A method for producing cold-drawn steel pipes by two-pass continuous drawing

A cold-drawn steel pipe and secondary cooling technology, which is applied in the field of two-pass continuous drawing production of cold-drawn steel pipes, can solve the problem that the set value of the wall thickness reduction value has errors, the outer diameter and the wall thickness reduction value are small, and the elongation of the barren pipe is insufficient. and other problems, to achieve the effect of reducing uneven wall thickness, reducing heat treatment costs, and reducing cold drawing passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

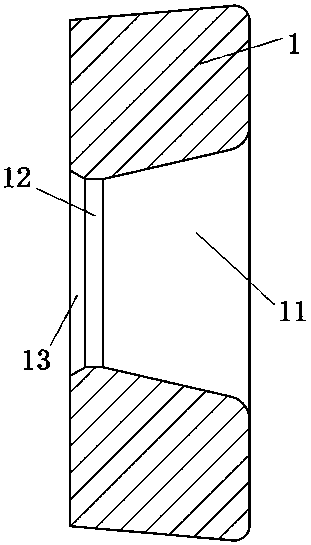

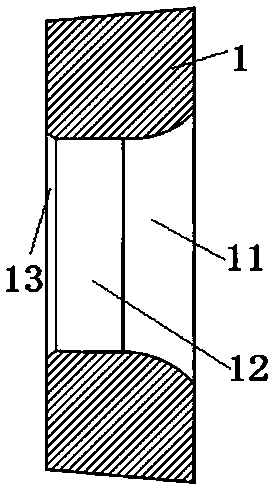

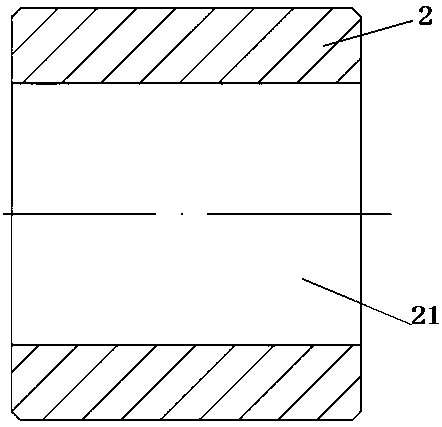

Image

Examples

Embodiment 1

[0062] Using steel grade 20G, specification Ф76×5.3mm pipe billet as raw material, use the above method to produce 10 cold-drawn steel pipes with steel grade 20G and finished product specification Ф51×5mm:

[0063] 1) Pretreatment: Drill and start the tube blank to obtain the pretreated waste tube;

[0064] 2) Pickling: Put the pretreated waste pipe obtained in step 1) into the pickling tank for pickling until there is no iron scale on the pretreated waste pipe; then wash it with water for 2 to 3 times to remove the residual pickling solution , to get the pickling barren pipe. The pickling solution is a sulfuric acid solution with a mass fraction of 17-20%, and the temperature is 45-60°C, and a corrosion inhibitor is added to prevent excessive pickling.

[0065] 3) Phosphating: Put the above acid-washed waste tubes in a phosphating tank for 20-35 minutes to phosphate, so that a phosphating film is formed on the surface, and then wash 2-3 times with clean water to obtain phosp...

Embodiment 2

[0080]Using the tube blank with steel grade of 20G and specification Ф76×6.3mm as raw material, the above method is used to produce 10 cold-drawn steel pipes with steel grade of 20G and finished product specification Ф51×6mm:

[0081] 1) Pretreatment: drilling and heading the tube blank to obtain a pretreated waste tube;

[0082] 2) Pickling: put the pretreated waste pipe obtained in step 1) into a pickling tank for pickling until there is no iron oxide scale on the pretreated waste pipe; then wash it with clean water for 2 to 3 times to remove the residual pickling solution , to get pickled waste pipes. The pickling solution is a sulfuric acid solution with a mass fraction of 17-20%, and the temperature is 45-60 °C, and a corrosion inhibitor is also added to prevent excessive pickling.

[0083] 3) Phosphating: place the above-mentioned pickling waste pipe in a phosphating tank for phosphating for 20 to 35 minutes to form a phosphating film on its surface, and then wash it wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com