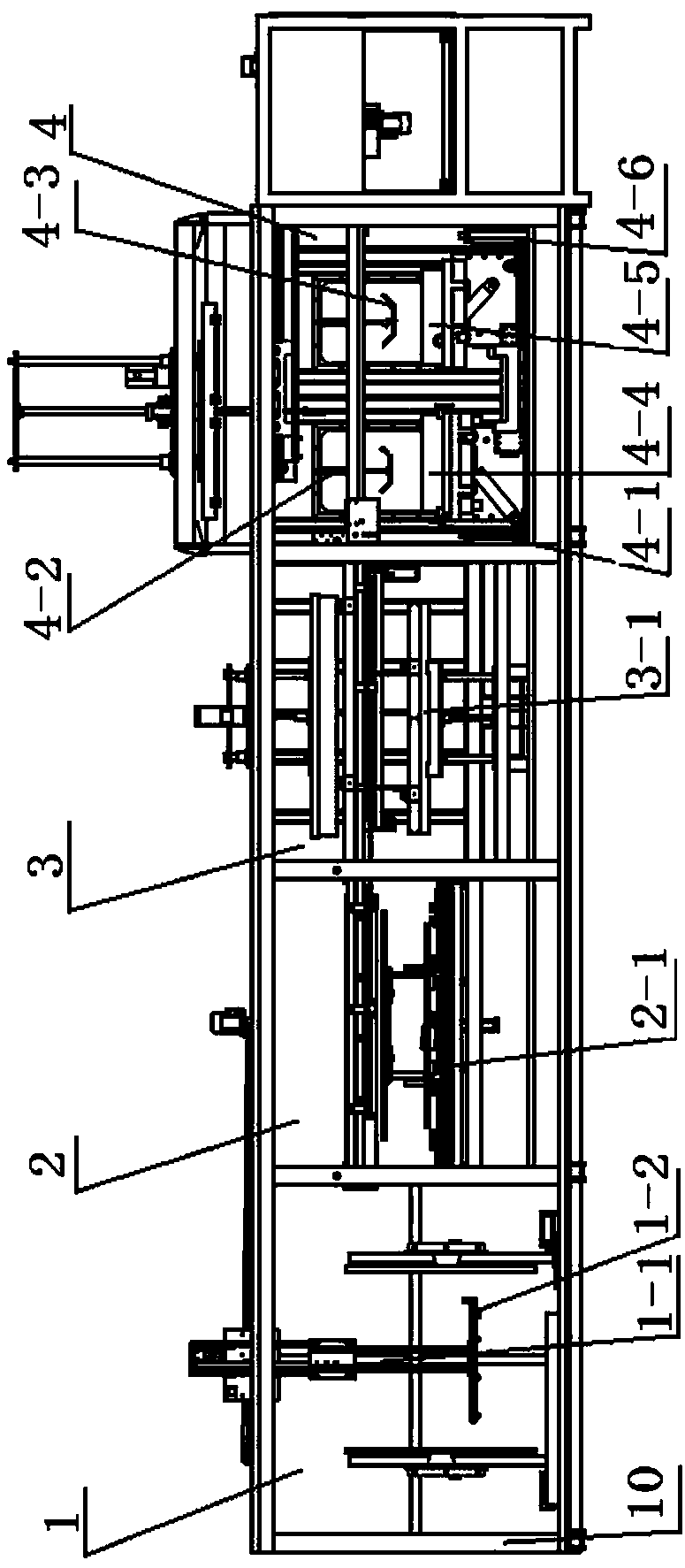

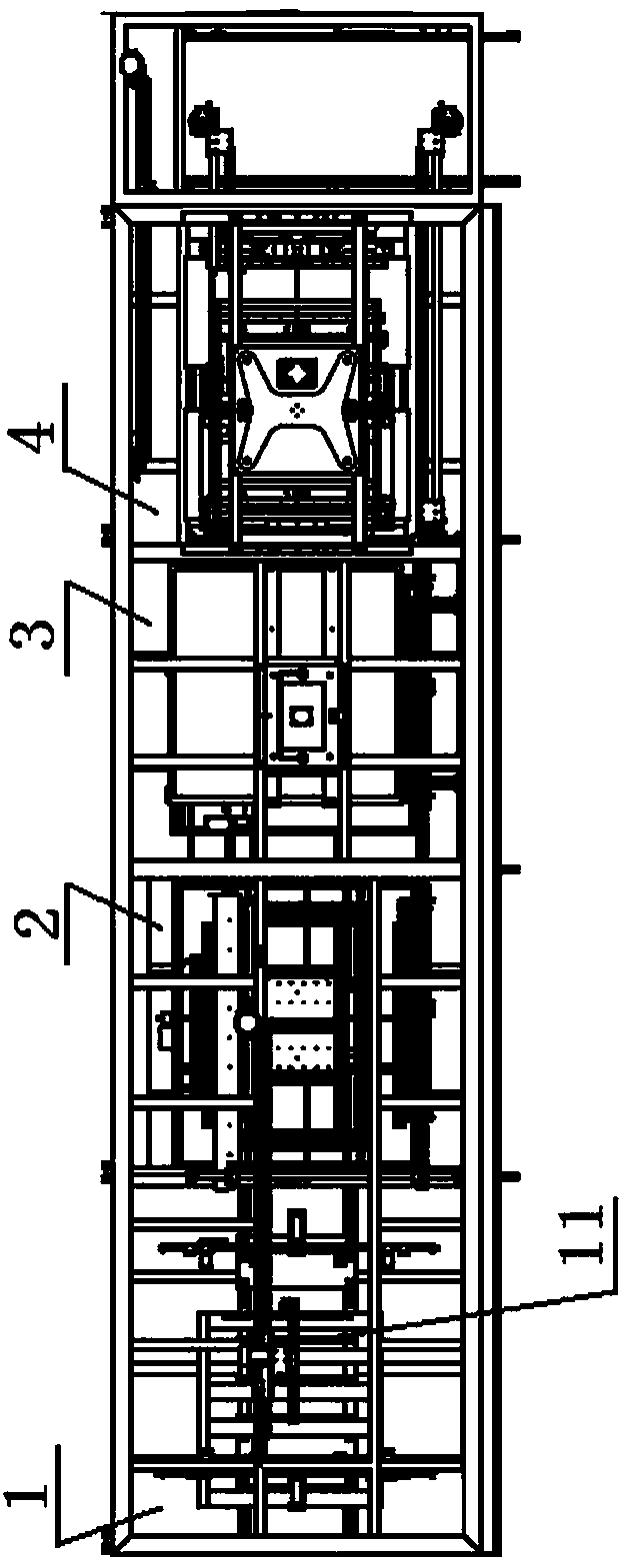

[0017] Such as figure 1 , figure 2 The shown processing method of the lightweight XPE automobile air-conditioning air duct includes processing a lightweight XPE automobile air-conditioning air duct by using an air duct forming production line.

[0018] The air duct forming production line includes a frame 10 that sequentially forms feeding, correcting, heating, and mold-closing molding stations, a feeding station 1, a calibration station 2, a heating station 3, and a mold-closing molding station 4. The frame 10 is connected with the lateral transfer unit, which can hold the plates on the frame 10 and move laterally between different stations. The frame 10 of the feeding station 1 is provided with a lifting drive unit, and the bottom of the lifting unit is provided with a suction cup connected to a vacuum pump. The frame 10 of the correction sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com