Bamboo and wood composite veneer for structure and decoration, and method for manufacturing the same

A bamboo-wood composite and plywood technology, which is applied in the direction of manufacturing tools, wood layered products, and the joining of wooden veneers, and can solve the problems of new structures, decorative plywood related products and manufacturing technology reports that have not yet been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

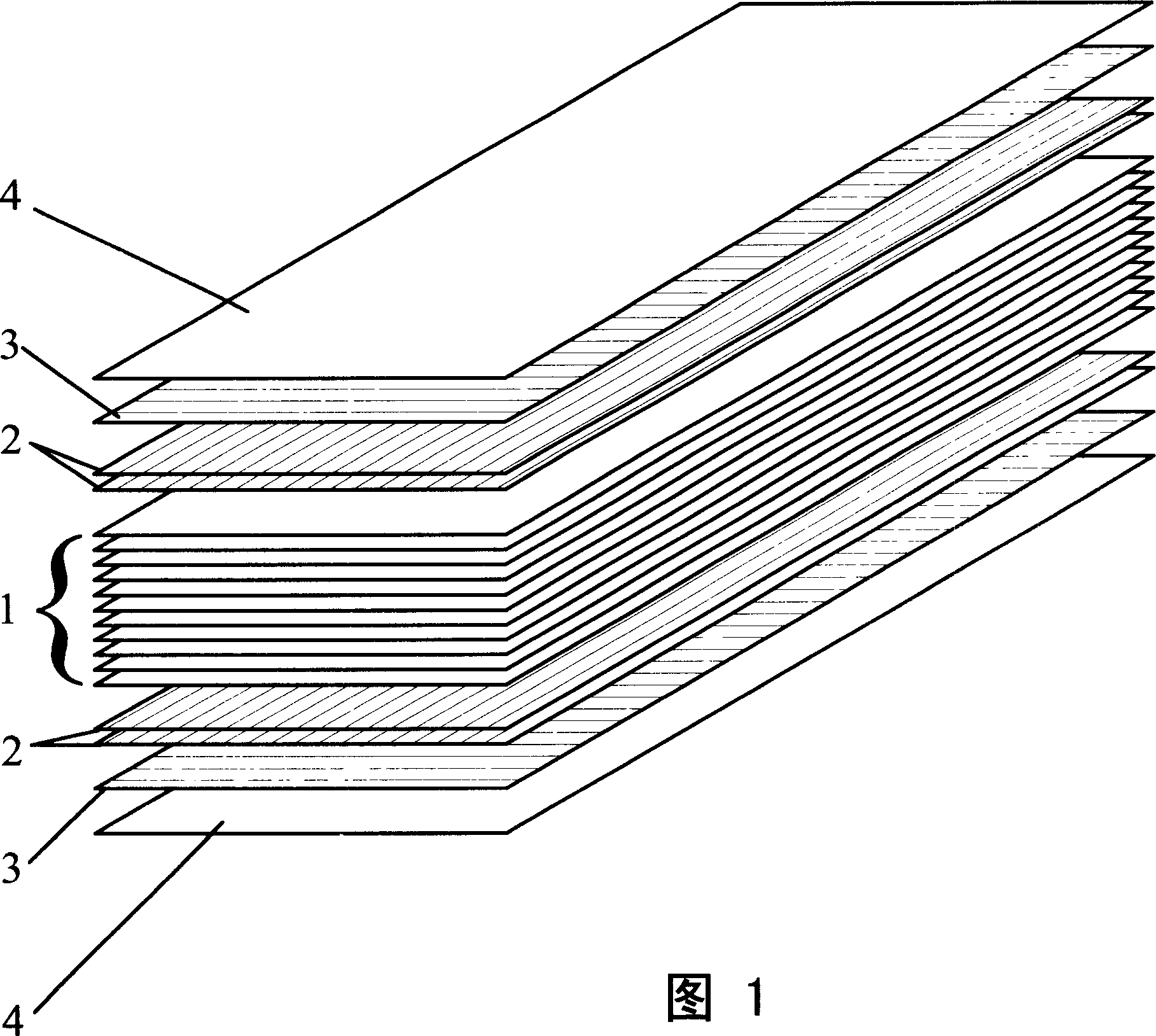

[0017] Bamboo and wood veneer are used as raw materials to manufacture structural and decorative bamboo-wood composite plywood. The structure and manufacturing method of bamboo-wood composite plywood for structure and decoration are as follows:

[0018] a. Cut the wood into veneers; cut the bamboo into strips, and weave them into bamboo curtains with cotton threads. The moisture content of the veneer and bamboo curtain is controlled at about 8%;

[0019] b. Use 2 layers of bamboo curtains and 11 layers of wood veneer to form the core layer (1);

[0020] c. The two outer layers (2) each use two layers of bamboo curtains, and the texture directions of the two layers of bamboo curtains are in the same direction when forming the billet;

[0021] d. Each of the two surface layers (3) uses a layer of wood veneer with a thickness of 1.5mm, and the grain direction of the wood veneer is perpendicular to the grain direction of the bamboo curtain when forming the billet;

[0022] e. O...

Embodiment 2

[0034] Since the grain direction of the wood veneer must be perpendicular to the grain direction of the bamboo curtain when the billet is assembled, when the grain of the bamboo (curtain) is parallel to the length direction of the finished product, the width of a single wood veneer generally cannot completely cover the board surface and It needs to be extended horizontally. In order to ensure the flatness of the joints at the horizontal joints of the wood veneers, a slope of 1:8-10 can be milled at the transverse joints of the wood veneers, so that adjacent wood veneers can be overlapped to form blanks.

[0035] All the other are with embodiment 1.

Embodiment 3

[0037] In order to improve the physical and mechanical properties and transverse strength of the finished product to a higher extent, four layers of bamboo screens can be used for the two outer layers (2). When assembling the blanks, the textures of the three layers of bamboo curtains on the outer surface can be made in the same direction, and the texture direction of the innermost layer of bamboo curtains is perpendicular to the texture direction of the other three layers of bamboo curtains; it is also possible to make the two layers of bamboo curtains on the outer surface and the innermost bamboo curtains The grain of the bamboo curtain of 1 layer is in the same direction, and the grain direction of the bamboo curtain of the remaining 1 layer is perpendicular to the grain direction of other 3 layers of bamboo curtains.

[0038] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com