Method for renovation and reinforcement of pipe using basalt fibre complex material

A technology of basalt fiber and composite materials, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve problems such as difficult availability of raw materials, lack of basalt fiber pipeline repair and reinforcement, and thick reinforcement layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Evaluation of the technical scheme of the present invention by the hydraulic blasting test method

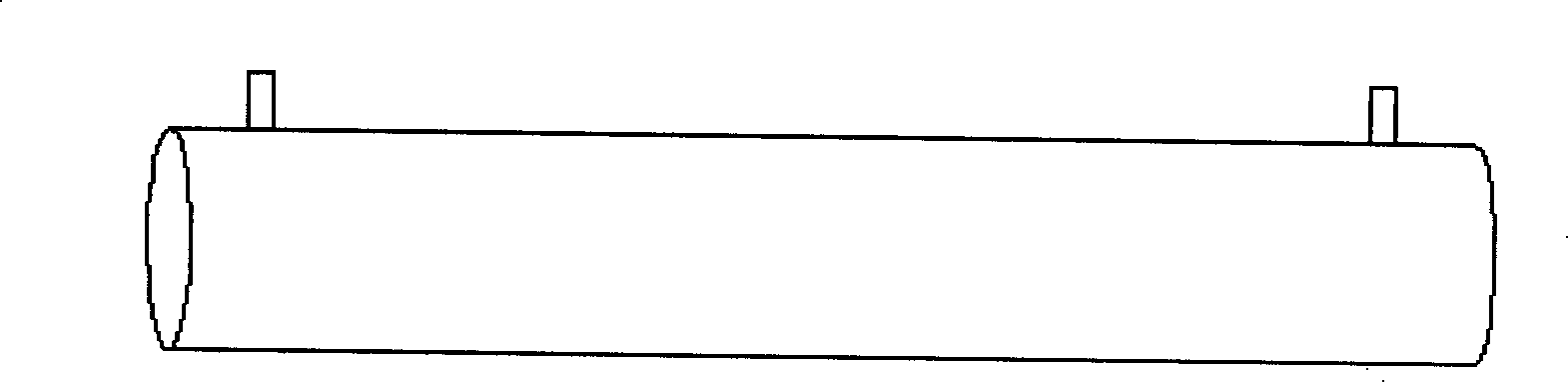

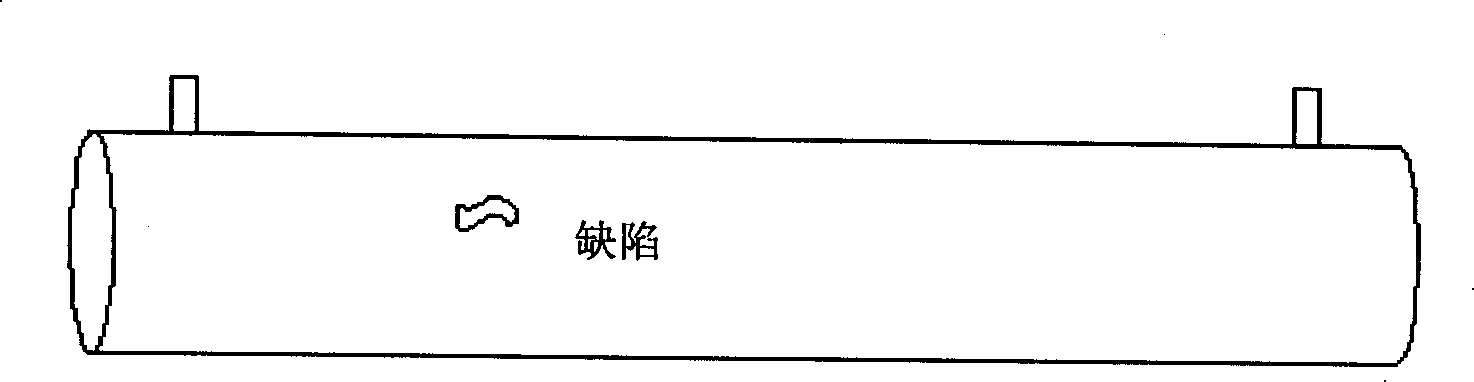

[0038] In order to test the effect of the implementation of this technology, φ273 steel pipe is taken as an example to simulate the possible defect sizes of oil and gas pipelines, and the technology is evaluated by the hydraulic blasting test method. Opinions on test tubes and defects figure 1 .

[0039] The test process is as follows:

[0040] 1) Intercept 3m of commonly used pipes for oil and gas pipelines (the pipe is a Q235 spiral welded pipe, the pipe diameter is 273mm, and the wall thickness is 7mm), and both ends are plugged with heads with vent holes and water inlet holes (see figure 1 ).

[0041] 2) Make a defect with a defect size (49mm×18mm×3.5mm).

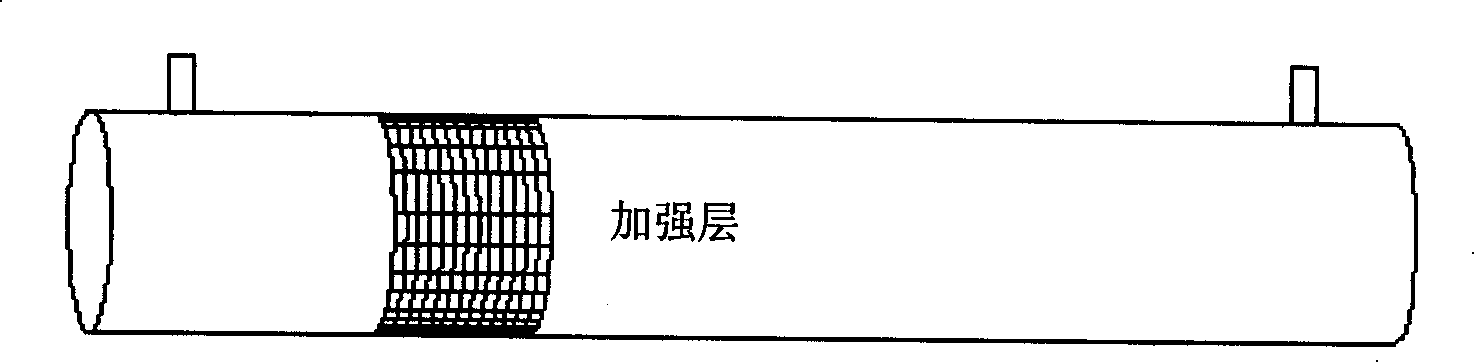

[0042] 3) Clean up the parts of the pipe body that need to be reinforced to remove the anti-corrosion layer, rust and other dirt on the outer surface of the pipe, and make the surface treatment quality reac...

Embodiment 2

[0048] Similar to Example 1, the basalt fiber composite material is used to reinforce the spiral weld defects, and then the hydrostatic blasting experiment is used to verify the reinforcement effect.

[0049] The experiment process is as follows:

[0050] 1) Intercept the commonly used pipe pipeline 3.5m for oil and gas pipelines (the pipe is a Q235 spiral welded pipe, the pipe diameter is 325mm, and the wall thickness is 7mm), and both ends are plugged with heads with vent holes and water inlet holes.

[0051] 2) Defects of size (length×width×depth=60mm×10mm×5.16mm) are made at the spiral weld of the pipeline.

[0052] 3) Degrease and remove rust on the part of the pipe body that needs to be reinforced.

[0053] 4) Fill the defect with anko filling resin.

[0054] 5) After the surface of the filling material is dry, lay a 500mm wide basalt fiber prepreg on the surface of the pipeline. A total of 10 layers are laid. Then heat it to cure.

[0055] Among them, the preparation proces...

Embodiment 3

[0059] Similar to Example 1, the basalt fiber composite material is used to repair and strengthen the pipeline that needs to be pressurized, and then the hydrostatic blasting experiment is used to verify its reinforcement effect.

[0060] The experiment process is as follows:

[0061] 1) Intercept the commonly used pipe pipeline 3.5m for oil and gas pipelines (the pipe is a Q235 spiral welded pipe, the pipe diameter is 325mm, the wall thickness is 7mm, and the design pressure is 7.3MPa, which is to be increased to 7.8MPa),

[0062] Both ends are sealed with heads with vent holes and water inlet holes.

[0063] 2) Degrease and rust the entire pipe body.

[0064] 3) Coat the surface of the pipe with an epoxy-based curable polymer, and then lay the bidirectional cross-woven basalt fiber along the circumferential direction of the pipe. After rolling, repeat a few more times, laying a total of 8 layers.

[0065] 4) After the reinforcement layer is solidified, the test tube is filled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com