A control method of wall thickness accuracy of hot-rolled seamless steel pipe and roll pass

A technology of seamless steel pipe and control method, which is applied in the direction of rolling mill control devices, rolls, metal rolling, etc., can solve the problems of uneven wall thickness of seamless steel pipes, and achieve the advantages of reduced wall thickness unevenness, enhanced flow, and active lateral flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

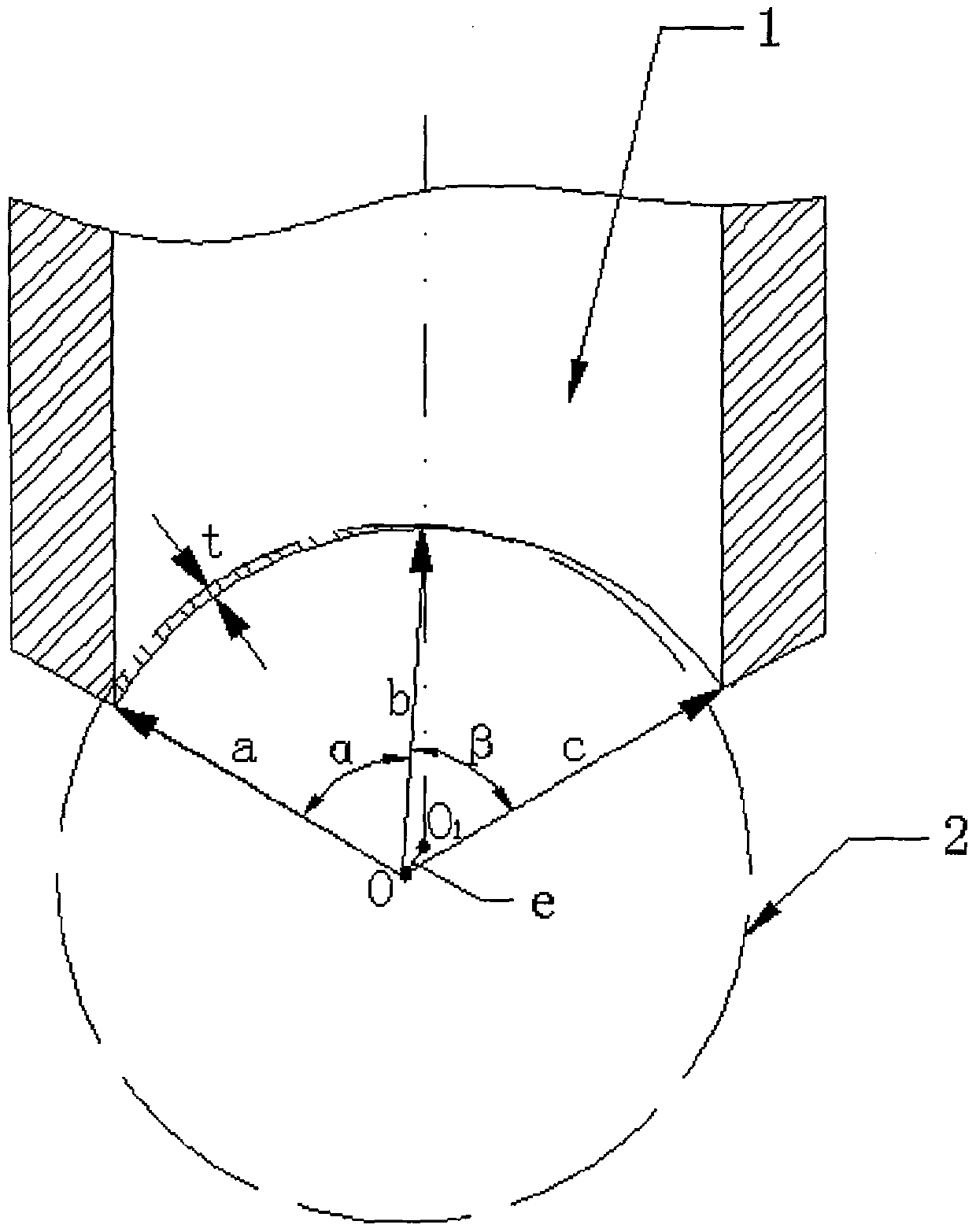

[0013] figure 1 Shown is a schematic diagram of the roll pass. In the figure, the number 1 is the roll, and 2 is the outer circle of the steel pipe. The pass shape of the roll is a continuous smooth line. There is an eccentric distance e between the centroid O1 of the pass and the center O of the cross-section of the steel pipe. The steel pipe center O is the reference origin, and the characteristic dimensions of the pass mainly include dimension a, dimension b and dimension c, as well as angles α and β, and the sum of angles α and β is 120°. figure 1 Among them, t represents the amount of diameter reduction. In the range of α angle, t is a positive value. There is a reduction amount, and there is an interaction force between the steel pipe and the roll. In the range of β angle, t is a negative value. Clearance, no diameter reduction wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com